TopChiller can design and manufacture all types of recirculating chillers for you

- Cooling capacity ranges from 0.5 Ton – 50 Ton

- Temperature control ranges –25 °C to 30 °C

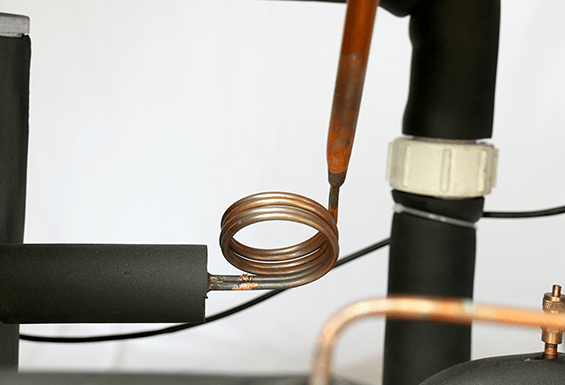

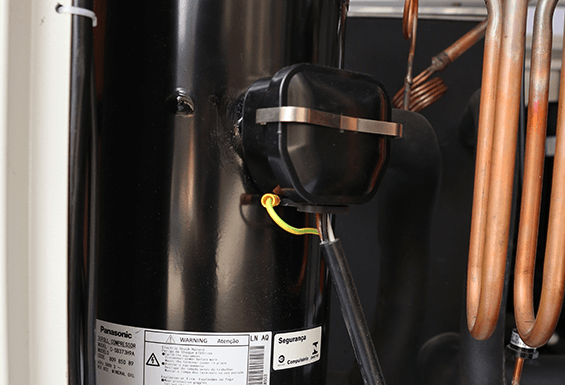

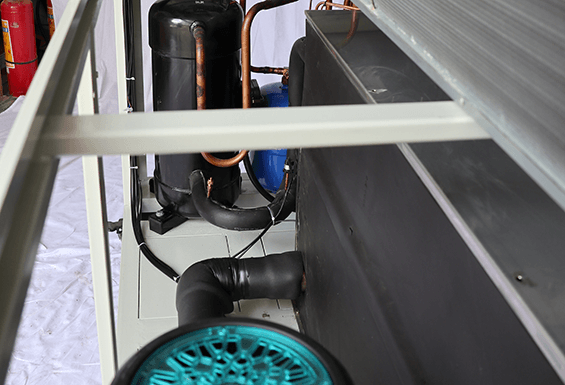

- Proficient working top brand scroll compressor

- Air-cooled & water-cooled reliable condenser

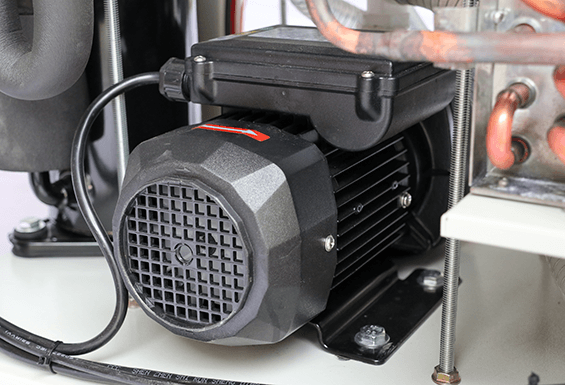

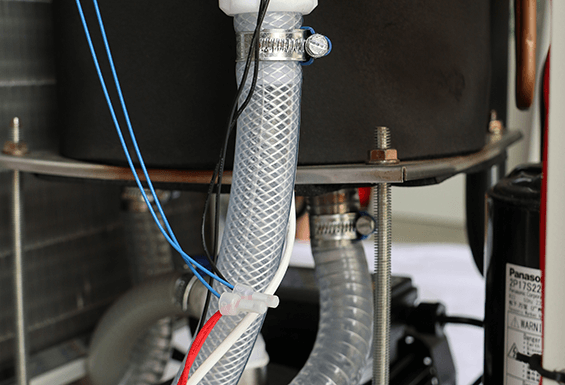

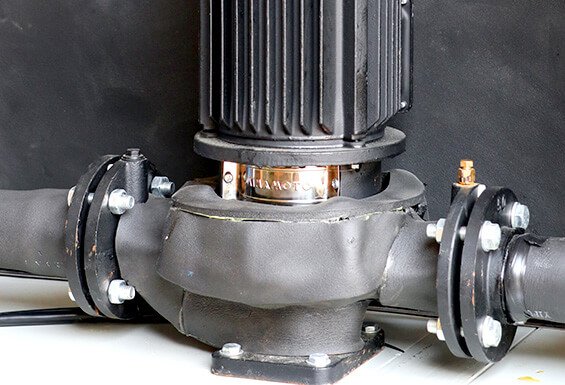

- Fluent water circulation enforcing water pumps

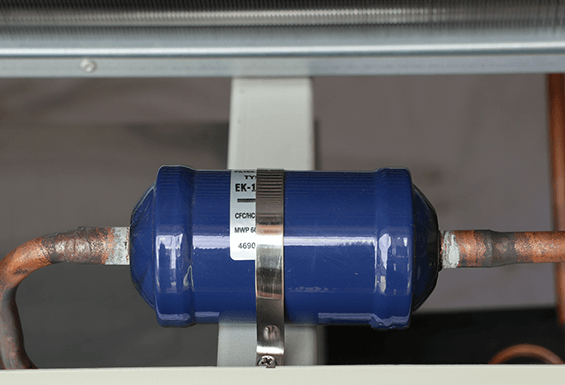

- CFC free, and environmentally friendly refrigerant

- Hot gas bypass & compressor crankcase heater

- Technology advanced &hassle free operation

Your Professional Recirculating Chiller Expert Over 20 Years

Recirculating Chiller is a reliable cooling device that provides a consistent chilling effect by using liquid coolant for laboratories and clinical instrumentation cooling.

Recirculating Chiller fulfills the constant chilling requirements of laboratories by providing recirculating chilled water.

TopChiller is a reliable and trustworthy company of China, working as manufacturer and supplier of Recirculating Chiller and supplying all over the world with a reputed appreciation from customers since 1991.

TopChiller is profoundly acclaiming quality assured full line of Recirculating Chiller numerous variants and models with varying capacity ranges elaborating customization services among the worldwide markets by last twenty years.

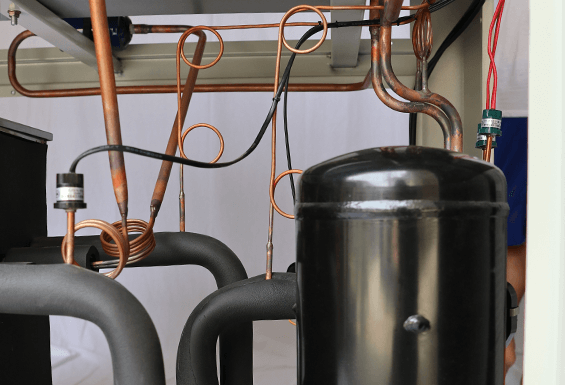

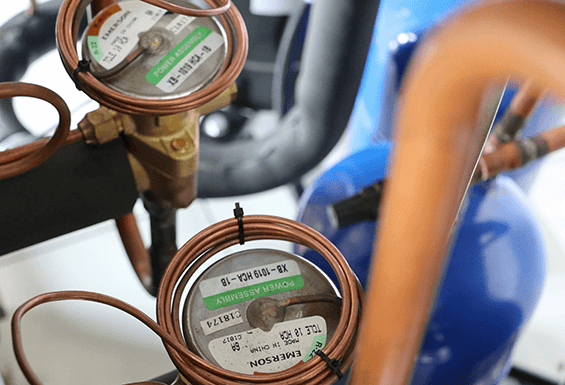

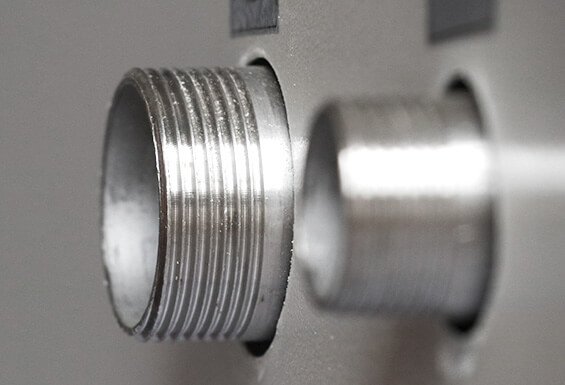

Scroll compressor, crankcase heater, plate type heat exchangers, condensers, water tank, water pump, PID temperature Controller, hot gas bypass, evaporator, protecting devices, and power supply are primary components of efficient working Recirculating Chiller.

TopChiller manufactured Recirculating Chiller has vast the R&D and lab processing with its large number of benefits as given below.

- Recirculating Chiller is highly suited to laboratory machines processing by maintaining an exact temperature producing chilling effect continuously featured by chilled water circulation around lab instruments instantly exchanging heat with chilling effect.

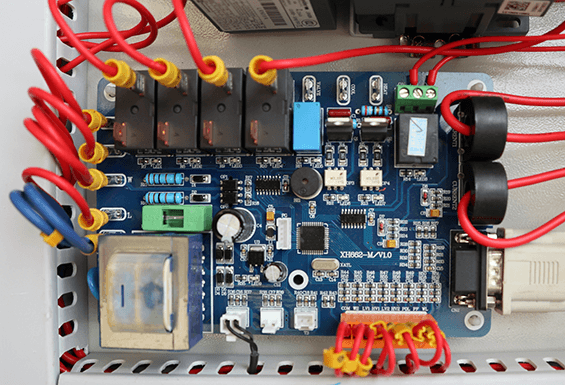

- TopChiller designed Recirculating Chiller is featured with PID temperature controller and control providing a tight temperature, precisely and pre-diagnostic of temperature elevation and prevention from damages by cut-off power supply by a control system.

- Recirculating Chiller is featured with CFC friendly refrigerant installation and insulated wetted surfaces prevent the unit from corrosive damage and accumulation of dust and debris ensuring steadfast and fluent chilling to a machine.

- TopChiller engineered Recirculating Chiller is configured with sound insulator ensuring quiet performance preventing distortion and disturbance in a lab for smooth performance without irritation.

- Recirculating Chiller is energy efficient in its performance and environment friendly equipped with continuous double loop recirculation and efficient compressor.

Recirculating Chiller Used for a variety of clinical and researching applications as given below.

Laboratory machinery, MRI machine, CT scanning, laboratory testing, sample preservation, blood samples and other body fluids chilling, research and development manufacturer, laser machines, printing machines, and X-ray diffraction, etc.

If you are looking for a highly precise and reliable working Recirculating Chiller for your application?

If you want to come in contact with the best leading Recirculating Chiller manufacturing company providing automation services and built-in customization to enhance your business?

TopChiller is the best-certified company to rely on and to meet your needs. Make contact with TopChiller professionals and experts who are trained to get notified of the customers’ queries and provide a proper guide about Recirculating Chiller.

TopChiller team is directed to satisfy our customers with soft behavior and appreciable support in purchasing a best Recirculating Chiller at suitable costs for your application

General Description:

Recirculating Chiller is an effective temperature regulating machine which eliminates the heat produced by heavy machinery and exothermic processes in laboratories and industries. It can use either air or water as the cooling agents.

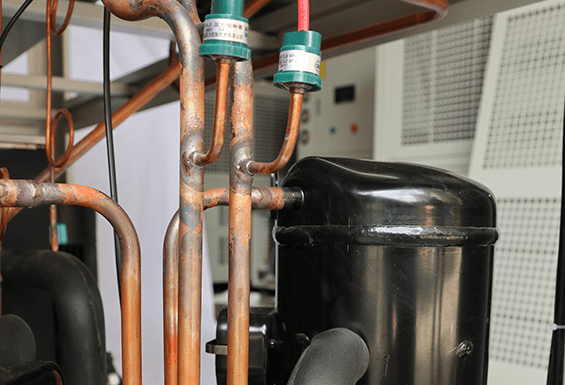

The components taking part in the refrigeration cycle include a branded compressor, evaporator, expansion valve, and condenser. Recirculating Chiller designed by TopChiller aims at a minimum expenditure of the coolant since it is recirculated into the system efficiently.

A Recirculating Chiller designed and by TopChiller use is appreciated in an extensive range of applications, including research projects, laboratories, hospital laboratories, semiconductor industries, lasers, etc.

Whether you are looking for a cost-friendly or highly convenient Recirculating Chiller, TopChiller has an inventory full of various models, sizes, and types, ready to be dispatched at your doorstep.

TopChiller is a reliable brand of China, working as manufacturer and supplier of Recirculating Chiller and supplying worldwide with a reputed appreciation from customers.

Contact us right now; our team is directed to satisfy our customers with professional behavior and significant support in purchasing a suitable Recirculating Chiller at a very affordable price.

Features and Advantages:

Here is a list of a few excellent features and advantages of a Recirculating Chiller:

- It cools down the water to a temperature as low as 40 – 45 °F (4 – 7 °C). The water is recirculated, and therefore the total water consumption can be calculated by using the heat removed, condenser flow rate, and evaporator flow rate. It helps in the monitored use of water.

- The temperature is maintained at an appropriate and safe level and provides thermoelectric control of ±0.3℃ It helps to achieve more accurate results in laboratories.

- Recirculating Chiller uses hydrofluorocarbons (HFC) and hydrofluoric-olefins (HFO) to avoid harmful effects on the environment and add to the integrity of the ozone layer.

- It is easier to obtain the targeted temperature with variable speed drives when equipped with different speed retrofits. You can join multiple chillers in series for enhanced efficiency.

- It has ultra-protection and anti-siphon system convenience due to the correct positioning of valves. Recirculating Chiller has the most advanced features like PID controlled microprocessor, sensitive alarms, an efficient thermostat, and precise temperature control.

- Data Sheet

- Image Gallery

- Main Parts

- Video

| Recirculating Chiller Technical Specifications | ||||||||||||||

| Items Model | AC-0.5A | AC-1A | AC-1.5A | AC-2A | AC-2.5A | AC-3A | AC-4A | AC-5A | AC-6A | AC-8AD | AC-10AD | AC-12AD | AC-15AD | |

| Cooling capacity | Kcal/h 50HZ/60HZ | 1419 | 2451 | 3182 | 4833 | 5848 | 7181 | 9288 | 11988 | 14534 | 18576 | 23994 | 29068 | 38270 |

| 1703 | 2941 | 3784 | 5800 | 7018 | 8617 | 11146 | 14386 | 17441 | 22291 | 28793 | 34882 | 45924 | ||

| KW 50HZ/60HZ | 1.65 | 2.85 | 3.7 | 5.62 | 6.8 | 8.35 | 10.8 | 13.94 | 16.9 | 21.6 | 27.9 | 33.8 | 44.5 | |

| 1.98 | 3.42 | 4.4 | 6.74 | 8.2 | 10.02 | 12.96 | 16.73 | 20.28 | 25.92 | 33.48 | 40.56 | 53.4 | ||

| Input power | KW | 0.88 | 1.35 | 2 | 2.25 | 2.66 | 3.27 | 4.07 | 5.75 | 6.45 | 8.25 | 11.5 | 12.9 | 17.45 |

| Max Current | A | 5.4 | 8.2 | 12 | 13.6 | 6.6 | 8.2 | 10.1 | 13.8 | 15.5 | 20 | 27.9 | 31.3 | 42.4 |

| Power source | 1PH~220V/3PH~220V/380V 50HZ/60HZ | 3PH~380V/415V/480V~50HZ/60HZ(3PH~200V/220V 50HZ/60HZ) | ||||||||||||

| Refrigerant | Type | R22/R407C/134a/404A/410A | ||||||||||||

| Control | Capillary / thermostatic expansion valve | |||||||||||||

| Compressor | Type | Hermetic Rotary | Hermetic scroll ( piston ) | |||||||||||

| Power(KW) | 0.45 | 0.89 | 1.3 | 1.73 | 2.1 | 2.7 | 3.5 | 4.55 | 5.25 | 3.5×2 | 4.55×2 | 5.25×2 | 7×2 | |

| Condenser | Type | Efficient finned copper tube with aluminum+low noise external rotor fan | ||||||||||||

| Air flow (m3/h) | 750 | 1000 | 1500 | 2000 | 2500 | 3000 | 4000 | 5000 | 6000 | 8000 | 10000 | 12000 | 15000 | |

| Air blower(KW) | 0.06 | 0.09 | 0.15 | 0.15 | 0.19 | 0.14×2 | 0.14×2 | 0.19×2 | 0.19×2 | 0.25×2 | 0.45×2 | 0.45×2 | 0.6×2 | |

| Evaporator | Type | SS Tank coil / shell and tube type / Plate type heat exchanger | ||||||||||||

| Chilled water (m3/h) | 0.28 | 0.49 | 0.64 | 0.97 | 1.12 | 1.44 | 1.86 | 2.4 | 2.91 | 3.71 | 4.8 | 5.81 | 7.65 | |

| 0.34 | 0.59 | 0.76 | 1.16 | 1.4 | 1.72 | 2.23 | 2.88 | 3.49 | 4.46 | 5.76 | 7 | 9.18 | ||

| Water tank(L) | 10.6 | 18.3 | 27 | 27 | 50 | 50 | 60 | 60 | 110 | 120 | 200 | 200 | 270 | |

| Inlet/outlet pipe (inch) i | 1/2″ | 1/2″ | 1/2″ | 1/2″ | 1″ | 1″ | 1″ | 1″ | 1″ | 1-1/2″ | 2″ | 2″ | 2″ | |

| Water pump | Power (kw) | 0.37 | 0.37 | 0.37 | 0.37 | 0.37 | 0.37 | 0.37 | 0.75 | 0.75 | 0.75 | 1.5 | 1.5 | 2.2 |

| Max lift(m) | 22 | 22 | 22 | 22 | 22 | 22 | 22 | 30 | 30 | 25 | 25 | 25 | 28 | |

| Max flow (m3) | 5.4 | 5.4 | 5.4 | 5.4 | 5.4 | 5.4 | 5.4 | 8.1 | 8.1 | 8.1 | 13.5 | 13.5 | 25.2 | |

| Safety protection | Compressor inner protection, over current protection, high/low pressure protection, over temperature protection, flow rate protection, phase sequence/phase missing protection, low level coolant protection, anti freezing protection, exhaust overheat protection | |||||||||||||

| Dimension | L(mm) | 550 | 550 | 600 | 600 | 720 | 980 | 980 | 1150 | 1150 | 1350 | 1500 | 1500 | 1860 |

| W(mm) | 350 | 450 | 500 | 500 | 550 | 520 | 520 | 560 | 560 | 680 | 760 | 760 | 850 | |

| H(mm) | 695 | 845 | 985 | 985 | 1350 | 1170 | 1170 | 1215 | 1215 | 1530 | 1660 | 1660 | 1900 | |

| Net weight(KG) | 45 | 62 | 85 | 95 | 125 | 152 | 175 | 185 | 215 | 283 | 345 | 382 | 580 | |

| Note: The above specifications are according to the following design conditions: 1, 12℃/7℃.Chilled water inlet/outlet temperature 12℃/7℃. 2, 33℃/38℃.Cooling air inlet/outlet temperature 33℃/38℃. We reserve the right to modify the specification without further notice. | ||||||||||||||

Why TopChiller is Your Reliable Recirculating Chiller Manufacturer and Supplier In China?

Recirculating Chiller-An Ultimate FAQ Guide by TopChiller.

- What is a Recirculating Chiller?

- What are the Prominent Features of a Recirculating Chiller?

- How Does a Recirculating Chiller Work?

- What are the Major Applications of a Recirculating Chiller?

- What are the Key Components of a Recirculating Chiller?

- Which Laboratory Processes Required a Recirculating Chiller?

- What are the Major Types of a Recirculating Chiller?

- How to Determine the Right Size of your Recirculating Chiller?

- What are the Essentials of Electronic Control Systems in a Recirculating Chiller?

- What are the General and Unique Requirements of a Recirculating Chiller?

- What is the Significance of Using Glycol in a Recirculating Chiller?

- How to Operate your Recirculating Chiller?

- How to Adjust the Temperature of your Recirculating Chiller?

- What are the FCC Requirements of a Recirculating Chiller?

- What are the Benefits of Using a Recirculating Chiller for your Industry?

- What Factors Should you Consider Before Purchasing your Recirculating Chiller?

- What are the Maintenance and Servicing Requirements for your Recirculating Chiller?

- How to Obtain Maximum Efficiency of your Recirculating Chiller?

- What are the Protective Measures for Using a Recirculating Chiller?

- What are the Major Problems and their Solutions of a Recirculating Chiller?

What is a Recirculating Chiller?

A Recirculating Chiller is an ideal cooling device for indoor applications as it can provide uninterrupted cooling for several hours. It works by recirculating the refrigerant, thus making its use convenient and affordable.

The primary use is in the laboratories where it carries out temperature regulation for various processes. It ensures the safety of the machinery being used and the maximum productivity of your application.

It has a precise and accurate function, and it helps maintain a specific temperature for long hours. Even the heat from the thermal reactions cannot alter the temperature because of efficient regulation.

The refrigeration circuit involves an extensive network of distribution coils along with the primary components. Only high-quality refrigerant is used to make sure that the function is harmless.

The best temperature for its work is 130º and 302º Fahrenheit. There is a high-pressure pump that helps in the high-temperature processes.

Energy Saving Recirculating Chiller by TopChiller

What are the Prominent Features of a Recirculating Chiller?

The prominent features of a Recirculating Chiller are mentioned below:

- An external flow adjustment allows maximum control of the flow of coolant.

- It has a hot gas bypass system that helps you deal with very hot gases in applications dealing with exothermic chemical reactions.

- According to the information fed into the central microprocessor unit, built-in high and low-temperature alarms indicate the alarming situation.

- You can easily access a full-featured PID controller that can be auto-tuned.

- The body is highly resistant and has a wetted surface which enables it to be stable against chemicals, oxidizing agents, and other corrosives.

- A positive displacement pump of 60 Hz is an additional functionality and safety factor.

- A seamless polyethylene tank stores the refrigerant, which is recirculated in the refrigeration cycle.

- You can get your Recirculating Chiller customized according to your demands and needs.

- It comes with easy installation and simple maintenance, making it an ideal device for indoor use.

- You can obtain remote-controlled functions from a distant site with the help of a robust central processor.

- Minimum vibration and silent operation are guaranteed.

- Highly sensitive pressure and temperature sensors enable you to stay in a very narrow range, adjusted on the microprocessor unit.

- Voltage supply of all ranges, 110V, 220V, 380V, and 440V, is workable.

- It has a temperature stability of ±0.1℃ to 0.5℃.

- The sturdy and stable stainless steel body has a 12kW heating capacity.

Recirculating Chiller ECO Friendly Refrigerant

How Does a Recirculating Chiller Work?

A Recirculating Chiller works by incorporating refrigeration circulation with the high-pressure flow to speed up the heat removal process of a procedure.

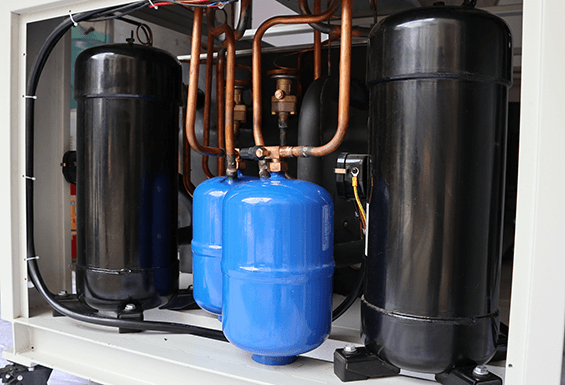

The four essential components consist of an evaporator, a compressor, a condenser, and an expansion unit. The refrigerant is also an important component, and it must meet the standards to ensure maximum productivity.

Step 1:

This chilling cycle starts with entering a low-pressure refrigerant into an evaporator. The evaporator is responsible for heating this refrigerant and converting it into a gaseous form.

Step 2:

This transition uses up a lot of heat energy, thus taking the heat from the process and incorporating it for breaking the bonds in the liquid refrigerant.

Step 3:

This gaseous refrigerant enters into the compressor, where its pressure increases. This thing enhances the velocity of these gaseous particles, resulting in efficient flow throughout the system

Step 4:

This high-pressure refrigerant enters the compressor, removing its extra heat by using chilled water from a cooling tower.

Step 5:

As the refrigerant flows through the condenser coils, the chilled water around it absorbs all the heat due to high-temperature differences.

Step 6:

This condensed refrigerant now enters the expansion unit. Here an expansion valve is present to control the limited refrigerant flow into the system.

Step 7:

Now, the pressure of the refrigerant again decreases, so it starts this cooling cycle again. This mechanism is called the refrigeration cycle and is being performed repeatedly.

What are the Major Applications of a Recirculating Chiller?

The major applications of a Recirculating Chiller include the following:

- Medical Laboratories

- Research Laboratories

- MRI Machines

- Semiconductor Industries

- Laser Machines

The primary purpose is to maintain a narrow range of optimum temperatures for a particular process.

If this temperature is not maintained due to poor regulation, you cannot obtain a high yield and positive output from a reaction leading to loss of money and wastage of time.

What are the Key Components of a Recirculating Chiller?

The main components of a Recirculating Chiller make a refrigerant cycle which makes the base of its function.

Compressor

It works by creating a high-pressure difference in the chiller to enable the maximum flow of refrigerant. The greater the temperature difference, the greater will be the refrigerant movement.

The different types work by increasing the pressure and reducing the distance between two particles of the refrigerant, making the particles more vigorous.

The compressor is present between the condenser and the evaporator, and an electric motor provides the driving force.

Condenser

It lies above the expansion valve and below the compressor. It removes the heat from the refrigerant which is received from the evaporator.

The chilled condenser water continuously recirculates between the condenser coils and the cooling tower.

The condenser coils are well laminated for maximum heat exchange, which increases with the increase in temperature difference.

Expansion Valve

It allows the expansion of the refrigerant, thus lowering its pressure and increasing the volume. Situated between the evaporator and the condenser, it helps absorb excess heat from the evaporator.

Evaporator

It works by absorbing heat from the application and incorporating it into the molecules of the refrigerant leading to the transition from liquid to gas.

This refrigerant is then compelled to flow towards the compressor.

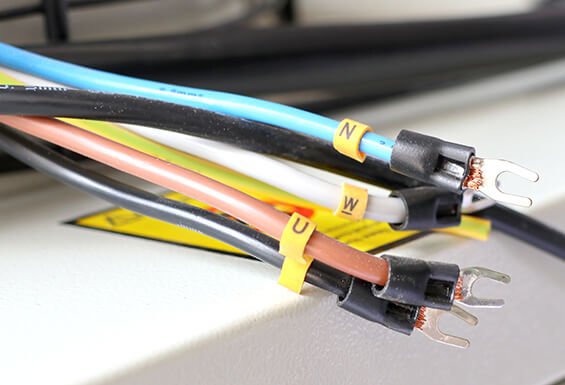

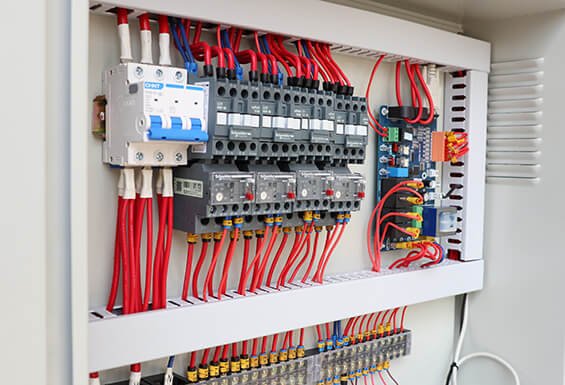

Power Supply

It comprises a speed controller, starter, monitoring devices, and circuit breaker. It helps in the regulation of overall power flow.

You can get it installed as a built-in component for convenience. However, it comes in a separate configuration as well so that you can install it on the wall.

Control Unit

It enables remote control and monitoring of the chiller for long hours. Central adjustment and memory will allow you to feed specific temperatures and control settings.

Water Box

It helps in the direct flow of water as it is installed on the condenser. It plays a vital role in creating the barrier between the entry and exit, controlling the fluid flow through the holes.

Recirculating Chiller Control Unit

Which Laboratory Processes Required a Recirculating Chiller?

You can use a Recirculating Chiller in a laboratory for the following processes and equipment:

- Mass Spectrometers

- Cooling Analytical Instruments

- Commercial Digital Printing

- X-Ray Diffraction

- Sputtering Systems

- Diffusion Pumps

- Electron Microscopes

- Reaction Vessels

- Extractors

- Critical Point Dryers

- Ophthalmic Lens Manufacturing Equipment

- Laser Lithography

What are the Major Types of a Recirculating Chiller?

The basis of classification is the size mode of working; the following are the common types of a Recirculating Chiller:

Compact Recirculating Chiller

Due to its compact size and efficient function, it is valued for applications with small cooling loads.

FL Recirculating Chiller

It is capable of dealing with an extensive range of applications and provides accurate temperature regulation for various processes.

FC Recirculating Chiller

It has two variants such as water-cooled and air-cooled. Provides an efficient recirculating cycle that can deal with moderate cooling loads

Semichill Recirculating Chiller

It has maximum reliability and provides continuous operation for several hours, even in extreme conditions.

Compact Recirculating Chiller

How to Determine the Right Size of your Recirculating Chiller?

For calculating the ideal size of your Recirculating Chiller for your industry, you must follow the given points:

- First of all, start by calculating the temperature differential.

- Take out the value of BTU/hour.

- Now calculate the tons of cooling capacity BTU/hour.

- Consider the size of the chiller by oversizing it by a 20% ideal size in tons.

- This is the best size of your chiller, appropriate for dealing with your application.

What are the Essentials of Electronic Control Systems in a Recirculating Chiller?

The electronic control system of a Recirculating Chiller must be well equipped and efficient enough to deal with the changing requirements.

The crucial factors regarding the electrical components are as follows:

- Necessary for providing the voltage required by the model and type of the Recirculating Chiller.

- Capable of handling the load of all the connections.

- Have enough fuses and safety measures like insulation and circuit breaker to ensure protected use of the chiller.

- Be able to deal with the different phase changes and provide a steady current supply.

What are the General and Unique Requirements of a Recirculating Chiller?

The general requirements of a Recirculating Chiller include:

- The installation site must be well ventilated.

- A good supply of water and electricity is required.

- Maintenance and cleanliness routines must be followed.

- It must be installed at a higher level than the ground for maximum heat exchange.

- Filters shall be installed to avoid dirt and debris.

The unique requirements include:

- The refrigerant must be high quality as it keeps recirculating.

- The glycol must be mixed with water for maximum efficiency.

- The optimum temperatures for all the processes must be known so that they can be fed into the system accordingly.

Wear PPE Before Operating your Recirculating Chiller

What is the Significance of Using Glycol in a Recirculating Chiller?

The primary purpose of using glycol in combination with water is to decrease the freezing point even beyond 0 degrees Celsius.

Freezing Temperature

When the external temperature is extremely low, water alone tends to freeze in the coils and the tank, especially in winters.

The frozen water is of no use since the flow is partially or entirely blocked. There is no refrigeration cycle and no efficient cooling.

Ethylene, propylene, or glycol is used by mixing it with the water in the ratio of 1:1 or 1:2, depending upon the requirement of the process being carried out.

Glycol Water Ratio

The ratio of glycol and water is extremely crucial since only the proper ratio can prevent freezing. If both the components are mixed in random quantities, there will be no considerable output.

When the temperature is below the freezing point, the atmospheric moisture can be condensed to glycol water mix in an open system.

In this case, the glycol concentration is lowered, and the freezing point increases.

You can check and measure the freezing point with the help of a refractometer or hydrometer.

Boiling Temperature

Glycol increases the boiling temperature and can be mixed to obtain more excellent water stability for processes that require a higher boiling point.

How to Operate your Recirculating Chiller?

To operate your Recirculating Chiller, follow the given steps:

- Connect the power lead to the IEC connector at the back of the unit.

- Verify if there is enough refrigerant in the system.

- Ensure that the pump and power switches are switched off in the control panel.

- Now connect the power cable to the main supply.

- Turn on the power switch and ensure that the main control panel is switched on.

- The current temperature will be visible on the screen.

- It starts automatically if the temperature is 0.5 degrees Celsius higher than the set value.

- For a new process, enter the values of the temperature, pressure, humidity, and other external conditions and have them to the microprocessor unit.

How to Adjust the Temperature of your Recirculating Chiller?

To adjust the temperature of your Recirculating Chiller, you must follow the given steps:

- Press the SET key and wait for the screen to change from the current temperature to the required temperature. Use the up and down keys to adjust the value in the blinking bar.

- You can either hold the up or down key to scroll the range of temperatures already present in the system.

- Once the operation has been performed, the display screen will revert to showing the current temperature. If you leave the screen unattended for some time, it automatically reverts after pressing the SET key.

Recirculating Chiller Temperature Adjustment

What are the FCC Requirements of a Recirculating Chiller?

The FCC requirements of a Recirculating Chiller include the following points:

It must be according to the FCC rules and the radio interference regulations of the Canadian Department of Communications. It can only be proved through testing and making sure that it is compliant with the standards of an A-Class digital device.

These standards enable you to obtain maximum efficiency and protection in working applications where you might face harmful interference.

Its use and operation involve a refrigerant and an elaborate refrigeration cycle, and it is responsible for radiating radiofrequency energy. Therefore, it must be installed and used in the right way with proper protective measures.

What are the Benefits of Using a Recirculating Chiller for your Industry?

The benefits of using a Recirculating Chiller include:

High Productivity

The overall downtime is significantly reduced due to uninterrupted function and no wastage of refrigerant and water.

Protective Function

As it is equipped with sensitive alarms and maintains the temperature within the required limit, it can detect any harmful rise in the temperature.

This can be used to perform prompt action and save the equipment from overheating.

Low Maintenance

It does not involve any extensive maintenance routine, and therefore you can obtain high reliability with little attention to maintenance.

Affordable Operation

Since it uses recycled chilled water and refrigerant, it helps you save up on spending on these things again and again.

Customization

You can obtain the desired results by demanding the most suitable design for your application. The size, model, and refrigeration mode can be selected to enhance efficiency.

Accessories

Various accessories like motors, alarms, PID controllers, and compressor accessories can help increase productivity.

Certification

With proper testing and certification, the optimum function of the chiller is guaranteed.

What Factors Should you Consider Before Purchasing your Recirculating Chiller?

The factors to be considered before purchasing your Recirculating Chiller include:

Do your Homework

Make sure you undergo thorough research about all the models to select the best one for your application. The appropriate size and the refrigerant can also be decided through research.

Look for Reasonable Options in your Budget

Once you are aware of all the variety, you can shortlist the models that are accessible to you in terms of pricing.

It is a one-time investment since it provides temperature regulation as well as equipment protection enabling you to save money in the long run.

Go for a front filling port and avoid side vents so that there is a minimum chance of water damage.

Microprocessor

Pay due attention to the selection of the microprocessor because it plays an integral role in the chiller function.

Make sure it is updated with the recent technology and enables the proper function.

What are the Maintenance and Servicing Requirements for your Recirculating Chiller?

The maintenance and servicing requirements of your Recirculating Chiller include:

Inspection

It would be best if you kept a keen eye on your chiller’s performance by evaluating its efficiency from time to time. Keep checking all the vents and pipelines for any organic growth or accumulation of dirt and debris.

Keep a Log

You should carry out a monthly, bi-annual, and annual inspection and keep the record. It helps in the assessment of the chiller function with time and refrigerant use.

Refrigerant and Oil Level

The refrigerant and oil level must be strictly monitored as lower levels decrease efficiency and cause long-term damage to the chiller. It may also lead to exhaustion.

Lubrication

All the parts should be lubricated so that there is minimum friction leading to minimal wear and tear. It helps to obtain higher efficiency with no noise production.

Electrical Connections

All the electrical connections shall be safe and well protected. The wires shall be insulated, and there should be a stable supply of electricity with constant phase and voltage.

Filters and Motors

Keep checking the filters and motors as they tend to clog up with time leading to obstruction in the refrigeration cycle. You should clean and replace them whenever required.

Recirculating Chiller Electrical Connections Maintenances

How to Obtain Maximum Efficiency of your Recirculating Chiller?

For maximum efficiency of your Recirculating Chiller, you must keep the following things in mind:

Regular Monitoring

Keep a strict check on your chiller’s performance so that any lag can be detected as soon as possible. It helps in avoiding more significant problems.

Refrigerant Quality

For medium capacity, the ideal refrigerants are R-410A and R-407C. However, for more extensive applications with greater cooling loads, you should go for R-134a and

R-123.

The quality of the refrigerant must never be compromised. It shall be harmless to the environment.

Water Treatment

Any scaling and fouling can be avoided using well-treated and clean water. It helps in increasing the life of your Recirculating Chiller.

Recirculating Chiller Regular Monitoring

What are the Protective Measures for Using a Recirculating Chiller?

The protective measures for using a Recirculating Chiller include the following:

Trained Operator

There must be a well-trained person for the operation of the chiller. He is responsible for setting the thermostats and other regulatory functions, and therefore he must have basic knowledge of all the processes.

Supervision of an experienced person is also necessary.

Insulation

All the electrical components shall be well insulated because heavy electrical flow tends to heat the wires, which can be dangerous. Insulated wires are a safe option.

Refrigerant Precautions

Make sure you take all the precautions regarding the refrigerant. It shall never be inhaled or injected, and it must meet the quality criterion.

External Pressure Relief Valve

An additional valve allows maintenance of the run pressure and temperature if the equipment flow is interrupted temporarily.

What are the Major Problems and their Solutions of a Recirculating Chiller?

Here are some of the significant problems and their solutions regarding a Recirculating Chiller:

Power Supply

Faults

- Low voltage

- Defective wiring

- Switch off

- Phase difference

- Circuit breaker

Solutions

- Correct the voltage issue

- Maintain a stable supply of electricity

- Correct the phase connection

- Replace the circuit or fuse

- If the switch is open, close it.

Flow Rate Decreased

Faults

- Accumulation of dust, dirt, soil, fungi, etc., in the pipes.

- Accumulation of minerals in the pipes.

- Narrow passageway

- Incompetent valve

- Fluid reservoirs decreased

Solutions

- Remove the obstruction by thorough cleaning.

- Check the valves and replace them if required.

- Check the level of coolant in the reservoir.

Poor Cooling

Faults

- Incompetent components like the compressor, condenser, etc.

- Low refrigerant and lubricant levels.

Solutions

- The condenser shall be patented appropriately.

- Must consider the heat properties of the refrigerant.

- Any refrigerant leaks shall be repaired immediately.

Corrosion

Fault

- Untreated water

- Increased moisture content on corrosion susceptible parts

- Poor quality of metal

Solution

- Always go for the best quality, stable metal.

- Look for anti-corrosion properties for all components.

Compressor Failure

Fault

- Blown fuse

- Overload

- Excessive wear and tear

Solution

- Go for prompt damage repair as soon as possible.

- Correct phase errors.

Recirculating Chiller Troubleshooting