TopChiller can design and manufacture all types of semiconductor chillers for you

- Cooling capacity ranges from 1 Ton to 85 Ton

- Temperature control ranges from 5℃to 35℃

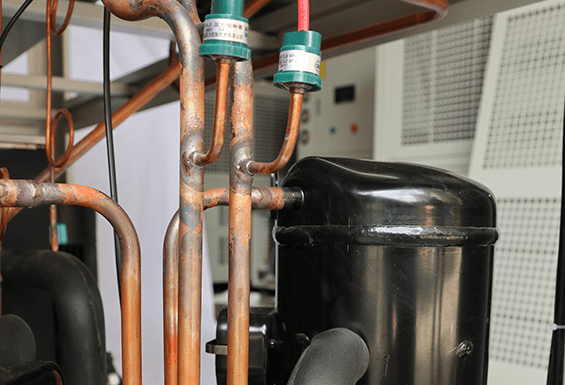

- Scroll compressor with superb efficiency

- Low and high-temperature sensitive alarms

- Water refilling & external pressure adjustment

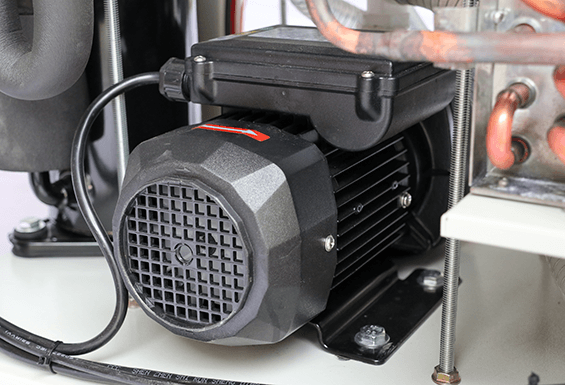

- Unified polyethylene tank & water pump

- Temperature and pressure-flow adjustment

- Non-marring locking caster & small footprint

Your Premier Semiconductor Chiller Manufacturer and Supplier in China

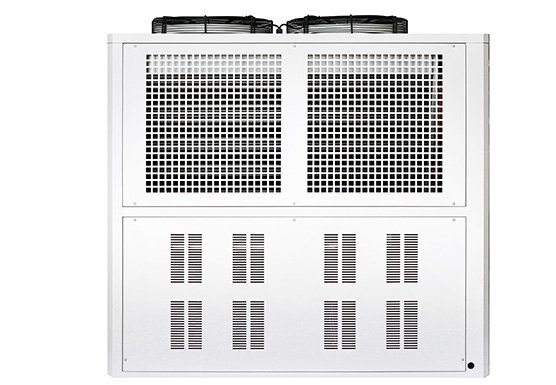

Semiconductor Chiller is a peculiar design cooling machine working on refrigeration principle for heat exchange and cooling products in semiconductor manufacturing and microchip processing by using chilled water or air circulation.

TopChiller is a renowned company in China that has engineered the best systemized Semiconductor Chiller with a superb performance to meet the needs of specific applications of the customers since 1999.

For over the last twenty years TopChiller has successfully manufactured a full stock of certified Semiconductor Chiller and supplied it to a various array of well-known companies all over the world.

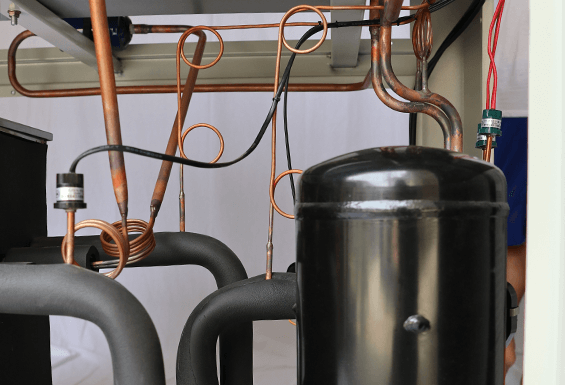

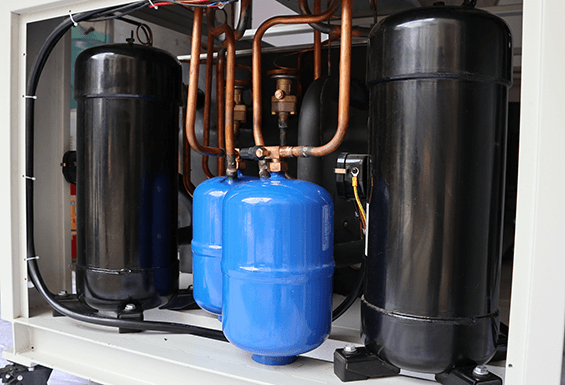

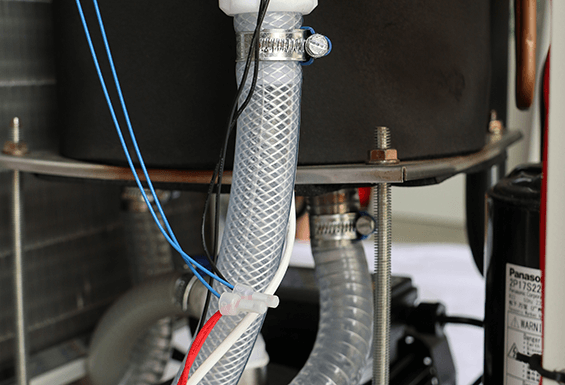

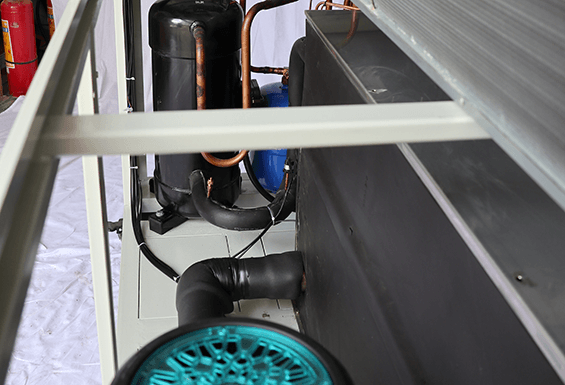

TopChiller has designed Semiconductor Chiller by using different branded components as scroll compressor, heat exchanger, water tank, water/air-cooled condenser, water pump, control system, pressure flow adjusting unit, temperature sensor, fluid reservoir, Airflow inlet, hot gas bypass, and eco-friendly refrigerant.

TopChiller designed Semiconductor Chiller has a large number of remarkable benefits for Semiconductor processing industries as given below.

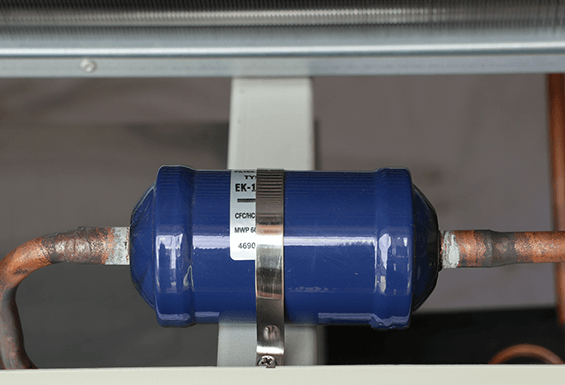

- Semiconductor Chiller is installed with environment-friendly CFC refrigerant and corrosion-free wetted surfaces that enable coolant streamline flow by protecting from erosion and obstruction in coils.

- TopChiller designed Semiconductor Chiller has an energy-efficient compressor featured with a hot gas bypass that automatically regulates heat load and pressure ultimately protecting the compressor and pressure from heating damage.

- Semiconductor Chiller is easy to install for small space applications, easy to move and standby as well as supports the microchip processing configured by locking caster wheels and small footprint.

- TopChiller brand Semiconductor Chiller provides a consistent cooling effect to semiconductor machines either by using air conditioning or chilled water circulation inside insulated coils of the unit triggered with consistent compression force.

- Semiconductor Chiller performs a reliable and noise-free quiet operation featured by suction valves and smoothly working scroll compressor.

- TopChiller engineered Semiconductor Chiller protects the owner from extra expenses for unit maintenance configured by the installation of high/low-temperature sensors that cut-off power supply in an emergency.

Semiconductor Chiller is used for a variety of applications as given below:

Process chamber cooling, semiconductors processing, ATE regulation, microchip manufacturing, PVD, lithography, CMP, mass spectroscopy (MS), Ion torrent machines, metrology tools cooling, UV cure system, crystal growing, and cutting, etc.

If you want to purchase a best-suited and highly applicable Semiconductor Chiller for your application?

If you are sourcing to find the best manufacturing company of Semiconductor Chiller with superb reliability and flawless performance in China?

TopChiller Company is best to choose supporting customers significantly. For further details and solutions for your problem, make contact with TopChiller sales and technocrats to get the best optimal solution and buying assistance for Semiconductor Chiller.

Our team is committed to availing our clients with notations about a Semiconductor Chiller best suited to your application after thoroughly understanding customer requirements.

General Description:

A Semiconductor Chiller is a competent cooling machine for removing heat produced by exothermic processes in semiconductor industries. It utilizes a quality coolant to transfer heat, which can be later dissipated to the environment.

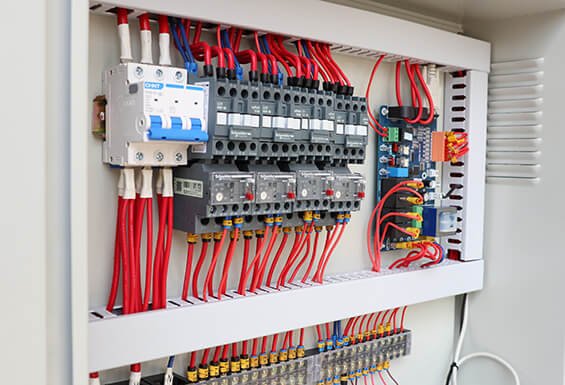

Semiconductor Chiller manufactured by TopChiller contains branded parts including condenser, evaporator, compressor, and expansion valve that work in close coordination to run the refrigeration cycle. It comes in various sizes and models. Each type has a specific kind of compressor depending upon the cooling load. The microprocessor unit and sensitive alarm sensors allow precise function.

TopChiller designed Semiconductor Chiller is famous for UV cure system cooling, equipment wafer chuck burn-in heating or cooling, process chamber cooling, automatic test equipment (ATE) test head cooling, metrology tool cooling, and laser trimming system cooling

If you want to protect your equipment in the semiconductor industry and prevent overheating by removing excess heat, then the TopChiller brand shall be your first choice.

TopChiller specializes in highly efficient and advanced technology, Semiconductor Chiller, with various unique features.

With over 20 years of experience, TopChiller excels in multiple types of Semiconductor Chillers. You can get your hands on the most demanded and popular cooling system for your semiconductor industry by contacting our active customer service.

Features and Advantages:

The unique features and advantages of a Semiconductor Chiller are mentioned below.

- With 3,000 or 5,000 watts of cooling capacity and ±0.05°C temperature stability, it enables you to obtain maximum precision and accuracy.

- Enabled with thermoelectric technology, it provides higher thermal energy transfer ensuring maximum productivity of your cooling applications.

- The modular design uses high-quality, environment-friendly refrigerants, eliminating expensive coolants like Golden or Fluorinert. It leads to cost-effective use with minimum maintenance.

- Screw, scroll, and centrifugal compressors can be joined in series to maximize efficiency and a more stable function.

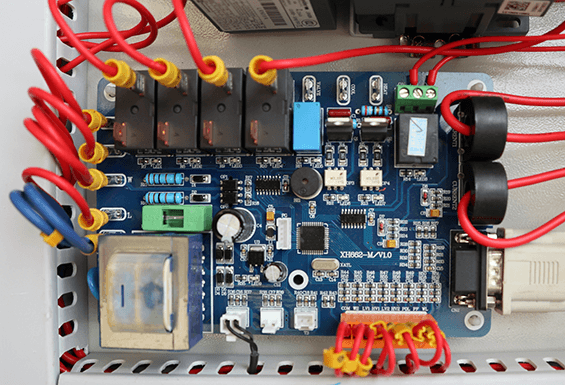

- A highly efficient and advanced PID microprocessor unit provides centralized control through active, sensitive sensors that indicate deviation from any set conditions. It ensures the protection of your equipment and safe function.

- Data Sheet

- Image Gallery

- Main Parts

- Video

| Semiconductor Chiller Technical Specifications | ||||||||||||||

| Items Model | AC-0.5A | AC-1A | AC-1.5A | AC-2A | AC-2.5A | AC-3A | AC-4A | AC-5A | AC-6A | AC-8AD | AC-10AD | AC-12AD | AC-15AD | |

| Cooling capacity | Kcal/h 50HZ/60HZ | 1419 | 2451 | 3182 | 4833 | 5848 | 7181 | 9288 | 11988 | 14534 | 18576 | 23994 | 29068 | 38270 |

| 1703 | 2941 | 3784 | 5800 | 7018 | 8617 | 11146 | 14386 | 17441 | 22291 | 28793 | 34882 | 45924 | ||

| KW 50HZ/60HZ | 1.65 | 2.85 | 3.7 | 5.62 | 6.8 | 8.35 | 10.8 | 13.94 | 16.9 | 21.6 | 27.9 | 33.8 | 44.5 | |

| 1.98 | 3.42 | 4.4 | 6.74 | 8.2 | 10.02 | 12.96 | 16.73 | 20.28 | 25.92 | 33.48 | 40.56 | 53.4 | ||

| Input power | KW | 0.88 | 1.35 | 2 | 2.25 | 2.66 | 3.27 | 4.07 | 5.75 | 6.45 | 8.25 | 11.5 | 12.9 | 17.45 |

| Max Current | A | 5.4 | 8.2 | 12 | 13.6 | 6.6 | 8.2 | 10.1 | 13.8 | 15.5 | 20 | 27.9 | 31.3 | 42.4 |

| Power source | 1PH~220V/3PH~220V/380V 50HZ/60HZ | 3PH~380V/415V/480V~50HZ/60HZ(3PH~200V/220V 50HZ/60HZ) | ||||||||||||

| Refrigerant | Type | R22/R407C/134a/404A/410A | ||||||||||||

| Control | Capillary / thermostatic expansion valve | |||||||||||||

| Compressor | Type | Hermetic Rotary | Hermetic scroll ( piston ) | |||||||||||

| Power(KW) | 0.45 | 0.89 | 1.3 | 1.73 | 2.1 | 2.7 | 3.5 | 4.55 | 5.25 | 3.5×2 | 4.55×2 | 5.25×2 | 7×2 | |

| Condenser | Type | Efficient finned copper tube with aluminum+low noise external rotor fan | ||||||||||||

| Air flow (m3/h) | 750 | 1000 | 1500 | 2000 | 2500 | 3000 | 4000 | 5000 | 6000 | 8000 | 10000 | 12000 | 15000 | |

| Air blower(KW) | 0.06 | 0.09 | 0.15 | 0.15 | 0.19 | 0.14×2 | 0.14×2 | 0.19×2 | 0.19×2 | 0.25×2 | 0.45×2 | 0.45×2 | 0.6×2 | |

| Evaporator | Type | SS Tank coil / shell and tube type / Plate type heat exchanger | ||||||||||||

| Chilled water (m3/h) | 0.28 | 0.49 | 0.64 | 0.97 | 1.12 | 1.44 | 1.86 | 2.4 | 2.91 | 3.71 | 4.8 | 5.81 | 7.65 | |

| 0.34 | 0.59 | 0.76 | 1.16 | 1.4 | 1.72 | 2.23 | 2.88 | 3.49 | 4.46 | 5.76 | 7 | 9.18 | ||

| Water tank(L) | 10.6 | 18.3 | 27 | 27 | 50 | 50 | 60 | 60 | 110 | 120 | 200 | 200 | 270 | |

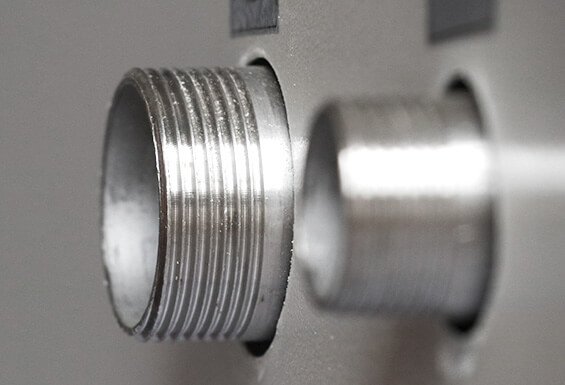

| Inlet/outlet pipe (inch) i | 1/2″ | 1/2″ | 1/2″ | 1/2″ | 1″ | 1″ | 1″ | 1″ | 1″ | 1-1/2″ | 2″ | 2″ | 2″ | |

| Water pump | Power (kw) | 0.37 | 0.37 | 0.37 | 0.37 | 0.37 | 0.37 | 0.37 | 0.75 | 0.75 | 0.75 | 1.5 | 1.5 | 2.2 |

| Max lift(m) | 22 | 22 | 22 | 22 | 22 | 22 | 22 | 30 | 30 | 25 | 25 | 25 | 28 | |

| Max flow (m3) | 5.4 | 5.4 | 5.4 | 5.4 | 5.4 | 5.4 | 5.4 | 8.1 | 8.1 | 8.1 | 13.5 | 13.5 | 25.2 | |

| Safety protection | Compressor inner protection, over current protection, high/low pressure protection, over temperature protection, flow rate protection, phase sequence/phase missing protection, low level coolant protection, anti freezing protection, exhaust overheat protection | |||||||||||||

| Dimension | L(mm) | 550 | 550 | 600 | 600 | 720 | 980 | 980 | 1150 | 1150 | 1350 | 1500 | 1500 | 1860 |

| W(mm) | 350 | 450 | 500 | 500 | 550 | 520 | 520 | 560 | 560 | 680 | 760 | 760 | 850 | |

| H(mm) | 695 | 845 | 985 | 985 | 1350 | 1170 | 1170 | 1215 | 1215 | 1530 | 1660 | 1660 | 1900 | |

| Net weight(KG) | 45 | 62 | 85 | 95 | 125 | 152 | 175 | 185 | 215 | 283 | 345 | 382 | 580 | |

| Note: The above specifications are according to the following design conditions: 1, 12℃/7℃.Chilled water inlet/outlet temperature 12℃/7℃. 2, 33℃/38℃.Cooling air inlet/outlet temperature 33℃/38℃. We reserve the right to modify the specification without further notice. | ||||||||||||||

| Semiconductor Chiller Technical Specifications | |||||||||||||

| Items Model | AC-15AT | AC-20AD | AC-20AF | AC-25AD | AC-25AF | AC-30AD | AC-30AT | AC-40AD | AC-40AF | AC-50AD | AC-50AF | AC-60AD | |

| Cooling capacity | Kcal/h 50HZ/60HZ | 36120 | 49966 | 47988 | 58480 | 58136 | 74734 | 74922 | 98040 | 99760 | 119024 | 116960 | 144996 |

| 43344 | 59959 | 57586 | 70176 | 69763 | 89681 | 89990 | 117648 | 119712 | 142829 | 140352 | 173995 | ||

| KW 50HZ/60HZ | 42 | 58.1 | 55.8 | 68 | 67.6 | 86.9 | 87.2 | 114 | 116 | 138.4 | 136 | 168.6 | |

| 50.4 | 69.72 | 66.96 | 81.6 | 81.12 | 104.28 | 104.64 | 136.8 | 139.2 | 166.08 | 163.2 | 202.3 | ||

| Input power | KW | 17.1 | 21.73 | 22 | 25.4 | 24.8 | 33.39 | 33.1 | 44.91 | 43.3 | 57.3 | 54 | 65 |

| Max Current | A | 43.2 | 52.7 | 53.3 | 63.7 | 61.3 | 81 | 80.2 | 109 | 106 | 135.5 | 128.5 | 135 |

| Power source | 3PH~380V/415V/480V~50HZ/60HZ(3PH~200V/220V 50HZ/60HZ) | ||||||||||||

| Refrigerant | Type | R22/R407C/134a/404A/410A | |||||||||||

| Control | Capillary / Thermostatic expansion valve | ||||||||||||

| Compressor | Type | Hermetic scroll ( piston ) | |||||||||||

| Power(KW) | 4.55×3 | 8.96×2 | 4.55×4 | 10.8×2 | 5.25×4 | 13.62×2 | 8.96×3 | 18.78×2 | 8.96×4 | 23.6×2 | 10.8×4 | 27.4×2 | |

| Condenser | Type | Efficient finned copper tube with aluminum+low noise external rotor fan | |||||||||||

| Air flow (m3/h) | 15000 | 20000 | 20000 | 25000 | 25000 | 30000 | 30000 | 40000 | 40000 | 50000 | 50000 | 60000 | |

| Air blower(KW) | 0.6×2 | 0.78×2 | 0.78×2 | 0.78×2 | 0.78×2 | 0.42×6 | 0.42×6 | 0.6×6 | 0.6×6 | 0.78×6 | 0.78×6 | 0.78×6 | |

| Evaporator | Type | SS Tank coil/ shell and tube type/Plate type heat exchanger | |||||||||||

| Chilled water (m3/h) | 7.22 | 10 | 9.6 | 11.69 | 11.62 | 14.94 | 15 | 19.6 | 19.95 | 23.8 | 23.4 | 29 | |

| 8.67 | 11.99 | 11.51 | 14.03 | 13.95 | 17.93 | 18 | 23.52 | 23.94 | 28.6 | 28.1 | 34.8 | ||

| Water tank(L) | 270 | 350 | 350 | 350 | 350 | 420 | 420 | 580 | 580 | 580 | 580 | 580 | |

| inlet/outlet pipe (inch) | 2″ | 2″ | 2″ | 2-1/2″ | 2-1/2″ | 2-1/2″ | 2-1/2″ | 3″ | 3″ | 3″ | 3″ | 3″ | |

| Water pump | Power(kw) | 2.2 | 2.2 | 2.2 | 2.2 | 2.2 | 4 | 4 | 4 | 4 | 5.5 | 5.5 | 5.5 |

| Max lift(m) | 28 | 28 | 28 | 28 | 28 | 30 | 30 | 30 | 30 | 32 | 32 | 32 | |

| Max flow (m3) | 25.2 | 25.2 | 25.2 | 25.2 | 25.2 | 36 | 36 | 36 | 36 | 40 | 40 | 40 | |

| Safety devices | Compressor inner protection, over current protection, high/low pressure protection, over temperature protection, flow rate protection, phase sequence/phase missing protection, low level coolant protection, anti freezing protection, exhaust overheat protection | ||||||||||||

| Dimension | L(mm) | 1860 | 2020 | 2020 | 2020 | 2020 | 2200 | 2200 | 2350 | 2350 | 2600 | 2600 | 2600 |

| W(mm) | 850 | 950 | 950 | 950 | 950 | 1150 | 1150 | 1350 | 1350 | 1500 | 1500 | 1500 | |

| H(mm) | 1900 | 2000 | 2000 | 2000 | 2000 | 1980 | 1980 | 2000 | 2000 | 2100 | 2100 | 2100 | |

| Net weight(KG) | 580 | 650 | 650 | 810 | 810 | 890 | 890 | 1112 | 1112 | 1320 | 1320 | 1320 | |

| Note: The above specifications are according to the following design conditions: 1, Chilled water inlet/outlet temperature 12℃/7℃. 2, Cooling air inlet/outlet temperature 33℃/38℃. We reserve the right to modify the specification without further notice. | |||||||||||||

Why TopChiller is Your Reliable Semiconductor Chiller Manufacturer and Supplier In China?

Semiconductor Chiller-An Ultimate FAQ Guide by TopChiller.

- What is a Semiconductor Chiller?

- What are the Key Components of a Semiconductor Chiller?

- What are the Top Features of a Semiconductor Chiller?

- What are the Types of a Semiconductor Chiller?

- How Does a Semiconductor Chiller Work?

- What are the Applications of a Semiconductor Chiller?

- How is a Semiconductor Chiller Beneficial for your Applications?

- How is a Semiconductor Chiller Different from a Standard Industrial Chiller?

- How to Choose the Best Semiconductor Chiller for your Industry?

- How is a Semiconductor Chiller Energy-Efficient?

- What are the Different Refrigerants Compatible With your Semiconductor Chiller?

- What are the Different Compressors Used for a Semiconductor Chiller?

- How to Reduce the Noise Level of your Semiconductor Chiller?

- What are the ISO Quality Requirements of a Semiconductor Chiller?

- How to Customize your Semiconductor Chiller?

- What are the Protection Devices Installed in a Semiconductor Chiller?

- How to Protect your Semiconductor Chiller from Corrosion?

- How to Maintain your Semiconductor Chiller?

- What are the Precautions for Operating your Semiconductor Chiller?

- How to Troubleshoot your Semiconductor Chiller?

What is a Semiconductor Chiller?

A Semiconductor Chiller is a cooling unit that controls the heat released during manufacturing semiconductors.

It has an optimum working temperature range of +5° to +35°C. It helps control the temperature of the semiconductor manufacturing process and environment, which results in maximum process efficiency and yield.

Different processes are being carried out in the semiconductor industry, such as couple plasma, wet etching, etc., requiring sharp cooling and precise temperature control.

A Semiconductor Chiller has high-quality non-marring locking casters, features a low-profile design, and provides maximum reliability and performance.

It also has a hot gas bypass that provides maximum thermal protection and increased stability in the working of the compressor, motor, and pump.

Moreover, it also involves the use of CFC refrigerant that is environment-friendly, making it safe for the workers as well as the environment.

The refrigerant is also RoHS compliant, ensuring that the standard quality protocols are being followed. It is also anti-corrosive, ensuring that the operation runs smoothly and efficiently.

Semiconductor Chiller Designed by TopChiller

What are the Key Components of a Semiconductor Chiller?

The main components of a Semiconductor Chiller include:

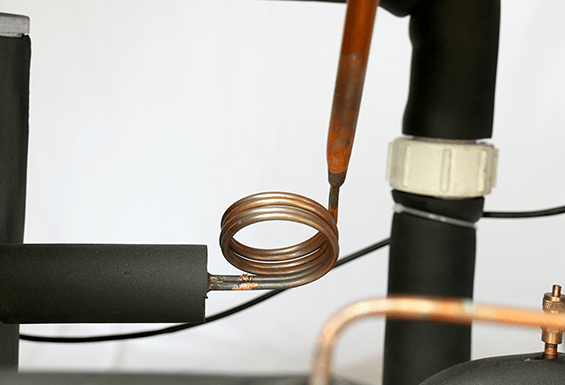

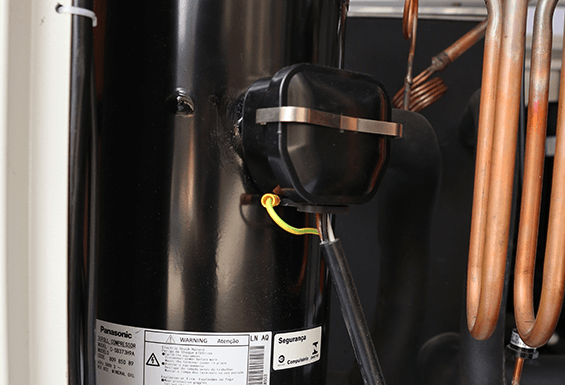

Compressor

The compressor is responsible for maintaining the pressure and speed of the liquid-filled pump. For this, the phenomenon of liquid compression takes place.

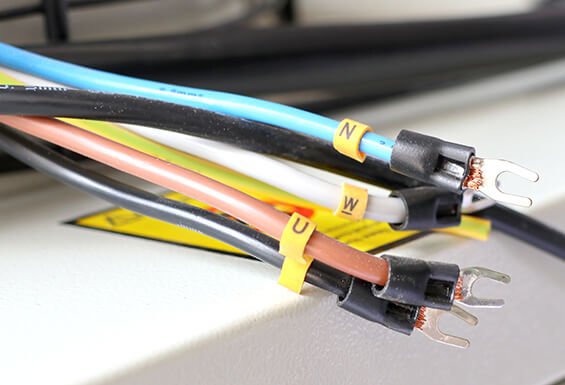

Control Panel

Modern microprocessors are used in making the control panel. It usually has a touchscreen control system.

This panel has the necessary controls to control and adjust your Semiconductor Chiller’s operations.

Condenser

The hot evaporated liquid is condensed back to its solid state by the action of the condenser.

During the process of condensation, an optimum cooling level is reached by removing the extra heat generated during the operation.

Refrigeration System

The refrigeration system collects the entire heat generated in the system. This heat is passed to the condenser from the refrigeration system, from where it is finally removed.

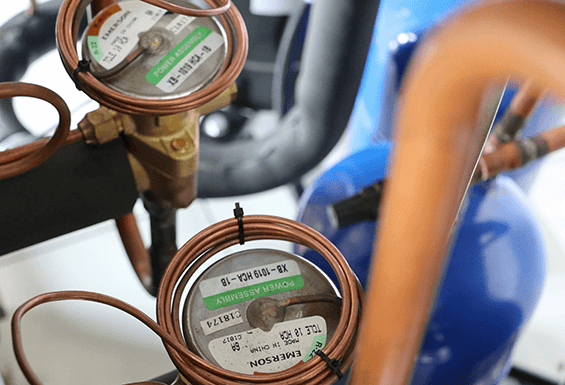

Expansion Valve

These valves work as a pipeline through which the liquid travels in the circuit. Once the cooling cycle is completed, this pipeline also takes the cooled liquid back to the system.

![]()

Semiconductor Chiller Compressor

What are the Top Features of a Semiconductor Chiller?

The top features of a Semiconductor Chiller are:

- CFC refrigerant that is environment-friendly

- Anti-corrosive wetted surfaces

- Easy auto-tuning and full-featured PID controller

- Flow adjustments for external pressure

- 60Hz positive displacement pump

- Cooling output indicator

- O-Ring seal fittings

- Refrigerant receiver with access valve

- Adjustable low and high-temperature alarms

- Liquid filled pressure gauges

- Stainless steel plate heat exchanger with high efficiency

- Removable side and cover access panels

- Remote status signal

- Swivel casters standard

- Dual-frequency compatible

![]()

Semiconductor Chiller Pressure Gauges

What are the Types of a Semiconductor Chiller?

The different types of Semiconductor Chiller available are:

Water Cooled

It uses water as the coolant for the regulation, management, and maintenance of the temperature of the machinery.

The water being used must be pure and clean. This type of Semiconductor Chiller is majorly used for aluminum-based processes.

Air Cooled

In this type, ambient air is used as the refrigerant, which cools down the equipment.

Central Type

It has a large capacity that can reach up to 100 tons and is used for cooling the operation area or room. This is necessary to treat the heat generated by the processes being carried out.

Water Cooled Semiconductor Chiller

How Does a Semiconductor Chiller Work?

The Semiconductor Chiller firstly prepares itself for the operation. This step by making suitable adjustments via the control unit-specific flow rate, pressure, speed, and temperature settings are set.

These settings should be according to the process being carried out. Next comes the liquid compression step, where the refrigerant is changed from its liquid state to evaporated gaseous state.

After compression, all the extra heat generated by the system is collected by the refrigeration system.

This extra heat is then removed via the condenser. In the final step, once the cooling cycle is completed, the refrigerant moves back to the system and starts a new cooling cycle.

What are the Applications of a Semiconductor Chiller?

Semiconductor Chiller is being used in the following industries:

- UV Cure System Cooling

- Equipment Wafer Chuck Burn-In Heating Or Cooling

- Process Chamber Cooling

- Automatic Test Equipment (ATE) Test Head Cooling

- Metrology Tool Cooling

- Laser Trimming System Cooling

How is a Semiconductor Chiller Beneficial for your Applications?

A Semiconductor Chiller offers various benefits for your applications, some of which are:

Advanced Control Unit

It has an innovative and modern control unit that has a touchscreen operation. It has all the required control options necessary for controlling your chiller efficiently.

Temperature Fluctuations Flexibility

It also works well in managing sharp temperature fluctuations during the operation.

As a result, your Semiconductor Chiller becomes highly flexible in terms of controlling temperature changes.

Corrosion Resistant

The body is made of a combination of different materials, including high-grade plastic, stainless steel, and copper. These materials are well-known to resist rust and corrosion.

![]()

Semiconductor Chiller Cabinet Material Manufacturing

How is a Semiconductor Chiller Different from a Standard Industrial Chiller?

The most significant difference between a standard and a Semiconductor Chiller is the process that is responsible for collecting and removing the excess heat produced.

The standard chiller uses different mechanisms, but only one single machine is used in the Semiconductor Chiller, which requires refrigerant first to undergo compression, then refrigeration, and finally condensation.

Another notable difference between these two chiller varieties is their extent of safety features.

In terms of safety and operation, a Semiconductor Chiller is preferable to a standard industrial chiller.

How to Choose the Best Semiconductor Chiller for your Industry?

Some of the most important factors to consider when choosing your best Semiconductor Chiller are:

Versatile Cooling Capacities

Different processes have different cooling requirements. For this reason, choose a Semiconductor Chiller that offers multiple cooling capacities to meet the cooling needs of various processes.

Efficient Performance

The performance should be highly efficient for the smooth and problem-free conduction of the process.

Cooling Precision

Your chiller must have maximum precision temperature and chilling control for fast and quality operation.

Durability

The better the durability, the longer your chiller will live. This will ultimately help you save energy, money, and time using the same Chiller for years.

Eco-Friendly Operation

Your chiller must guarantee eco-friendly operation for the safety of the workers and the environment.

How is a Semiconductor Chiller Energy-Efficient?

A Semiconductor Chiller is highly energy-efficient, which helps in achieving maximum process efficiency with less energy expenditure.

The following benefits can be used to determine its energy efficiency. It carefully regulates temperature and speeds up the process.

Using less energy in a shorter period saves a significant proportion of energy monthly or yearly.

It is entirely lead-free and free of any malfunctions. The procedure will be more energy efficient if there are no leaks.

Appropriate settings are the most fundamental and crucial strategy to enhance cooling performance.

The capacity of the Semiconductor Chiller should guide your parameter selection.

The person operating must be well-trained to ensure running smoothly and without faults or difficulties. The key to optimization has a precise operating system.

What are the Different Refrigerants Compatible With your Semiconductor Chiller?

The different refrigerants compatible with your Semiconductor Chiller are mentioned below:

Refrigerant No. 1

- Type: HC

- Refrigerant: R-600a

- Normal Boiling Point: −11.7

- GWP: 3

- ODP: 0

- Safety Group: A3

- Molecular Weight:122

Refrigerant No. 2

- Type: HFC

- Refrigerant: R-134a

- Normal Boiling Point: −26.3

- GWP: 1,430

- ODP: 0

- Safety Group: A1

- Molecular Weight:03

Refrigerant No. 3

- Type: PFC

- Refrigerant: R-218

- Normal Boiling Point: −36.7

- GWP: 8,830

- ODP: 0

- Safety Group: A1

- Molecular Weight:02

Refrigerant No. 4

- Type: HC

- Refrigerant: R-290

- Normal Boiling Point: −42.1

- GWP:3

- ODP: 0

- Safety Group: A3

- Molecular Weight:096

Refrigerant No. 5

- Type: PFC

- Refrigerant: R-116

- Normal Boiling Point: −78.2

- GWP: 12,200

- ODP: 0

- Safety Group: A1

- Molecular Weight:01

Refrigerant No. 6

- Type: HFC

- Refrigerant: R-23

- Normal Boiling Point: −82.1

- GWP: 14,800

- ODP: 0

- Safety Group: A1

- Molecular Weight:014

Refrigerant No. 7

- Type: PFC

- Refrigerant: R-14

- Normal Boiling Point: −127.8

- GWP: 7,390

- ODP: 0

- Safety Group: A1

- Molecular Weight:010

![]()

Semiconductor Chiller Eco-Friendly Refrigerants

What are the Different Compressors Used for a Semiconductor Chiller?

The different types of compressors used in a Semiconductor Chiller include:

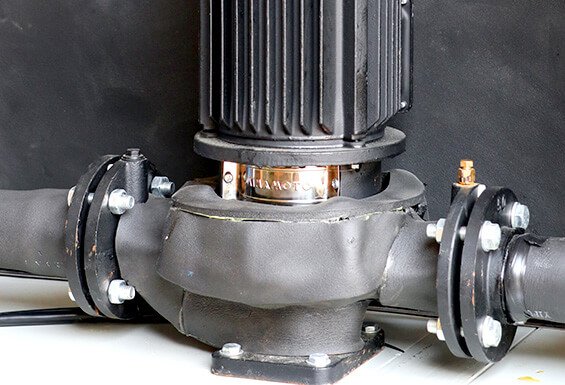

Screw Compressor

A screw compressor is required for managing significant pressure and flow rate ranges. It involves the working of two or more rotating screws.

The rotation of these screws achieves the required flow rate and pressure.

Scroll Compressor

As the name says, metal scrolls are involved in the working of the scroll compressor. They follow a back and front pattern for providing the required flow rates and pressure.

One scroll is constantly moving, whereas the remaining scroll (one or two) is stationary.

Centrifugal Compressor

It uses centrifugal force principles to obtain the required flow rate and pressure changes.

![]()

Semiconductor Chiller Centrifugal Compressor

How to Reduce the Noise Level of your Semiconductor Chiller?

Working in a noisy environment is never comfortable. For this reason, you should always ensure maximum noise reduction in the performance of your Semiconductor Chiller.

Grease and lubricant should be applied to any moving parts that generate noise. As a result, the rotating parts will run smoothly with low noise emissions.

An appropriate proportion of rubber, paper pads, wood, or any other type of noise-reducing material should be used to keep the bottom free from noise.

Proper lubrication and operation of sliding components are essential. As a result, the noise production will be minimal to non-existent.

![]()

Semiconductor Chiller Noise Reduction

What are the ISO Quality Requirements of a Semiconductor Chiller?

It is crucial that your Semiconductor Chiller must comply with the ISO standards. Here is a list of some essential quality elements that you must ensure:

- RoHS Safety and Quality Certification

- DIN EN ISO 14001 for 2002 and 2004

- WCCL Quality Certifications by AHRI

- DIN EN ISO 14001 for 2015

- ACCL Quality Certifications by AHRI

- UL Quality Standards and Certifications

Some Additional Safety Requirements

- ADOCE (Accredited Disposal Operations for Cooling Equipment) QSK to dispose of the discarded components safely.

- The US EPA Safety Standard for Environmental Protection protects the environment and workers.

- Safety certification from local safety standardization organization or agency certified safety certification.

- DIN EN ISO 4001 Environmental Management System Certification.

How to Customize your Semiconductor Chiller?

Some customization options available for a Semiconductor Chiller are:

- Interlocks or Controls

- PLC Controller

- Remote Start and Stop

- RS232 And RS485 Communication

- Visual Alarm Beacon

- Audible Alarm With Silence

- Fluid Monitoring And Control Devices

- 24V Control Systems

- NEMA 4 Controls (Outdoor)

- Power Cord Extension

- NRTL Certifications

- Remote Control

- Multiple Pump Upgrades

- Electrical

- Remote Temp Sensing

- Phase Monitor

- Specialty Wetted Construction Materials

- CE Compliance

- Immersion Heaters

- Particle Filters

- Anti-Drain Back Prevention

- UV Filters

- Drain Kits

- Fluid Circuit Insulation

- Fluid Conductivity Control Systems

- Manifolds

- Automatic Fluid PH Control Systems

- Corrosion Inhibitors

![]()

Semiconductor Chiller PLC Controller

What are the Protection Devices Installed in a Semiconductor Chiller?

Some primary protection devices installed in a Semiconductor Chiller are:

- Motor Overheat Protection

- Motor Overload Protection

- Low And High-Pressure Protection

- Low And High Water Flow Level Protection

- Anti-Freeze Protection

Protection Protocols

There are various protection protocols that you must follow when using your Semiconductor Chiller.

The safety of the industry and workers is the primary concern of the preventive measures. Both of these are discussed below.

Worker Safety

Chiller safety procedures should be taught to all employees. Personal Protective Equipment (PPE) should be required for everyone who works at a job.

Wearing goggles, gloves, and safety shoes are mandatory for the individual operating the machine.

Industrial Safety

The Semiconductor Chiller must be managed and maintained such that no damage is done to the surrounding area.

A good guideline is to avoid overloading it. Unexpected explosions and destruction to the nearby property are the two possibilities in this case.

If it makes a lot of sound and vibrations, seek professional help.

![]()

Wear PPE Before Handling your Semiconductor Chiller

How to Protect your Semiconductor Chiller from Corrosion?

Corrosion is a significant problem that disturbs the performance of metal machinery. The same is the case with Semiconductor Chiller.

You can protect it against rusting by following these guidelines.

- Extraordinarily acidic or essential compounds should be avoided.

- The use of cleaning products must be done according to the established standards.

- The component’s outside surfaces should be kept dry at all times.

- Internal corrosion may be caused by wear, states, holes, etc. Repair all these minor issues.

Exterior elements of any equipment are also coated with corrosion-resistant materials to prevent corrosion.

There are various coating options for a Semiconductor Chiller, including rubber coating, paint, corrosion inhibitor coatings, and more.

However, a coating with suitable corrosion blockers is the best option.

This sort of coating is extremely thin and also performs exceptionally well. It also enhances the aesthetic appeal of the chiller.

How to Maintain your Semiconductor Chiller?

The maintenance of your Semiconductor Chiller is based on a list of several essential considerations.

Using this guide, you can ensure that all components are being maintained correctly.

A few items should be on your regular maintenance to-do list.

- Regular check all the water inlets and outlets.

- Compressor unit problems like leakage, vibrations, and oil levels should be inspected.

- Electrical contacts should be inspected and cleaned.

- Clean, inspect and replace the filter units timely.

Maintenance Duration

The maintenance duration is different for various models, designs, and kinds of refrigerants.

To keep a water-cooled system in good condition, it should be serviced every week. After ten days, a thorough examination and maintenance must be performed for air-cooled systems.

For some models, monthly maintenance is also sufficient. In the event of complex and professional maintenance, an expert is needed to get the job done.

If you don’t have the competence to maintain and repair the control unit, you won’t be able to do so. Vast and versatile knowledge is required to run a Semiconductor Chiller smoothly.

![]()

Semiconductor Chiller Maintenances

What are the Precautions for Operating your Semiconductor Chiller?

A Semiconductor Chiller requires highly accurate and precise temperature control operation.

Even a slight problem in the environment of operation area a chiller can suffer from small-scale to large-scale damage.

During the operation, you should have the following concerns in mind.

- Cleanliness and dryness are essential in every setting.

- It should be free of any odors, vapors, or other humid particles of gases.

- Moisture levels in the surrounding area should be ideal, which means absolutely low.

Operator error is one of the most serious mistakes you can make. It’s frequently because of a worker’s inability to use the chiller.

A significant loss might be due to the result of unprofessional service and operation processes. You won’t be able to detect any damage, leading to a more considerable collapse in the future.

This includes using refrigerants from dirty water sources and adjusting the wrong operation settings.

The Semiconductor Chiller may not provide the desired temperature control efficiency if the standard process parameters are not followed.

How to Troubleshoot your Semiconductor Chiller?

For troubleshooting your Semiconductor Chiller, follow these practices:

Late or No Maintenance

There are several things that lower the efficiency of a chiller, but this is the most common.

If it is not maintained, it will have minor to significant issues and will not perform at its best.

Overloading

The cooling performance of your Semiconductor Chiller might be drastically reduced if you use it above its optimum capacity.

Improper Power Source

If the power supply is unsuitable, it may not function correctly, and the performance efficiency will drop.

When it Fails to Start

This might be due to an issue with the power wire connections. Or perhaps as a result of the fault with the control unit.

With the assistance of an expert, inspect the control unit and power lines and get them fixed.

Improper Cooling

This might be due to various issues, including leaking, delayed maintenance, and inadequate flow rate. Find out and resolve any such problems.

You should replace the worn-out and outdated components with new ones. Replacing such parts enables your Semiconductor Chiller to operate more efficiently.

Also, it will lower the maintenance cost by ensuring low energy usage. Moreover, you will not face performance issues or breakdowns, particularly with demanding applications.

Eventually, you may upgrade the damaged components using the latest technology, increasing the system’s efficiency.

Troubleshoot of Semiconductor Chiller