TopChiller can design and manufacture all types of water cooled chillers for you

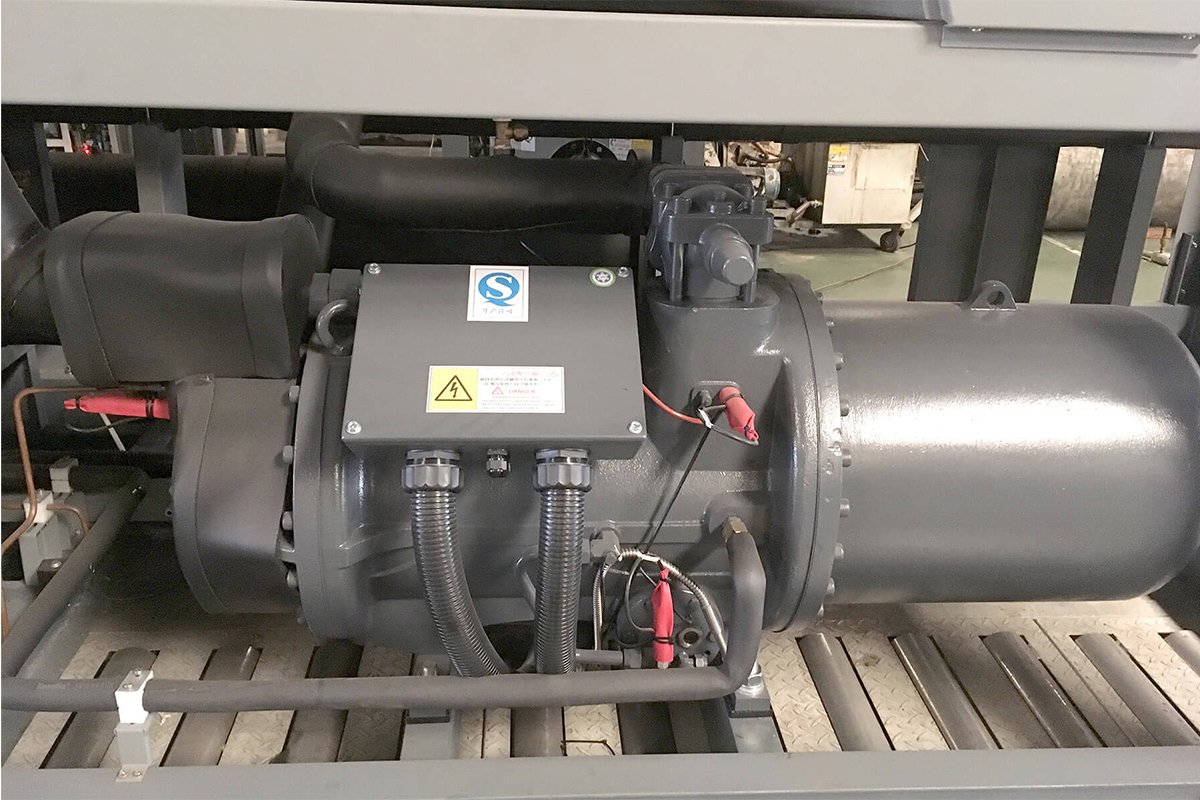

- Highly efficient scroll and screw compressor

- Condenser pump, cooling tower & TES reservoir

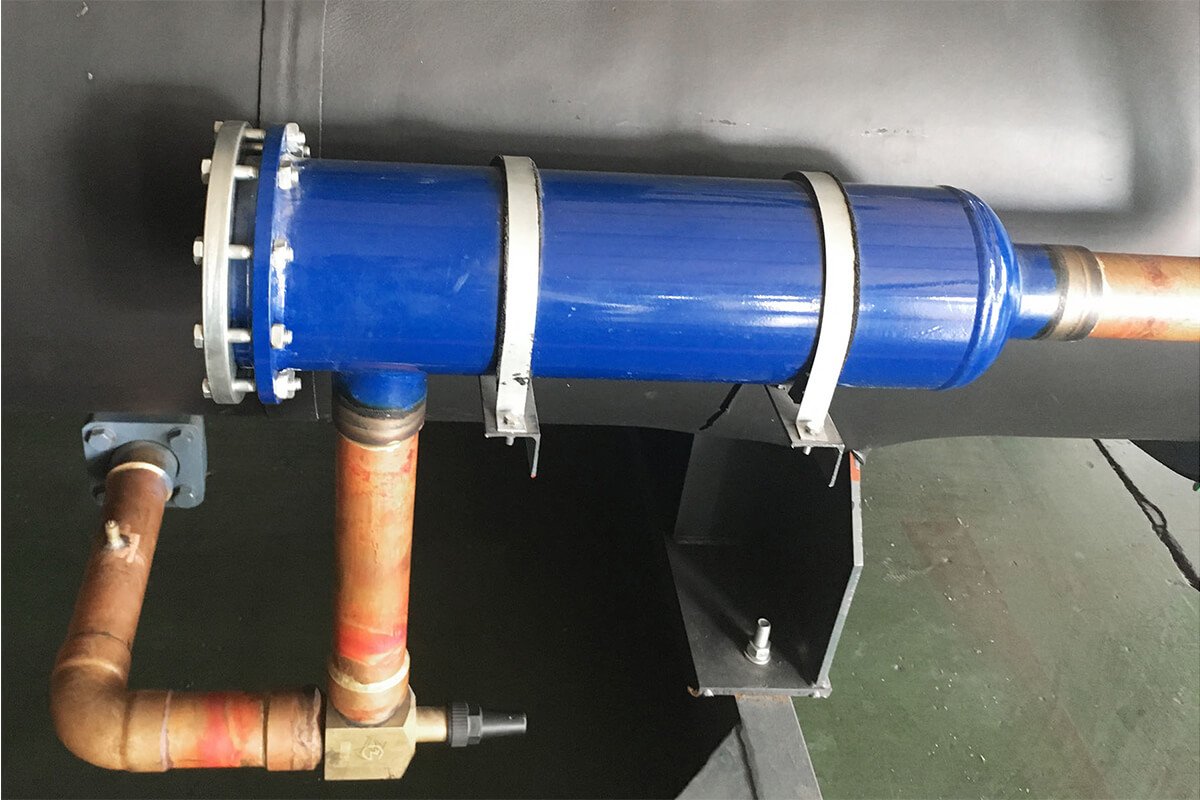

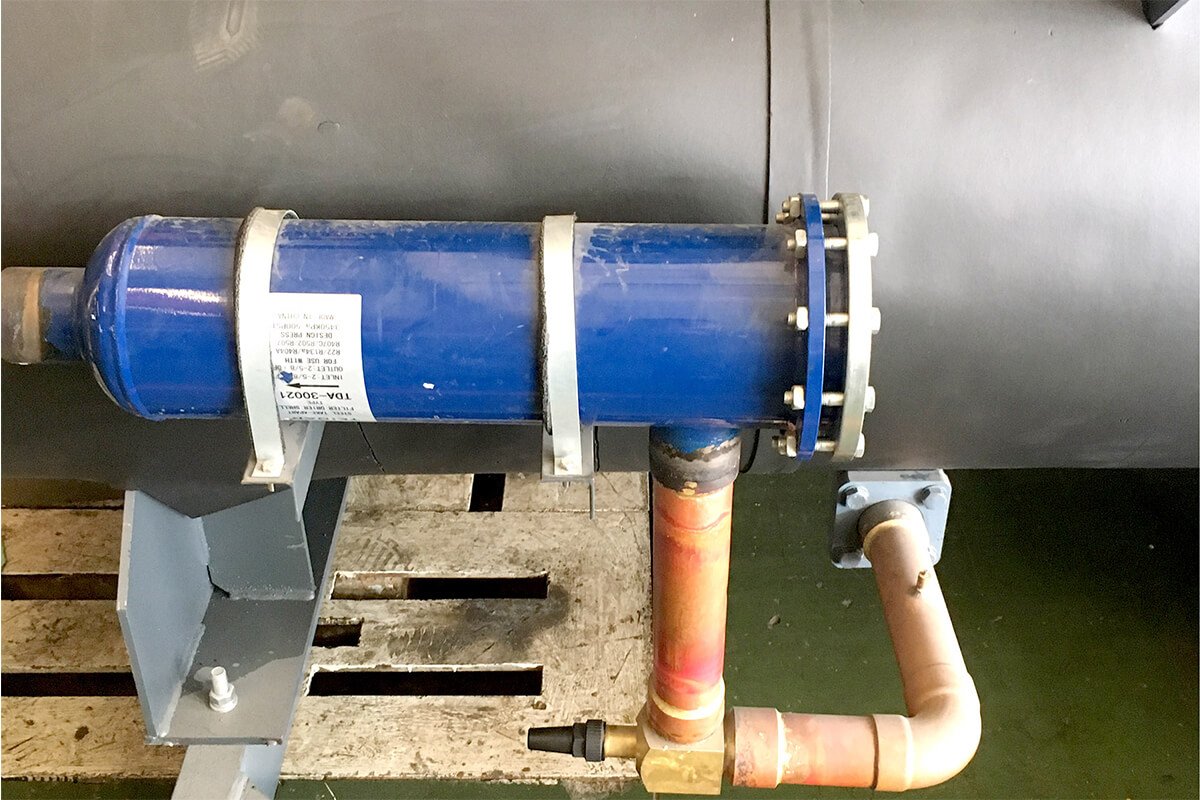

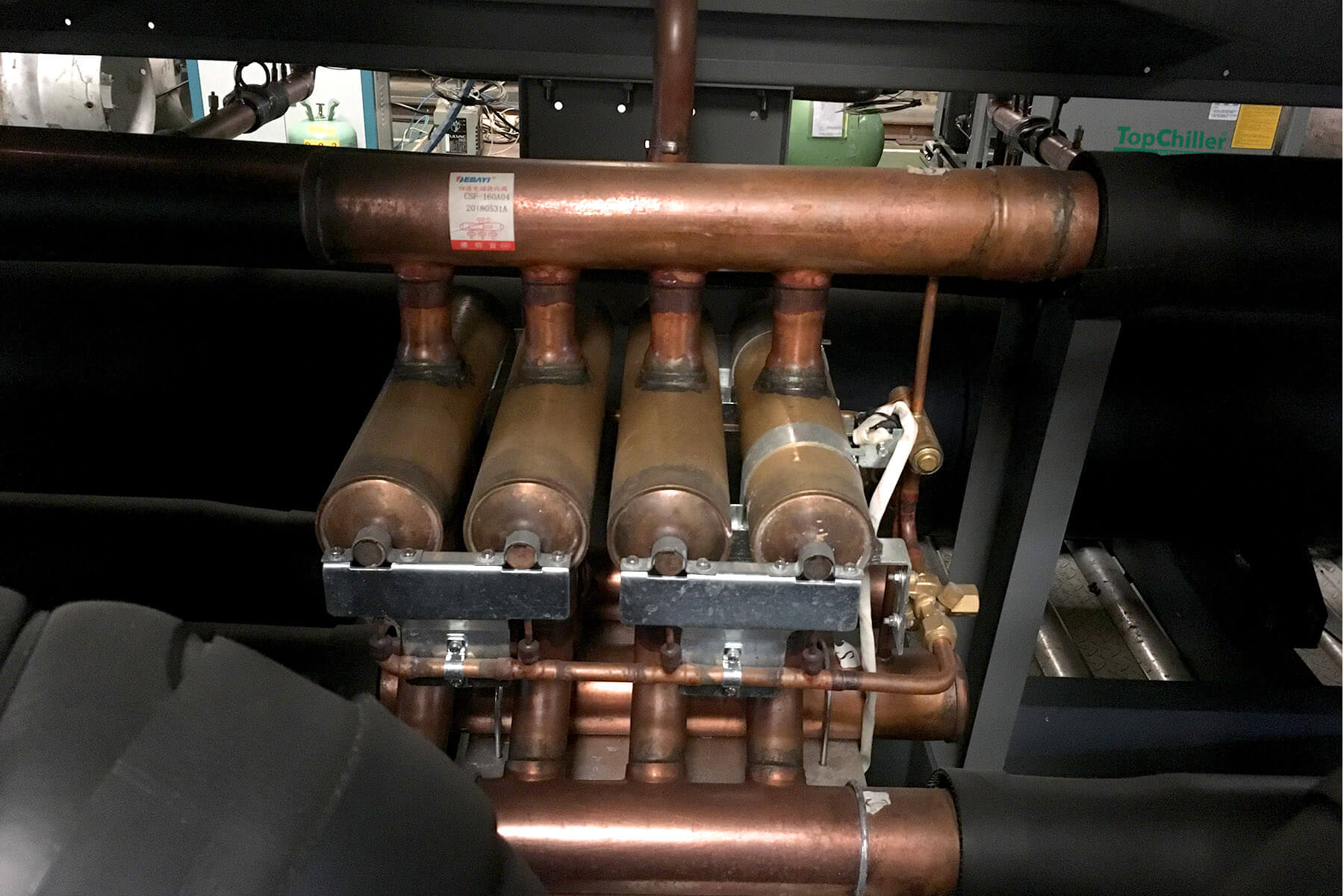

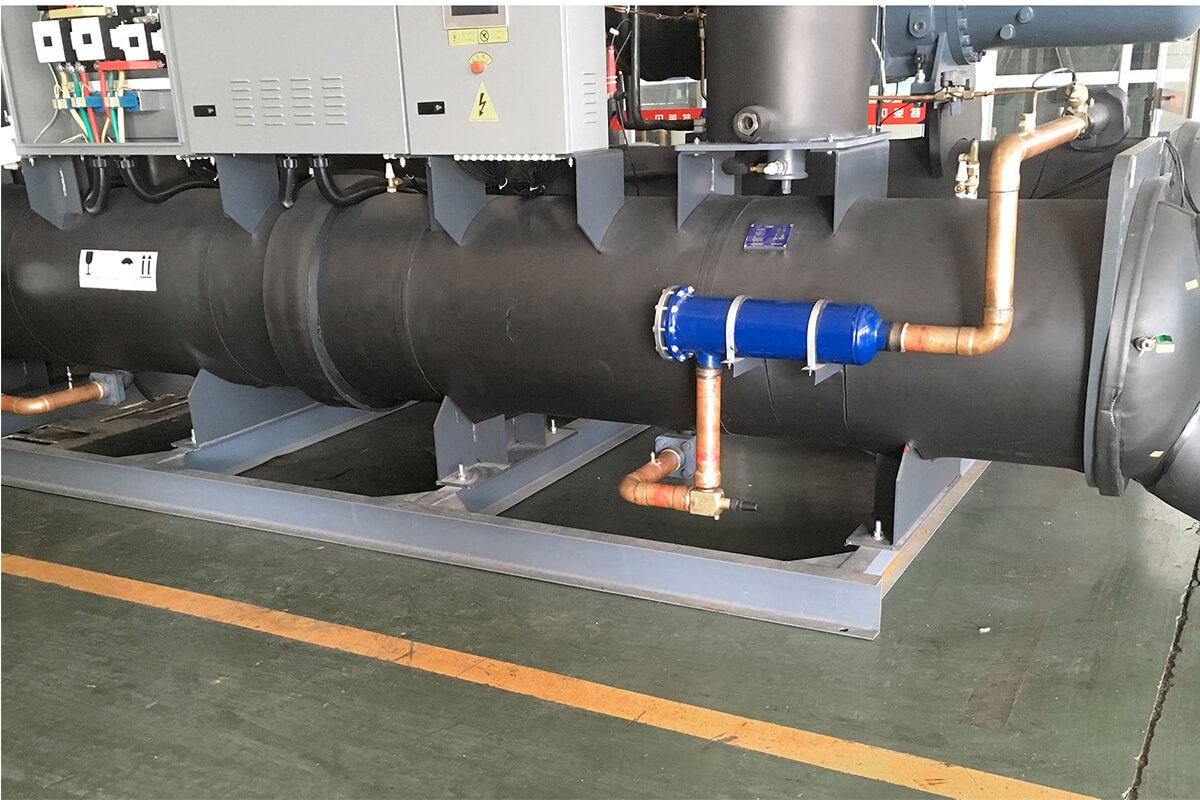

- Prime quality water-cooled shell and tube condenser

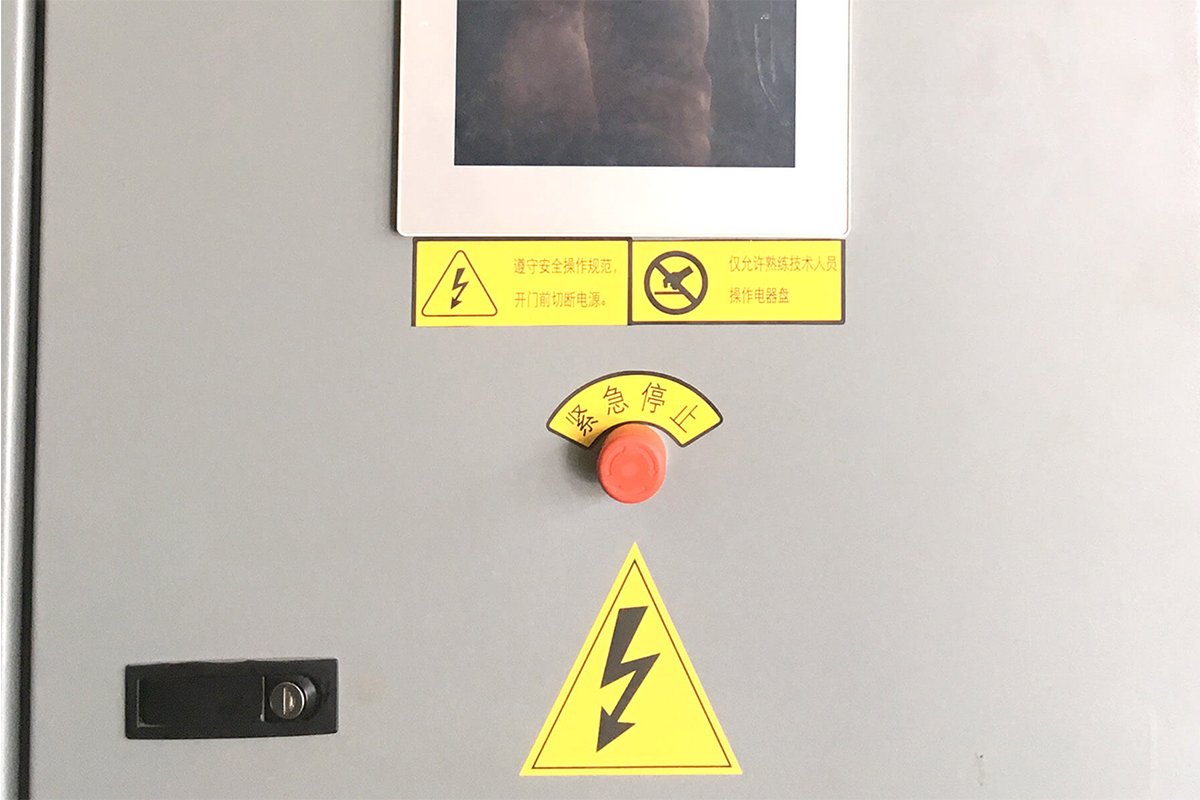

- Built-in water level indicator, and control panel

- Shell & tube type heat exchanger & condenser

- Temperature controlling PID based system

- Full protection devices with the chiller unit

- Magnetic bearing technology eliminates friction

Your Premier Water Cooled Chiller Manufacturer and Supplier in China

Water Cooled Chiller is a prestigious designed cooling unit that uses condensed recirculating water to cool the processed water coming in a cooling tower by condensing refrigerant following refrigeration principle.

Since 1999, after its establishment, TopChiller Company is working with unbridled passion, manufacturing proficient and stable Water Cooled Chiller to overcome ever-evolving challenges with standardized credibility and reliability.

By delivering energy-efficient and precise working full stock of Water Cooled Chiller, TopChiller has become the leading company of China with great appreciation from customers who leveraged our products for over last twenty years.

Water Cooled Chiller constitutes reliable branded spare parts as a scroll/screw compressor, condenser tank, SS heat exchanger, PLC temperature controller, water level indicator, evaporator, control panel, TES reservoir water tank, and power supply.

Best quality Water Cooled Chiller is broadly used due to its outstanding advantages as given below:

- Water Cooled Chiller is highly versatile and sustainable in its chilling operation configured by a full line of different capacity units for different applications and low direct/indirect fluid emission.

- TopChiller brand Water Cooled Chiller has water-wetted surfaces and corrosion protective insulation inside coils that act as lubricant ensuring the unit produces noise-free operation.

- Water Cooled Chiller has its easy installation both indoor and outdoor configured by mechanical support for indoor application and power supply with full protections for outdoor applications.

- Water Cooled Chiller is featured with a water-cooled condenser that ensures water cycling between water tank and condenser by releasing heat from the heated refrigerant and releasing it out in the water.

- Water in condensing unit gets evaporated by absorbing the heat of the unit and discharges out, ultimately a decrease in water level indicated and maintained by water indicators.

TopChiller brand Water Cooled Chiller is used for different water-based chilling applications in different fields as:

The pharmaceutical industry, beer and beverage industries, metalwork, plastic and rubber industry, injection and bottle blowing machines, dairy cooling, printing machines, and chemical processing, etc.

Do you want to buy water installed, energy-efficient, and steadily working Water Cooled Chiller to support your plant in a water plentiful area?

Are you dealing with high heat-producing applications and searching out for a trustworthy Water Cooled Chiller manufacturing and retailing company to get innovative ideas and tips about the establishment of your own business?

Make a handsome decision by selecting TopChiller as your retailer and cooperative association. Commence on a conversation with TopChiller sales and expertise, discuss in detail all the queries you want to get clear.

TopChiller employees and technocrats are instructed to provide detailed guidelines about Water Cooled Chiller operation and specifications assisting customers to select the unit that exactly matches your application requirements.

General Description:

Water Cooled Chiller is a cooling machine that lowers the temperature of the industrial process by absorbing heat and then releasing it to the external atmosphere via a refrigerant cycle.

It cools down the industrial process by dissipating unwanted heat produced by various means and transferring it to the surrounding environment.

Water Cooled Chillers manufactured by TopChiller contain a high-quality compressor evaporator, condenser, and expansion valve that drive the whole system. It has a vast area of commercial and industrial applications, widely used in manufacturing plants, shopping malls, industrial mills, the food industry, and even in residential buildings.

TopChiller brand has introduced a wide range of Water Cooled Chillers trusted by millions of customers for more than twenty years of successful journey. We manufacture and supply an entire range of highly efficient water cooling systems with incredible features and working performance.

Are you looking for a high-performance Water Cooled Chiller to dehumidify air and dissipate excessive heat from your industrial plants or even from your commercial buildings?

You may choose TopChiller; we are the best choice to buy high-quality Water Cooled Chillers that are even budget-friendly.

Features and Advantages:

A highly efficient Water Cooled Chiller manufactured by TopChiller that have featured out with the following unprecedented characteristics:

- It uses high-quality compressors that detect the load and respond accordingly, which increases the overall working efficiency of your application.

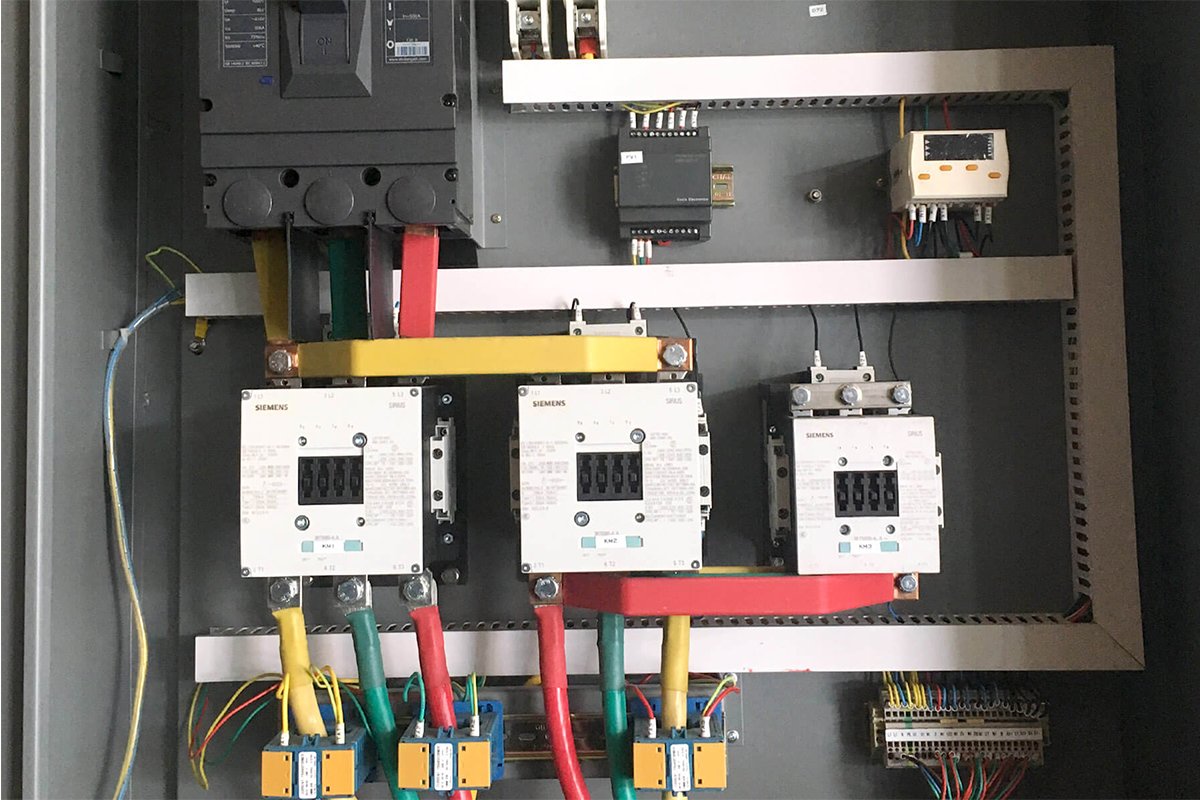

- Various protection devices such as temperature and voltage controllers, emergency stop switches, overload current protectors, antifreeze temperature protectors, safety valves, and overheat protectors increase durability and ensure long life.

- It lowers the temperature of the industrial process with equal efficiency even in high ambient temperature conditions.

- Prime quality evaporators absorb heat competently, preventing cooling loss.

- Water Cooled Chiller designed by TopChiller is highly energy efficient. Its configurable coil adjusts the relevant operating power by the ambient temperature.

- Image Gallery

- Main Parts

- Video

Why TopChiller is Your Reliable Water Cooled Chiller Manufacturer and Supplier In China?

Water Cooled Chiller-An Ultimate FAQ Guide by TopChiller.

- What is a Water Cooled Chiller?

- What are the Characteristics of a Water Cooled Chiller?

- What are the Uses of a Water Cooled Chiller?

- What are the Major Parts of Water Cooled Chiller?

- How Does a Water Cooled Chiller Work?

- Why Do you Need a Water Cooled Chiller for your Applications?

- What are the Prominent Applications of Water Cooled Chiller?

- What is the Difference Between Operational Cost of Water Cooled Chiller and Air Cooled Chiller?

- How Proficient is a Water Cooled Chiller?

- How to Calculate the Working Efficiency of your Water Cooled Chiller?

- What is the Accurate Water Temperature for Water Cooled Chiller?

- What are the Refrigerant Types for a Water Cooled Chiller?

- What are the Protection Devices of a Water Cooled Chiller?

- What are the Benefits of Protection Devices for your Water Cooled Chiller?

- How to Select a Suitable Water Cooled Chiller for your Industry?

- How to Choose Between Water Cooled Chiller and Air Cooled Chiller?

- What are Common Problems of Water Cooled Chiller?

- What are Troubleshooting Tips for your Water Cooled Chiller?

- What is the Estimated Cost of a Water Cooled Chiller?

- How to Maintain and Monitor your Water Cooled Chiller?

What is a Water Cooled Chiller?

A Water Cooled Chiller can be defined as a cooling system that facilitates heat exchange by recirculating water from a cooling tower.

It dissipates heat from the process by absorbing it and then releasing it into the environment. In this way, it functions to decrease the temperature of the industrial process.

It is has a vast area of applications and used to maintain the temperature of industrial machinery during industrial processes.

The chilled water is processed through the equipment, where it absorbs heat, and the warmed water returns to be processed again. This is how the whole refrigerant cycle works.

The heat produced as a necessary by-product needs to be released outside the applications. Cooling towers installed with the chiller play a role in getting rid of this leftover heat.

Water Cooled Chiller provides a highly efficient method that cools and dehumidifies air and significantly dissipates heat from industrial applications forming a closed loop.

Energy Saving Water Cooled Chiller Designed by TopChiller

What are the Characteristics of a Water Cooled Chiller?

A Water Cooled Chiller is primarily characterized by:

Temperature Control Panel

It is provided with a high-precision electric temperature control panel that can be operated stably for a long time.

Heat Exchangers

Highly efficient heat exchangers minimize the loss of cooling and prevent the frost cracking of heat transfer tubes.

Recirculating Pumps

It is based on the recirculating principle. The circulating pumps circulate water again and again through the system that prevents excessive water loss.

Safety Devices

Temperature protectors, voltage controllers, overheat protectors, and safety valves are installed to improve the durability of the Water Cooled Chiller.

Cooling Towers

A cooling tower acts as a heat exchanger that removes heat from a coolant.

Water Cooled Chiller Highly Efficient Heat Exchanger

What are the Uses of a Water Cooled Chiller?

A Water Cooled Chiller is a reliable source of cooling an industrial environment that is used:

Cool Down the Equipment

Even at extreme temperature conditions, it has an enormous cooling capacity and provides efficient cooling between 180,000 to 18,000,000 BTUs per hour.

It is optimal for large industrial applications to remove excessive heat from the industrial equipment where ordinary air conditioners fail.

Protect from Heat Damages

The Water Cooled Chiller protects your industrial equipment from excessive heat damages.

At extremely high temperatures in the industrial environment, the mechanical devices suffer damages from heat.

Heat accumulates there over time. It reduces the durability of the applications, and ultimately the equipment gets destroyed.

Excessive Cooling With Minimal Expenses

It efficiently lowers the temperature of the industrial process and is far more effective than the use of many ordinary air conditioners.

This method of cooling is highly energy-efficient. Moreover, it recirculates water within the system, thus, reduces your costs on extensive water supply and electricity consumption.

What are the Major Parts of Water Cooled Chiller?

Water Cooled Chiller consists of various parts; some significant parts are listed below:

Compressor

The compressor converts the low pressure and temperature refrigerant into high pressure and temperature gas.

It drives the refrigerant around the system by forming a pressure difference. Centrifugal, screw, or scroll compressors are used in it.

Condenser

The compressed refrigerant traveled through a condenser. Water-cooled shell and tube-type condenser are installed in a Water Cooled Chiller.

A condenser removes heat from the refrigerant and condenses it into liquid.

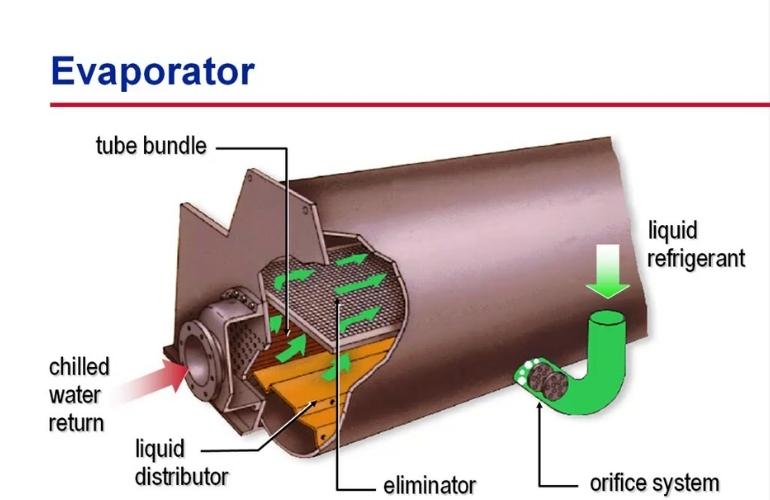

Evaporator

The refrigerant and fluid interact in the evaporator. The refrigerant goes back to the evaporator, where it absorbs heat from the water.

Shell and tube, copper coil, and plate are commonly used evaporators.

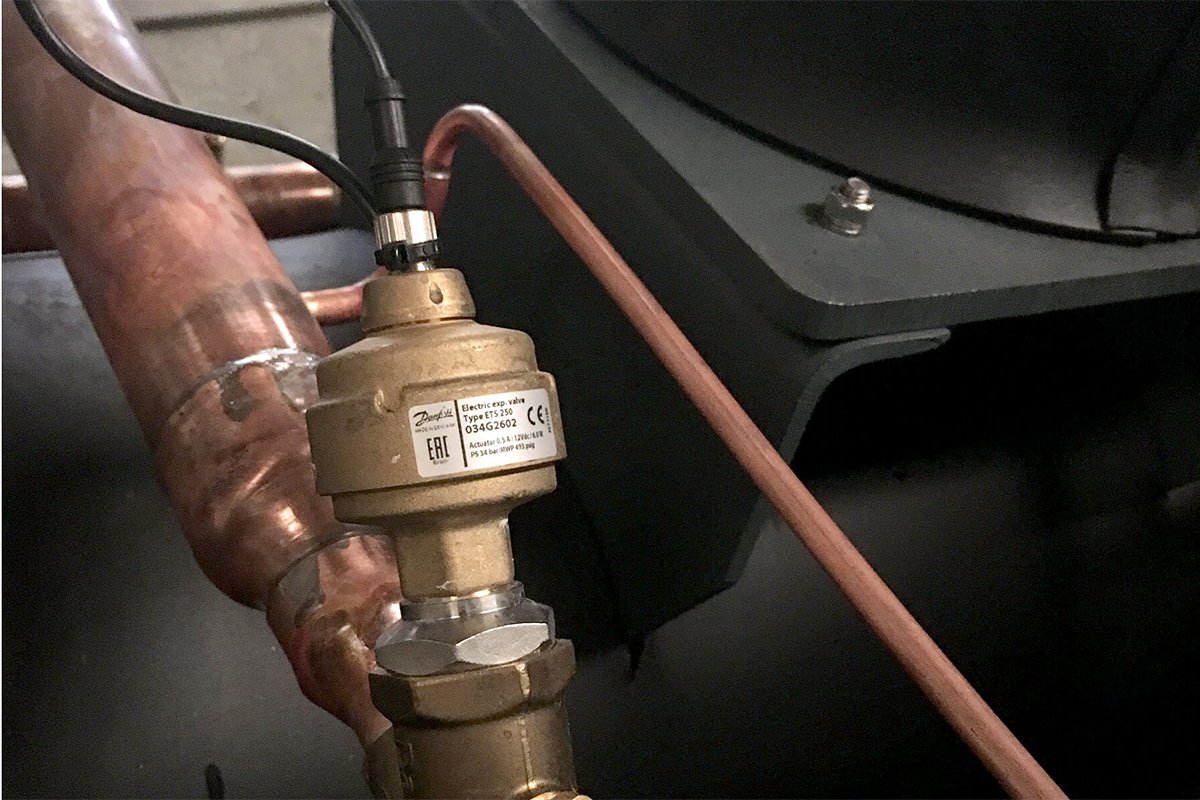

Expansion Valve

The expansion valve manages the amount of refrigerant that passes between the evaporator and condenser.

It changes the flow of refrigerant based on cooling load.

Pump

The entire pumping system circulates the water from the chiller to the process that needs to be cooled.

Filter

The function of a filter is to capture contaminants and dirt particles that enter the chiller fluid.

Water Cooled Chiller Evaporator Details

How Does a Water Cooled Chiller Work?

The entire process of a Water Cooled Chiller operates under the principle of vapor compression refrigeration cycle.

In the cycle, refrigerant converts from liquid to gas and from gas to liquid through heat exchangers.

The fluid pressure increases and decreases by the compressor and expansion valve, respectively.

The refrigerant cycle starts with the compressor that converts the refrigerant from low-pressure gas to high-pressure gas.

It is then passed to a condenser that acts as a heat exchanger. It transfers heat from the refrigerant to the water.

Consequently, the refrigerant is cooled and condenses into a liquid state.

The liquefied refrigerant with high pressure then passes by expansion valves to reduce the pressure. The low pressured refrigerant interacts with water in the evaporator.

The refrigerant absorbs heat from water in the evaporator and vaporizes. The low-pressure refrigerant gas returns to the condenser, and the cycle repeats.

Water releases unwanted heat to the cooling towers from where it is lost in the environment.

Water circulates again and again through the system and absorbs heat. The recirculating process goes on.

Why Do you Need a Water Cooled Chiller for your Applications?

A machine with 100% efficiency doesn’t exist. Heat is an essential by-product of all industrial processes.

If this heat is not efficiently removed from the process, it may accumulate there over time. This extra heat can cause the premature failure of industrial machinery, equipment shutdown, and reduced production rate.

Therefore, it is necessary to withdraw heat from your industrial process system.

A Water Cooled Chiller is frequently used to avoid the over-accumulation of heat in industrial systems.

It lowers the system’s temperature by recirculating water through the system with minimal loss of water.

What are the Prominent Applications of Water Cooled Chiller?

In industries, chilled water is circulated through the system that needs to be cooled, and heat is dissipated from the system by this means.

A Water Cooled Chiller is utilized to stabilize the temperature of various products and machinery in most of the manufacturing industries, medical and research centers, and many vast areas.

The prominent applications are:

- Plastic Manufacturing Industry

- Metal Plating

- Food and Beverage Production

- Pharmaceutical Industry

- Hospitals

- Tool and Die-Cutting

- Paper and Cement Industries

- Chemical Processing

- Power Generation Stations

- Metalworking

- Welding Tools

- Semiconductors Industries

It is also broadly used in hotels, schools, and even in residential buildings.

What is the Difference Between Operational Cost of Water Cooled Chiller and Air Cooled Chiller?

In a Water Cooled Chiller, the condenser is connected with a cooling tower anduses water as the condensing medium.

In contrast, the air is the condensing medium in air cooled chillers; the condenserdissipates heat from the refrigerant to ambient air.

For air cooled chillers, the refrigerant condensing temperature relies on the ambient dry-bulb temperature.

On the other hand, the Water Cooled Chiller refrigerant condensing temperature relies on the flow rate and condensing water temperature that equals the wet-bulb temperature.

Thus, the operational costs of the latter one relatively lower than the former.

In other words, the condenser that operates at lower pressure has lower functioning costs.

A Water Cooled Chiller is efficient in terms of electricity consumption. Still, its maintenance and initial costs are higher than the air cooled chiller because it needs the installation of a cooling tower and a constant supply of water.

How Proficient is a Water Cooled Chiller?

A Water Cooled Chiller is 20 percent more efficient than an air cooled chiller. It usesa water-cooled shell and tube-type condenser, with an outdoor cooling tower and water circulation pumps that increase its cooling efficiency.

The cooling tower increases its ability to condense water far better than the ambient air. It decreases the energy consumption of the chiller.

The energy consumption of a Water Cooled Chiller is approximately 10 percent that is 60 percent for air cooled chillers. It has a relatively long life.

How to Calculate the Working Efficiency of your Water Cooled Chiller?

The working proficiency of a Water Cooled Chiller can be calculated in terms of the coefficient of performance (COP).

The coefficient of performance is simply a ratio of the refrigerant effect produced by your chiller and the amount of electricity consumed by the chiller.

Both of these values are measured in watts.

For instance, the cooling capacity of your chiller is 2,500kW; it can be measured in terms of BTU that will be, in the case, 8,533,364BTU/h.

If its power consumption demand is 460kW, the energy efficiency ratio or COP will be 5.4.

What is the Accurate Water Temperature for Water Cooled Chiller?

The accurate water temperature for Water Cooled Chiller is usually 4℃ but can range somewhere between 5℃ and 7℃.

It may vary significantly according to the type of application for which the chiller is used.

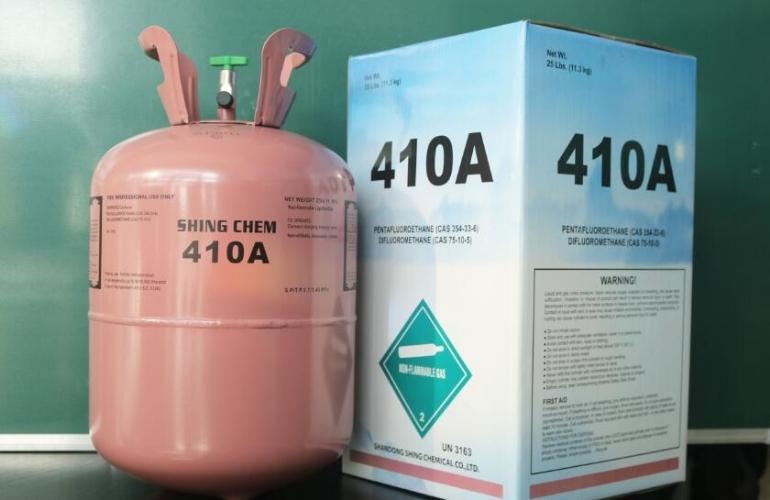

What are the Refrigerant Types for a Water Cooled Chiller?

These are the following five types of refrigerants according to their chemical make-up:

- Saturated hydrocarbon cooling agent

- Unsaturated hydrocarbon cooling agent

- Freon

- Azeotrope refrigerant

- Inorganic substance cooling agent

Water Cooled Chiller most commonly uses Freon and R-22 type cooling refrigerants.

The chemical composition of R-22 is difluoro-chloromethane. It is primarily used in industrial and residential air conditioning, catering, and commercial refrigeration systems.

Water Cooled Chiller Refrigerant

What are the Protection Devices of a Water Cooled Chiller?

A Water Cooled Chiller contains various protection devices to ensure its long life.

- Exhaust Overheat Protector

- Water Flow Protector

- Antifreeze Temperature Protector

- Overload Current Protector

- Emergency Stop Switch

- Temperature Sensing Fusible Plugs

- Compressor Motor Overheat Protector

- High and Low Voltage Protector

- Safety Valves

What are the Benefits of Protection Devices for your Water Cooled Chiller?

Various protection devices in your Water Cooled Chiller are specified in their particular functioning to prevent any loss.

They are beneficial in one way or another. For example:

Anti-freezing Protectors

Anti-freezing protection devices prevent the frosting of water in the system to ensure the accurate functioning of the cooling system.

Motor Overload Protectors

Extremely high ambient temperature and unstable voltage damage the water pump motors, compressors, and fan motors.

If the motor keeps on running, it may fall short. Motor overload protection devices shut down the chiller under these conditions and alarm you in case of any malfunctioning.

Water Flow Protectors

The water flow switch regulates the flow of water in the system. It prevents any damage by water leakage and circuit blockage.

Overheat Protector

The refrigeration cycle reduces the temperature of water between 3℃ and 8℃.

In case if the chiller is not working correctly or the ambient temperature is too high, the temperature in the circuit will go on increasing higher and higher. It can damage the circuit as well as equipment.

Overheat protectors alarm in such dangerous conditions.

Emergency Stop Switch

Sometimes, it produces strange noises or vibrations due to irregular voltage, overload, or other reasons.

There is an emergency stop switch to shut down the chiller immediately in case of such an emergency.

Other protection devices are also activated in an emergency to prevent any mechanical failure and ensure the long life of your chiller.

Water Cooled Chiller Water Flow Switch

How to Select a Suitable Water Cooled Chiller for your Industry?

Follow the following steps to choose a suitable Water Cooled Chiller for your industry:

The first step towards your selection is to determine the heat load of the application where to install a chiller. The selected one must be bigger enough for the intended application.

After determining the heat load, the next step is to analyze the installation application and environment. It has distinct varieties in the market according to its application.

Various parameters like the indoor temperature, contamination proportion in the atmosphere, etc., need to be considered.

Because they can affect the sizing and require accessories such as sump heaters, air filters, etc.

Use chiller performance curves to choose a suitable model for your industry.

It should meet the required capacity based on the highest expected ambient air temperature and the chilled water supply temperature.

The prices vary incredibly concerning manufactures, quality, and design. Different Water Cooled Chillers suppliers design and cost their systems distinctively.

Analyze them thoroughly, compare costs and consider your requirements before purchasing.

A Water Cooled Chiller Protected With Air Filters

How to Choose Between Water Cooled Chiller and Air Cooled Chiller?

You need to consider the following factors to choose between an air cooled chiller and Water Cooled Chiller:

Performance

There is a wide range of chillers depending upon their sizes and performance.

A Water Cooled Chiller size ranges from 10 tons to 9,000 tons, and the overall performance varies relatively from 35 kW to 14,000 kW.

Air cooled chillers have compact size ranges between 7.5 to 500 tons. They are appropriate for smaller installations.

Durability

It is usually installed indoors; it has a comparably longer life.

But in contrast, air cooled chillers are outdoors and operate at higher condenser pressure. So, they are more vulnerable to damage.

Maintenance

Water Cooled Chiller requires the installation of cooling towers to remove excessive heat.

It increases its maintenance demands, such as mechanical maintenance, water treatment, and tube cleaning.

Air cooled chillers have a lower cooling capacity, but it is easy to maintain. While a Water Cooled Chiller is more proficient and has a higher cooling capacity, but it has more maintenance costs.

Air Cooled Chiller Fabricated by TopChiller

What are Common Problems of Water Cooled Chiller?

A Water Cooled Chiller consists of many components. When any of these components fall short, it triggers a problem to the entire system.

Some of the most common problems you have to overcome while using it are:

Insufficient Cooling

The major problem is the insufficient cooling caused by several variables, including high ambient temperatures, refrigerant leaks, or a clogged air filter.

Insufficient Fluid Flow

Insufficient fluid flow is caused when the pump stops working or obstructs the fluid filter.

Whatever the cause, it might adversely affect the overall performance of the chiller.

Corrosion

Corrosion decreases its efficiency. Poor water circulation can sometimes be a cause of corrosion.

Whenever you experience any of such problems, it is best to seek advice from an expert.

They will highlight the cause of the problem to enable you to get better cooling efficiency from the system.

What are Troubleshooting Tips for your Water Cooled Chiller?

Firstly, you need to analyze the problem to troubleshoot your Water Cooled Chiller.

There are multiple causes behind these problems; identify their causes and locate the area where the problem lies.

A few of the problems and their solutions are discussed below:

Failure Due to Oil Clogging

In case of failure due to oil clogging, filter oil clogging needs to be changed with a new filter.

It is done by using an electric hair dryer to heat the condenser.

Preferably in the passage of nitrogen gas if using high-pressure nitrogen gas to the condenser part of the accumulation of refrigerant oil.

Error Due to Ice Blockage

Ice blockage failure occurs because of excess moisture in the system, so the entire refrigeration system must be dried out.

For the treatment, you should use nitrogen segmentation to remove dirt. Replace the filter, refrigerant oil, or replace the refrigerant until the water indicator in the sight glass turns green.

High Condensing Pressure

The high condensing pressure is caused by fouling of the condenser surface, small condenser surface, or the presence of air or other incompressible gases in the chilling system.

It can be treated by the following method.

- Clean the condenser by starting and restarting the system. Keep it running until thesystem reaches operating temperature

- Replace the larger condenser

- Recover refrigerant until the condensing pressure normalizes

- Set the accurate pressure

- Clean the condenser

What is the Estimated Cost of a Water Cooled Chiller?

Water Cooled Chiller costs vary concerning location, manufacturer, and technology alternatives.

The entire cost can be split into equipment, installation, energy, and maintenance expenditures.

Depending on the cooling capacity, it costs approximately $250 to $350 per ton.

Without accounting for a specified application, you could expect the total installed cost of $1,500 to $1,800 per ton for a new Water Cooled Chiller.

How to Maintain and Monitor your Water Cooled Chiller?

Maintaining and monitoring your Water Cooled Chiller regularly is an essential factor in ensuring the long life and efficient functioning

The following steps should be a part of your general maintenance checklist:

- Keep the chiller tubes clean

- Check operation of control systems

- Note down the oil and refrigerant levels

- Check the water temperature control

- Reduce the temperature of the condenser water

- Monitor for refrigerant leaks

- Inspect the condenser water loops

- Maintain an optimal chilled water flow rate

- Install variable speed drives

- Ensure the accurate working of motors

- Inspect the voltage of compressor motor

- Inspect moisture indicator

- Measure condenser and evaporator pressures

- Check water flow through the evaporator

- Take an instant action in case any noise or vibration produces

Water Cooled Chiller Maintenances