TopChiller can design and manufacture all types of air chillers for you

- Cooling capacity ranges up to 200 Ton

- Temperature control ranges from -35°C to 20°C

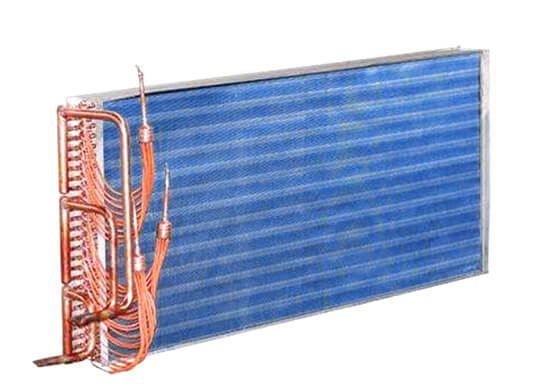

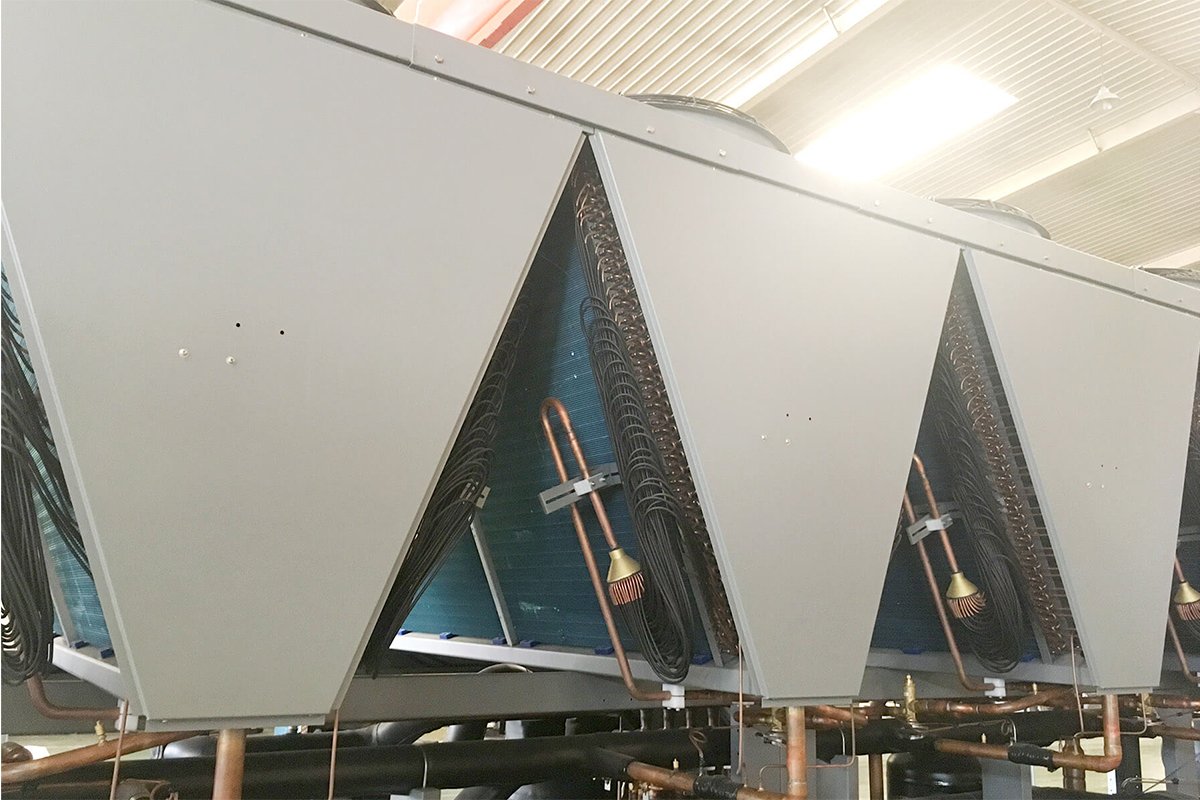

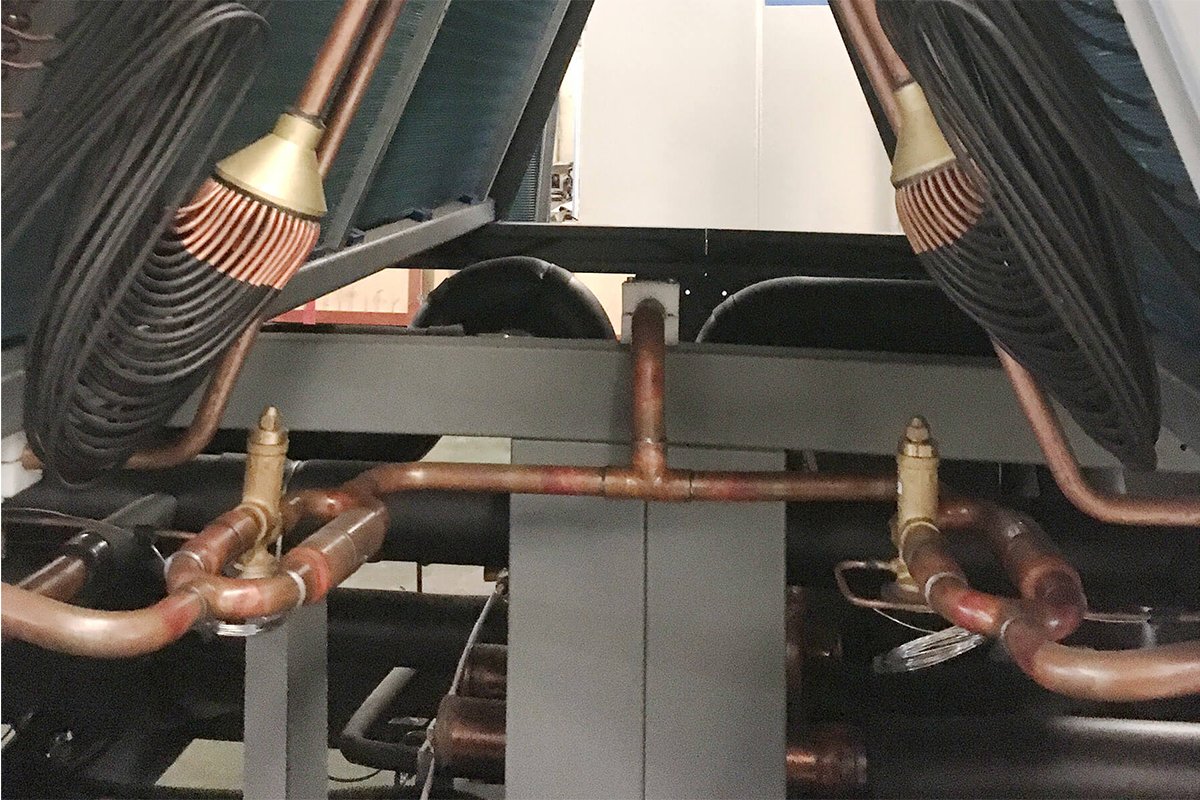

- Finned type air cooled copper condenser

- Scroll& screw type efficient compressor

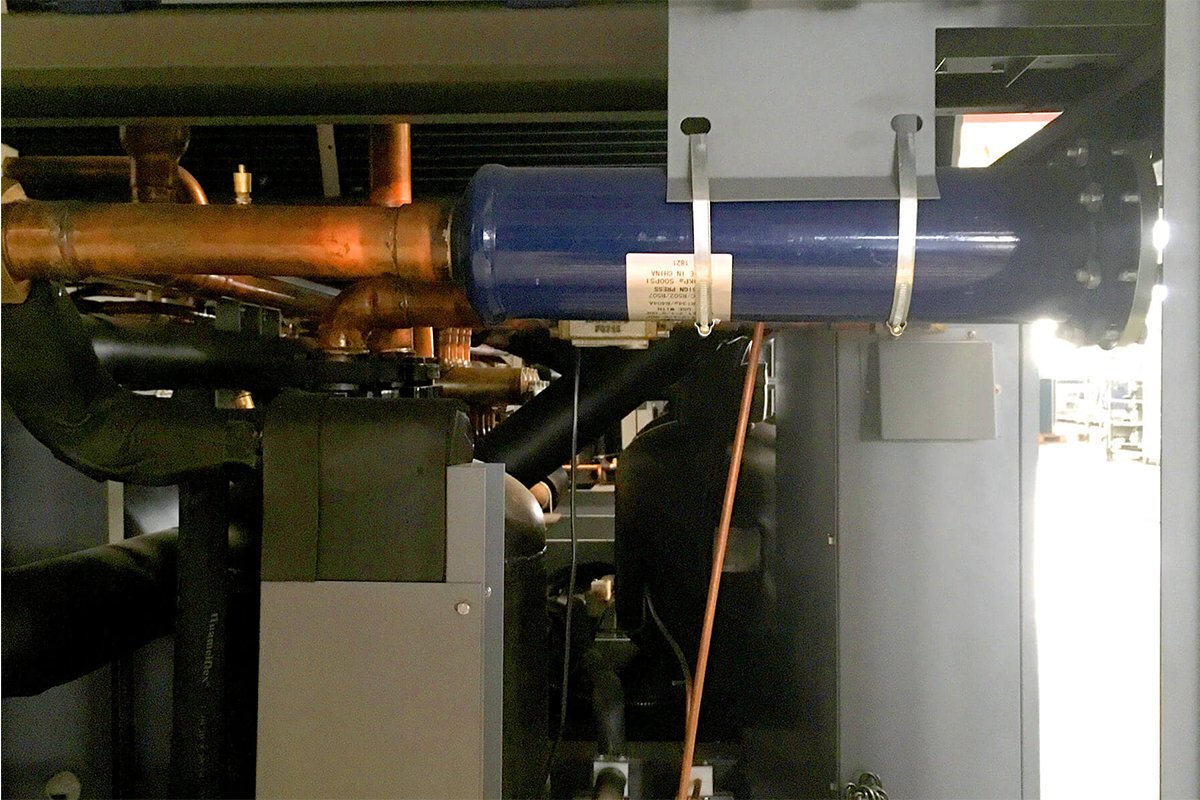

- Plate or shell and tube type heat exchanger

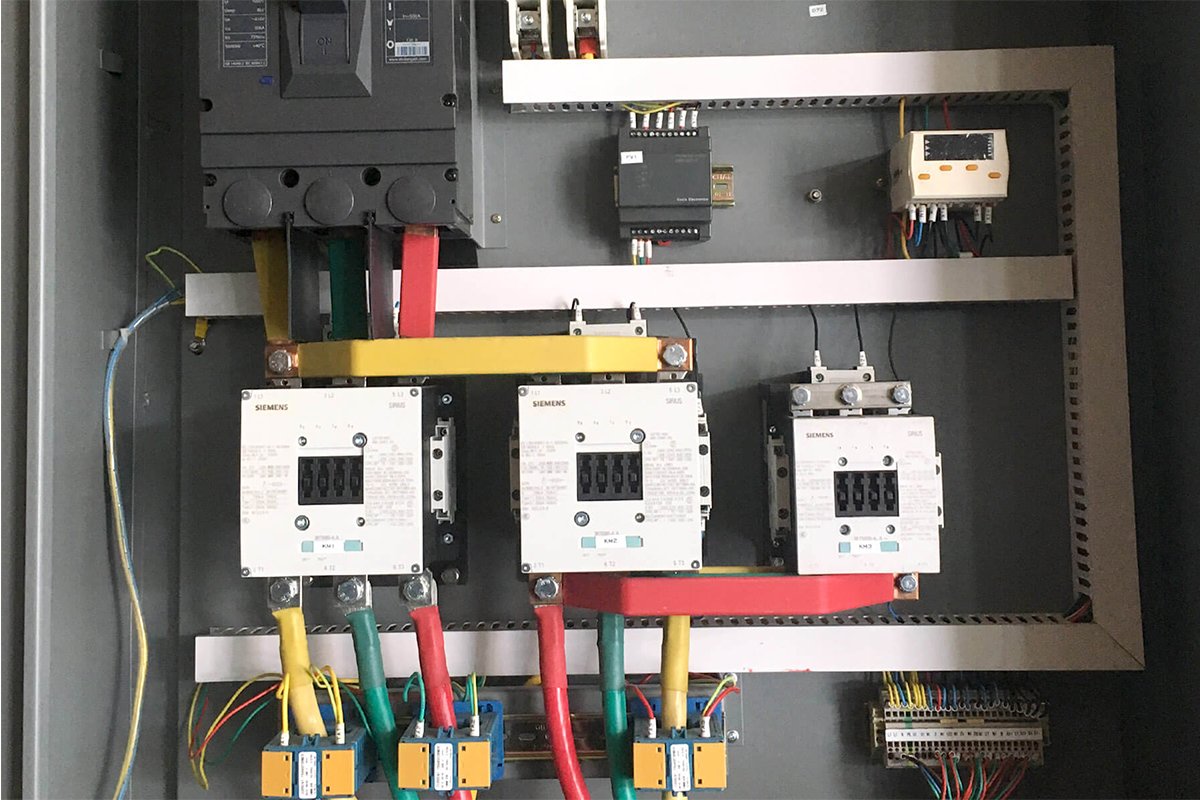

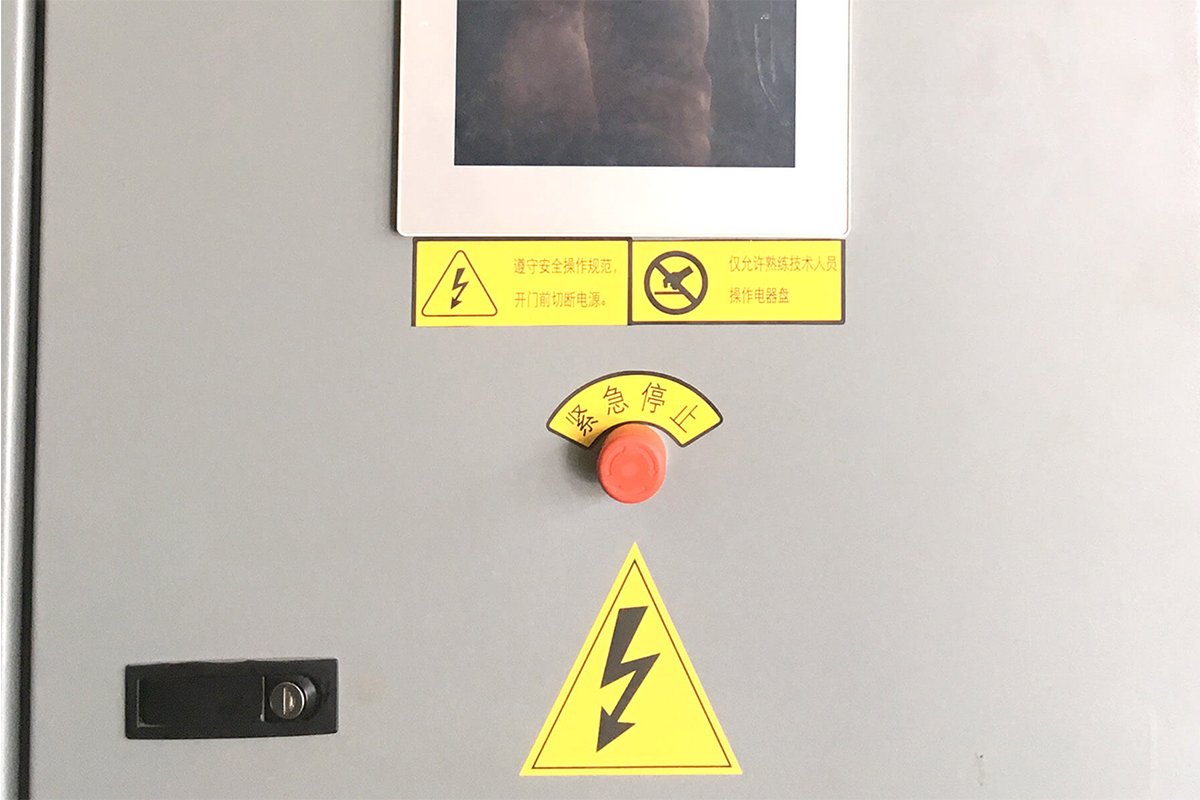

- High-quality electric parts & SS evaporator

- Temperature controlling PID based unit

- Warranty time 24 months after purchase

Your Premier Air Chiller Manufacturer and Supplier in China

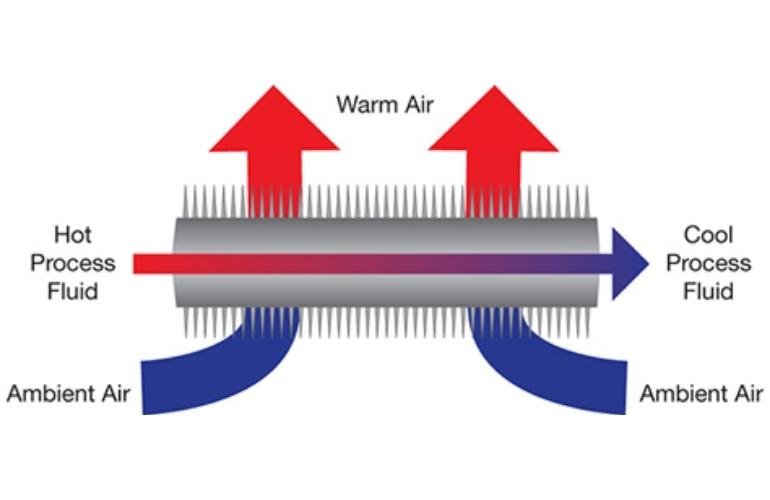

Air Chiller is a precisely customized water cooling machine that configures the cooling effect for different heat-generating machines by using ambient air circulation around the chiller and dissipating heat from the system.

TopChiller is the leading company of China that emerged on the world map by its marvelous achievements by combining breakthrough technologies and advanced designs in the manufacturing of reliable Air Chiller.

From the year of its establishing, TopChiller has got twenty years of professional experience and an appreciation from customers by manufacturing a full line of Air Chiller models and supplied to all world markets with easy accessibility.

Air Chiller is made of different branded spare parts as a scroll /screw compressor, air-cooled condenser, PID temperature controller, wooden shell, protecting devices, electric units, SS evaporator, water pumps, and plate type heat exchanger for steadfast operation.

Air Chiller made by TopChiller has outstanding benefits as given below:

- TopChiller designed Air Chiller is profoundly accurate and precise in its working featured by copper-coated condenser with a high heating load that releases the heat from processing machine by ambient air circulation around the condenser.

- Air Chiller is configured to release heat in such type of application where the discharge of heat is not a key factor by spreading the discharged heat around the machine in cooled weather preventing the machine from severe environmental effect.

- TopChiller designed Air Chiller has lower costs of maintenance featured by no cooling tower and water installation by saving costs required for water clearing.

- Air Chiller maintains the regulation of temperature and pressure inside unit By PID temperature controller that automatically diagnose the changes and adjust all at set point preventing the unit from damage.

- TopChiller designed Air Chiller is constructed with air filters, rugged design, and wooden shell, making an easy indoor and outdoor installation ensuring prevention from corrosion and obstructions by dust.

TopChiller designed Air Chiller is being used for different industrial applications based on different niches as:

Mechanical industries, frozen food processing, chemicals production, food preservation, warehouses, seafood frozen, medical industries, hospitals, clinical labs, construction machines, plastic industries, hotels, etc.

If you have intentions to buy a steady, precise working, air dependent Air Chiller for your application?

If you are pondering over to hit a reliable company manufacturing optimized and water-scarce areas supporting Air Chiller for the betterment of your own business?

TopChiller is the best company providing different quality services to customers. You can surely rely on it. So come ahead and make contact with TopChiller technocrats and personnel you will get unmatched support from our company.

TopChiller experts and trained engineers are sitting for you to provide aftermarket services regarding Air Chiller customization for your application at affordable costs.

General Description:

An Air Chiller is a highly efficient chiller unit that uses a refrigeration system to produce a steady cooling water source in both commercial and industrial applications. The cooling effect is the result of heat absorbed from processed water.

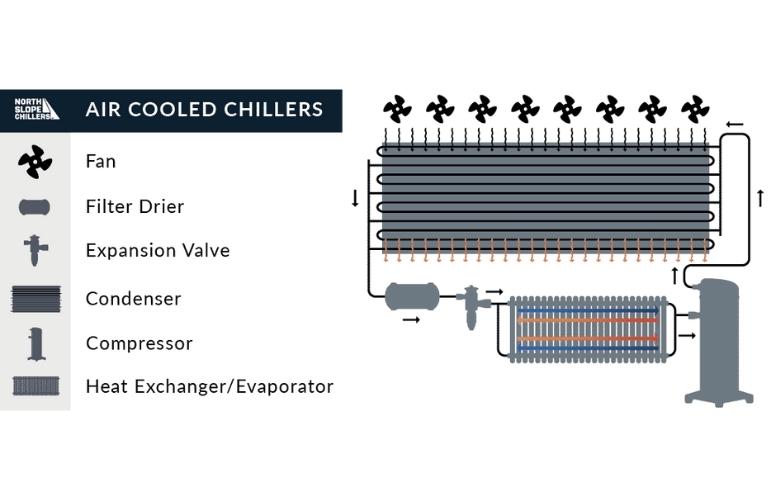

The essential components of an Air Chiller include a prime quality compressor, air cooled condenser, expansion valve, evaporator, and power unit.

Air Chiller manufactured by TopChiller is a perfect chiller solution for areas of applications where heat disposal is not an issue. It is being used in several industrial and commercial applications, including restaurants, mega sports events, shopping malls, schools and colleges, hospital buildings, laser cutting, the food industry, manufacturing industries, and so forth.

TopChiller is a well-known Air Chiller manufacturer and supplier. We have a complete Air Chiller model available to suit your multiple applications. Each one is equipped with unique features, minimum cost, and energy-conserving operation.

Are you searching for a high-quality Air Chiller that reduces water costs and ensures better environmental stability while providing you desired cooling?

TopChiller has all the answers related to Air Chiller you need. Contact us to get your desired Air Chiller as per your budget and industrial requirements.

Features and Advantages:

TopChiller manufactures an Air Chiller that outshines the rest of the cooling systems in the market. Some of its outstanding benefits are mentioned as:

- Designed for smooth performance, an evaporator, compressor, condenser, and expansion valve produce the cooling by eliminating maximum heat out of the system. It does not involve any cooling tower, which makes easy installation and usage.

- Saving power and additional costs, it is functional with a fluid flow switch, suction accumulator, and filter drier. These secondary components ensure that there is no backward process taking place in the system.

- The Air Chiller designed by TopChiller is as productive as it could get. Evaporators integrated with compressor and condenser effectively absorb unwanted heat and transfer it. Its components undergo thermodynamic processes to get the job done.

- Using air to fuel condenser cooling requires essential maintenance and delivers peak efficiency, which is ensured by certified performance. It also puts the extra heat to use, therefore, a better and more valuable option in the market.

- TopChiller can design and manufacture all types of Air Chillers to meet your special cooling requirements.

- Data Sheet

- Image Gallery

- Main Parts

- Video

| Air Chiller Technical Specifications | ||||||||||||||

| Model Items | TPAS-80ASH | TPAS-110ASH | TPAS-140ASH | TPAS-160ASH | TPAS-190ASH | TPAS-210ASH | TPAS-250ASH | TPAS-290ASH | TPAS-310ASH | TPAS-340ASH | TPAS-400ASH | TPAS-430ASH | ||

| Cooling capacity | kcal/h | 68800 | 94600 | 122980 | 135020 | 164260 | 180600 | 212420 | 245100 | 266600 | 292400 | 348300 | 369800 | |

| KW | 80 | 110 | 143 | 157 | 191 | 210 | 247 | 285 | 310 | 340 | 405 | 430 | ||

| Input power | KW | 32.5 | 43.6 | 54.7 | 59.7 | 73.6 | 79.6 | 88.2 | 101.2 | 112.8 | 123.8 | 145 | 155 | |

| Max Current | A | 57 | 75 | 95 | 103 | 125 | 135 | 151 | 173 | 191 | 211 | 246 | 263 | |

| Power source | 3PH~380V/415V/480V~50HZ/60HZ(3PH~200V/220V 50HZ/60HZ) | |||||||||||||

| Refrigerant | Type | R22(R134a/R407c/R404A) | ||||||||||||

| Charge | kg | 21 | 28 | 35 | 42 | 49 | 56 | 63 | 70 | 77 | 84 | 98 | 112 | |

| Control | Thermostatic expansion valve | |||||||||||||

| Compressor | Type | Semi-hermetic screw | ||||||||||||

| Power | KW | 30 | 40 | 50 | 55 | 67 | 73 | 82 | 95 | 104 | 115 | 134 | 142 | |

| Start mode | Y-△ | |||||||||||||

| Capacity control | % | 0-33-66-100 | 0-25-50-75-100 | |||||||||||

| Evaporator | Type | Shell and tube (SS plate heat exchanger) | ||||||||||||

| Chilled water | m³/h | 13.8 | 18.9 | 24.6 | 27.0 | 32.8 | 36.1 | 42.5 | 49.0 | 53.3 | 58.4 | 70.0 | 74.0 | |

| Water pressure | KPa | 32 | 32 | 35 | 38 | 42 | 42 | 45 | 43 | 43 | 43 | 41 | 43 | |

| Pipe connection | Inch | 3″ | 3″ | 3″ | 4″ | 4″ | 4″ | 4″ | 4″ | 5″ | 5″ | 6″ | 6″ | |

| Condenser | Type | Air cooled type high efficiency finned cooper tube | ||||||||||||

| Fan | Type | m³/h | Big volume & low noise axil fan | |||||||||||

| Power | KW | 0.42×6 | 0.6×6 | 0.78×6 | 0.78×6 | 1.1×6 | 1.1×6 | 0.78×8 | 0.78×8 | 1.1×8 | 1.1×8 | 1.1×10 | 1.1×12 | |

| Air volume | m³/h | 30000 | 40000 | 50000 | 60000 | 70000 | 80000 | 90000 | 100000 | 110000 | 116000 | 145000 | 165000 | |

| Safety protection devices | Inner thermostat for compressor motor, unit overload relay,high and low pressure switch, freeze protection thermostat, reverse phase protection relay, discharge gas thermostat, flow switch | |||||||||||||

| Dimension | Length | mm | 2200 | 2350 | 2600 | 2600 | 2650 | 2650 | 3400 | 3400 | 3800 | 3800 | 4800 | 5800 |

| Width | mm | 1150 | 1350 | 1500 | 1500 | 1900 | 1900 | 1700 | 1700 | 1900 | 1900 | 1900 | 1900 | |

| Height | mm | 1980 | 2000 | 2100 | 2100 | 2200 | 2200 | 2200 | 2200 | 2200 | 2200 | 2200 | 2200 | |

| Net weight | kg | 1100 | 1300 | 1600 | 1900 | 2200 | 2350 | 2550 | 2800 | 2850 | 2950 | 3200 | 3550 | |

| Running weight | kg | 1300 | 1500 | 1840 | 2200 | 2530 | 2700 | 2950 | 3250 | 3350 | 3560 | 3650 | 3950 | |

| The above specifications are according to the following design conditions: 1, Chilled water inlet/outlet temperature 12℃/7℃. 2, Cooling air inlet/outlet temperature 30℃/38℃. We reserve the right to modify the specifications without further notice. | ||||||||||||||

| Air Chiller Technical Specifications | ||||||||||||||

| Model Items | TPAS-160ADH | TPAS-220ADH | TPAS-285ADH | TPAS-315ADH | TPAS-380ADH | TPAS-420ADH | TPAS-495ADH | TPAS-570ADH | TPAS-620ADH | TPAS-680ADH | TPAS-810ADH | TPAS-860ADH | ||

| Cooling capacity | kcal/h | 137600 | 189200 | 245960 | 270040 | 328520 | 361200 | 424840 | 490200 | 533200 | 584800 | 696600 | 739600 | |

| KW | 160 | 220 | 286 | 314 | 382 | 420 | 494 | 570 | 620 | 680 | 810 | 860 | ||

| Input power | KW | 64.7 | 86.6 | 106.2 | 118.8 | 145 | 159.2 | 177.2 | 207.6 | 225.6 | 247.6 | 290 | 310.4 | |

| Max Current | A | 114 | 149 | 185 | 205 | 250 | 274 | 308 | 358 | 388 | 428 | 500 | 533 | |

| Power Source | 3PH~380V/415V/480V~50HZ/60HZ(3PH~200V/220V 50HZ/60HZ) | |||||||||||||

| Refrigerant | Type | R22(R134a/R407c/R404A) | ||||||||||||

| Charge | kg | 21×2 | 28×2 | 35×2 | 42×2 | 49×2 | 56×2 | 63×2 | 70×2 | 77×2 | 84×2 | 98×2 | 112×2 | |

| Control | Thermostatic expansion valve | |||||||||||||

| Compressor | Type | Semi-hermetic screw | ||||||||||||

| Power | KW | 30×2 | 40×2 | 50×2 | 55×2 | 67×2 | 73×2 | 82×2 | 95×2 | 104×2 | 115×2 | 134×2 | 142×2 | |

| Start mode | Y-△ | |||||||||||||

| Capacity control | % | 0-33-66-100 | 0-25-50-75-100 | |||||||||||

| Evaporator | Type | Shell and tube (SS plate heat exchanger) | ||||||||||||

| Chilled water | m³/h | 27.5 | 37.8 | 49.1 | 54 | 65.7 | 72.2 | 85 | 98 | 106.6 | 117 | 139.3 | 147.9 | |

| Water pressure | KPa | 32 | 32 | 35 | 38 | 42 | 42 | 45 | 43 | 43 | 43 | 41 | 43 | |

| Pipe connection | Inch | 4″ | 4″ | 4″ | 5″ | 6″ | 6″ | 6″ | 6″ | 8″ | 8″ | 8″ | 10″ | |

| Condenser | Type | Air cooled type high efficiency finned cooper tube | ||||||||||||

| Fan | Type | m³/h | Big volume & low noise axil fan | |||||||||||

| Power | KW | 0.78×6 | 1.1×6 | 0.78×8 | 1.1×8 | 1.1×10 | 1.1×12 | 1.1×12 | 1.1×16 | 1.1×16 | 1.1×16 | 1.1×20 | 1.1×24 | |

| Air volume | m³/h | 60000 | 80000 | 100000 | 116000 | 145000 | 165000 | 180000 | 205000 | 225000 | 242000 | 285000 | 325000 | |

| Safety protection devices | Inner thermostat for compressor motor, unit overload relay, high and low pressure switch, freeze protection thermostat, reverse phase protection relay, discharge gas thermostat, flow switch | |||||||||||||

| Dimension | Length | mm | 2600 | 2650 | 3400 | 3800 | 4800 | 5800 | 5800 | 7800 | 7800 | 8000 | 9800 | 11600 |

| Width | mm | 1500 | 1900 | 1700 | 1900 | 1900 | 1900 | 2200 | 2000 | 2200 | 2200 | 2200 | 2200 | |

| Height | mm | 2100 | 2200 | 2200 | 2200 | 2200 | 2200 | 2300 | 2250 | 2250 | 2300 | 2350 | 2350 | |

| Net weight | kg | 2050 | 2520 | 2980 | 3180 | 3420 | 3730 | 3950 | 4330 | 4650 | 4930 | 5450 | 5850 | |

| Running weight | kg | 2360 | 2870 | 3420 | 3690 | 3780 | 4180 | 4380 | 4650 | 4920 | 5360 | 5830 | 6530 | |

| The above specifications are according to the following design conditions: 1, Chilled water inlet/outlet temperature 12℃/7℃. 2, Cooling air inlet/outlet temperature 30℃/38℃. We reserve the right to modify the specifications without further notice. | ||||||||||||||

| Air Chiller Technical Specifications | ||||||||||||||

| Items Model | AC-0.5A | AC-1A | AC-1.5A | AC-2A | AC-2.5A | AC-3A | AC-4A | AC-5A | AC-6A | AC-8AD | AC-10AD | AC-12AD | AC-15AD | |

| Cooling capacity | Kcal/h 50HZ/60HZ | 1419 | 2451 | 3182 | 4833 | 5848 | 7181 | 9288 | 11988 | 14534 | 18576 | 23994 | 29068 | 38270 |

| 1703 | 2941 | 3784 | 5800 | 7018 | 8617 | 11146 | 14386 | 17441 | 22291 | 28793 | 34882 | 45924 | ||

| KW 50HZ/60HZ | 1.65 | 2.85 | 3.7 | 5.62 | 6.8 | 8.35 | 10.8 | 13.94 | 16.9 | 21.6 | 27.9 | 33.8 | 44.5 | |

| 1.98 | 3.42 | 4.4 | 6.74 | 8.2 | 10.02 | 12.96 | 16.73 | 20.28 | 25.92 | 33.48 | 40.56 | 53.4 | ||

| Input power | KW | 0.88 | 1.35 | 2 | 2.25 | 2.66 | 3.27 | 4.07 | 5.75 | 6.45 | 8.25 | 11.5 | 12.9 | 17.45 |

| Max Current | A | 5.4 | 8.2 | 12 | 13.6 | 6.6 | 8.2 | 10.1 | 13.8 | 15.5 | 20 | 27.9 | 31.3 | 42.4 |

| Power source | 1PH~220V/3PH~220V/380V 50HZ/60HZ | 3PH~380V/415V/480V~50HZ/60HZ(3PH~200V/220V 50HZ/60HZ) | ||||||||||||

| Refrigerant | Type | R22/R407C/134a/404A/410A | ||||||||||||

| Control | Capillary / thermostatic expansion valve | |||||||||||||

| Compressor | Type | Hermetic Rotary | Hermetic scroll ( piston ) | |||||||||||

| Power(KW) | 0.45 | 0.89 | 1.3 | 1.73 | 2.1 | 2.7 | 3.5 | 4.55 | 5.25 | 3.5×2 | 4.55×2 | 5.25×2 | 7×2 | |

| Condenser | Type | Efficient finned copper tube with aluminum+low noise external rotor fan | ||||||||||||

| Air flow (m3/h) | 750 | 1000 | 1500 | 2000 | 2500 | 3000 | 4000 | 5000 | 6000 | 8000 | 10000 | 12000 | 15000 | |

| Air blower(KW) | 0.06 | 0.09 | 0.15 | 0.15 | 0.19 | 0.14×2 | 0.14×2 | 0.19×2 | 0.19×2 | 0.25×2 | 0.45×2 | 0.45×2 | 0.6×2 | |

| Evaporator | Type | SS Tank coil / shell and tube type / Plate type heat exchanger | ||||||||||||

| Chilled water (m3/h) | 0.28 | 0.49 | 0.64 | 0.97 | 1.12 | 1.44 | 1.86 | 2.4 | 2.91 | 3.71 | 4.8 | 5.81 | 7.65 | |

| 0.34 | 0.59 | 0.76 | 1.16 | 1.4 | 1.72 | 2.23 | 2.88 | 3.49 | 4.46 | 5.76 | 7 | 9.18 | ||

| Water tank(L) | 10.6 | 18.3 | 27 | 27 | 50 | 50 | 60 | 60 | 110 | 120 | 200 | 200 | 270 | |

| Inlet/outlet pipe (inch) i | 1/2″ | 1/2″ | 1/2″ | 1/2″ | 1″ | 1″ | 1″ | 1″ | 1″ | 1-1/2″ | 2″ | 2″ | 2″ | |

| Water pump | Power (kw) | 0.37 | 0.37 | 0.37 | 0.37 | 0.37 | 0.37 | 0.37 | 0.75 | 0.75 | 0.75 | 1.5 | 1.5 | 2.2 |

| Max lift(m) | 22 | 22 | 22 | 22 | 22 | 22 | 22 | 30 | 30 | 25 | 25 | 25 | 28 | |

| Max flow (m3) | 5.4 | 5.4 | 5.4 | 5.4 | 5.4 | 5.4 | 5.4 | 8.1 | 8.1 | 8.1 | 13.5 | 13.5 | 25.2 | |

| Safety protection | Compressor inner protection, over current protection, high/low pressure protection, over temperature protection, flow rate protection, phase sequence/phase missing protection, low level coolant protection, anti freezing protection, exhaust overheat protection | |||||||||||||

| Dimension | L(mm) | 550 | 550 | 600 | 600 | 720 | 980 | 980 | 1150 | 1150 | 1350 | 1500 | 1500 | 1860 |

| W(mm) | 350 | 450 | 500 | 500 | 550 | 520 | 520 | 560 | 560 | 680 | 760 | 760 | 850 | |

| H(mm) | 695 | 845 | 985 | 985 | 1350 | 1170 | 1170 | 1215 | 1215 | 1530 | 1660 | 1660 | 1900 | |

| Net weight(KG) | 45 | 62 | 85 | 95 | 125 | 152 | 175 | 185 | 215 | 283 | 345 | 382 | 580 | |

| Note: The above specifications are according to the following design conditions: 1, 12℃/7℃.Chilled water inlet/outlet temperature 12℃/7℃. 2, 33℃/38℃.Cooling air inlet/outlet temperature 33℃/38℃. We reserve the right to modify the specification without further notice. | ||||||||||||||

| Air Chiller Technical Specifications | |||||||||||||

| Items Model | AC-15AT | AC-20AD | AC-20AF | AC-25AD | AC-25AF | AC-30AD | AC-30AT | AC-40AD | AC-40AF | AC-50AD | AC-50AF | AC-60AD | |

| Cooling capacity | Kcal/h 50HZ/60HZ | 36120 | 49966 | 47988 | 58480 | 58136 | 74734 | 74922 | 98040 | 99760 | 119024 | 116960 | 144996 |

| 43344 | 59959 | 57586 | 70176 | 69763 | 89681 | 89990 | 117648 | 119712 | 142829 | 140352 | 173995 | ||

| KW 50HZ/60HZ | 42 | 58.1 | 55.8 | 68 | 67.6 | 86.9 | 87.2 | 114 | 116 | 138.4 | 136 | 168.6 | |

| 50.4 | 69.72 | 66.96 | 81.6 | 81.12 | 104.28 | 104.64 | 136.8 | 139.2 | 166.08 | 163.2 | 202.3 | ||

| Input power | KW | 17.1 | 21.73 | 22 | 25.4 | 24.8 | 33.39 | 33.1 | 44.91 | 43.3 | 57.3 | 54 | 65 |

| Max Current | A | 43.2 | 52.7 | 53.3 | 63.7 | 61.3 | 81 | 80.2 | 109 | 106 | 135.5 | 128.5 | 135 |

| Power source | 3PH~380V/415V/480V~50HZ/60HZ(3PH~200V/220V 50HZ/60HZ) | ||||||||||||

| Refrigerant | Type | R22/R407C/134a/404A/410A | |||||||||||

| Control | Capillary / Thermostatic expansion valve | ||||||||||||

| Compressor | Type | Hermetic scroll ( piston ) | |||||||||||

| Power(KW) | 4.55×3 | 8.96×2 | 4.55×4 | 10.8×2 | 5.25×4 | 13.62×2 | 8.96×3 | 18.78×2 | 8.96×4 | 23.6×2 | 10.8×4 | 27.4×2 | |

| Condenser | Type | Efficient finned copper tube with aluminum+low noise external rotor fan | |||||||||||

| Air flow (m3/h) | 15000 | 20000 | 20000 | 25000 | 25000 | 30000 | 30000 | 40000 | 40000 | 50000 | 50000 | 60000 | |

| Air blower(KW) | 0.6×2 | 0.78×2 | 0.78×2 | 0.78×2 | 0.78×2 | 0.42×6 | 0.42×6 | 0.6×6 | 0.6×6 | 0.78×6 | 0.78×6 | 0.78×6 | |

| Evaporator | Type | SS Tank coil/ shell and tube type/Plate type heat exchanger | |||||||||||

| Chilled water (m3/h) | 7.22 | 10 | 9.6 | 11.69 | 11.62 | 14.94 | 15 | 19.6 | 19.95 | 23.8 | 23.4 | 29 | |

| 8.67 | 11.99 | 11.51 | 14.03 | 13.95 | 17.93 | 18 | 23.52 | 23.94 | 28.6 | 28.1 | 34.8 | ||

| Water tank(L) | 270 | 350 | 350 | 350 | 350 | 420 | 420 | 580 | 580 | 580 | 580 | 580 | |

| inlet/outlet pipe (inch) | 2″ | 2″ | 2″ | 2-1/2″ | 2-1/2″ | 2-1/2″ | 2-1/2″ | 3″ | 3″ | 3″ | 3″ | 3″ | |

| Water pump | Power(kw) | 2.2 | 2.2 | 2.2 | 2.2 | 2.2 | 4 | 4 | 4 | 4 | 5.5 | 5.5 | 5.5 |

| Max lift(m) | 28 | 28 | 28 | 28 | 28 | 30 | 30 | 30 | 30 | 32 | 32 | 32 | |

| Max flow (m3) | 25.2 | 25.2 | 25.2 | 25.2 | 25.2 | 36 | 36 | 36 | 36 | 40 | 40 | 40 | |

| Safety devices | Compressor inner protection, over current protection, high/low pressure protection, over temperature protection, flow rate protection, phase sequence/phase missing protection, low level coolant protection, anti freezing protection, exhaust overheat protection | ||||||||||||

| Dimension | L(mm) | 1860 | 2020 | 2020 | 2020 | 2020 | 2200 | 2200 | 2350 | 2350 | 2600 | 2600 | 2600 |

| W(mm) | 850 | 950 | 950 | 950 | 950 | 1150 | 1150 | 1350 | 1350 | 1500 | 1500 | 1500 | |

| H(mm) | 1900 | 2000 | 2000 | 2000 | 2000 | 1980 | 1980 | 2000 | 2000 | 2100 | 2100 | 2100 | |

| Net weight(KG) | 580 | 650 | 650 | 810 | 810 | 890 | 890 | 1112 | 1112 | 1320 | 1320 | 1320 | |

| Note: The above specifications are according to the following design conditions: 1, Chilled water inlet/outlet temperature 12℃/7℃. 2, Cooling air inlet/outlet temperature 33℃/38℃. We reserve the right to modify the specification without further notice. | |||||||||||||

Why TopChiller is Your Reliable Air Chiller Manufacturer and Supplier In China?

Air Chiller-An Ultimate FAQ Guide by TopChiller.

- What is an Air Chiller?

- What are the Main Components of an Air Chiller?

- What is the Working Principle of an Air Chiller?

- What are the Major Applications of Air Chiller?

- What are the Advantages of Air Chiller for your Applications?

- What is the Difference Between Air Chiller and Water Chiller?

- Why is an Air Chiller Preferred Over a Water Chiller?

- What is the Role of Compressor in an Air Chiller?

- What are the Types of an Air Chiller?

- How an Air Chiller is an Energy-Efficient Option for your Industry?

- What is the Process of Heat Transfer in an Air Chiller?

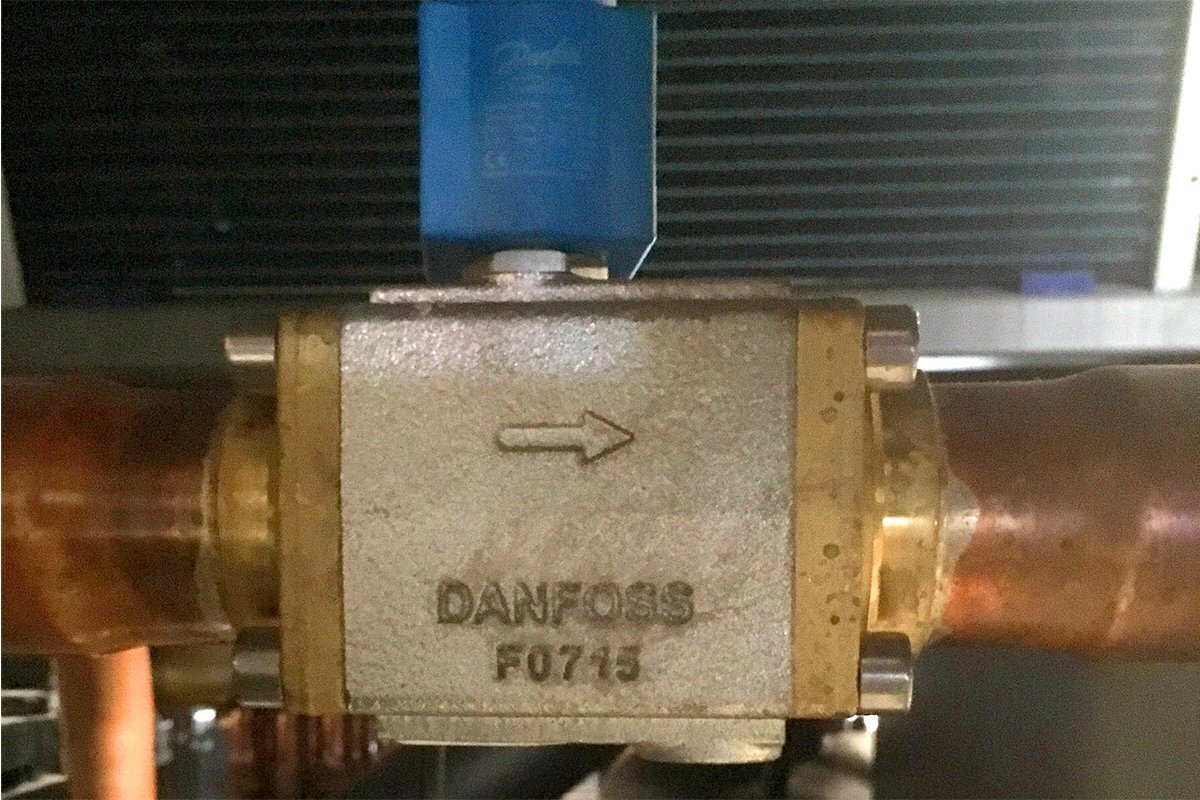

- How to Check the Refrigerant Flow in your Air Chiller?

- What are the Routine Maintenance Tasks for your Air Chiller?

- What Industrial Operations Require Air Chiller?

- How is Air Chiller the Best Option for your Industry?

- What are the Important Points to Consider Before Purchasing your Air Chiller?

- What is the Air Chiller Cooling Capacity?

- How to Maintain the Quality of your Air Chiller Before Summer?

- How to Install your Air Chiller?

- How to Increase the Life of your Air Chiller?

What is an Air Chiller?

Air Chiller is an outstanding cooling unit that removes heat from industrial and commercial applications and provides cooling to the system.

The emitted heat is transferred to other sources such as water or ambient air using a refrigeration system.

Air Chiller is best fitted for industrial environments with limited water supply. It is being used in various industries because of its effective operation and reliable performance.

The cooling process is simple as it does not require any cooling tower or a condenser water pump. It is easy to maintain and install.

Utilizing ambient air instead of water, it doesn’t have any concerns regarding condenser water treatment, cooling tower service, availability of abundant water, and tower-freeze protection.

Energy Saving Air Chiller Fabricated by TopChiller

What are the Main Components of an Air Chiller?

The main components of an Air Chiller include:

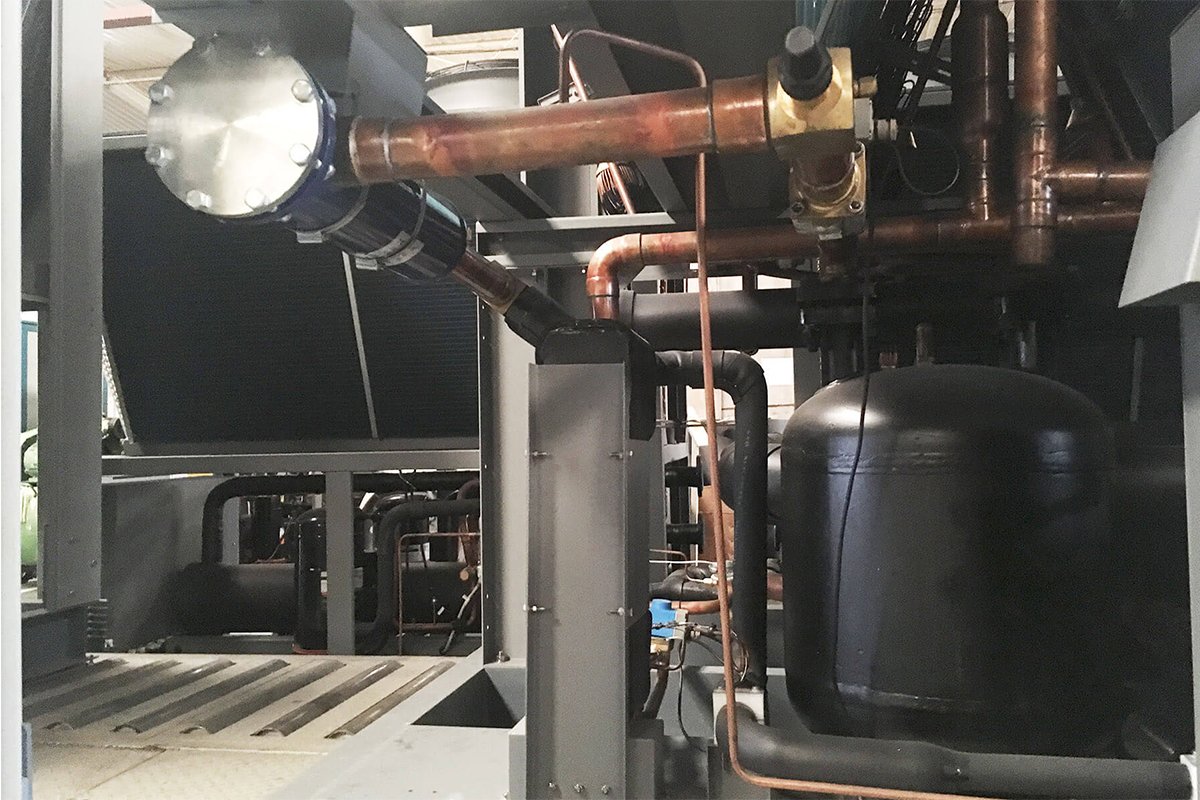

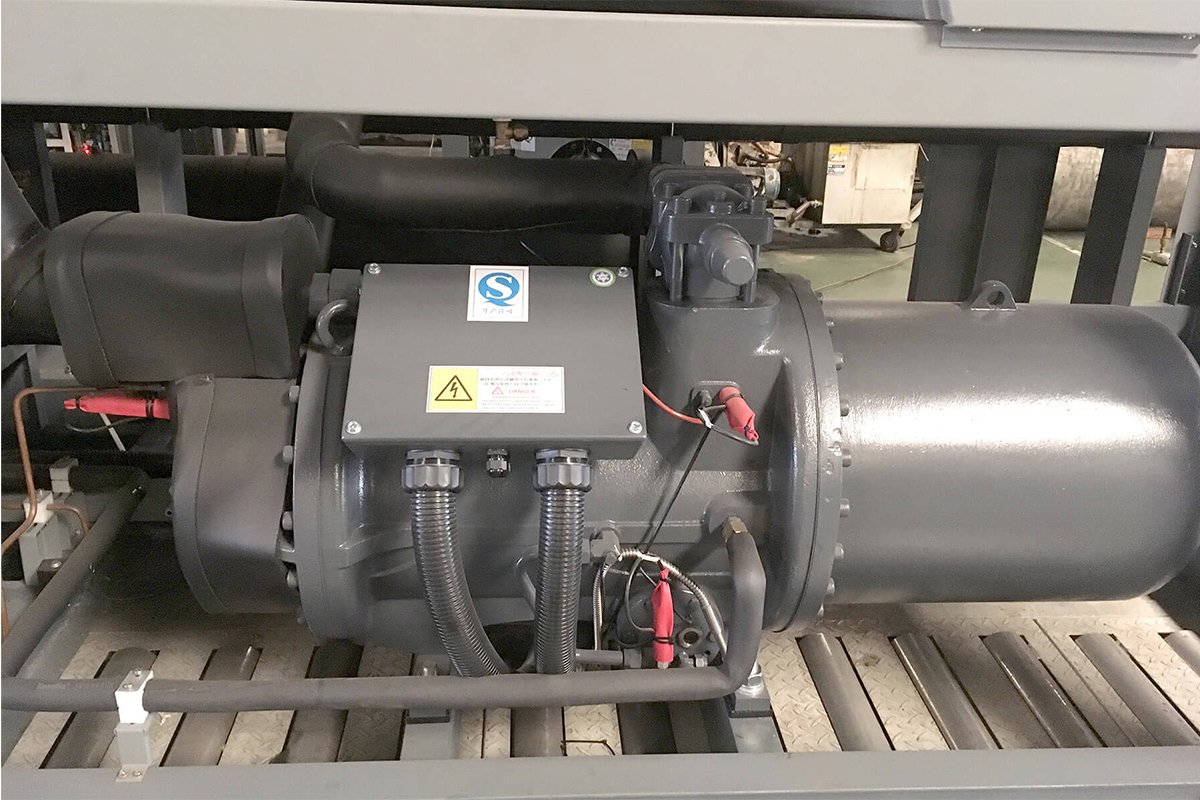

Compressor

The compressor is the central part that compresses the refrigerant and transfers it to the condenser for future processing. The type of compressor typically depends on the size and capacity of the chiller.

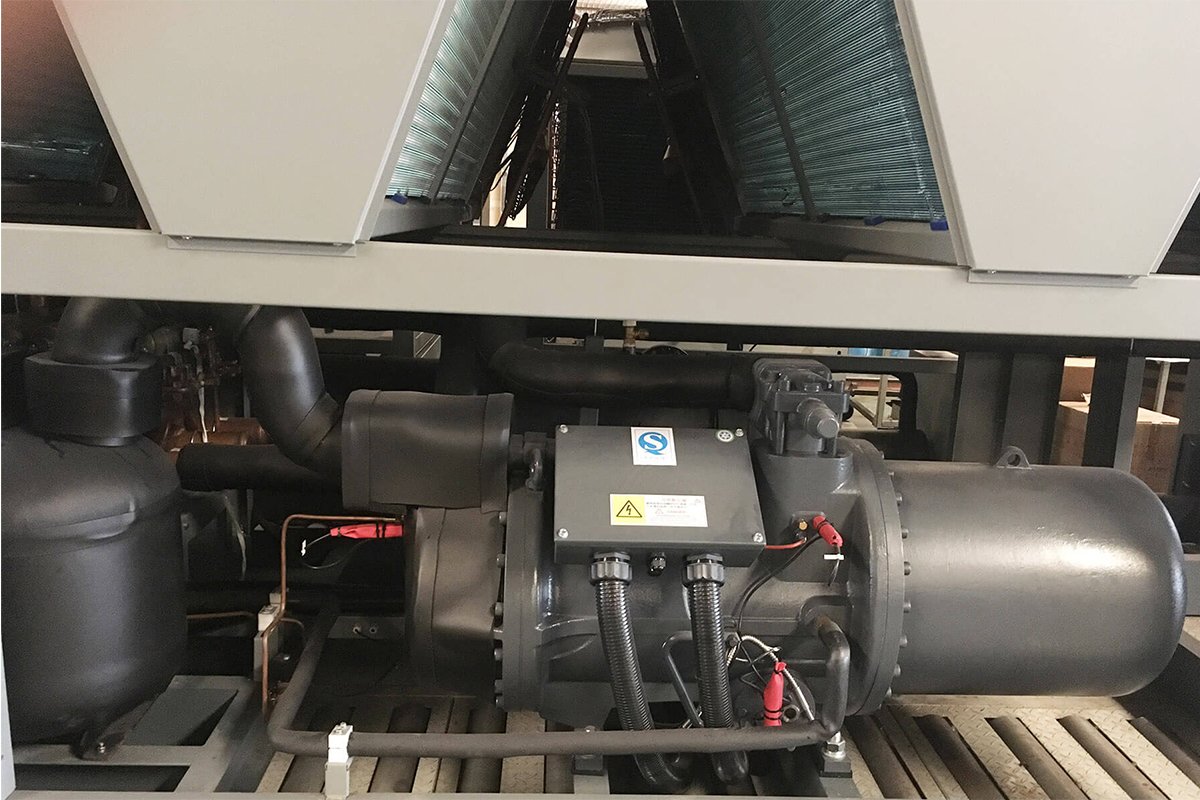

Condenser

The condenser cools the compressed refrigerant, further used as a heat medium for the chilled water. It also has a role in increasing the refrigeration effect and system capacity.

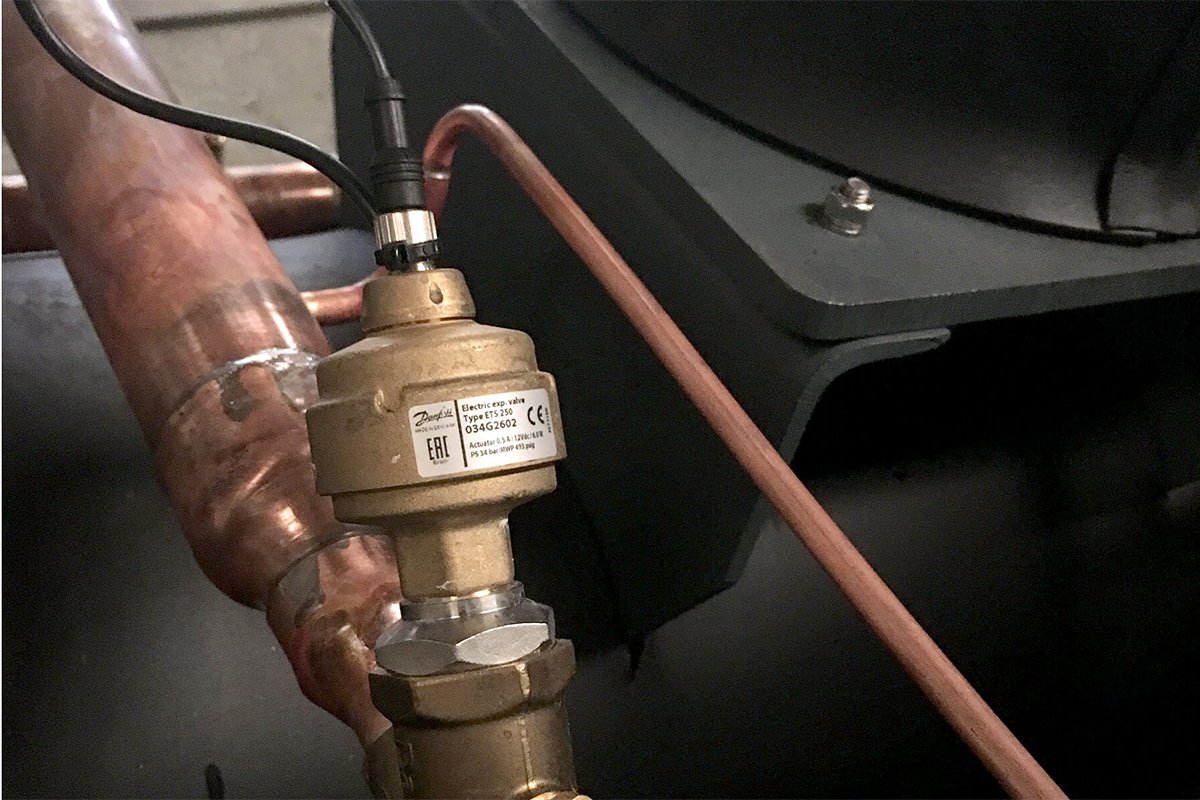

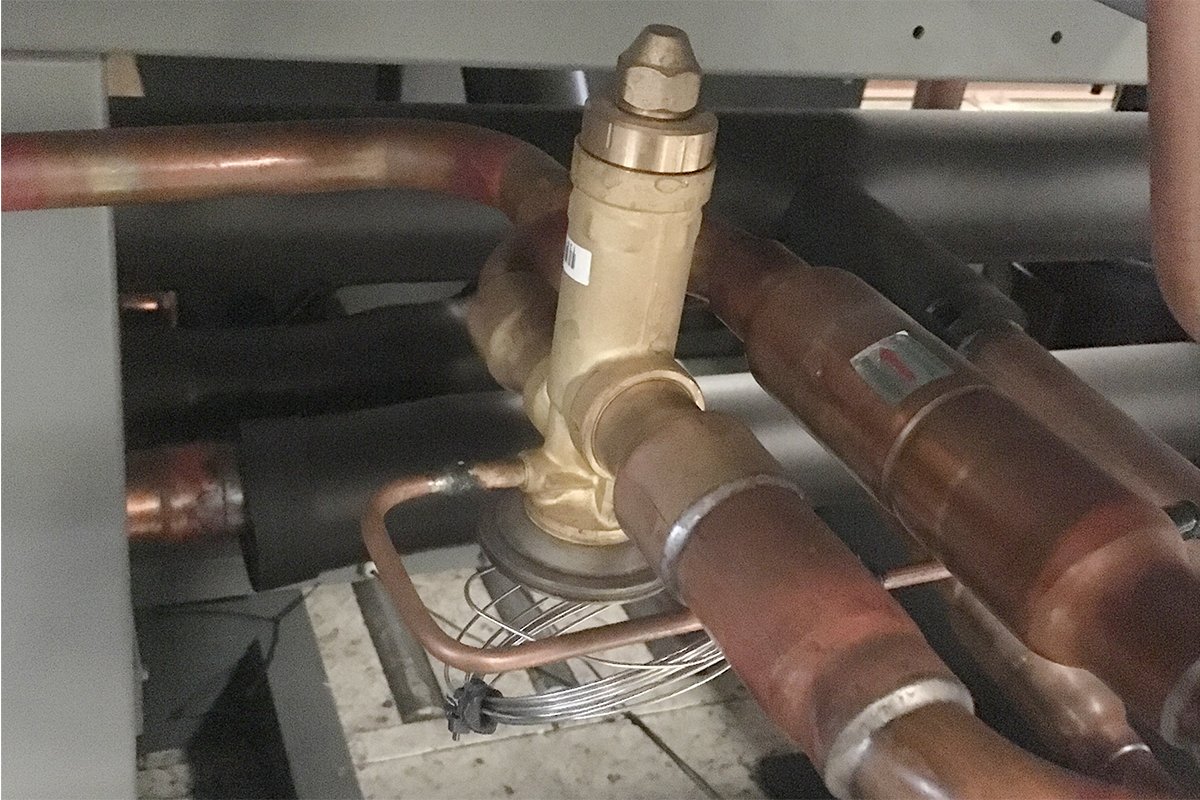

Expansion valve

As soon as the liquefied refrigerant is passed through the expansion valve, there is a reduction in pressure and temperature, becoming the cooling refrigerant.

The expansion valves integrated with Air Chiller can either be thermostatic or electronic.

Built-in Motor Fan

It has a built-in motor fan readily installed and an integrated system to cool the refrigerant with air by drawing the outdoor air over the coil.

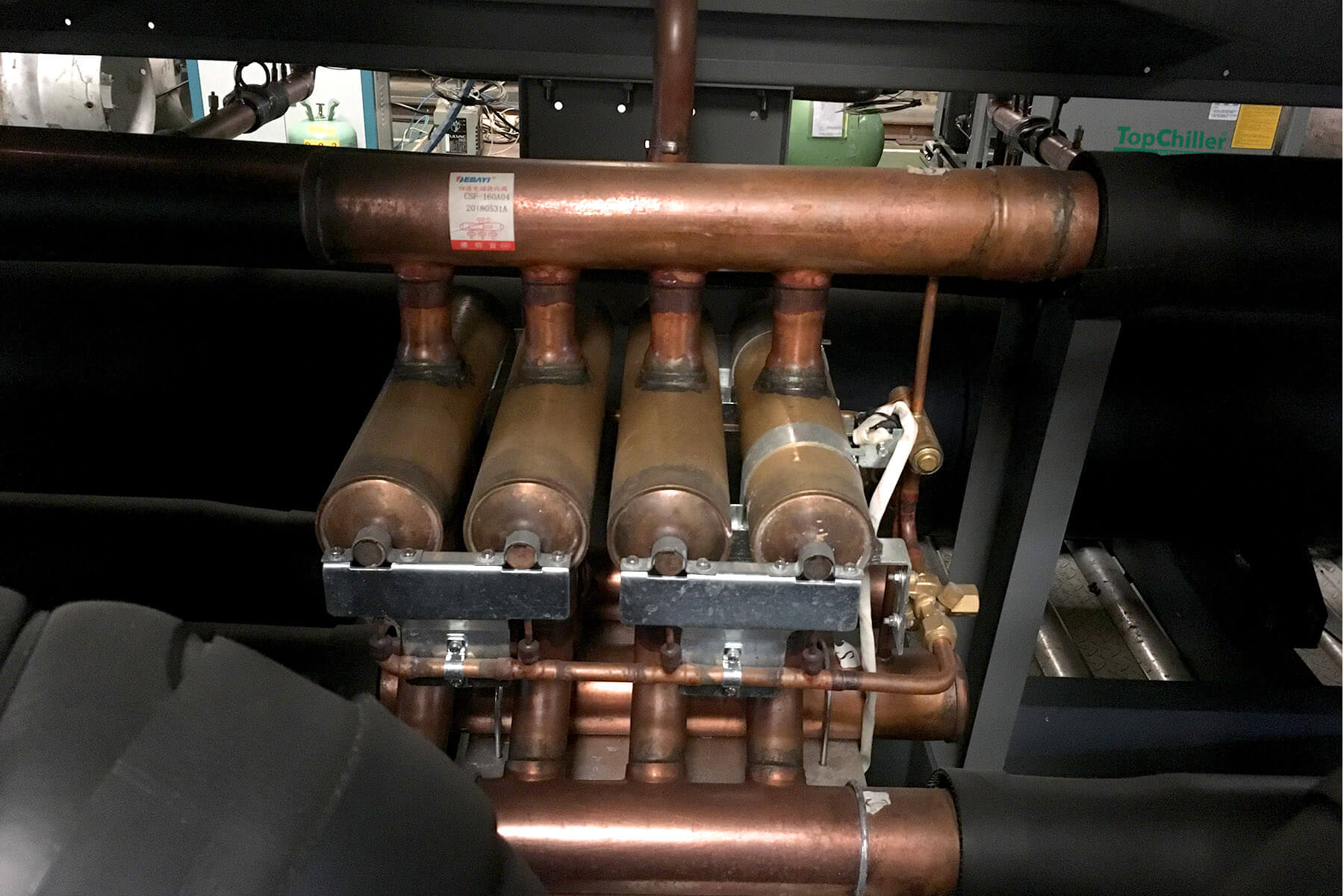

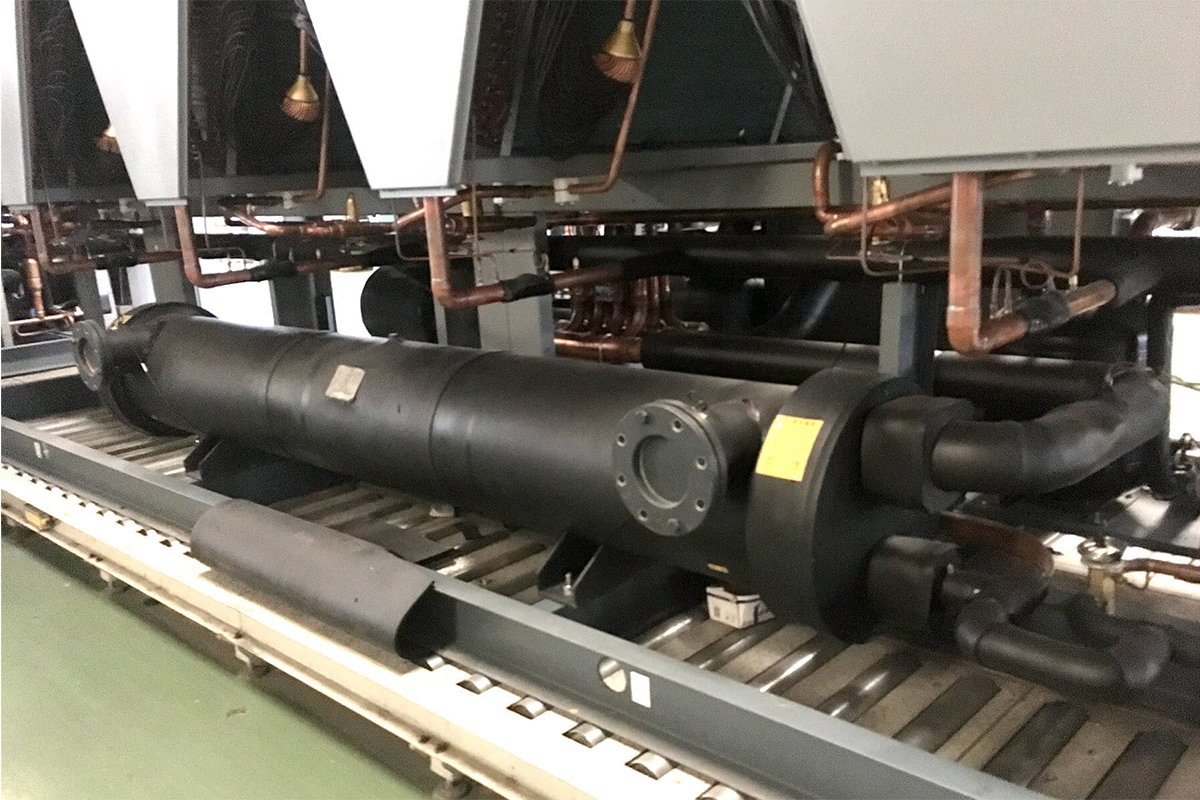

Evaporator

The role of an evaporator is to pick up heat from the load and transfer it to the refrigerant. It creates a low-pressure area where the refrigerant can be evaporated, and the heat can be absorbed.

Air Chiller Parts

What is the Working Principle of an Air Chiller?

Air Chiller actively absorbs heat from the processed water and then transfers this heat to other sources like the air around the chiller unit.

Each component of the chiller undergoes thermodynamic processes. The evaporator in the system starts the cooling process by letting the liquid refrigerant flow over the evaporation tube bundle.

The evaporation takes over those tubes where the chilled water is circulating, and water absorbs the heat.

The compressor pumps the refrigerant vapor to the condenser, which raises the temperature and pressure.

The resultant high-pressure liquid flows through the expansion device and then into the evaporator.

In this way, the cycle carries on, and the heat exchange keeps on taking place.

What are the Major Applications of Air Chiller?

Air Chiller is the heart of all industries as it serves the crucial function of generating a cooling effect and hence, a comfortable environment.

Its applications can be found in the following areas:

- HVAC Comfort Cooling Applications

- Refinery Projects

- Commercial Industries

- Laser Applications

- Plating Solvents

- Food Processing Companies

- Warehousing

- Rubber Fabrication

- Cutting Oil

- Cooling Plastic Moulded Products

- Printing Houses

- Brewing Tanks

- Microbrewery

- Water Jet Cutting

- Hydroponic

- Winery

- Metal Finishing

- Floral Facilities

- Ice Rinks

- Commercial Industries

- Emergency Operating Conditions

- Packaging Industry

What are the Advantages of Air Chiller for your Applications?

Both commercial and industrial facilities get excellent benefits from using the Air Chiller.

A few advantages are listed below:

- It is used to get rid of extra heat from the system and transfer it to the external environment.

- It offers cooling solutions for industrial applications like dairy, brewing, food processing, etc. These industrial processes cannot run smoothly without an Air Chiller.

- The potential costs of water availability and treatment are saved as it does not require a cooling tower. It is always a preference for industries running low on budget.

- The longevity of this chiller is ensured as soon as it is installed. It can work for 15 to 20 years while delivering consistent performance.

- The packed system of Air Chiller is integrated yet straightforward. Installation is also relatively easy because of the compact design.

- There is no need for cooling towers and condenser-water piping.

- It can work fine in all weathers. It is relatively easier to operate in winters because it does not have to deal with the problem of operating a cooling tower.

- An Air Chiller is preferred because the mechanism of cooling towers is complicated. It involves basin heaters, control sequences, and safety for indoor operations.

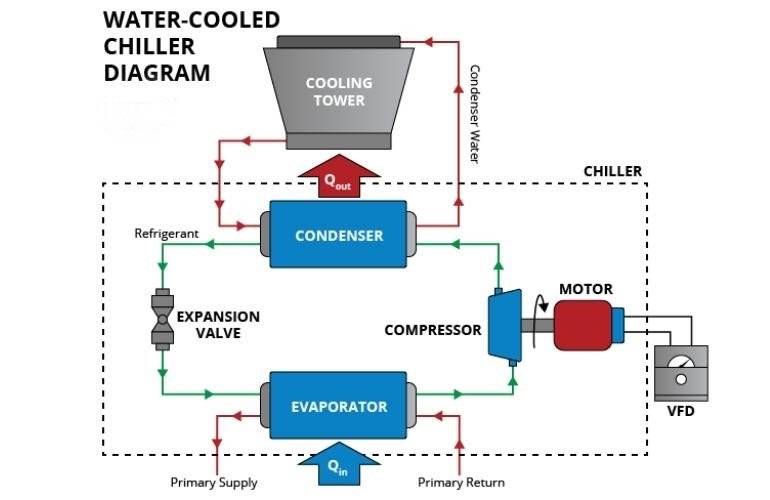

What is the Difference Between Air Chiller and Water Chiller?

Both Air Chiller and water chiller are made of the same components. However, the difference lies in the mechanism of cooling the refrigerant.

As the name indicates, Air Chiller uses air to provide cooling. The condenser of the chiller employs air as a condensing medium.

A motor fan moves over the coil. The hot refrigerant in the condenser is transferred to ambient air, which works. Air removes the heat without letting it condense back to a liquid state.

A water chiller cools the refrigerant by using water. The water is sent down from a cooling tower. The condenser of the water chiller uses water as a condensing medium.

Water is circulated in a condenser and cooling tower through a pump. An Air Chiller can operate in below-freezing weather, whereas a water chiller cannot.

This is why it is ideal for process applications like computer centers where cooling is required all around the year.

The efficiency of water chillers can be significantly reduced if the condenser tubes are fouled because of continuous water running in tubes, bacteria, and algae growth within the condenser.

Therefore, water chillers owners have to enforce a condenser water treatment program to eliminate the contamination. Thus high maintenance and cost.

Why is an Air Chiller Preferred Over a Water Chiller?

Air Chiller is preferred over the Water Chiller due to the following significant reasons:

No Cooling Tower

It does not need any cooling tower or huge condenser pumps, so it gives you a free space-saving advantage. It does not require a mechanical room to function either.

No Water Problem

Not all industries are rooted in areas with rich water supplies. Some of them are working in areas that are prone to drought. Others have a limited water supply because of environmental stabilities.

Saves Time and Money

Air Chiller delivers an optimal performance using ambient air to cool the process by providing an alternative to the traditional water-cooled systems. Besides water, it also saves time and money.

Heating Advantage

The emission of heat from the system is high, which can warm the facility in winter.

Low Maintenance

Water chillers need to go through periodic condenser water treatment as they repeatedly form mineral deposits in the system.

Cost

It is costly to install a water chiller. On the other hand, an Air Chiller is cheap and straightforward to install.

Occupies Less Space

Facilities with space problems can openly place it anywhere, occupying less space than the water chiller.

Outdoor Instalment

It is the best choice for industries facing space restraint problems. It can be installed outdoors as well.

Water Chiller Detailed Diagram

What is the Role of Compressor in an Air Chiller?

The compressor is the most crucial component in an Air Chiller. It comes in a variety of options to suit your needs and applications.

The different types include reciprocating, scrolling, and screwing. The latter shows the highest excellence and reliability.

The efficiency of the compressor is remarkable, especially at part loads. The functions of the compressor are not limited and have a decisive role in many tasks.

The compressor pulls the refrigerant vapor from the evaporator of an Air Chiller and raises its pressure.

Its job is to ensure the maintenance of low pressure in the evaporator to absorb as much heat as it needs to.

The pressure of outgoing refrigerant vapor also needs to be raised with the help of a compressor.

The raised pressure of vapor results in a high temperature that is crucial for releasing heat into the condenser. It transfers the heated refrigerant to the condenser.

Explosion Proof Air Chiller Compressor

What are the Types of an Air Chiller?

Air Chiller can be divided into two types:

Stationary Air Chiller

It is used in an industrial environment where excessive heat is not a problem. The discharged heat can be put to use in other applications.

It is equally functional as a Stationary Air Chiller. The only difference is that it is portable and easily carried or transported to your desired site.

Portable Air Chiller Designed by TopChiller

How an Air Chiller is an Energy-Efficient Option for your Industry?

An Air Chiller is an energy-efficient and power-saving cooling unit because it has electronically commutated fans. This feature dramatically reduces energy consumption.

It works without using water. Instead, it uses ambient air to remove heat from the load. That’s why it is preferably installed in places where water is expensive or hardly available.

Industries running in places facing water shortage can also put it efficiently to work.

Companies that are highly functional in the winter months can utilize the emitted heat from the system.

The heat energy is exceptionally conserved, and the costs are significantly saved due to free heat received from the industrial processes.

The need for cooling towers is eliminated by installing Air Chiller. The latter has strict maintenance demands for being functional.

With an Air Chiller, you don’t have to worry about tower mechanical maintenance, condenser tube cleaning, water treatment, freeze protection, and decontamination.

What is the Process of Heat Transfer in an Air Chiller?

Heat transfer is the most critical process in the cooling mechanism by an Air Chiller:

- The refrigerant, a cooling fluid, actively absorbs heat in the air and starts chilling it. It is then pushed out of the vent.

- Available in multiple shapes like coil, shell, or tube, an evaporator is a device that connects vapor compression mechanical refrigeration systems and processed water systems.

- Evaporator has a crucial role in getting rid of the absorbed heat from running water in the industrial process. It receives the refrigerant and allows the flow of absorbed heat from the fluid.

- The heat is then reused in other areas of work. It also boils the refrigerant, and the liquid is converted into superheated vapor.

- The temperature of vapors coming from the evaporator depends on the air temperature going in. This whole process is called heat transfer.

Air Chiller Heat Transfer Process

How to Check the Refrigerant Flow in your Air Chiller?

So many factors contribute to the proper running of the Air Chiller. One of the factors is the specific refrigerant flow. Its level has to be maintained just like the oil in your car.

- Each component of the system has a manufacturer-required condition for its optimal performance.

- The level of refrigerant flow is related to the condenser tube. The drop in the refrigerant flow can cause problems in the condenser tube. It is highly suggested to keep an eye on the levels of refrigerant.

- The cooling quotient of the Air Chiller is directly related to the proper refrigerant level. Cooling costs can be lowered by 5-10 % if the refrigerant level is appropriate.

- Sometimes there are leaks in the system, causing a drop in the refrigerant flow. Make sure you have solutions for these problems. If you can’t do it yourself, get an expert to do it for you.

What are the Routine Maintenance Tasks for your Air Chiller?

Air Chiller requires routine maintenance because it holds vast electrical loads in the system. Otherwise, it starts using more electricity if there are any refrigerant leaks or defects in the condenser tubes.

The use of more electricity can cause budget problems and energy costs issues. Preventive maintenance keeps your entire facility efficient and running.

Routine maintenance also ensures the appropriate temperature requirements and prevents minor problems from turning into large ones. The operating costs are reduced and easily affordable.

It is healthy to make annual or semi-annual appointments with your technician and get your Air Chiller checked.

The technician can perform some tasks and give a review of your chiller. These tasks may include:

- Condenser tube cleaning

- Checking compressor oil

- Repairing wiring

- Cleaning the evaporator coil

- Repairing the leaky refrigerants

- Tests for load balance

- Inspecting the refrigerant for metals and acids

TopChiller’s Engineer Maintaining Air Chiller

What Industrial Operations Require Air Chiller?

An Air Chiller covers a wide range of applications in and beyond the industries. It is equally valuable for schools, offices, and other commercial buildings.

The compact installation and high energy efficiency make it perfect for tall buildings.

Most industries are dealing with manufacturing, food processes, and brewing crucially requires an Air Chiller to deal with the heat load to maintain their production capacity.

Elimination of extra heat saves a lot of costs and energy in every industry.

How is Air Chiller the Best Option for your Industry?

Known for getting rid of heat from the system and offering cooling solutions, Air Chiller is the best option for your industry. It is helpful because of the following reasons:

Safety of your Equipment

No matter what business you are in, it is vital to provide maximum protection to your industrial equipment.

Overheating of continuously running equipment can significantly reduce the efficiency of your application and damage the equipment permanently. But with an Air Chiller, your vital machinery is safe from all heating effects.

Reduced Costs

Your money is saved as an Air Chiller functions with only air. The expenses of water are cut short. It costs very little to run the system.

The heat produced in the process is used somewhere else in the cycle.

Huge Cooling Output

Having reduced costs to run, it provides massive cooling levels. This is why it is perfect for every industrial space, large or small.

What are the Important Points to Consider Before Purchasing your Air Chiller?

Following are some crucial points to go through before buying your Air Chiller:

Understanding the Options

Factors like capacity of the unit, size, and flow rate of the fluid, configuration, and shape of the chiller should be double-checked.

The Usage Conditions

The usage conditions are primary, so it is necessary to consider them. Besides, the cooling capacity from the equipment to be cooled and the pump’s capacity are also significant.

Heat Exchanger

The type of heat exchangers varies with the kind of Air Chiller you are using. The average capacity of the heat exchanger is the primary factor to consider.

Type of Compressor

There is various Air Chiller available in the market as per the type of compressor installed in them. Compressors do the task of compressing the refrigerant to reduce its volume.

Pumping Arrangements

Pumps and tubes setting are solely responsible for distributing the chilled water throughout the system.

The pumping arrangement needs to be observed thoroughly. The thickness, length, and shape of the piping can also decide the system.

What is the Air Chiller Cooling Capacity?

The cooling capacity of an Air Chiller is a guide to know how much it can cool the system. It is expressed in Watts and units of Kcal/h. Usually, the average cooling capacity can reach up to 200kW.

Elements like degree of the endothermic, process fluid, chiller maintenance, a difference of temperature from the room temperature, self-heating, etc., are significant when dealing with the cooling capacity.

The Air Chiller capacity is enhanced mainly by installing multiple reciprocating compressors in a single chiller. Doing so can raise the chilling capacity to 500 tonnes.

Scroll compressors are more efficient than reciprocating compressors, increasing the chilling capacity even more.

Air Chiller Reciprocating Compressor 3D View

How to Maintain the Quality of your Air Chiller Before Summer?

The quality of your Air Chiller can be maintained by following simple steps as mentioned under:

- End the connection of your unit from electrical power.

- Get rid of all the external weatherproof covers.

- The filter pads need to be removed and replaced if worn out. However, if they don’t look so bad, just clean them gently with a hose.

- Remove every drop of water in your unit.

- Clean the tank with a clean cloth. After doing the cleaning, flush the tank with freshwater.

- Ensure that the water has been removed from the pipes as well.

- Do a thorough inspection and check for leaks and drains.

- Leave no moisture in the internal components.

- Make sure you cover the exposed units.

- Do the dusting of sediments with the brush.

- Apply biocide to disinfect the unit. However, be careful while using the disinfectant as the use of chlorine-based bleach can do more harm than benefit. It can cause the growth of harmful microorganisms.

How to Install your Air Chiller?

Air Chiller is relatively easy to install and maintain. Its simple installation process saves your time and money.

Reach out to an electrician if playing with electric machines is not your thing. However, if you want to do it yourself, here’s how you can do it.

- After confirming that you have got the power to your unit, make sure to check and reset all the breakers just to ensure that nothing was tripped.

- Now take the panels off and fill the reservoir with water. Once the water is filled, make sure that the pressure on the system is correct. In most cooling systems, it’s somewhere around 20 psi.

- Make sure that the return ball valve stays closed. It will prevent water from coming back to the reservoir.

- Once you have verified that all the containment has been flushed out of the system, leave the pump running to drain the water.

- Moreover, it’s a good rule of thumb to buy a refractometer to check the coolant. Bear in mind that a hydrometer is not appropriate to be used for this purpose.

How to Increase the Life of your Air Chiller?

Knowing that Air Chiller is easy to maintain and look after, it can last for 15-20 years. Its average life cycle is very fulfilling and assuring.

- You must clean the evaporator tubes once every year and let the chiller run smoothly.

- For an Air Chiller to work efficiently, the transfer of heat through the tubes of the evaporator and compressor must be quick and trouble-free.

- Efficient chiller operations are possible only with smooth heat transfer. Dirty tubes cannot do the work and reduce efficiency.

- Corrosion is widespread with time. The reason is that the water in the system can make it prone to algae growths and corrosion. These factors can be significantly eliminated by using water treatment chemicals.

- Simply add these chemicals to water running in the system once a year. It is also recommended to check chilled water loops and piping.

- Keeping track of trends in equipment operation can promise you the systematic running of the cooling mechanism.

- The records of operational factors like temperature, pressure, and compressor oil can give you the idea of anomalies that need to be repaired or replaced.