TopChiller can design and manufacture all types of scroll chillers for you

- Cooling capacity ranges from 5 Ton to 120 Ton

- The ambient temperature ranges from up to 125°F

- Optimized scroll compressor from top brands

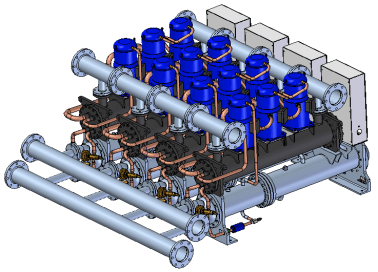

- Heat exchanger & separate refrigeration circuits

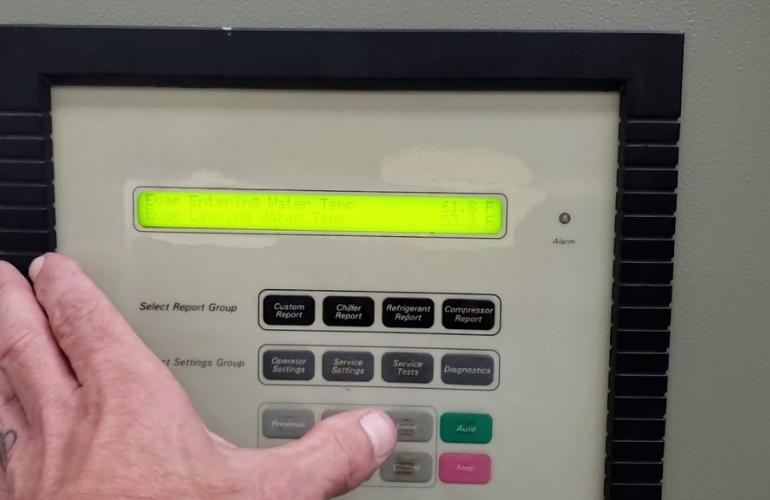

- Suction service valves, relief valves, screen display

- Copper fin condenser coils & vibration isolator

- Factory-installed strainer or flow switches

- Sound attenuating ultra-quiet efficient fans

Your Premier Scroll Chiller Manufacturer and Supplier in China

Scroll Chiller is a type of water cooling tropicalized machine that is accounted for chilling in industrial applications with scroll compression on chilled water circulation to release heat.

TopChiller is a renowned company of China among the worldwide industries for manufacturing and supplying highly reliable, efficient, and diligent working Scroll Chiller with the magnificent experience of almost twenty years.

TopChiller is dedicated to supplying Scroll Chiller proudly to all over the world marketplace with different sizes/ ranges and ultimately got famed credibility on the global map for its commitment to workmanship and integrity in –performance since 1999.

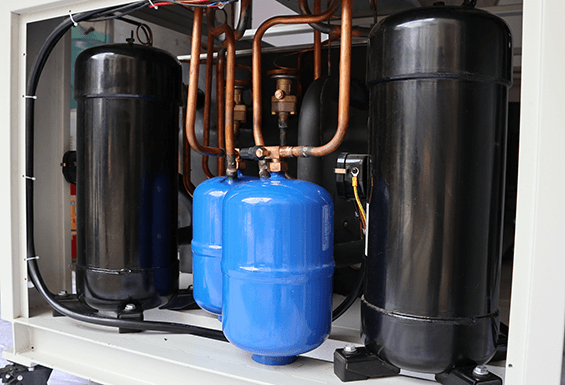

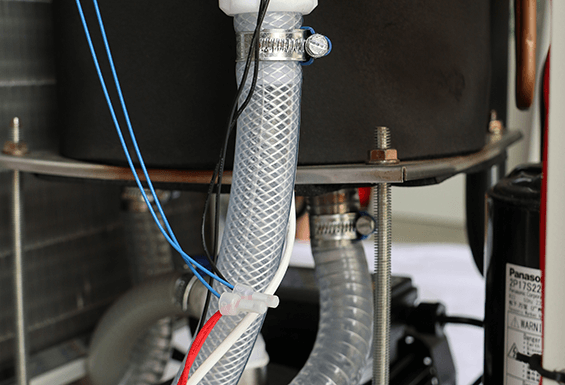

Efficient evaporator, spiral scroll compressor, storage tank, hot gas bypass, distribution units, defensive devices, temperature controller, expansion valves, brazed plate heat exchanger, water-cooled condenser, suction solenoid valves, are components used for Scroll Chiller manufacturing.

TopChiller engineered Scroll Chiller is steadfast in performance with assorted benefits in different fields as given below:

- Scroll Chiller is highly reliable in its working configured by the installation of separate refrigeration circuits with each compressor, manipulating stabilize and consistent flow if there would be damage or leakage in one circulation, another compressor will continue working independently.

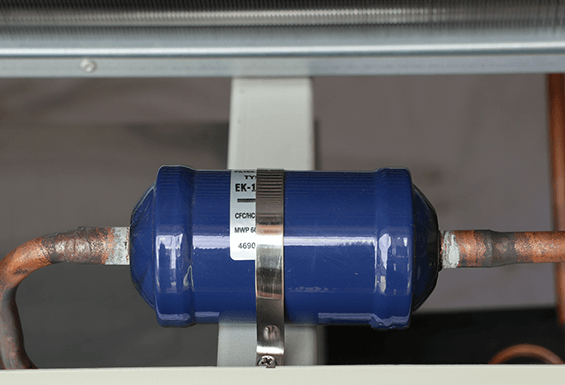

- TopChiller designed Scroll Chiller prevents the unit from clogging or obstruction in circulation and refrigerant freezing featured by the installation of dry filters that ensures to control moisture and dust particles.

- Scroll Chiller certifies vibration-free performance, and over current optimization featured by rotor fans and condenser motors attached with a condenser that absorbs the sounds and dissipates extra power preventing unit damages.

- TopChiller designed Scroll Chiller is equipped with a cooling tank having some extra capacity to compensate the heating load during operation in tropical regions as Scroll Chiller efficiently operates with the normal level heat load.

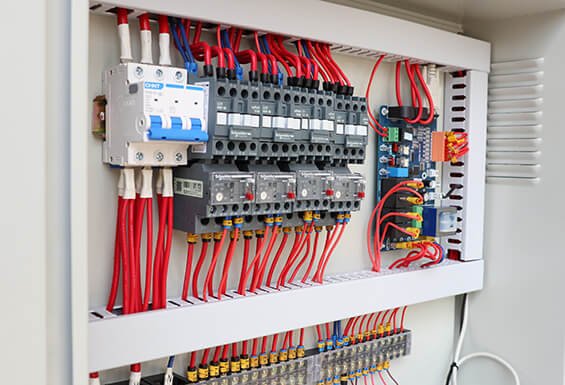

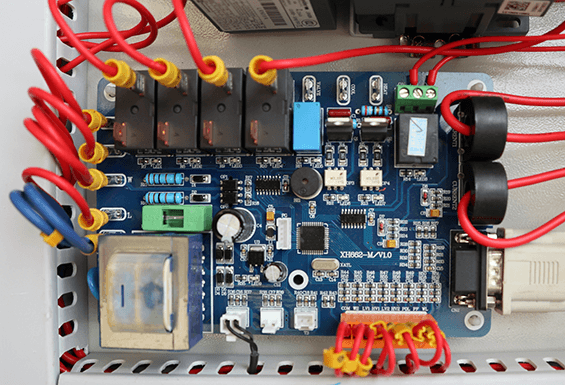

- Control panel installation inside Scroll Chiller prevents the unit from high or low pressure, temperature, and power supply alterations confirming streamlined and steady performance with less energy consumption.

Scroll Chiller has been applied for different industrial and commercial applications as given below:

Water jet, plating, blow molding, plastic manufacturing, beverage industry, vacuum coating, pharmaceutical industry, electrochemical processing, and construction industry.

Are you looking for a superb cooling and precisely temperature maintaining Scroll Chiller for your application development?

Are you ready to develop a collaboration with a renowned company of China manufacturing distinctive featured Scroll Chiller to scale up your business?

TopChiller is the best leading company in China providing 24 hours service to our customers. You just need to make a call to TopChiller experts for getting updates about the working and sizing of Scroll Chiller favorable for your application at a handsome price.

TopChiller experts and technocrats are directed to step forward for providing repairing solutions and technical assistance to our clients.

General Description:

The Scroll Chiller is a prime quality cooling unit that uses a scroll compressor to compress the refrigerant. It provides a cooling source mainly to the industrial plants by dissipating the intense amount of heat produced by the equipment.

It recirculates chilled water throughout the system and removes excess heat using air or water mediums into the atmosphere. The unit is based on the principle of the vapor-compression cycle.

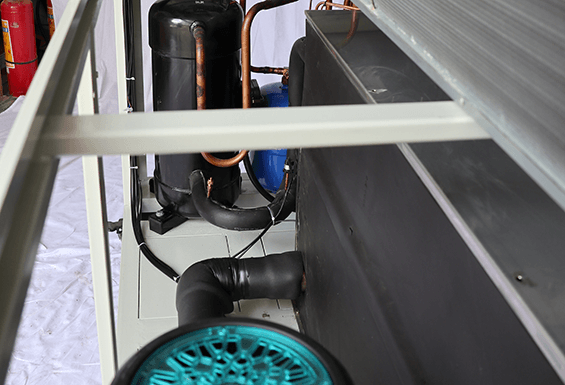

The refrigerant of the Scroll Chiller is cycled by various components: an evaporator, branded scroll compressor, condenser, and a thermal expansion valve. It keeps on changing its state from a gas to liquid and then liquid to a gas in the entire process.

The Scroll Chiller manufactured by TopChiller provides efficient cooling solutions for many applications. It is trusted and used in various industries, including thermoforming, laser, semiconductors, injection molding, food processing, welding, chemical industries, and many more.

TopChiller is a famous brand with a rich manufacturing experience of more than twenty years; it offers you a high-quality Scroll Chiller with heavy-duty performance and reliability.

If you are looking for a reliable and durable cooling source to prevent the accumulation of heat in your industrial plant, nothing can be better than TopChiller.

Contact our sales engineer and get your heavy-duty Scroll Chiller at your doorstep at a very affordable price.

Features and Advantages:

The Scroll Chiller designed by TopChiller is being recognized for its following known features and advantages:

- The Scroll Chiller contains single or multiple hermetic scroll compressors with a variable speed drive optimized specifically for part-load conditions. The compressor contains a refrigerant dispersing device advanced for motor cooling.

- The unit is designed with a compact structure that enhances durability and reliability. It is configured with a compressor sound insulation box that ensures the serenity of your industrial area by working quietly.

- The aluminum fin condenser is coated with corrosion-resistant materials that prevent corrosive damages. High-quality brazed plate heat exchangers have high heat exchanging capacity along with an energy-saving ability. The unit has a microprocessor-based control system for the automatic control of functions.

- It is featured with various safety devices that prevent damage to the unit. These include high and low-pressure protection, antifreeze protection, discharge temperature overheating detection, water flow switch, over-current protection, and more.

- The refrigerants used in a Scroll Chiller are R410A, R407c, or R134a that are environmentally friendly and do not cause any harm to the ozone layer.

TopChiller can provide you a customized Scroll Chiller according to your applications.

- Data Sheet

- Image Gallery

- Main Parts

- Video

| Scroll Chiller Technical Specifications | ||||||||||||||

| Items Model | AC-0.5A | AC-1A | AC-1.5A | AC-2A | AC-2.5A | AC-3A | AC-4A | AC-5A | AC-6A | AC-8AD | AC-10AD | AC-12AD | AC-15AD | |

| Cooling capacity | Kcal/h 50HZ/60HZ | 1419 | 2451 | 3182 | 4833 | 5848 | 7181 | 9288 | 11988 | 14534 | 18576 | 23994 | 29068 | 38270 |

| 1703 | 2941 | 3784 | 5800 | 7018 | 8617 | 11146 | 14386 | 17441 | 22291 | 28793 | 34882 | 45924 | ||

| KW 50HZ/60HZ | 1.65 | 2.85 | 3.7 | 5.62 | 6.8 | 8.35 | 10.8 | 13.94 | 16.9 | 21.6 | 27.9 | 33.8 | 44.5 | |

| 1.98 | 3.42 | 4.4 | 6.74 | 8.2 | 10.02 | 12.96 | 16.73 | 20.28 | 25.92 | 33.48 | 40.56 | 53.4 | ||

| Input power | KW | 0.88 | 1.35 | 2 | 2.25 | 2.66 | 3.27 | 4.07 | 5.75 | 6.45 | 8.25 | 11.5 | 12.9 | 17.45 |

| Max Current | A | 5.4 | 8.2 | 12 | 13.6 | 6.6 | 8.2 | 10.1 | 13.8 | 15.5 | 20 | 27.9 | 31.3 | 42.4 |

| Power source | 1PH~220V/3PH~220V/380V 50HZ/60HZ | 3PH~380V/415V/480V~50HZ/60HZ(3PH~200V/220V 50HZ/60HZ) | ||||||||||||

| Refrigerant | Type | R22/R407C/134a/404A/410A | ||||||||||||

| Control | Capillary / thermostatic expansion valve | |||||||||||||

| Compressor | Type | Hermetic Rotary | Hermetic scroll ( piston ) | |||||||||||

| Power(KW) | 0.45 | 0.89 | 1.3 | 1.73 | 2.1 | 2.7 | 3.5 | 4.55 | 5.25 | 3.5×2 | 4.55×2 | 5.25×2 | 7×2 | |

| Condenser | Type | Efficient finned copper tube with aluminum+low noise external rotor fan | ||||||||||||

| Air flow (m3/h) | 750 | 1000 | 1500 | 2000 | 2500 | 3000 | 4000 | 5000 | 6000 | 8000 | 10000 | 12000 | 15000 | |

| Air blower(KW) | 0.06 | 0.09 | 0.15 | 0.15 | 0.19 | 0.14×2 | 0.14×2 | 0.19×2 | 0.19×2 | 0.25×2 | 0.45×2 | 0.45×2 | 0.6×2 | |

| Evaporator | Type | SS Tank coil / shell and tube type / Plate type heat exchanger | ||||||||||||

| Chilled water (m3/h) | 0.28 | 0.49 | 0.64 | 0.97 | 1.12 | 1.44 | 1.86 | 2.4 | 2.91 | 3.71 | 4.8 | 5.81 | 7.65 | |

| 0.34 | 0.59 | 0.76 | 1.16 | 1.4 | 1.72 | 2.23 | 2.88 | 3.49 | 4.46 | 5.76 | 7 | 9.18 | ||

| Water tank(L) | 10.6 | 18.3 | 27 | 27 | 50 | 50 | 60 | 60 | 110 | 120 | 200 | 200 | 270 | |

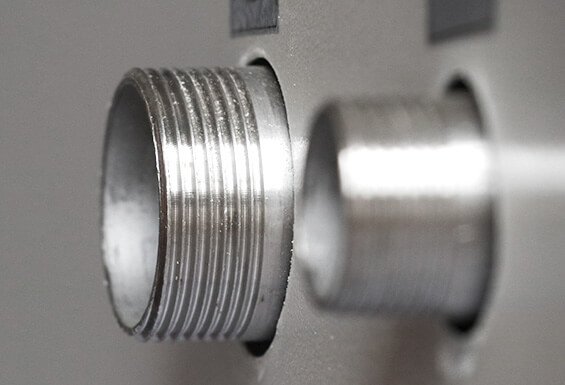

| Inlet/outlet pipe (inch) i | 1/2″ | 1/2″ | 1/2″ | 1/2″ | 1″ | 1″ | 1″ | 1″ | 1″ | 1-1/2″ | 2″ | 2″ | 2″ | |

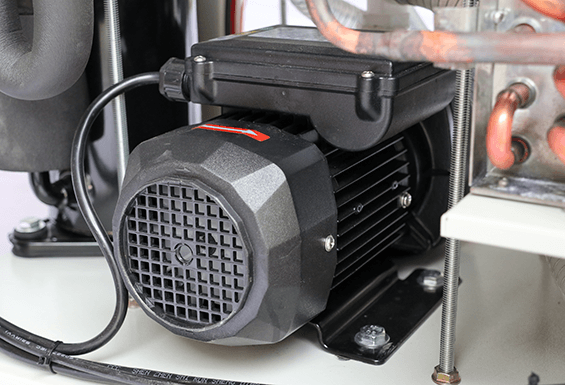

| Water pump | Power (kw) | 0.37 | 0.37 | 0.37 | 0.37 | 0.37 | 0.37 | 0.37 | 0.75 | 0.75 | 0.75 | 1.5 | 1.5 | 2.2 |

| Max lift(m) | 22 | 22 | 22 | 22 | 22 | 22 | 22 | 30 | 30 | 25 | 25 | 25 | 28 | |

| Max flow (m3) | 5.4 | 5.4 | 5.4 | 5.4 | 5.4 | 5.4 | 5.4 | 8.1 | 8.1 | 8.1 | 13.5 | 13.5 | 25.2 | |

| Safety protection | Compressor inner protection, over current protection, high/low pressure protection, over temperature protection, flow rate protection, phase sequence/phase missing protection, low level coolant protection, anti freezing protection, exhaust overheat protection | |||||||||||||

| Dimension | L(mm) | 550 | 550 | 600 | 600 | 720 | 980 | 980 | 1150 | 1150 | 1350 | 1500 | 1500 | 1860 |

| W(mm) | 350 | 450 | 500 | 500 | 550 | 520 | 520 | 560 | 560 | 680 | 760 | 760 | 850 | |

| H(mm) | 695 | 845 | 985 | 985 | 1350 | 1170 | 1170 | 1215 | 1215 | 1530 | 1660 | 1660 | 1900 | |

| Net weight(KG) | 45 | 62 | 85 | 95 | 125 | 152 | 175 | 185 | 215 | 283 | 345 | 382 | 580 | |

| Note: The above specifications are according to the following design conditions: 1, 12℃/7℃.Chilled water inlet/outlet temperature 12℃/7℃. 2, 33℃/38℃.Cooling air inlet/outlet temperature 33℃/38℃. We reserve the right to modify the specification without further notice. | ||||||||||||||

| Scroll Chiller Technical Specifications | |||||||||||||

| Items Model | AC-15AT | AC-20AD | AC-20AF | AC-25AD | AC-25AF | AC-30AD | AC-30AT | AC-40AD | AC-40AF | AC-50AD | AC-50AF | AC-60AD | |

| Cooling capacity | Kcal/h 50HZ/60HZ | 36120 | 49966 | 47988 | 58480 | 58136 | 74734 | 74922 | 98040 | 99760 | 119024 | 116960 | 144996 |

| 43344 | 59959 | 57586 | 70176 | 69763 | 89681 | 89990 | 117648 | 119712 | 142829 | 140352 | 173995 | ||

| KW 50HZ/60HZ | 42 | 58.1 | 55.8 | 68 | 67.6 | 86.9 | 87.2 | 114 | 116 | 138.4 | 136 | 168.6 | |

| 50.4 | 69.72 | 66.96 | 81.6 | 81.12 | 104.28 | 104.64 | 136.8 | 139.2 | 166.08 | 163.2 | 202.3 | ||

| Input power | KW | 17.1 | 21.73 | 22 | 25.4 | 24.8 | 33.39 | 33.1 | 44.91 | 43.3 | 57.3 | 54 | 65 |

| Max Current | A | 43.2 | 52.7 | 53.3 | 63.7 | 61.3 | 81 | 80.2 | 109 | 106 | 135.5 | 128.5 | 135 |

| Power source | 3PH~380V/415V/480V~50HZ/60HZ(3PH~200V/220V 50HZ/60HZ) | ||||||||||||

| Refrigerant | Type | R22/R407C/134a/404A/410A | |||||||||||

| Control | Capillary / Thermostatic expansion valve | ||||||||||||

| Compressor | Type | Hermetic scroll ( piston ) | |||||||||||

| Power(KW) | 4.55×3 | 8.96×2 | 4.55×4 | 10.8×2 | 5.25×4 | 13.62×2 | 8.96×3 | 18.78×2 | 8.96×4 | 23.6×2 | 10.8×4 | 27.4×2 | |

| Condenser | Type | Efficient finned copper tube with aluminum+low noise external rotor fan | |||||||||||

| Air flow (m³/h) | 15000 | 20000 | 20000 | 25000 | 25000 | 30000 | 30000 | 40000 | 40000 | 50000 | 50000 | 60000 | |

| Air blower(KW) | 0.6×2 | 0.78×2 | 0.78×2 | 0.78×2 | 0.78×2 | 0.42×6 | 0.42×6 | 0.6×6 | 0.6×6 | 0.78×6 | 0.78×6 | 0.78×6 | |

| Evaporator | Type | SS Tank coil/ shell and tube type/Plate type heat exchanger | |||||||||||

| Chilled water (m³/h) | 7.22 | 10 | 9.6 | 11.69 | 11.62 | 14.94 | 15 | 19.6 | 19.95 | 23.8 | 23.4 | 29 | |

| 8.67 | 11.99 | 11.51 | 14.03 | 13.95 | 17.93 | 18 | 23.52 | 23.94 | 28.6 | 28.1 | 34.8 | ||

| Water tank(L) | 270 | 350 | 350 | 350 | 350 | 420 | 420 | 580 | 580 | 580 | 580 | 580 | |

| inlet/outlet pipe (inch) | 2″ | 2″ | 2″ | 2-1/2″ | 2-1/2″ | 2-1/2″ | 2-1/2″ | 3″ | 3″ | 3″ | 3″ | 3″ | |

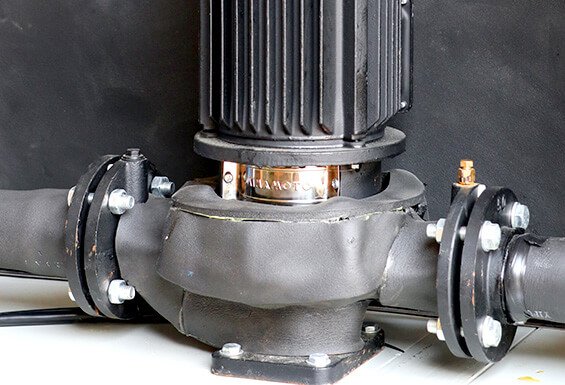

| Water pump | Power(kw) | 2.2 | 2.2 | 2.2 | 2.2 | 2.2 | 4 | 4 | 4 | 4 | 5.5 | 5.5 | 5.5 |

| Max lift(m) | 28 | 28 | 28 | 28 | 28 | 30 | 30 | 30 | 30 | 32 | 32 | 32 | |

| Max flow (m³) | 25.2 | 25.2 | 25.2 | 25.2 | 25.2 | 36 | 36 | 36 | 36 | 40 | 40 | 40 | |

| Safety devices | Compressor inner protection, over current protection, high/low pressure protection, over temperature protection, flow rate protection, phase sequence/phase missing protection, low level coolant protection, anti freezing protection, exhaust overheat protection | ||||||||||||

| Dimension | L(mm) | 1860 | 2020 | 2020 | 2020 | 2020 | 2200 | 2200 | 2350 | 2350 | 2600 | 2600 | 2600 |

| W(mm) | 850 | 950 | 950 | 950 | 950 | 1150 | 1150 | 1350 | 1350 | 1500 | 1500 | 1500 | |

| H(mm) | 1900 | 2000 | 2000 | 2000 | 2000 | 1980 | 1980 | 2000 | 2000 | 2100 | 2100 | 2100 | |

| Net weight(KG) | 580 | 650 | 650 | 810 | 810 | 890 | 890 | 1112 | 1112 | 1320 | 1320 | 1320 | |

| Note: The above specifications are according to the following design conditions: 1, Chilled water inlet/outlet temperature 12℃/7℃. 2, Cooling air inlet/outlet temperature 33℃/38℃. We reserve the right to modify the specification without further notice. | |||||||||||||

| Scroll Chiller Technical Specifications | |||||||||||

| Model Items | AW-3W | AW-4W | AW-5W | AW-6W | AW-8WD | AW-10WD | AW-12WD | AW-15WD | AW-15WT | AW-20WD | |

| Cooling Capacity | kcal/h 50HZ/60HZ | 8170 | 11266 | 14018 | 16340 | 22532 | 28036 | 32680 | 43172 | 42140 | 56760 |

| 9804 | 13519 | 16822 | 19608 | 27038 | 33643 | 39216 | 51806 | 50568 | 68112 | ||

| KW 50HZ/60HZ | 9.5 | 13.1 | 16.3 | 19 | 26.2 | 32.6 | 38 | 50.2 | 49 | 66 | |

| 11.4 | 15.72 | 19.56 | 22.8 | 31.44 | 39.12 | 45.6 | 60.24 | 58.8 | 79.2 | ||

| Input Power | KW | 3.07 | 3.87 | 5.3 | 5.95 | 7.75 | 10.6 | 11.9 | 16.25 | 15.85 | 19.71 |

| Max Current | A | 7.5 | 9.4 | 12.9 | 14.4 | 18,8 | 25.7 | 28.9 | 39.4 | 38.2 | 47.8 |

| power source | 3PH~380V/415V/480V~50HZ/60HZ(3PH~200V/220V 50HZ/60HZ) | ||||||||||

| Refrigerant | Type | R22/R407C/134a/404A/410A | |||||||||

| Control | Capillary / Thermostatic expansion valve | ||||||||||

| Compressor | Type | Hermetic scroll ( piston ) | |||||||||

| Power(KW) | 2.7 | 3.5 | 4.55 | 5.2 | 3.5×2 | 4.55×2 | 5.2×2 | 7×2 | 4.55×3 | 8.96×2 | |

| Condenser | Type | Shell and tube/ SS plate type heat exchanger | |||||||||

| Cooling water (m³/h) | 2.1 | 2.9 | 3.6 | 4.2 | 5.7 | 7.1 | 8.3 | 11 | 10.8 | 14.4 | |

| 2.4 | 3.3 | 4.1 | 4.8 | 6.6 | 8.3 | 9.6 | 12.8 | 12.5 | 16.7 | ||

| Inlet/outlet pipe (inch) | 1 1/2″ | 1 1/2″ | 1 1/2″ | 1 1/2″ | 1 1/2″ | 1 1/2″ | 1 1/2″ | 2″ | 2″ | 2″ | |

| Evaporator | Type | SS Tank with cooper coil / Shell and tube/Plate heat exchanger | |||||||||

| Chilled water | 1.63 | 2.25 | 2.8 | 3.27 | 4.5 | 5.6 | 6.53 | 8.63 | 8.43 | 11.35 | |

| 1.96 | 2.7 | 3.36 | 3.92 | 5.4 | 6.73 | 7.84 | 10.36 | 10.1 | 13.62 | ||

| Water tank(L) | 60 | 60 | 60 | 90 | 150 | 200 | 200 | 330 | 330 | 330 | |

| inlet/outlet pipe (inch) | 1″ | 1″ | 1″ | 1″ | 1-1/2″ | 2″ | 2″ | 2″ | 2″ | 2″ | |

| Water pump | Power(kw) | 0.37 | 0.37 | 0.75 | 0.75 | 0.75 | 1.5 | 1.5 | 2.2 | 2.2 | 2.2 |

| Max lift(m) | 22 | 22 | 30 | 30 | 25 | 25 | 25 | 28 | 28 | 28 | |

| Max flow (m³) | 5.4 | 5.4 | 8.1 | 8.1 | 8.1 | 13.5 | 13.5 | 25.2 | 25.2 | 25.2 | |

| Safety protection | Compressor inner protection, over current protection, high/low pressure protection, over temperature protection, flow rate protection, phase sequence/phase missing protection, low level coolant protection, anti freezing protection, exhaust overheat protection | ||||||||||

| Dimension | L(mm) | 910 | 910 | 910 | 910 | 1250 | 1250 | 1250 | 1600 | 1600 | 1600 |

| W(mm)) | 480 | 480 | 480 | 480 | 680 | 680 | 680 | 750 | 750 | 750 | |

| H(mm)) | 1000 | 1000 | 1000 | 1000 | 1380 | 1380 | 1380 | 1600 | 1600 | 1600 | |

| Net weight(KG) | 125 | 135 | 160 | 180 | 230 | 260 | 330 | 420 | 420 | 460 | |

| Note: The above specifications are according to the following design conditions: 1, Chilled water inlet/outlet temperature 12℃/7℃. 2, Chiller temperature control range 5℃/35℃. We reserve the right to modify the specification without further notice. | |||||||||||

| Scroll Chiller Technical Specifications | |||||||||||

| Model Items | AW-20WF | AW-25WD | AW-25WF | AW-30WD | AW-30WT | AW-40WD | AW-40WF | AW-50WD | AW-50WF | AW-60WD | |

| Cooling capacity | kcal/h 50HZ/60HZ | 56072 | 66048 | 65360 | 83420 | 85140 | 114036 | 113520 | 134504 | 132096 | 169764 |

| 67286 | 79258 | 78432 | 100104 | 102168 | 136843 | 136224 | 161405 | 158515 | 203717 | ||

| KW 50HZ/60HZ | 65.2 | 76.8 | 76 | 97 | 99 | 132.6 | 132 | 156.4 | 153.6 | 197.4 | |

| 76.56 | 92.16 | 91.2 | 116.4 | 118.8 | 159.12 | 158.4 | 187.68 | 184.32 | 236.88 | ||

| Input power | KW | 20.4 | 23.8 | 23 | 30.99 | 30.63 | 41.31 | 39.59 | 52.7 | 48.7 | 59.3 |

| Max Current | A | 48.5 | 61.7 | 60 | 75.2 | 74.8 | 100.3 | 96.6 | 127.9 | 119.7 | 143.9 |

| Power Source | 3PH~380V/415V/480V~50HZ/60HZ(3PH~200V/220V 50HZ/60HZ) | ||||||||||

| Refrigerant | Type | R22/R407C/134a/404A/410A | |||||||||

| Control | Thermostatic expansion valve | ||||||||||

| Compressor | Type | Hermetic scroll ( piston ) | |||||||||

| Power(KW) | 4.55×4 | 10.8×2 | 5.2×4 | 13.62×2 | 8.96×3 | 18.78×2 | 8.96×4 | 23.6×2 | 10.8×4 | 26.9×2 | |

| Condenser | Type | Shell and tube/ SS plate type heat exchanger | |||||||||

| Cooling Water (m³/h) | 14.4 | 17 | 16.7 | 21.4 | 21.7 | 29.3 | 28.9 | 35 | 33.9 | 43.2 | |

| 16.6 | 19.6 | 19.3 | 24.7 | 25.1 | 33.8 | 34.4 | 40.4 | 39.1 | 50 | ||

| inlet/outlet pipe (inch) | 2″ | 2″ | 2 1/2″ | 2 1/2″ | 2 1/2″ | 3″ | 3″ | 3″ | 3″ | 4″ | |

| Evaporator | Type | SS Tank with cooper coil / Shell and tube/Plate heat exchanger | |||||||||

| Chilled Water (m³/h) | 11.21 | 13.21 | 13.1 | 16.68 | 17.02 | 22.8 | 22.7 | 26.9 | 26.41 | 33.95 | |

| 13.45 | 15.85 | 15.68 | 20.02 | 20.43 | 27.36 | 27.24 | 32.27 | 31.7 | 40.73 | ||

| Water Tank (L) | 330 | 350 | 350 | 450 | 450 | 580 | 580 | 620 | 620 | 620 | |

| inlet/outlet pipe (inch) | 2″ | 2″ | 2″ | 2-1/2″ | 2-1/2″ | 3″ | 3″ | 3″ | 3″ | 4″ | |

| Water pump | Power(kw) | 2.2 | 2.2 | 2.2 | 4 | 4 | 4 | 4 | 5.5 | 5.5 | 5.5 |

| Max lift(m) | 28 | 28 | 28 | 30 | 30 | 30 | 30 | 32 | 32 | 32 | |

| Max flow (m³) | 25.2 | 25.2 | 25.2 | 36 | 36 | 36 | 36 | 40 | 40 | 40 | |

| Safety protection | Compressor inner protection, over current protection, high/low pressure protection, over temperature protection, flow rate protection, phase sequence/phase missing protection, low level coolant protection, anti freezing protection, exhaust overheat protection | ||||||||||

| Dimension | L(mm) | 1600 | 1950 | 1950 | 1950 | 1950 | 2000 | 2000 | 2000 | 2000 | 2200 |

| W(mm) | 750 | 850 | 850 | 850 | 850 | 980 | 980 | 980 | 980 | 1100 | |

| H(mm) | 1600 | 1700 | 1700 | 1700 | 1700 | 1700 | 1700 | 1700 | 1700 | 1850 | |

| Net weight(KG) | 460 | 680 | 680 | 720 | 720 | 870 | 870 | 980 | 980 | 1120 | |

| Note: The above specifications are according to the following design conditions: 1, Chilled water inlet/outlet temperature 12℃/7℃. 2, Chiller temperature control range 5℃/35℃. We reserve the right to modify the specification without further notice. | |||||||||||

Why TopChiller is Your Reliable Scroll Chiller Manufacturer and Supplier In China?

Scroll Chiller-An Ultimate FAQ Guide by TopChiller.

- What is a Scroll Chiller?

- What are the Leading Components of a Scroll Chiller?

- How Does a Scroll Chiller Work?

- What are the Characteristics of a Scroll Chiller?

- What are the Prominent Applications of a Scroll Chiller?

- What are the Types of a Scroll Chiller?

- What are the Advantages of a Scroll Chiller for your Applications?

- What is the Estimated Cost of a Scroll Chiller?

- What is the Difference Between a Scroll Chiller and Screw Chiller?

- How to Measure the Cooling Capacity of your Scroll Chiller?

- What are the Safety Devices of a Scroll Chiller?

- What Type of Sensors are Installed in a Scroll Chiller?

- What are the Technological Advancements of a Scroll Chiller?

- What is the Difference Between Single Compressor Scroll Chiller and Multiple Compressor Scroll Chiller?

- How to Choose an Appropriate Scroll Chiller for your Industry?

- What Type of Microprocessor Controllers are Placed in a Scroll Chiller?

- What are the Common Problems of a Scroll Chiller?

- How to Increase the Working Efficiency of a Scroll Chiller?

- What are the Maintenance Guidelines for your Scroll Chiller?

- What are the Troubleshooting Tips for your Scroll Chiller?

What is a Scroll Chiller?

A Scroll Chiller is a cooling device that helps remove excess heat accumulated in the industries and maintains the temperature within optimized ranges.

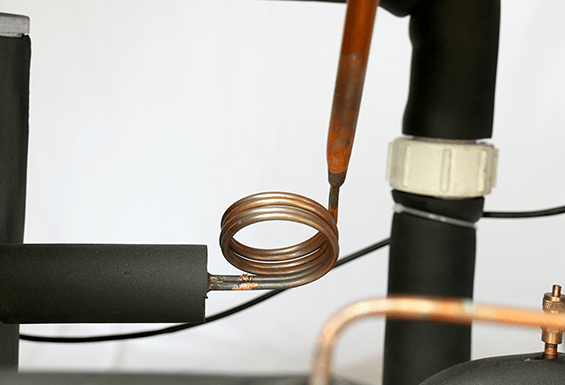

A refrigerant passes by all the components that drive the whole refrigeration cycle. The Scroll Chiller is named after the scroll compressor used as a significant component. Other principal parts are a condenser, evaporator, and expansion valve.

The chilled water and the refrigerant circulate and help dissipate excess heat. It uses water or air as a medium by which heat is released to the outer atmosphere through a cooling tower or fans.

It is used in many industries, out of which plastic manufacturing, laser, semiconductors, injection molding, food processing, welding, chemical and pharmaceutical industries, and plasma cutting are the most prominent ones.

Customized Scroll Chiller Designed by TopChiller

What are the Leading Components of a Scroll Chiller?

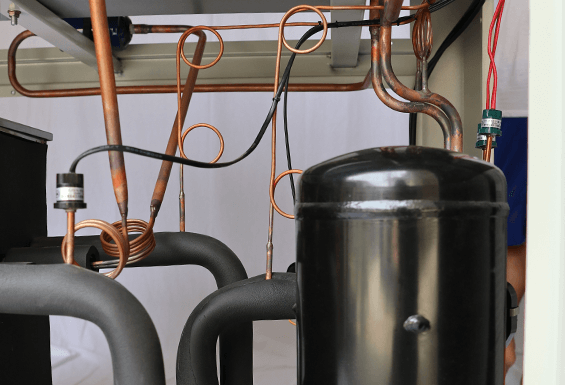

The Scroll Chiller contains many components but the leading components through which the vapor compression cycle drives are the following:

Evaporator

The evaporator is a heat exchanger in which the liquid refrigerant absorbs heat from the processed water and evaporates (converts into a gaseous state). The refrigerant then directs towards the compressor.

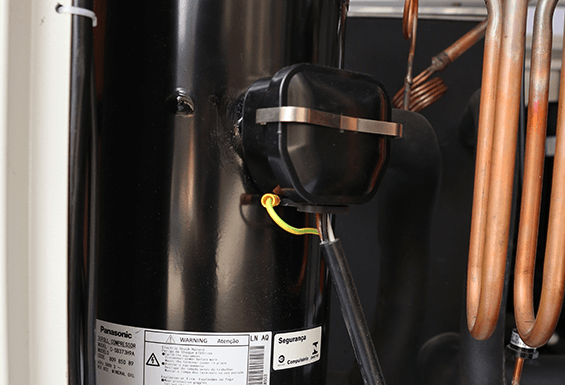

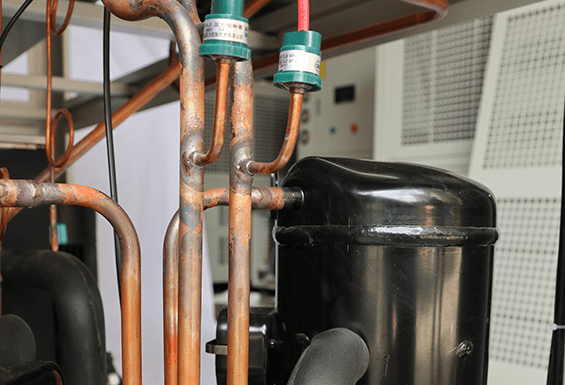

Compressor

The compressor in the Scroll Chiller is a scroll compressor that is the driving force of the refrigeration cycle.

It is a refrigerant gas pump that increases the temperature and pressure of the refrigerant and passes it to the condenser.

Condenser

The condenser is meant for the compression of the refrigerant. The compressor’s highly pressurized superheated refrigerant vapors release heat in the condenser and get converted into liquid.

Tank

The tank is the reservoir in the condenser that stores the refrigerant until the condenser condenses the refrigerant.

It is used to adjust and store the refrigerant. It acts as a container to increase the cooling efficiency of the condenser by increasing its cooling area.

Dry Filter

The dry filter is essential to prevent moisture and dirt particles (such as iron, oil, copper scrap) from entering the refrigeration cycle.

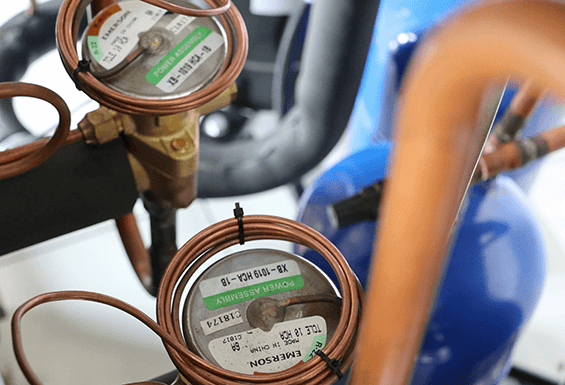

Thermal Expansion Valve

The expansion valve is the flow regulating valve that regulates the flow of the refrigerant as it leaves the condenser.

Scroll Chiller Thermal Expansion Valve

How Does a Scroll Chiller Work?

The Scroll Chiller is based on the vapor compression principle by which the refrigerant circulates in the cycle and interchanges its state from gas to liquid and liquid to gas.

The cycle starts with a compressor, a core component of the entire refrigeration system responsible for compressing refrigerant vapors.

The less pressurized refrigerant gas with low temperature gets converted into highly pressurized, superheated gas in the compressor.

The refrigerant vapors then pass to the condenser under warmer and pressurized conditions. The condenser condenses the refrigerant and converts it into a liquid state

.

The refrigerant releases its heat into the condenser pipes, passing it into the reservoir. The heat leaves the system through air or water mediums.

When leaving the condenser, the refrigerant has cooled down into the liquid.

Next is the thermal expansion valve that controls refrigerant flow entering the evaporator and decreases its pressure to some extent.

The evaporator is the heat exchanger where the processed water and the refrigerant come into contact.

The processed water passes all its heat to the refrigerant, causing it to heat up. It ultimately gets boiled, and the refrigerant vapors shift towards the compressor.

Here the cycle completes, and the refrigerant is ready to proceed in the next cycle.

What are the Characteristics of a Scroll Chiller?

The following prominent features characterize a Scroll Chiller:

Superior Controls

The Scroll Chiller is advanced by its superior controlling technology with an automated control system. It provides a user-friendly environment for the operator.

The control system is designed to attain maximum efficiency, providing a continuous operation with reliability.

The microprocessor-based control system possesses precise temperature control, text display, alarm alerts in case of any failure.

High Efficiency

It contains interior grooved tubes having a spiral configuration that ensures the efficient exchange of heat through the refrigeration cycle.

High-quality brazed plate heat exchangers have a highly efficient operation. All the components are configured to maximize their efficiency.

Capacity Modulation

The unit is featured with optimized conditions that permit the usage of one or more compressors based on the requirements, each of which is specified with its refrigerant circuit.

Energy Efficiency

The advanced microprocessor controller makes sure to run the necessary number of compressors at a time that reduces the unit’s energy consumption, making it more energy-efficient.

Reliability

It offers superior reliability with its intelligent management and adaptive frequency drive having an easy user interface. It ensures efficient lubrication even in case of power failure.

Scroll Chiller Microprocessor-Based Control System

What are the Prominent Applications of a Scroll Chiller?

The Scroll Chiller is efficient in its functioning and provides an appropriate source of attaining desirable environmental conditions in the application area.

On a commercial scale, the Scroll Chiller has the following applications:

- Machine Tools

- Laser Machine

- Food Processing

- Welding

- Telecommunications

- Electrochemical Processing

- Beverage Industry

- Pharmaceutical Industry

- Plastics Processes

- Blow Molding

- Anodizing

- Printing

- Injection

- Extrusion

In addition, it is widely used in hotels, hospitals, schools, offices, and residential buildings owing to its quiet operation.

Applications of Scroll Chiller

What are the Types of a Scroll Chiller?

The Scroll Chiller can be of two types:

The working principle of both these types is nearly the same; both have a scroll condenser by which they compress the refrigerant with efficiency.

However, the primary difference is the condensing medium by which heat is dissipated to the outer environment.

Air Cooled Scroll Chiller

Air cooled scroll chiller uses air to remove excess heat from the exhaust fans system. It is appropriate for applications that encounter harsh climate conditions.

It is a self-contained system for which no additional exterior components are required. It is much convenient to maintain and install.

However, it is not much efficient as the scroll water cooled chiller.

Water Cooled Scroll Chiller

The water cooled scroll chiller exhausts heat using water as a condensing medium. It essentially requires a cooling tower and pumping system to cool the water cooled condenser.

Since water is a better cooling medium than air, scroll water cooled chiller is more efficient in cooling.

However, installing an immense water pumping system and the cooling tower is more complex.

Water Cooled Scroll Chiller

What are the Advantages of a Scroll Chiller for your Applications?

The Scroll Chiller offers you many advantages for your applications. Some of these are:

High Durability

The Scroll Chiller has high levels of durability. The heat exchangers are coated with corrosion-resistant materials, besides many other components are made up of stainless steel that prevents the unit from any corrosive damage.

The dry filters prevent the contaminants from entering the unit, ensuring efficient performance and long service life.

Easy to Install

The unit is already charged and pre-wired; it does not require many complications that make its installation easy with minimal effort.

Quiet Operation

It has a compact structure that operates silently and does not produce excessive noises. Thus, it is an appropriate cooling solution for applications like hospitals, schools, etc.

Eco Friendly

The unit entails a refrigerant that is safe for the environment. It has no threat to the ozone layer and plays its role in reducing air pollution.

High Compression Capability

The scroll compressor uses fixed and moving scrolls to compress the refrigerant. It performs its function with higher efficiency.

Easy Maintenance

The unit avoids maintenance complications. The whole maintenance process involves proper lubrication, cleaning, and replacing damaged parts.

What is the Estimated Cost of a Scroll Chiller?

The cost of a Scroll Chiller differs vastly depending on the unit’s tonnage, type, and quality.

Generally, the larger the size, the greater will be the costs. Likewise, a high-quality Scroll Chiller will charge you more than one with lower quality.

It costs somewhere between 500 to 600 dollars per ton—the estimated cost, excluding the installation, operational, and maintenance costs.

It will bebetween 2500 and 60,000 US dollars depending on the type of Scroll Chiller you choose.

What is the Difference Between a Scroll Chiller and Screw Chiller?

The Scroll Chiller and the screw chiller are nearly the same concerning the working principle. However, the fundamental difference is the type of compressor used in both.

It uses a scroll compressor to compress the refrigerant. It can handle small cooling loads, thus suitable for lower-scale industrial applications.

Contrarily, the screw chiller is equipped with a screw compressor. It is a perfect choice for broader commercial applications as it is advanced for larger-scale cooling demands.

Scroll Chiller is smaller than a screw chiller as the screw chiller is configured for larger cooling loads.

However, the screw chiller can run consistently for a day while the Scroll Chiller needs a little break between its operations.

How to Measure the Cooling Capacity of your Scroll Chiller?

The cooling capacity of a Scroll Chiller is its ability to remove excess heat from the application unit to lower its temperature.

It is usually measured in BTUs, although the S.I. unit is the watt.

Firstly, you need to determine the following factors to calculate the cooling capacity of your Scroll Chiller.

- The difference between the inlet temperature and the required temperature of the cooling medium.

- The flow rate of water per hour(m³/hour)

Ultimately, you will have the precise cooling capacity of the unit by the following expression:

Tons of cooling capacity = rate of water flow x Differential Temperature ÷ 0.86 ÷ 3.517

What are the Safety Devices of a Scroll Chiller?

The Scroll Chiller encompasses various safety devices. These devices prevent any damage to the system. In this way, they protect the unit and ensure its safety, reliability, and durability.

The unit principally consists of the following safety devices with their specified functions:

- Over-load protectors protect electrical motors provided in pumps and compressors in an overload or short circuit.

- Anti-freezing protection averts the water from being frozen in the evaporator.

- The emergency stop switch allows to shut the unit down instantly in any critical situation.

- Flow rate protection shuts the unit when the water flow drops down the minimal optimized range.

- Over-temperature protection prevents the thermistors from increasing temperature beyond limits.

- High and low-pressure protection activates when the suction pressure lowers or exceeds its optimized range.

- Compressor inner protection protects the compressor from any harm.

- A relief safety valve triggers when the pressure becomes too high to keep it within limits.

Scroll Chiller Emergency Stop Switch

What Type of Sensors are Installed in a Scroll Chiller?

The Scroll Chiller retains the following central sensors:

Temperature Sensors

The temperature sensors are installed in the evaporator and condenser at the water inlet and outlets.

Each circuit contains a suction temperature sensor that controls and monitors the superheated refrigerant temperatures.

Thermistors

PTC thermistors are equipped in each compressor. These are immersed into motor windings to ensure motor protection. They reach a high value if the motor temperature gets a hazardous temperature.

Pressure Transducers

The two pressure transducers are present in the circuit. They are used to measure the evaporating and condensing pressures.

Scroll Chiller Temperature Sensors

What are the Technological Advancements of a Scroll Chiller?

The Scroll Chiller has been advanced with various technological requirements to satisfy your relevant struggles.

Below are a few of these advancements that the modern Scroll Chiller is featured with:

- Automatic cleaning systems ensure the sanitation of your unit.

- Improved eco-friendly refrigerants with anti-freezing attributes.

- Automated sensors that ensure the protection of the unit

- Remote control systems.

What is the Difference Between Single Compressor Scroll Chiller and a Multiple Compressor Scroll Chiller?

The Scroll Chiller can be of two types based on the number of compressors used. These are manufactured to meet the cooling loads with various requirements.

Scroll Chiller uses only one scroll compressor to compress the refrigerant. It is specified for a lower cooling load.

On the other hand, the multiple compressor Scroll Chiller is composed of more than one compressor.

Multiple compressors produce a greater driving force for the refrigerant cycle and compress the refrigerant more precisely according to the requirements.

Multiple Compressor Scroll Chiller

How to Choose an Appropriate Scroll Chiller for your Industry?

The Scroll Chiller offers many alternatives for various requirements based on the size, features, and cooling capacity.

While purchasing your Scroll Chiller, you must be aware of the cooling demand of your application area.

Besides, it would be best to consider the following factors to choose an appropriate one for your industry.

Coolant Temperature

The first factor you should consider is the coolant temperature. It is the measurement of the coldness of the coolant in the system.

The coolant temperature expresses the amount of heat that the coolant can absorb.

Heat Load

It measures the amount of heat in BTUs produced by your application area in a unit hour. It is essential to consider because it helps determine how powerful Scroll Chiller you need for your application.

Condenser Heat Dissipation

The next to consider is the ability of the condenser to dissipate heat into the reservoir: the better the unit’s heat dissipation ability, the more efficient the chiller.

Coolant Flow and Pressure

The pressure and the rate at which the coolant flows directly impact the ability of the coolant to withdraw heat.

What Type of Microprocessor Controllers are Placed in a Scroll Chiller?

The Scroll Chiller is advanced by an automated microprocessor-based controller that provides the capacity control to the unit.

The microprocessor controller has three classic modes of operation that are:

- Building Management System (BMS mode).

- Local mode for start and stop control functions.

- The remote mode provides a remote start and stops control function through a digital input.

The microprocessor controller ensures the uniform runtime of compressors. The control system holds precise temperature control, text display, and alerts in case of failure.

What are the Common Problems of a Scroll Chiller?

The Scroll Chiller is an efficient source of cooling your industrial plant. However, sometimes it can suffer from some problems induced by varied causes.

Some of the most common problems your Scroll Chiller may endure are discussed below:

Slugging

Sometimes, the filters and the piping system get blocked from contaminants due to the growth of molds formation. It will cause the refrigerant or other fluids to turn back to the storage tanks.

You can prevent the filter and piping system from slugging by cleaning them regularly.

Overheating

Your device might get overheat due to high friction levels between the moving parts of the scroll compressor. It usually happens due to insufficient lubrication.

Electric Faults

Sometimes, various electric faults may suffer your Scroll Chiller. The unit fails to start or suddenly shuts down during regular operation.

The problems are mainly caused when the unit does not receive sufficient power due to faulty electrical installations.

Inadequate Cooling

You may have ever experienced that your unit does not produce enough cooling effect. It may be caused by extremely high ambient temperature, improper voltage, leak refrigerant, etc.

Insufficient Fluid Flow

The insufficient fluid in the reservoir, improper voltage, blocked fuel filter, failure of the pump, closed valves can be the primary reasons. These reasons can reduce pumping and insufficient flow of fluid.

How to Increase the Working Efficiency of a Scroll Chiller?

The following are the few possible ways by which you can increase the working efficiency of your Scroll Chiller.

Maintain Regular Inspection

To ensure your unit’s stable, efficient performance, make sure to inspect the machine regularly.

Inspect the flow of refrigerant and the coolant, working of the unit’s components, the valve, filters, oil heater, thermostat, and the lubrication system.

Maintain Proper Record

It is recommended to maintain a proper record of the regular checking of your Scroll Chiller.

Look for any damage or any other fault in the unit. Take notice of any irregular noise and vibration.

Cleaning the Machine

It will help clean your Scroll Chiller regularly to eliminate any dirt that may clog the filters. It would help clean the delivery pipes periodically to prevent any growing molds.

Fill the Refrigerant

Avoid operating the unit at lower refrigerant levels. Fill the refrigerant charge whenever it needs to be.

Repair the Damaged Parts

To ensure the efficient performance of the unit, you should repair the damaged parts. If you find any problem with your device, consult an expert and fix it immediately as soon as possible.

Maintain Optimal Conditions

You must maintain the optimized operating conditions to use the Scroll Chiller efficiently.

Scroll Chiller Refrigerant Filling

What are the Maintenance Guidelines for your Scroll Chiller?

If you properly maintain your Scroll Chiller, you will increase its working efficiency and durability.

Below are given a few maintenance guidelines you must follow:

- Clean the filter once a week by washing it with water.

- Look for any gas leaks in all refrigerant pipe joints.

- Inspect the protection devices to ensure that they are working well.

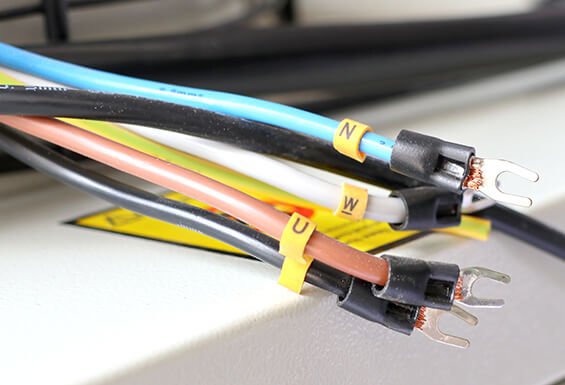

- Check the circuits in the control panel and ensure the tightening of loose wires.

- Inspect water pipe connections.

- Ensure no oil leaks by checking the compressor at least twice a year.

- Inspect the unit operating parameters.

- Replace the damaged parts immediately.

- Take notice of any unusual vibration or noises.

- Review the oil level of the unit in the compressor.

- Check the refrigerant charge of the unit.

Scroll Chiller Maintenance

What are the Troubleshooting Tips for your Scroll Chiller?

To make exclusive use of your Scroll Chiller, you should be well-versed about the tips by which you can troubleshoot your unit in case of any problem.

Below are a few ways that you may use to troubleshoot your device.

Extremely High Discharge Temperature

In this case, check whether the unit is being operated in optimized conditions or not. Ensure the proper functioning of the liquid injection valve and electronic expansion valve.

Look if either there is a refrigerant leakage or any blockage in pipelines.

Compressor Overloading

If the compressor is getting overloaded, check the set value of the compressor overload protection and restart the device after satisfying the controlling parameters.

Low Discharge Pressure

In this case, check for the ambient temperature if it is too low or the low suction pressure. Make sure that there is no refrigerant leak in the system.

High Discharge Pressure

If the discharge pressure is low beyond limits, inspect the ambient temperature if it is too high.

The problem may happen with excessive refrigerant or when any non-condensable gas enters the system.

Compressor Overheating

If the compressor is overheating, check the liquid injection valve to see if it is functioning correctly. Inspect the oil level.

The problem also occurs when compressor bearing lubrication went insufficient.

Compressor Failure

If the compressor fails to run, there may be various possible reasons behind that. Make sure to fix them.

The compressor may not be receiving enough power to start up, the current overload, startup switch may fail, or fuse for the power supply in the control circuit is burnt.

Troubleshooting Scroll Chiller