TopChiller can design and manufacture all types of water chillers for you

- Cooling capacity ranges from 5 Ton to 500 Ton

- Temperature control ranges -35°C to +25°C

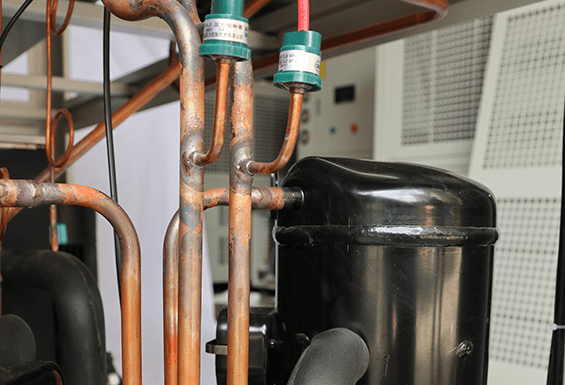

- Semi-screw compressor from top brands

- Water filter, water pump & SS water tank

- Highly efficient working heat exchanger

- Optional heater & temperature regulator

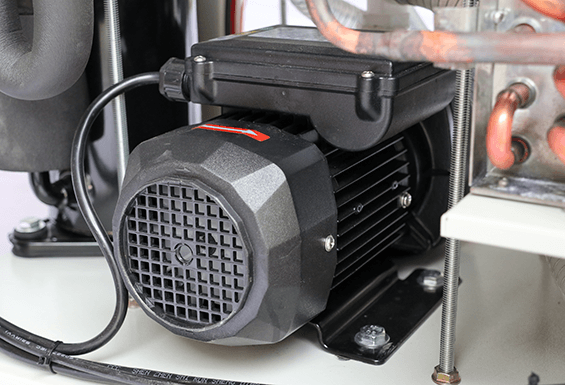

- Low noise fan motor & throttling mechanism

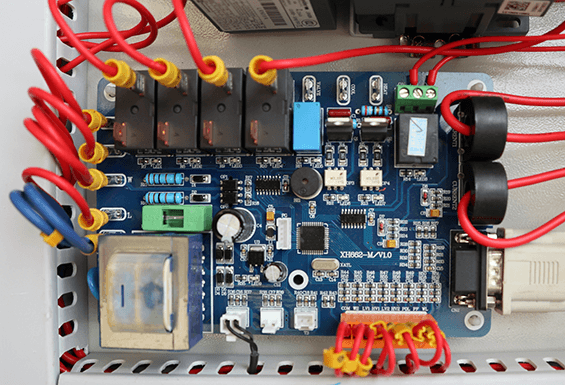

- Ergonomic panel and water indicating alarms

Your Premier Water Chiller Manufacturer and Supplier in China

Water Chiller is a specially designed chilling unit that releases extra heat from machines by using chilled water for heat exchange and water or air-cooled circulation to dissipate heat out the system.

TopChiller is a manufacturing company of China working over for the last twenty years and prepared a large variety of Water Chiller models with high experience and integrity in quality and successfully supplied all over the world.

To maintain its credibility and reputation among the world’s best enterprises, TopChiller is persistently working to manufacture reliable Water Chiller according to the customer requirements and specifications with innovative technologies installation since 1999.

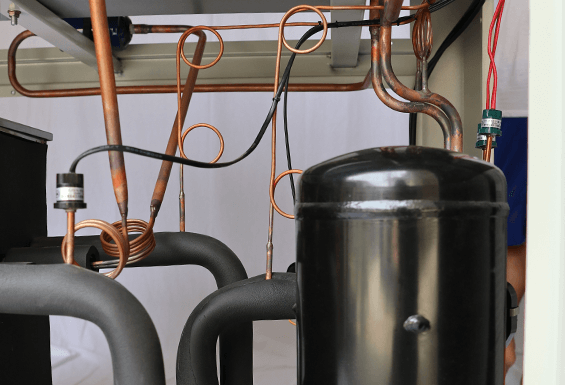

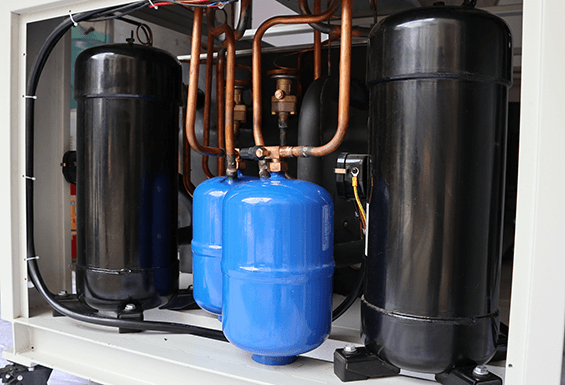

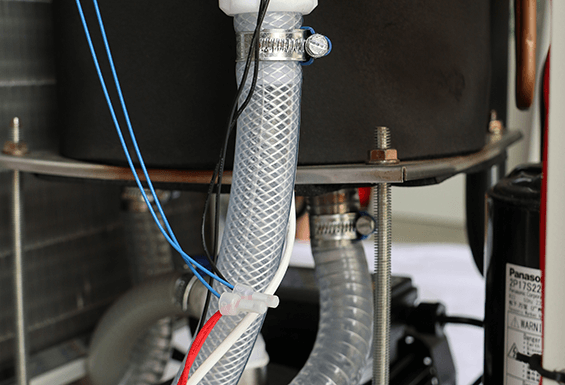

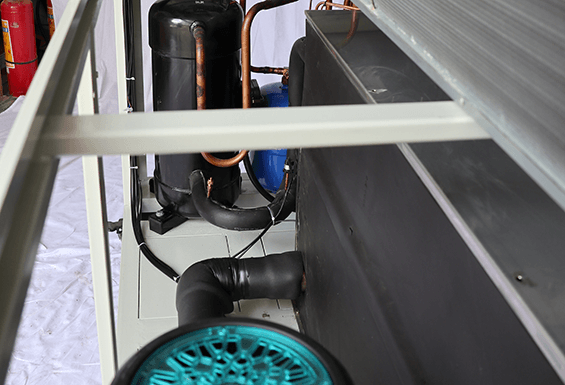

Water Chiller constitutes of water/air-cooled condenser, screw compressor, dual refrigeration circuit, throttling valves, water tank, power supplies, water pumps, multiple alarms, control panels, protecting devices for working efficiently.

Water Chiller has a wide variety of advantages for our customers as given below:

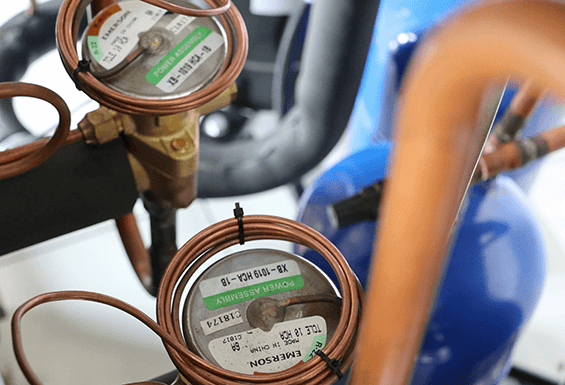

- TopChiller designed Water Chiller is steadfast in operation featured by the use of throttling system that discharges the pressure and compressibility from condensed refrigerant ensuring re-cycling of the whole process steadily for heat discharge.

- Water Chiller is configured with a water tank ensuring continuous water circulation by a water pump that enforces refrigerant to circulate in coils as well as a heat exchanger for exchange of heat with chilling effect.

- TopChiller designed Water Chiller is highly durable having long service life featured by compact stainless shell and ergonomic installation having corrosion resistance preventing the unit from any repairing damage.

- Water Chiller is featured with protective packages preventing the whole unit from different obstructions by maintaining proper water, current, and temperature, and pressure-flow rate supported by alarms giving an alert to owner.

- Water Chiller increases the stability of the unit by the installation of the dual condenser and dual refrigeration circuit providing alternative paths if there any change occurs in heating load during machine processing.

Water Chiller made by TopChiller is used in a quite number of applications for its cooling properties as:

Plastic industry, laser industry, welding machinery, chemical industry, commercial plazas, metal forming, drugs designing, medical industries, hospitals, food industries, plastic manufacturing.

Are you considering buying an energy-efficient and cost-effective Water Chiller for chilling purposes to support your application?

Are you thinking over to find a worldwide company manufacturing Water Chiller in China to come in collaboration for the establishment of your own business?

You are following the right way. TopChiller is a reliable company servicing our clients and the best option to choose.

Contact the TopChiller team and get buying assistance to size the best Water Chiller for your application at reasonable costs.

Our team is committed to providing technical support and repairing the unit at the company if you face a problem within 24 months of warranty time.

General Description:

A Water Chiller is a reliable machine that produces cooling using chilled water. It displaces the heat produced by industrial machinery by performing heat exchange mechanisms through an elaborate refrigeration cycle.

The Water Chiller contains significant components: a highly efficient evaporator, a prime quality compressor, a condenser, an expansion unit, water pumps, cooling towers, and TES reservoirs. One of its sound features is that it delivers maximum efficiency than an air chiller.

Water Chiller designed by TopChiller meets the cooling requirements of high-grade industries having massive cooling loads. You can customize the features and capacity according to your application.

At TopChiller, you can get a wide variety of Water Chillers specifically designed to lower the temperature of multiple industrial applications: plastic, electronic, medical, food, and many other manufacturing and commercial industries to maintain optimum temperature and a comfortable environment.

TopChiller is proud to introduce the most innovative and updated water cooling systems that enable you to meet a vast range of application requirements through various configurations and capacities.

Founded with the initiative of high quality and reliability, TopChiller has been the flag bearer of premium quality, customizable Water Chillers with great reviews worldwide.

Call our 24/7 active helpline number to book your Water Chiller at a very affordable price, and our customer care staff is at your service all around the clock.

Features and Advantages:

The unique features and advantages of the Water Chiller manufactured by TopChiller are listed below:

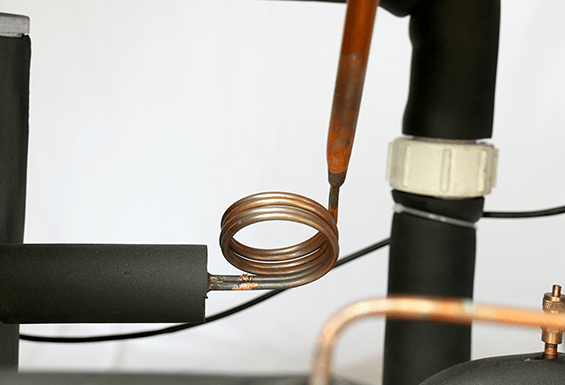

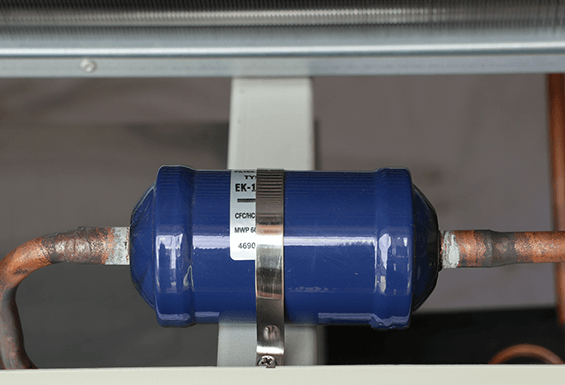

- One or more condensers are installed for efficient function, like a suction catheter and a coaxial steel copper tube.

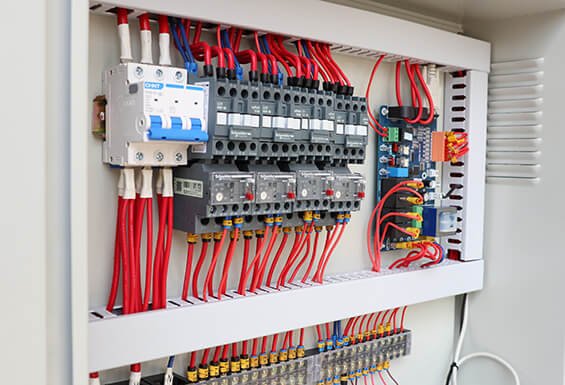

- It contained protective equipment preventing the unit from obstructions by maintaining water flow, temperature, and pressure-flow rate supported by alarms and sensors.

- A scroll compressor and a mechanical obligation system procedure pump enhance the capacity.

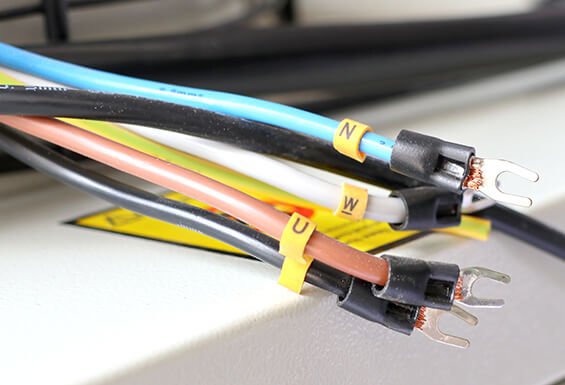

- The refrigerant and water pipes are brazed plate construction with electrified sheet metal. In this way, the pipes are more protected.

- Water Chiller enables you to run different automated industrial tests to assess all kinds of ambient and other conditions to find maximum efficiency.

- Data Sheet

- Image Gallery

- Main Parts

- Video

| Water Chiller Technical Specifications | |||||||||||

| Model Items | AW-3W | AW-4W | AW-5W | AW-6W | AW-8WD | AW-10WD | AW-12WD | AW-15WD | AW-15WT | AW-20WD | |

| Cooling Capacity | kcal/h 50HZ/60HZ | 8170 | 11266 | 14018 | 16340 | 22532 | 28036 | 32680 | 43172 | 42140 | 56760 |

| 9804 | 13519 | 16822 | 19608 | 27038 | 33643 | 39216 | 51806 | 50568 | 68112 | ||

| KW 50HZ/60HZ | 9.5 | 13.1 | 16.3 | 19 | 26.2 | 32.6 | 38 | 50.2 | 49 | 66 | |

| 11.4 | 15.72 | 19.56 | 22.8 | 31.44 | 39.12 | 45.6 | 60.24 | 58.8 | 79.2 | ||

| Input Power | KW | 3.07 | 3.87 | 5.3 | 5.95 | 7.75 | 10.6 | 11.9 | 16.25 | 15.85 | 19.71 |

| Max Current | A | 7.5 | 9.4 | 12.9 | 14.4 | 18,8 | 25.7 | 28.9 | 39.4 | 38.2 | 47.8 |

| power source | 3PH~380V/415V/480V~50HZ/60HZ(3PH~200V/220V 50HZ/60HZ) | ||||||||||

| Refrigerant | Type | R22/R407C/134a/404A/410A | |||||||||

| Control | Capillary / Thermostatic expansion valve | ||||||||||

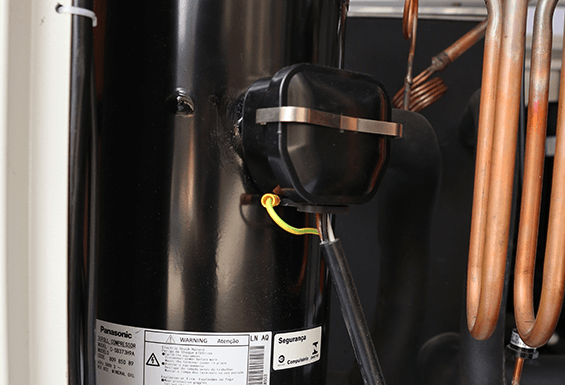

| Compressor | Type | Hermetic scroll ( piston ) | |||||||||

| Power(KW) | 2.7 | 3.5 | 4.55 | 5.2 | 3.5×2 | 4.55×2 | 5.2×2 | 7×2 | 4.55×3 | 8.96×2 | |

| Condenser | Type | Shell and tube/ SS plate type heat exchanger | |||||||||

| Cooling water (m³/h) | 2.1 | 2.9 | 3.6 | 4.2 | 5.7 | 7.1 | 8.3 | 11 | 10.8 | 14.4 | |

| 2.4 | 3.3 | 4.1 | 4.8 | 6.6 | 8.3 | 9.6 | 12.8 | 12.5 | 16.7 | ||

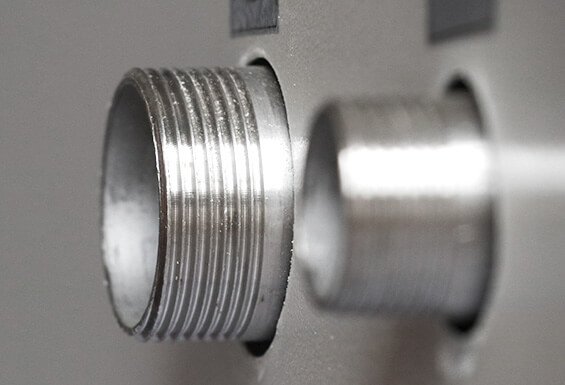

| Inlet/outlet pipe (inch) | 1 1/2″ | 1 1/2″ | 1 1/2″ | 1 1/2″ | 1 1/2″ | 1 1/2″ | 1 1/2″ | 2″ | 2″ | 2″ | |

| Evaporator | Type | SS Tank with cooper coil / Shell and tube/Plate heat exchanger | |||||||||

| Chilled water | 1.63 | 2.25 | 2.8 | 3.27 | 4.5 | 5.6 | 6.53 | 8.63 | 8.43 | 11.35 | |

| 1.96 | 2.7 | 3.36 | 3.92 | 5.4 | 6.73 | 7.84 | 10.36 | 10.1 | 13.62 | ||

| Water tank(L) | 60 | 60 | 60 | 90 | 150 | 200 | 200 | 330 | 330 | 330 | |

| inlet/outlet pipe (inch) | 1″ | 1″ | 1″ | 1″ | 1-1/2″ | 2″ | 2″ | 2″ | 2″ | 2″ | |

| Water pump | Power(kw) | 0.37 | 0.37 | 0.75 | 0.75 | 0.75 | 1.5 | 1.5 | 2.2 | 2.2 | 2.2 |

| Max lift(m) | 22 | 22 | 30 | 30 | 25 | 25 | 25 | 28 | 28 | 28 | |

| Max flow (m³) | 5.4 | 5.4 | 8.1 | 8.1 | 8.1 | 13.5 | 13.5 | 25.2 | 25.2 | 25.2 | |

| Safety protection | Compressor inner protection, over current protection, high/low pressure protection, over temperature protection, flow rate protection, phase sequence/phase missing protection, low level coolant protection, anti freezing protection, exhaust overheat protection | ||||||||||

| Dimension | L(mm) | 910 | 910 | 910 | 910 | 1250 | 1250 | 1250 | 1600 | 1600 | 1600 |

| W(mm)) | 480 | 480 | 480 | 480 | 680 | 680 | 680 | 750 | 750 | 750 | |

| H(mm)) | 1000 | 1000 | 1000 | 1000 | 1380 | 1380 | 1380 | 1600 | 1600 | 1600 | |

| Net weight(KG) | 125 | 135 | 160 | 180 | 230 | 260 | 330 | 420 | 420 | 460 | |

| Note: The above specifications are according to the following design conditions: 1, Chilled water inlet/outlet temperature 12℃/7℃. 2, Chiller temperature control range 5℃/35℃. We reserve the right to modify the specification without further notice. | |||||||||||

| Water Chiller Technical Specifications | |||||||||||

| Model Items | AW-20WF | AW-25WD | AW-25WF | AW-30WD | AW-30WT | AW-40WD | AW-40WF | AW-50WD | AW-50WF | AW-60WD | |

| Cooling capacity | kcal/h 50HZ/60HZ | 56072 | 66048 | 65360 | 83420 | 85140 | 114036 | 113520 | 134504 | 132096 | 169764 |

| 67286 | 79258 | 78432 | 100104 | 102168 | 136843 | 136224 | 161405 | 158515 | 203717 | ||

| KW 50HZ/60HZ | 65.2 | 76.8 | 76 | 97 | 99 | 132.6 | 132 | 156.4 | 153.6 | 197.4 | |

| 76.56 | 92.16 | 91.2 | 116.4 | 118.8 | 159.12 | 158.4 | 187.68 | 184.32 | 236.88 | ||

| Input power | KW | 20.4 | 23.8 | 23 | 30.99 | 30.63 | 41.31 | 39.59 | 52.7 | 48.7 | 59.3 |

| Max Current | A | 48.5 | 61.7 | 60 | 75.2 | 74.8 | 100.3 | 96.6 | 127.9 | 119.7 | 143.9 |

| Power Source | 3PH~380V/415V/480V~50HZ/60HZ(3PH~200V/220V 50HZ/60HZ) | ||||||||||

| Refrigerant | Type | R22/R407C/134a/404A/410A | |||||||||

| Control | Thermostatic expansion valve | ||||||||||

| Compressor | Type | Hermetic scroll ( piston ) | |||||||||

| Power(KW) | 4.55×4 | 10.8×2 | 5.2×4 | 13.62×2 | 8.96×3 | 18.78×2 | 8.96×4 | 23.6×2 | 10.8×4 | 26.9×2 | |

| Condenser | Type | Shell and tube/ SS plate type heat exchanger | |||||||||

| Cooling Water (m3/h) | 14.4 | 17 | 16.7 | 21.4 | 21.7 | 29.3 | 28.9 | 35 | 33.9 | 43.2 | |

| 16.6 | 19.6 | 19.3 | 24.7 | 25.1 | 33.8 | 34.4 | 40.4 | 39.1 | 50 | ||

| inlet/outlet pipe (inch) | 2″ | 2″ | 2 1/2″ | 2 1/2″ | 2 1/2″ | 3″ | 3″ | 3″ | 3″ | 4″ | |

| Evaporator | Type | SS Tank with cooper coil / Shell and tube/Plate heat exchanger | |||||||||

| Chilled Water (m³/h) | 11.21 | 13.21 | 13.1 | 16.68 | 17.02 | 22.8 | 22.7 | 26.9 | 26.41 | 33.95 | |

| 13.45 | 15.85 | 15.68 | 20.02 | 20.43 | 27.36 | 27.24 | 32.27 | 31.7 | 40.73 | ||

| Water Tank (L) | 330 | 350 | 350 | 450 | 450 | 580 | 580 | 620 | 620 | 620 | |

| inlet/outlet pipe (inch) | 2″ | 2″ | 2″ | 2-1/2″ | 2-1/2″ | 3″ | 3″ | 3″ | 3″ | 4″ | |

| Water pump | Power(kw) | 2.2 | 2.2 | 2.2 | 4 | 4 | 4 | 4 | 5.5 | 5.5 | 5.5 |

| Max lift(m) | 28 | 28 | 28 | 30 | 30 | 30 | 30 | 32 | 32 | 32 | |

| Max flow (m³) | 25.2 | 25.2 | 25.2 | 36 | 36 | 36 | 36 | 40 | 40 | 40 | |

| Safety protection | Compressor inner protection, over current protection, high/low pressure protection, over temperature protection, flow rate protection, phase sequence/phase missing protection, low level coolant protection, anti freezing protection, exhaust overheat protection | ||||||||||

| Dimension | L(mm) | 1600 | 1950 | 1950 | 1950 | 1950 | 2000 | 2000 | 2000 | 2000 | 2200 |

| W(mm) | 750 | 850 | 850 | 850 | 850 | 980 | 980 | 980 | 980 | 1100 | |

| H(mm) | 1600 | 1700 | 1700 | 1700 | 1700 | 1700 | 1700 | 1700 | 1700 | 1850 | |

| Net weight(KG) | 460 | 680 | 680 | 720 | 720 | 870 | 870 | 980 | 980 | 1120 | |

| Note: The above specifications are according to the following design conditions: 1, Chilled water inlet/outlet temperature 12℃/7℃. 2, Chiller temperature control range 5℃/35℃. We reserve the right to modify the specification without further notice. | |||||||||||

Why TopChiller is Your Reliable Water Chiller Manufacturer and Supplier In China?

Water Chiller-An Ultimate FAQ Guide by TopChiller.

- What is a Water Chiller?

- What are the Major Components of a Water Chiller?

- What are the Prominent Features of a Water Chiller?

- How Does a Water Chiller Work?

- How Does a Water Chiller Differ from an Air Chiller?

- What are the Industrial Applications of a Water Chiller?

- How to Choose a Suitable Size Water Chiller for your Industry?

- What are the Advantages of Using a Water Chiller for your Business?

- What are the Additional Accessories of a Water Chiller?

- What is the Cooling Capacity of a Water Chiller?

- What is the Temperature Ranges for a Water Chiller?

- How to Handle your Water Chiller in Harsh Weather?

- How to Test your Water Chiller?

- What are the Types of a Water Chiller?

- What are the Alternate Energy Sources for your Water Chiller?

- What are the System Configurations in a Water Chiller?

- What are the Tips and Tricks for Increasing the Life of your Water Chiller?

- How to Troubleshoot the Problems of your Water Chiller?

- What are the Maintenance Requirements of a Water Chiller?

What is a Water Chiller?

Water Chiller is a specifically designed chilling unit that releases extra heat from industrial machines by using chilled water. It is used in various business applications and industries worldwide.

It comes in various sizes, models, and configurations, and you can customize it to adjust it according to your application.

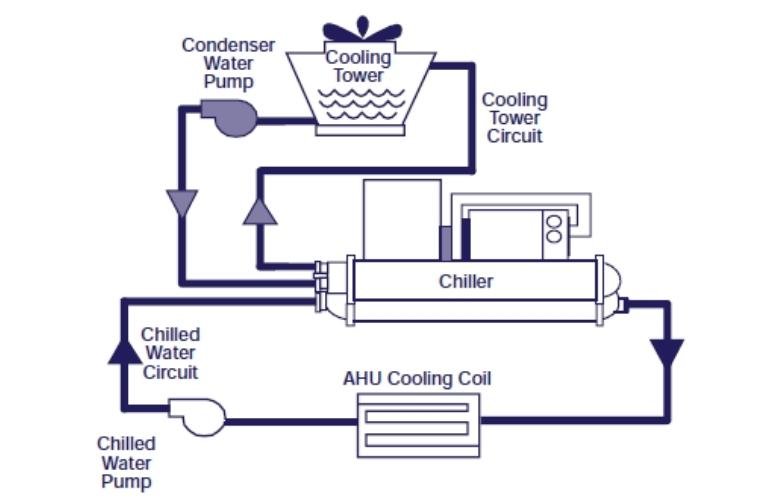

The working principle is similar to an air chiller. It starts by transferring heat from the refrigerant vapor to the condenser water.

In Water Chiller, the hot and chilled water from the condenser is pumped to the cooling tower. The chilled water cools down the industrial machinery, warming up with time. It is a non-biodegradable and user-friendly unit with excellent efficiency.

Water Chiller Designed by TopChiller

What are the Major Components of a Water Chiller?

The major components of a Water Chiller are listed below:

Evaporator

It deals with the evaporation and transitioning from high-pressure liquid to low-pressure gas. This transition helps in cooling as evaporation is a cooling process.

Condenser

The low-pressure gas is then sent to the condenser condensed back to a liquid form. The energy from this process is again utilized to lower the temperature of the refrigerant, which is moving in the coils.

Compressor

The resultant from the condenser is then fed into the compressor. There are different types of compressors available based on capacity and design.

The most common ones include a screw compressor, scroll compressor, and semi-hermetic compressor.

Cooling Tower

It is only present in a Water Chiller where the water is close to moist air. The heat travels from an area of higher energy to lower energy, and in this way, the water is chilled.

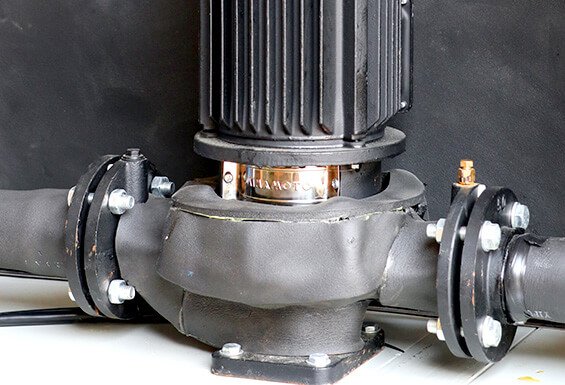

Pumps

There are specialized pumps for forcing the water against the gradient:

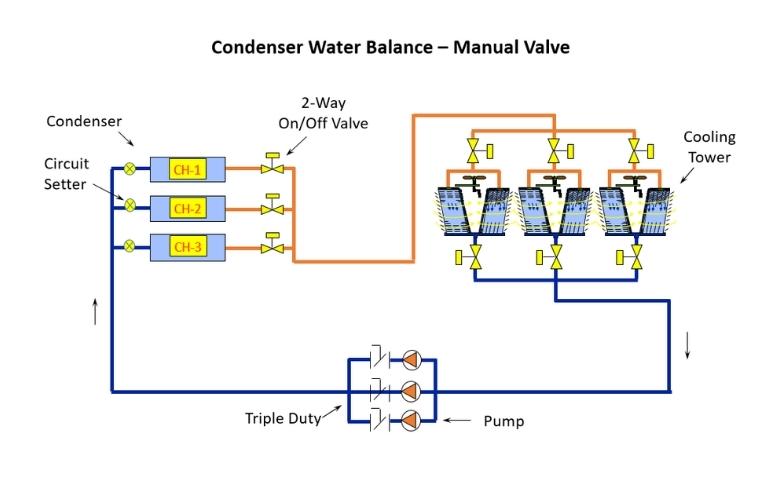

Condenser Water Pumps

Make-Up Water Pumps

Water Chiller Cooling Tower Working Diagram

What are the Prominent Features of a Water Chiller?

The most prominent features of a Water Chiller are as follows:

- The primary control comprises a microprocessor chip that is highly efficient and up to date with recent technology.

- Water Chiller has a user-friendly configuration that helps you run it for many hours without worrying about environmental degradation.

- The running costs are incredibly affordable and quite reasonable and provide the highest efficiency with long-lasting results.

- It protects your machinery by preventing overheating and helps you save money in the long run. It can work on high loads as well.

- Pressure valves, drain connections, and a proper venting system to not burn it out.

- The sturdy and reliable primary steel outline helps it run for many years since it protects against harmful agents like acids, alkalis, and chemicals. Resistance against harsh climate is also provided.

- The design is simple and efficient for all kinds of applications.

- It comes with removable boards of stainless steel and pumps made up of tempered glass. It allows you to enjoy smooth maintenance and increased resistance against damaging agents.

How Does a Water Chiller Work?

The working of Water Chiller includes the following essential steps:

Step 1

A mechanical refrigeration system is built using the Water Chiller’s evaporator for the phenomenon of vapor compression. The refrigerant flows through the cooling system’s evaporator, compressor, condensers, and valves.

Step 2

Heat exchange occurs at the evaporator level as the refrigerant is evaporated and transformed into a low-pressure vapor. Evaporation is a cooling process, and therefore the coolant loses all its heat.

Step 3

Then the refrigerant enters the compressor, where high pressure is applied, and the low-pressure vapor is converted to a high-pressure liquid.

Step 4

This liquid state is then fed to the condenser. The heat from the transition is released into the environment, leaving the system at a lower tension temperature, thus cooling the water medium.

Step 5

This water from the condenser goes to the cooling tower at a height and an ambient temperature lower than the system.

Step 6

Heat exchange occurs when air is fed through the water, and all the heat is transferred to the air leaving the water at an even lower temperature.

A stable water source must be established for bigger industrial setups with greater cooling loads. The water from the cooling tower is continuously used to cool down the circulating refrigerant.

Water flows through the coils and absorbs all the heat from the running machines and environment.

How Does a Water Chiller Differ from an Air Chiller?

A Water Chiller differs from an air chiller based on efficiency, usage of water, cooling load, capacity, and many other factors.

Efficiency

Water Chiller is more efficient than the air chiller because it uses water as a cooling medium and not air. The chilled water performs the heat exchange much faster than the air.

Cooling Tower

There is a need for a water reservoir and cooling tower in a Water Chiller since you must maintain a constant water flow.

It might add to running costs and may not be suitable for areas with a low water supply. The cost of installing the cooling tower also adds to the cost of the whole setup.

The air chiller does not need the cooling tower and therefore has a more straightforward structure.

Cooling Loads

The greater the cooling load, the greater the demand and higher efficiency required, which can only be met using a Water Chiller.

An air chiller cannot meet the demands of massive industrial setups because it is not as efficient.

Water Chiller can be set up indoors while the cooling tower is situated outside the facility, which adds to the advantages of having a modest size compared to the air chiller.

Air Currents

There’s no need to worry about the air currents because it is situated inside, and the water is used as the medium of cooling.

The cooling tower needs a moist air current, whereas the air chiller needs ambient airflow for working. The former is more long-lasting and produces significant results.

Air Chiller Fabricated by TopChiller

What are the Industrial Applications of a Water Chiller?

Industrial applications of a Water Chiller include:

- Plastic Industry

- Electromagnetic Industry

- Machinery Industry

- Mechanical Industry

- Vacuum Coating

- Construction Industry

- Electroplating Industry

- Food Industry

- Schools

- Shopping Malls

Water Chiller provides comfortable ambient temperature and suitable conditions for the synthesis and storage of products in these industries on an enormous scale.

How to Choose a Suitable Size Water Chiller for your Industry?

To choose the right Water Chiller for your application, consider the following factors:

Power

The most common power categories are 208-230V, 380-420V,440-480V,50Hz or 60Hz, 3phase. Although it changes with different nations and each one has its scale.

Water Pump

The water pump has to be proportional to the size of the system so that you can obtain maximum productivity.

Size Connection

The higher the flow rate, the greater is the efficiency. Therefore, the radius of the pipelines shall be per the size and the demand.

Refrigerant

R22, R410A, R407C, R404A, R134A are the most advised choices.

R22, although it is very efficient, it is illegal in many countries due to its damaging effects on the ozone layer.

R410A is highly eco-friendly and is being extensively used in many countries worldwide.

R407C, due to the great cooling impact, is preferred on R22.

R404A is ideal for low-temperature applications.

R134A is preferably used at a higher temperature.

What are the Advantages of Using a Water Chiller for your Business?

The advantages of using a Water Chiller are described below:

- The partial load energy effectiveness of up to 6.1 is offered. It has higher productivity, and the default control is step control.

- It uses a semi airtight screw compressor, short compression, and low-pressure proportion rather than overpressure.

- R134a, ODP=0, GWP=0.29 is used as an environmentally friendly refrigerant. It does not cause any damage to the ozone layer or the environment; thus, it is safe to use and lasts for many years.

- The size of the Water Chiller is modest, which is why it can be installed indoors and can easily be accessed by a proper operator.

- The water reservoir facility allows you to access the water even when no active supply is available.

- It needs less refrigerant recharge and low GMP impact.

- There is no running noise or vibration, and therefore it is ideal to be used at places close to residential areas or populations.

- The design has minimum voice production even if any noise reduction accessories can be conveniently used.

- You can opt for a power confinement switch which adds to the inbuilt power assurance and safety.

- The installation is simple with minimum maintenance requirements. It has a simple design that can be cleaned and maintained conveniently.

- It saves space as it has a one-sided water connection.

- A simple HMI-sensitive LCD or a touchscreen regulator allows you to have a fantastic user experience.

- You can record all the user experiences to be compared later to assess their efficiency with time.

- Self-diagnostic alarm and a weekly timer enable you to get notified whenever the capacity needs to be checked.

Water Chiller Durable Touch Screen

What are the Additional Accessories of a Water Chiller?

The evaporator, condenser, compressor, and expansion valves are present in the air and water type chiller. Still, the cooling tower and the water pump are exclusive and unique to the Water Chiller.

Cooling Tower

It is usually located outside the building, allowing the interaction between the air and the water.

The air used for this purpose is moist air which takes the heat from the water, and the water is chilled as a result.

The chilled water is then returned to the system to absorb heat as heat always travels from a higher medium to a lower medium.

Water Pump

A strong water pump is required to pump the water against the gradient. When the water flows from a height, it flows spontaneously and gives off energy, thus making a passive process.

However, when it is to be transported against gravity, it is an active process and needs energy in the form of a pump.

Water Chiller Energy Saving Water Pump

What is the Cooling Capacity of a Water Chiller?

The cooling capacity of a Water Chiller is its efficiency of producing cooling and lowering the temperature of its surroundings, absorbing heat produced in the industries.

You can determine the cooling capacity by the following method:

Compute Temperature Differential = Incoming Water Temperature (°c) – Required Chilled Water Temperature.

Calculate the water flow rate you need each hour (m³/hour).

High loads of cooling limit = Water Flow Rate into Temperature Differential

It is divided by 0.86 divided by 3.517.

Oversize the Water Chiller by 20% Ideal Size in Tons = Ton x 1.2.

This is the ideal size for your application requirements.

For instance, the size of chiller needed to cool 5m³ water from 25°c to 15 °c in 60 minutes is calculated as

Temperature Differential = 25°c-15°c=10°c.

Water Flow Rate = 5 m³/hour.

Ton Capacity = 5 x 10 ÷ 0.86 ÷ 3.517 = 16.53 Ton.

Oversize the Water Chiller = 16.53 x 1.2 = 19.84 Ton.

A 19.84 tons chiller is required.

What is the Temperature Ranges for a Water Chiller?

A Water Chiller is capable enough to control the range from 5 to 35 degrees Celsius. Talking about low temperatures, it can go as low as -40 degrees.

It covers a considerable range and applies to a vast range of applications.

Also, the ambient temperature shall be regulated, and it can be adjusted easily when the setup is indoors.

There is a need for special water treatment and preventive measures to maintain efficiency in harsh environments.

Water Chiller Ambient Temperature Adjustment

How to Handle your Water Chiller in Harsh Weather?

Handling the Water Chiller in extreme weather can be challenging.

Extremely Cold

- Check the level of the refrigerant.

- Use a good quality antifreeze like glycol to prevent the water from freezing in the pipes.

- Keep the chiller in a shade so that there is no snow, hail, or direct rain.

- Install your Water Chiller on a higher level from the ground to control the temperature.

Extremely Hot

- Prevent your chiller from direct sunlight by installing it in a shaded area.

- Keep a check on the pipelines to allow the expansion of the metal due to heat.

- The blower fan of the cooling tower shall be inspected regularly to ensure proper working.

How to Test your Water Chiller?

It is best to test your Water Chiller to evaluate any drop in performance and efficiency. Also, it must be tested when you are purchasing it so that there is no manufacturing fault.

Performance Testing

Every chiller manufacturing factory has a specialized performance testing facility or laboratory. The test is conducted according to the ARI Standard 550/5905 under strictly controlled conditions.

It needs specialized instruments and computerized data analysis.

This test confirms the performance potential, and if it does not meet the standard, corrections are made before it leaves the factory.

Limitations

When the Water Chiller is installed at the selected site, it becomes difficult to control all the external conditions, and therefore, the test results are not promising.

Other factors that help to evaluate the performance include:

- Calculation methods

- Calibration

- Resolution measurement

- Accuracy

- Uncertainty

- Average day’s outdoor air temperature

- Day’s high temperature

- Day’s low temperature

- Day’s high wet-bulb temperature

- Chilled-water supply temperature

- Total ton-hours (kWh) production of chilled water for the day

- Total kWh power input for each component for the day

- Average kW/ton for the plant for the day

What are the Types of a Water Chiller?

A Water Chiller has different types based on function and its application.

- Explosion Proof Water Chiller

- Water Cooled Scroll Chiller

- Stationary

- Industrial Water Chiller

- Low-Temperature

- Open Type

- Customized

- Portable Water Chiller

Portable Water Chiller

What are the Alternate Energy Sources for your Water Chiller?

To meet the application requirements, you must have alternate or backup energy resources to deal with any sort of causality.

It can be done by internally generated electricity or an alternate and constant chilled water source. It can be done by relying on fossil fuel, natural gas, extensively used to produce low-cost electricity.

Generator

A generator system can internally generate electricity. The generator is sized proportionally per the electricity demand of the application.

Electrical generation can also be outsourced to reduce internal capitalization. An engine is directly or indirectly coupled to a Water Chiller in this case.

Indirect Method

The chiller can operate by utilizing an alternative electricity source or fuel. For this purpose, the engine shall be coupled to the chiller directly.

Alternative Fuel

Some specific designs and configurations of a Water Chiller allow the utilization of renewable fuels or fossil fuels as a direct energy source.

These sources include hot water, biodiesel, waste to energy boilers, steam, landfill gas, and natural gas.

Thermal Storage

It is a great alternative to produce chilled water or ice when the electricity costs are high. This energy is stored in tanks and is used up when cooling loads are faced.

What are the System Configurations in a Water Chiller?

The system configurations of a Water Chiller have two main categories:

Series

Several units of a Water Chiller are connected in a series to increase the efficiency when they are in even number. All the units are run simultaneously.

It is done for very huge industrial setups that require multiple chillers at a time. This is to control the water flow.

Parallel

This configuration is offered when multiple units of a Water Chiller are used, and each one participates according to the requirement of the application. It is more common than series configuration.

Water Chiller Parallel Configurations Details

What are the Tips and Tricks for Increasing the Life of your Water Chiller?

The tips and tricks to Increase the life of your Water Chiller are as follows:

- Carry out a well-controlled assessment routine for your chiller to closely check the performance with time.

- Keep inspecting the coils and pipelines for the accumulation of any dust, calcium or magnesium ions, or debris to remove it timely, and no obstruction is created.

- Always maintain the refrigerant charge and don’t let it lower down as it lowers the performance by 5-10%.

- Routine upkeep and maintenance to investigate condenser coils for obstructing and free air sections.

- Keep a check on any damaging agents and if you find any damages, get them fixed as soon as possible so that there is no long-term effect.

- Maintain a good water supply, and it’s best to use chilled water.

How to Troubleshoot the Problems of your Water Chiller?

The most probable problems that arise in a Water Chiller and their solutions include:

Does Not Start

- Check all the electricity and other connections to make sure that it is connected to the main supply.

- Make sure that the voltage is sufficient to run it.

- The wiring shall be sturdy, intact, and powerful enough to allow the required flow of electricity.

Low Efficiency

- Check all the pipes and connections to see if there are any obstructions. Any accumulated dirt and debris tends to block the passage.

- The refrigerant level shall be well maintained.

- It must receive a sufficient amount of water with the required flow rate.

- There might be some leakage in the pipes which needs to be detected and fixed.

Noise and Vibration

- It may arise due to some damage or insufficiency of any component of the Water Chiller.

- Thorough inspection with strict maintenance can spare your unit from long-term damages.

What are the Maintenance Requirements of a Water Chiller?

The maintenance requirement of your Water Chiller includes:

- It must be placed in a well-ventilated area to allow maximum airflow.

- Prevent any dust or residue from entering the chiller as it can obstruct the pipes.

- Any untrained person shall not be allowed to operate or deal with the chiller, and only a well-experienced person should be responsible for the maintenance routine.

- Please keep a record of all the maintenance to compare it for assessment of the efficiency later.

- If you have voltage issues, use a stabilizer.

- Keep a check on the refrigerant level to detect any leaking on the initial level.

- Keep on checking the oil level and compressor working pressure.

- The pump and machine shall be regularly checked for any leakage or spills.

- See if there is any overheating of any components while running for long hours.

- The orientation of the fan and the pump shall be checked to see if there is any noise or grease.

Water Chiller Maintenances