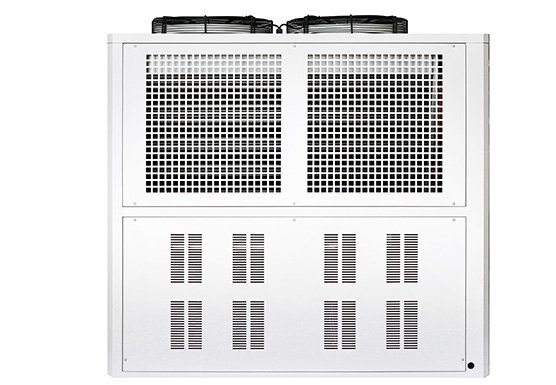

TopChiller can design and manufacture all types of Ice Cream&Yogurt Chiller&Cooling System

- Cooling capacity ranges 8KW to 360KW

- Temperature control ranges -5°C to 25°C

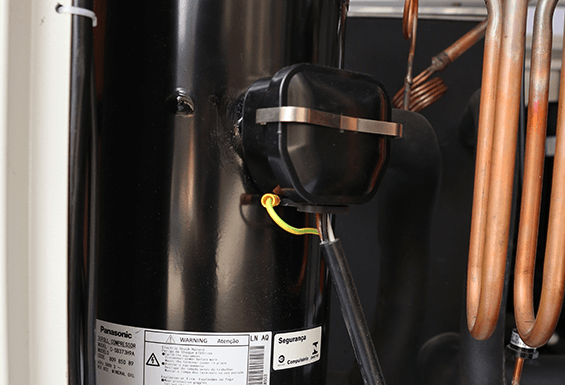

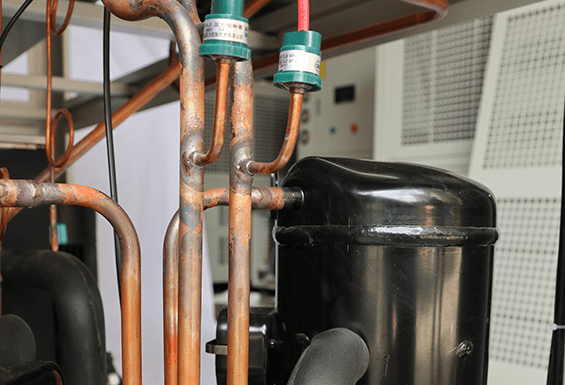

- Efficient scroll and screw compressor

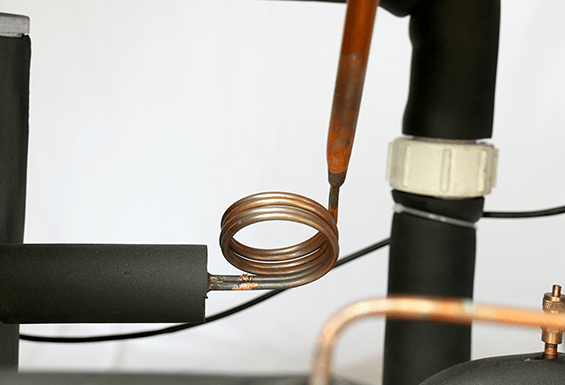

- Stainless steel brazed plate heat exchanger

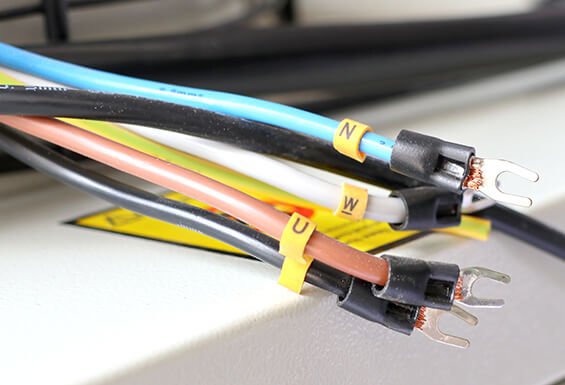

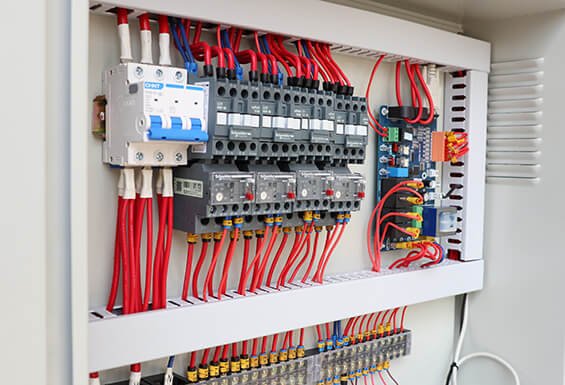

- Hot gas bypass, weatherproof electric panel

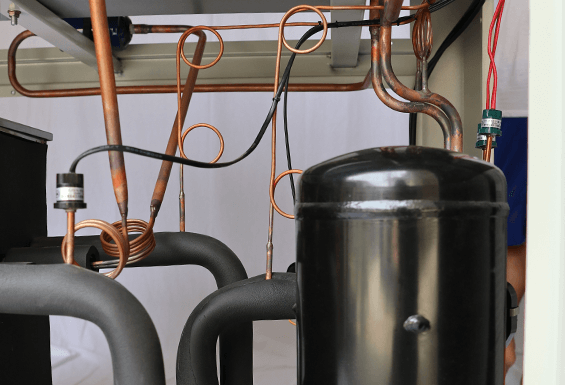

- Air-cooled condenser & copper water lines

- Crankcase heater & single refrigeration Circuit

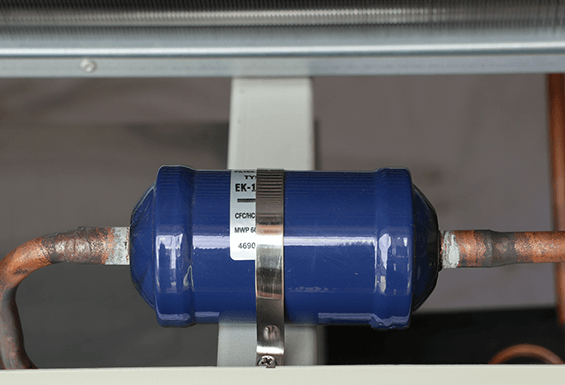

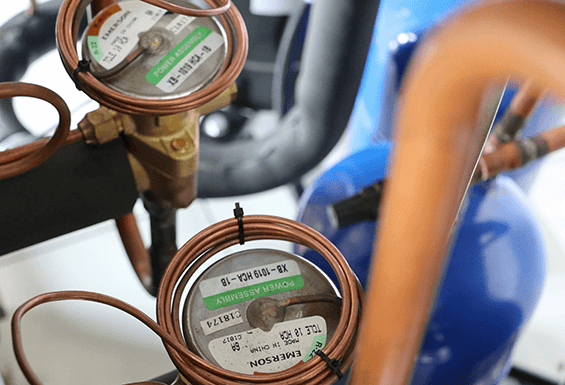

- Expansion valve with filter drier& sight glass

Your Professional Ice Cream & Yogurt Chiller & Cooling System Manufacturer and Supplier in China

Ice Cream& Yogurt Chiller& Cooling System is peculiarly used for ice cream and yogurt production processing to regulate temperature and cooling effect by chilled water circulation.

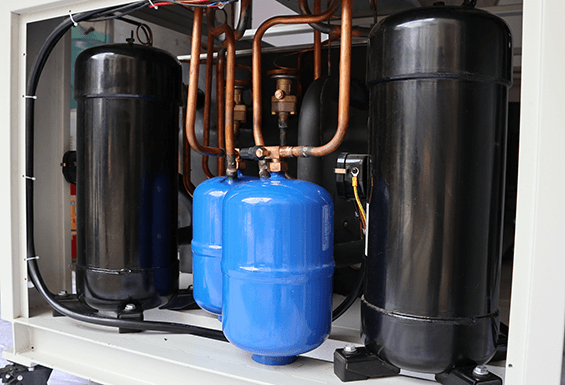

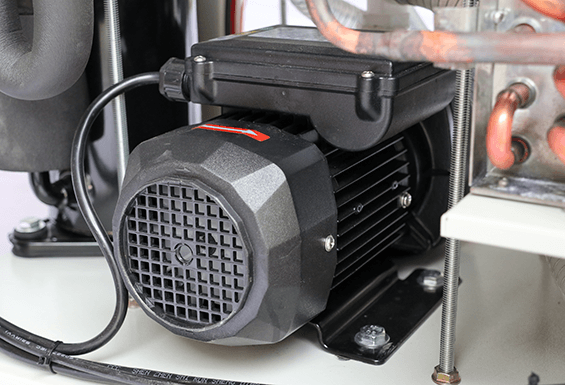

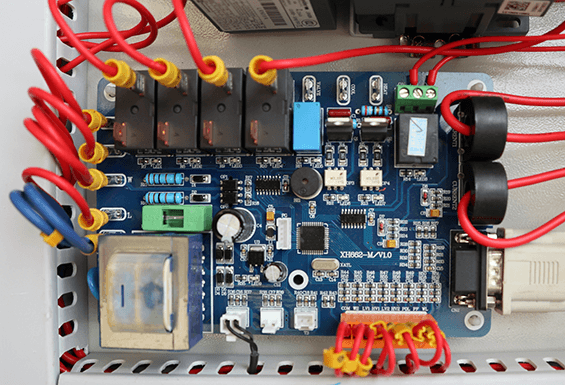

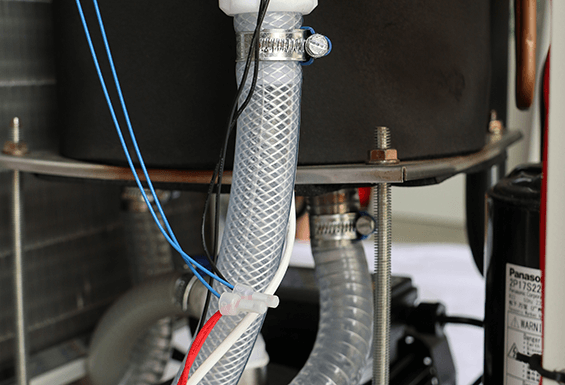

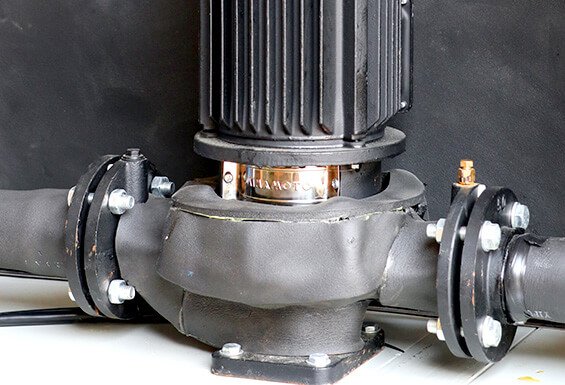

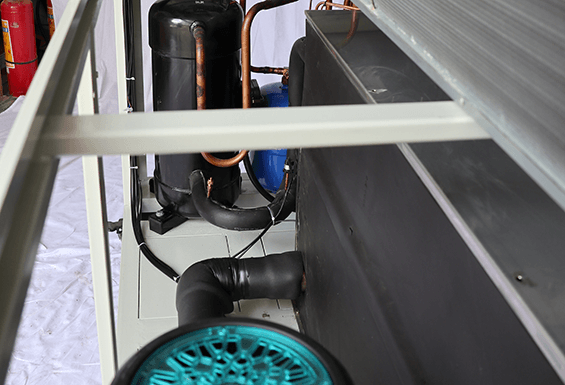

Ice Cream& Yogurt Chiller& Cooling System made by TopChiller consists of scroll/screw compressor, water tank, water pump, condenser, temperature controller, hot gas bypass, crankcase heater, solenoid valve, expansion valve, refrigerant tank, evaporator, power supply, and control system.

Since 1991, TopChiller Company is keenly working as a manufacturer and supplier of highly reliable Ice Cream& Yogurt Chiller& Cooling systems in China with superb accuracy.

By providing top-class and high-standard Ice Cream& Yogurt chillers & Cooling systems to the world market, TopChiller has got fabulous fame on the World map by working in China for the last twenty years of trust.

TopChiller has designed an Ice Cream& Yogurt Chiller& Cooling System providing a lot of benefits as given below:

Ice Cream& Yogurt Chiller& Cooling System makes a quiet operation without producing noise during the chilling process by using hot gas bypass and suction valves with condenser absorbing sounds generated by compressor rolling.

TopChiller designed Ice Cream& Yogurt Chiller& Cooling System ensures the best texture of ice cream and yogurt by releasing excess heat and maintains temperature for yeast activity(in yogurt production) by using cooled air to dissipate heat from the system.

Ice Cream& Yogurt Chiller& Cooling System is featured with a compact design to occupy lower space for installation configured by no supply lines and drains supporting small-scale applications.

TopChiller brand Ice Cream& Yogurt Chiller& Cooling System is configured with closed-loop water circulation that absorbs heat from the machine and efficiently releases out by chilled air circulating over condenser preventing water wastage by recycling.

Ice Cream& Yogurt Chiller &Cooling System is used in food processing applications as:

Fermentation industry, beverage industry, food manufacturing, yogurt manufacturing, ice–cream production, cheese production, and processed milk machining, etc.

Are you finding a highly trusted, energy-efficient Ice Cream& Yogurt Chiller &Cooling System with superb performance for your application?

Are you questing for a reliable manufacturing company of Ice Cream& Yogurt Chiller& Cooling System in China ensuring accuracy in performance to build up your business?

You need not look way around. TopChiller is the best preferred and reliable Company in China.

Make contact with TopChiller sales and engineers at any time if you have any queries about Ice Cream& Yogurt Chiller &Cooling System selection or need a quote.

Our team is awaiting our customer response to assist you in customizing the best chilling system for your application at reasonable costs.

- Data Sheet

- Image Gallery

- Main Parts

- Video

| Ice Cream&Yogurt Chiller&Cooling System Technical Specifications | |||||||||||||

| Items Model | AC-15AT | AC-20AD | AC-20AF | AC-25AD | AC-25AF | AC-30AD | AC-30AT | AC-40AD | AC-40AF | AC-50AD | AC-50AF | AC-60AD | |

| Cooling capacity | Kcal/h 50HZ/60HZ | 36120 | 49966 | 47988 | 58480 | 58136 | 74734 | 74922 | 98040 | 99760 | 119024 | 116960 | 144996 |

| 43344 | 59959 | 57586 | 70176 | 69763 | 89681 | 89990 | 117648 | 119712 | 142829 | 140352 | 173995 | ||

| KW 50HZ/60HZ | 42 | 58.1 | 55.8 | 68 | 67.6 | 86.9 | 87.2 | 114 | 116 | 138.4 | 136 | 168.6 | |

| 50.4 | 69.72 | 66.96 | 81.6 | 81.12 | 104.28 | 104.64 | 136.8 | 139.2 | 166.08 | 163.2 | 202.3 | ||

| Input power | KW | 17.1 | 21.73 | 22 | 25.4 | 24.8 | 33.39 | 33.1 | 44.91 | 43.3 | 57.3 | 54 | 65 |

| Max Current | A | 43.2 | 52.7 | 53.3 | 63.7 | 61.3 | 81 | 80.2 | 109 | 106 | 135.5 | 128.5 | 135 |

| Power source | 3PH~380V/415V/480V~50HZ/60HZ(3PH~200V/220V 50HZ/60HZ) | ||||||||||||

| Refrigerant | Type | R22/R407C/134a/404A/410A | |||||||||||

| Control | Capillary / Thermostatic expansion valve | ||||||||||||

| Compressor | Type | Hermetic scroll ( piston ) | |||||||||||

| Power(KW) | 4.55×3 | 8.96×2 | 4.55×4 | 10.8×2 | 5.25×4 | 13.62×2 | 8.96×3 | 18.78×2 | 8.96×4 | 23.6×2 | 10.8×4 | 27.4×2 | |

| Condenser | Type | Efficient finned copper tube with aluminum+low noise external rotor fan | |||||||||||

| Air flow (m³/h) | 15000 | 20000 | 20000 | 25000 | 25000 | 30000 | 30000 | 40000 | 40000 | 50000 | 50000 | 60000 | |

| Air blower(KW) | 0.6×2 | 0.78×2 | 0.78×2 | 0.78×2 | 0.78×2 | 0.42×6 | 0.42×6 | 0.6×6 | 0.6×6 | 0.78×6 | 0.78×6 | 0.78×6 | |

| Evaporator | Type | SS Tank coil/ shell and tube type/Plate type heat exchanger | |||||||||||

| Chilled water (m³/h) | 7.22 | 10 | 9.6 | 11.69 | 11.62 | 14.94 | 15 | 19.6 | 19.95 | 23.8 | 23.4 | 29 | |

| 8.67 | 11.99 | 11.51 | 14.03 | 13.95 | 17.93 | 18 | 23.52 | 23.94 | 28.6 | 28.1 | 34.8 | ||

| Water tank(L) | 270 | 350 | 350 | 350 | 350 | 420 | 420 | 580 | 580 | 580 | 580 | 580 | |

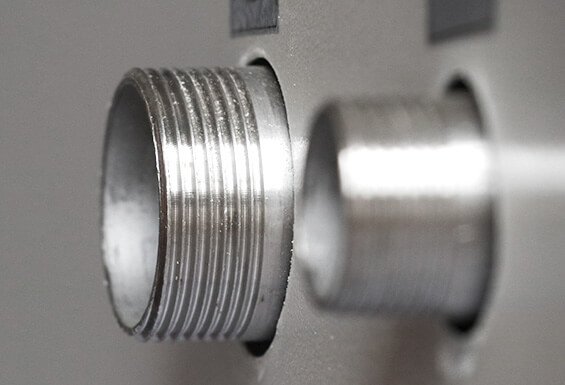

| inlet/outlet pipe (inch) | 2″ | 2″ | 2″ | 2-1/2″ | 2-1/2″ | 2-1/2″ | 2-1/2″ | 3″ | 3″ | 3″ | 3″ | 3″ | |

| Water pump | Power(kw) | 2.2 | 2.2 | 2.2 | 2.2 | 2.2 | 4 | 4 | 4 | 4 | 5.5 | 5.5 | 5.5 |

| Max lift(m) | 28 | 28 | 28 | 28 | 28 | 30 | 30 | 30 | 30 | 32 | 32 | 32 | |

| Max flow (m³) | 25.2 | 25.2 | 25.2 | 25.2 | 25.2 | 36 | 36 | 36 | 36 | 40 | 40 | 40 | |

| Safety devices | Compressor inner protection, over current protection, high/low pressure protection, over temperature protection, flow rate protection, phase sequence/phase missing protection, low level coolant protection, anti freezing protection, exhaust overheat protection | ||||||||||||

| Dimension | L(mm) | 1860 | 2020 | 2020 | 2020 | 2020 | 2200 | 2200 | 2350 | 2350 | 2600 | 2600 | 2600 |

| W(mm) | 850 | 950 | 950 | 950 | 950 | 1150 | 1150 | 1350 | 1350 | 1500 | 1500 | 1500 | |

| H(mm) | 1900 | 2000 | 2000 | 2000 | 2000 | 1980 | 1980 | 2000 | 2000 | 2100 | 2100 | 2100 | |

| Net weight(KG) | 580 | 650 | 650 | 810 | 810 | 890 | 890 | 1112 | 1112 | 1320 | 1320 | 1320 | |

| Note: The above specifications are according to the following design conditions: 1, Chilled water inlet/outlet temperature 12℃/7℃. 2, Cooling air inlet/outlet temperature 33℃/38℃. We reserve the right to modify the specification without further notice. | |||||||||||||

| Ice Cream&Yogurt Chiller&Cooling System Technical Specifications | ||||||||||||||

| Items Model | AC-0.5A | AC-1A | AC-1.5A | AC-2A | AC-2.5A | AC-3A | AC-4A | AC-5A | AC-6A | AC-8AD | AC-10AD | AC-12AD | AC-15AD | |

| Cooling capacity | Kcal/h 50HZ/60HZ | 1419 | 2451 | 3182 | 4833 | 5848 | 7181 | 9288 | 11988 | 14534 | 18576 | 23994 | 29068 | 38270 |

| 1703 | 2941 | 3784 | 5800 | 7018 | 8617 | 11146 | 14386 | 17441 | 22291 | 28793 | 34882 | 45924 | ||

| KW 50HZ/60HZ | 1.65 | 2.85 | 3.7 | 5.62 | 6.8 | 8.35 | 10.8 | 13.94 | 16.9 | 21.6 | 27.9 | 33.8 | 44.5 | |

| 1.98 | 3.42 | 4.4 | 6.74 | 8.2 | 10.02 | 12.96 | 16.73 | 20.28 | 25.92 | 33.48 | 40.56 | 53.4 | ||

| Input power | KW | 0.88 | 1.35 | 2 | 2.25 | 2.66 | 3.27 | 4.07 | 5.75 | 6.45 | 8.25 | 11.5 | 12.9 | 17.45 |

| Max Current | A | 5.4 | 8.2 | 12 | 13.6 | 6.6 | 8.2 | 10.1 | 13.8 | 15.5 | 20 | 27.9 | 31.3 | 42.4 |

| Power source | 1PH~220V/3PH~220V/380V 50HZ/60HZ | 3PH~380V/415V/480V~50HZ/60HZ(3PH~200V/220V 50HZ/60HZ) | ||||||||||||

| Refrigerant | Type | R22/R407C/134a/404A/410A | ||||||||||||

| Control | Capillary / thermostatic expansion valve | |||||||||||||

| Compressor | Type | Hermetic Rotary | Hermetic scroll ( piston ) | |||||||||||

| Power(KW) | 0.45 | 0.89 | 1.3 | 1.73 | 2.1 | 2.7 | 3.5 | 4.55 | 5.25 | 3.5×2 | 4.55×2 | 5.25×2 | 7×2 | |

| Condenser | Type | Efficient finned copper tube with aluminum+low noise external rotor fan | ||||||||||||

| Air flow (m3/h) | 750 | 1000 | 1500 | 2000 | 2500 | 3000 | 4000 | 5000 | 6000 | 8000 | 10000 | 12000 | 15000 | |

| Air blower(KW) | 0.06 | 0.09 | 0.15 | 0.15 | 0.19 | 0.14×2 | 0.14×2 | 0.19×2 | 0.19×2 | 0.25×2 | 0.45×2 | 0.45×2 | 0.6×2 | |

| Evaporator | Type | SS Tank coil / shell and tube type / Plate type heat exchanger | ||||||||||||

| Chilled water (m3/h) | 0.28 | 0.49 | 0.64 | 0.97 | 1.12 | 1.44 | 1.86 | 2.4 | 2.91 | 3.71 | 4.8 | 5.81 | 7.65 | |

| 0.34 | 0.59 | 0.76 | 1.16 | 1.4 | 1.72 | 2.23 | 2.88 | 3.49 | 4.46 | 5.76 | 7 | 9.18 | ||

| Water tank(L) | 10.6 | 18.3 | 27 | 27 | 50 | 50 | 60 | 60 | 110 | 120 | 200 | 200 | 270 | |

| Inlet/outlet pipe (inch) i | 1/2″ | 1/2″ | 1/2″ | 1/2″ | 1″ | 1″ | 1″ | 1″ | 1″ | 1-1/2″ | 2″ | 2″ | 2″ | |

| Water pump | Power (kw) | 0.37 | 0.37 | 0.37 | 0.37 | 0.37 | 0.37 | 0.37 | 0.75 | 0.75 | 0.75 | 1.5 | 1.5 | 2.2 |

| Max lift(m) | 22 | 22 | 22 | 22 | 22 | 22 | 22 | 30 | 30 | 25 | 25 | 25 | 28 | |

| Max flow (m3) | 5.4 | 5.4 | 5.4 | 5.4 | 5.4 | 5.4 | 5.4 | 8.1 | 8.1 | 8.1 | 13.5 | 13.5 | 25.2 | |

| Safety protection | Compressor inner protection, over current protection, high/low pressure protection, over temperature protection, flow rate protection, phase sequence/phase missing protection, low level coolant protection, anti freezing protection, exhaust overheat protection | |||||||||||||

| Dimension | L(mm) | 550 | 550 | 600 | 600 | 720 | 980 | 980 | 1150 | 1150 | 1350 | 1500 | 1500 | 1860 |

| W(mm) | 350 | 450 | 500 | 500 | 550 | 520 | 520 | 560 | 560 | 680 | 760 | 760 | 850 | |

| H(mm) | 695 | 845 | 985 | 985 | 1350 | 1170 | 1170 | 1215 | 1215 | 1530 | 1660 | 1660 | 1900 | |

| Net weight(KG) | 45 | 62 | 85 | 95 | 125 | 152 | 175 | 185 | 215 | 283 | 345 | 382 | 580 | |

| Note: The above specifications are according to the following design conditions: 1, 12℃/7℃.Chilled water inlet/outlet temperature 12℃/7℃. 2, 33℃/38℃.Cooling air inlet/outlet temperature 33℃/38℃. We reserve the right to modify the specification without further notice. | ||||||||||||||