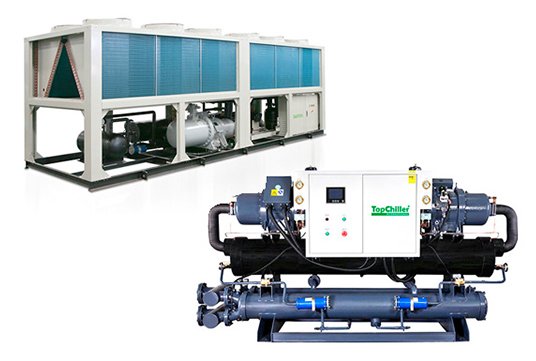

TopChiller can design and manufacture all types of screw chillers for you

- Cooling capacity ranges from 50 Ton – 250 Ton

- Temperature control ranges from -20 to 25°C

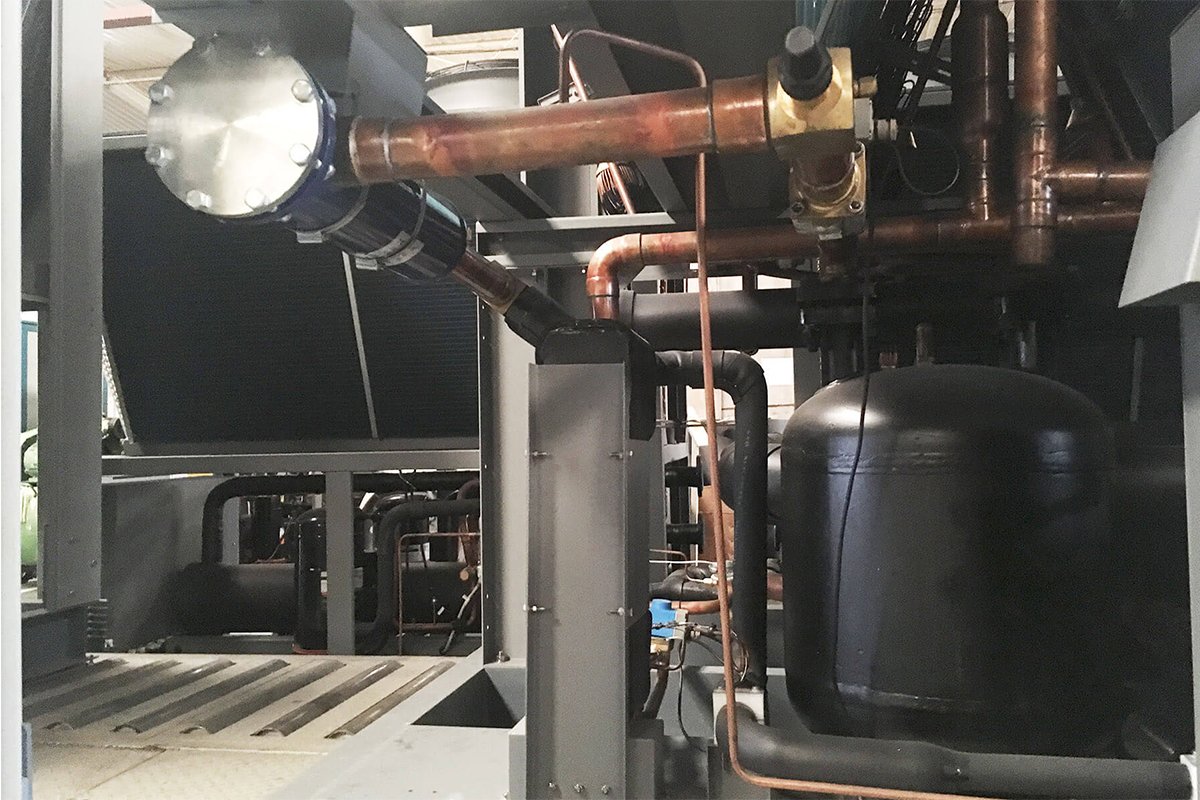

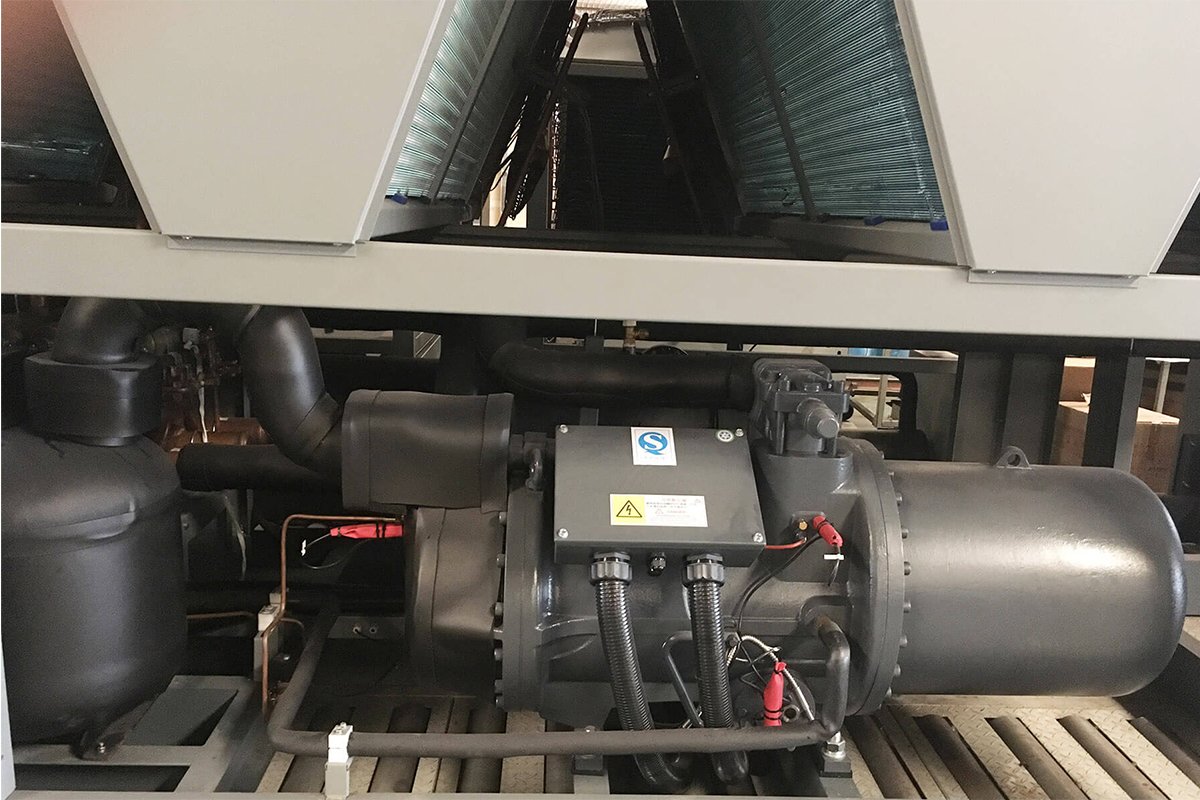

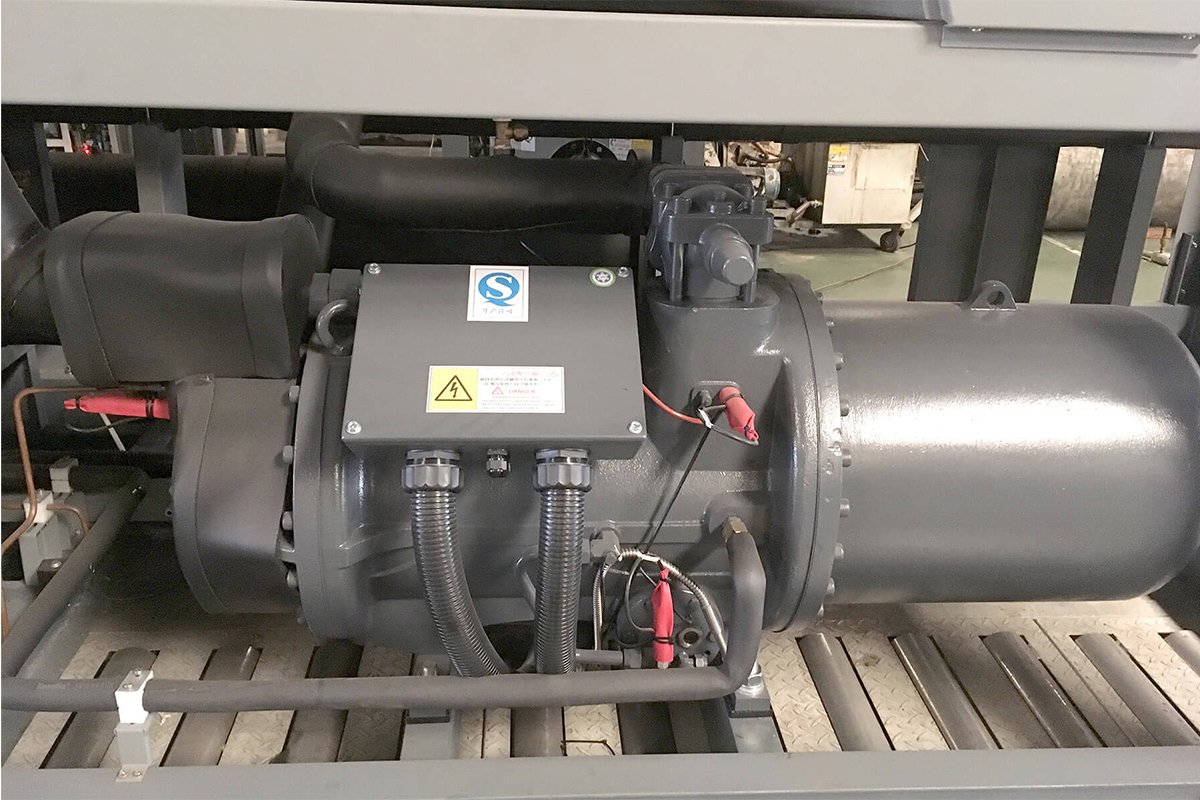

- Branded semi-hermetic screw compressor

- Both water-cooled or air-cooled condenser

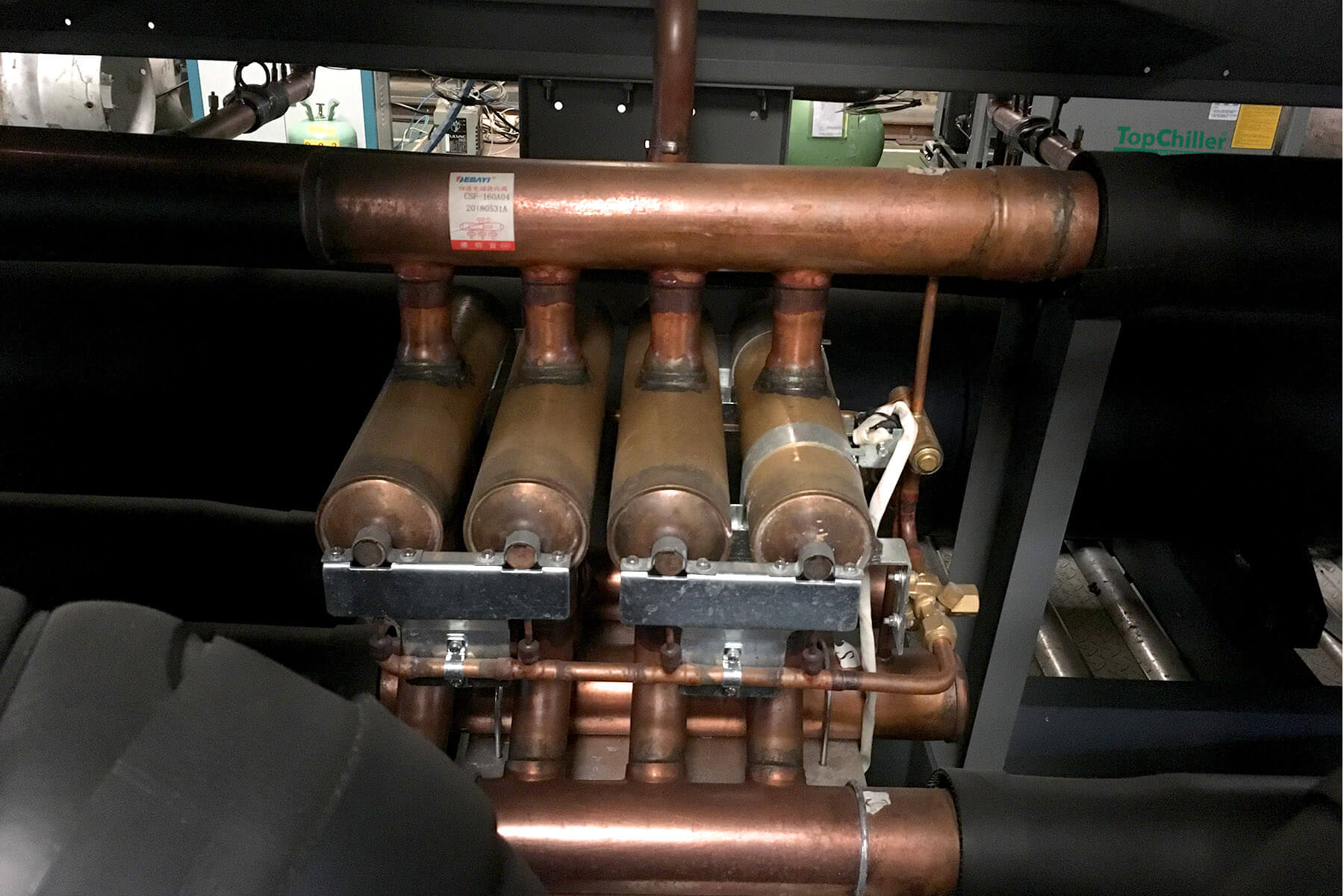

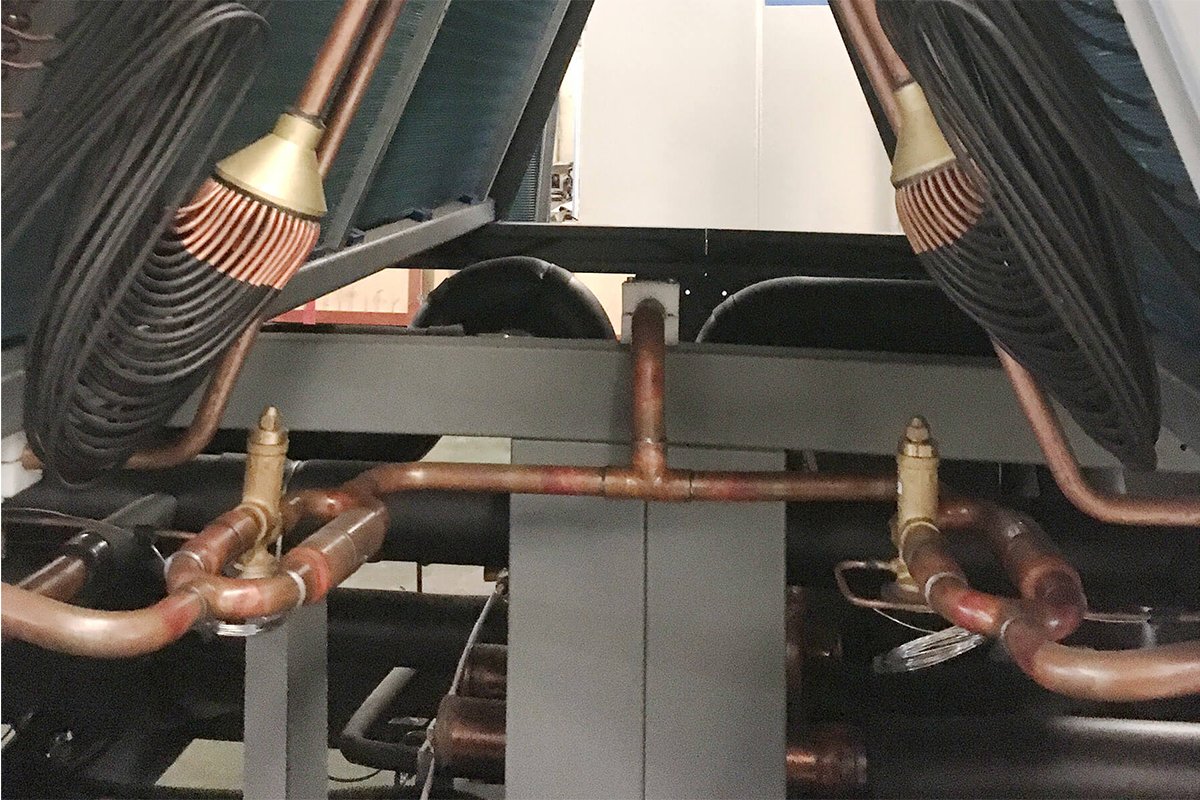

- Refrigerant with eliminator & evaporating tube

- Daily analysis and storage of operational records

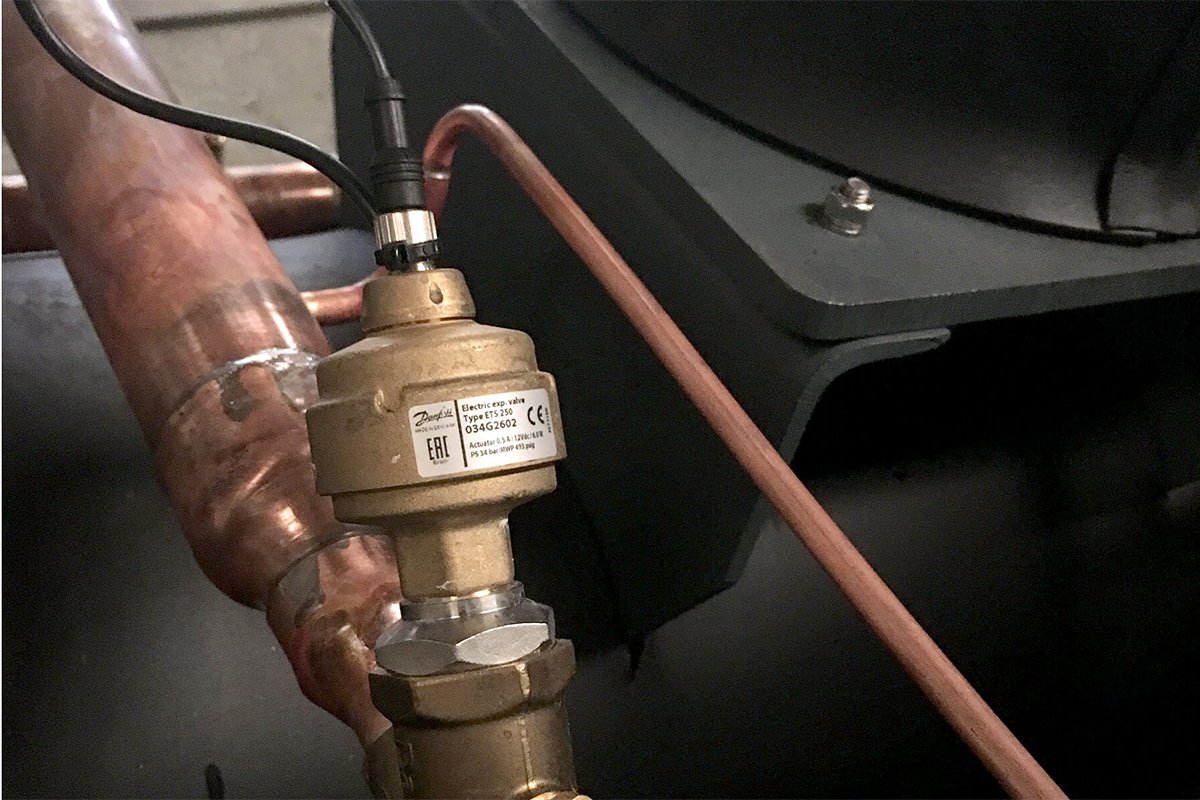

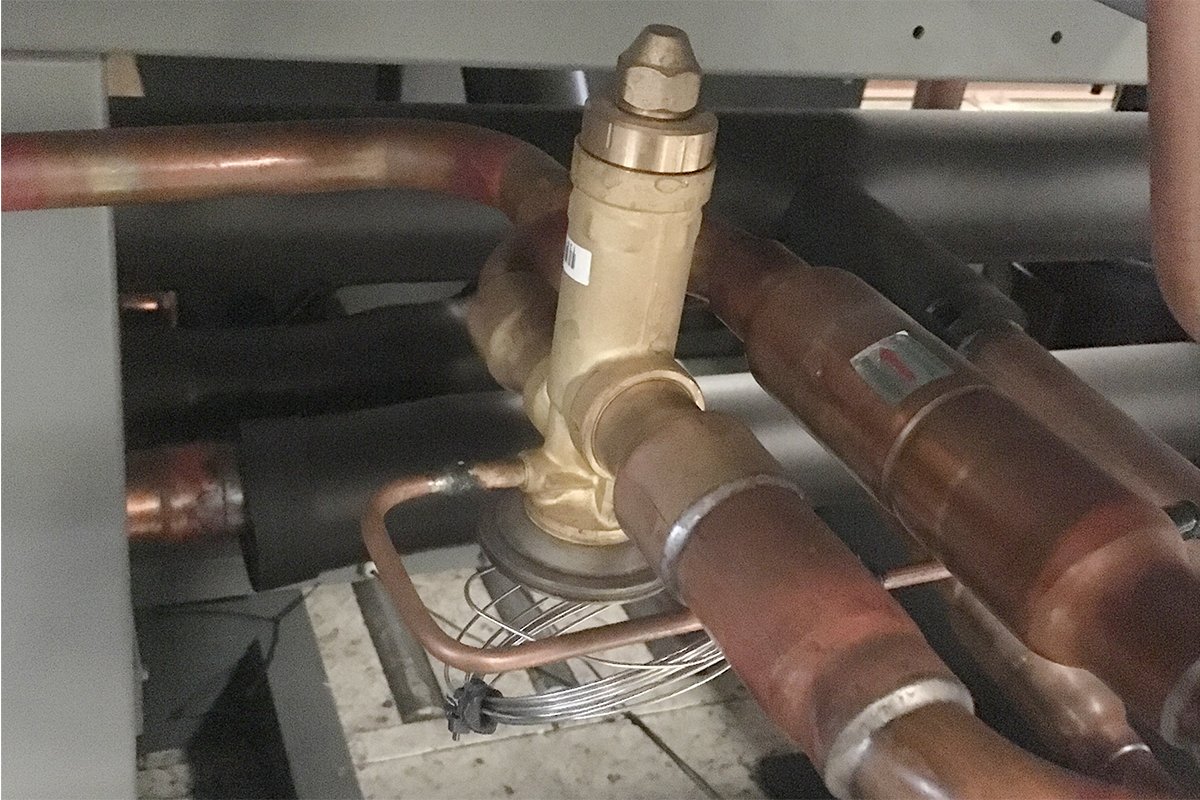

- Precise capacity controlling expansion valves

- Easy installation & lower costs of maintenance

Your Premier Screw Chiller Manufacturer and Supplier in China

Screw Chiller is a peculiar design cooling device that uses a screw compressor for cooling production mostly in central air conditioning systems by using either chilled water or air circulation.

TopChiller is a trustworthy company of China persistently working as manufacturer and supplier of Screw Chiller for over last twenty years of appreciating experience and credential integrity of products processing.

TopChiller Company is dedicated to using advanced technology and the best quality branded spare parts for the manufacturing of a full line of Screw Chiller models with varying capacities and supplying it around the world to meet the needs of customers proudly.

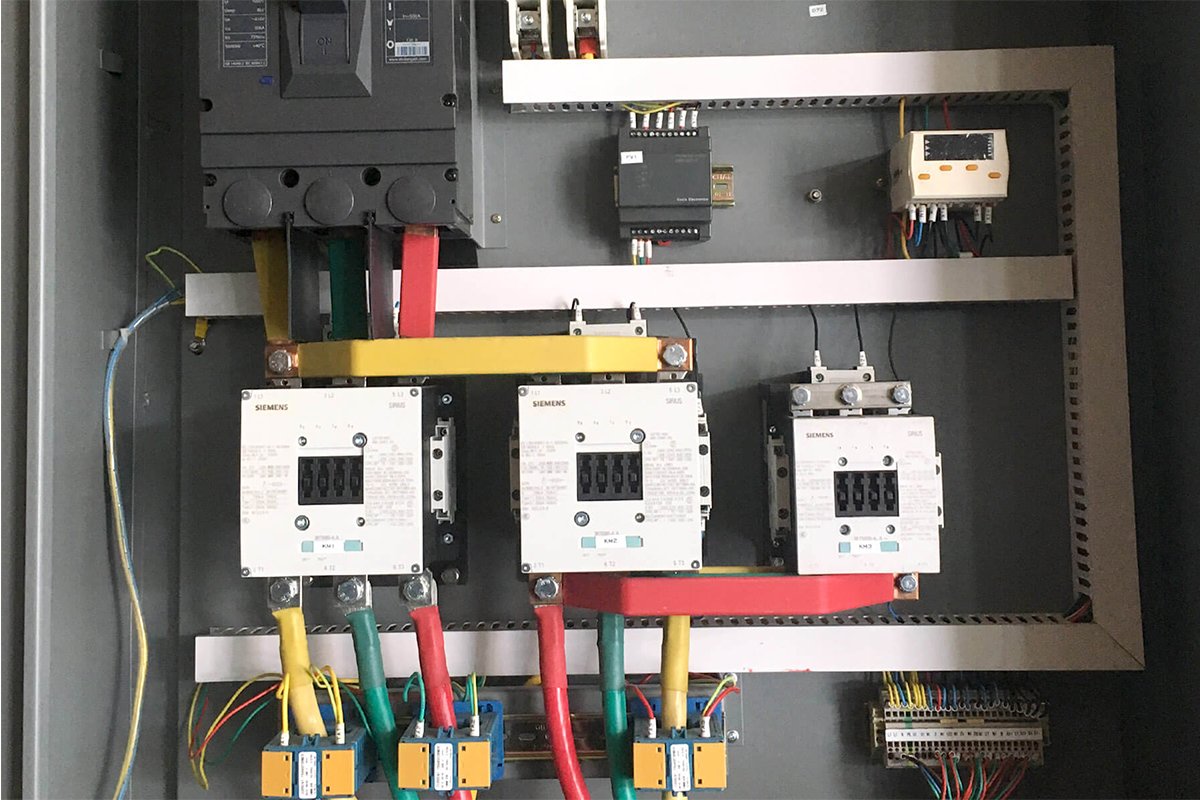

Screw Chiller is constituted of different components for efficient working as an evaporator, semi-hermetic screw compressor, evaporator tubes, eliminators, precise expansion valve, heat exchanger, suction filter, protecting devices, microprocessor control panel, and power supply.

TopChiller manufactured Screw Chiller has a wide variety of benefits to support different industrial processes as given below:

- Screw Chiller is highly precise and regular in its performance featured by PLC temperature controller that is capable of examining temperature fluctuations from set points with screen display and control it accordingly.

- TopChiller designed Screw Chiller is featured with an energy-efficient screw compressor generating compression on refrigerant for consistent heat release from equipment by using rotor and two-star wheels as its component.

- Screw Chiller has sound acoustic rotor fans and suction service valves ensuring the clean and steady flow of refrigerant in circulating coils of the unit by stopping air contaminants entry resulting in lower noise production.

- TopChiller brand Screw Chiller ensures reliable chilling supply to processing machines configured by the installation of a gravity-based refrigerant distribution system further supported by tubes and eliminators making instant circulation for all components of a machine.

- TopChiller designed Screw Chiller has rugged and compact design with corrosion-resistant stainless steel body prevents the unit from clogging and any obstruction by contamination bearing high ambient temperature.

- Screw Chiller has lower costs of maintenance having hot gas bypass valves and suction filters for cleaning as well as eco-friendly refrigerant installation makes it more reliable to use.

Screw Chiller is famous among different industrial applications as given below:

Central air conditioning systems as HVAC, commercial areas as hypermarkets and supermarkets, food processing, plastic industry, etc.

If you have intentions to purchase the best suitable, quality-assured, and industrious Screw Chiller for your application?

If you are planning to visit a manufacturing company of Screw Chiller guarantying consistent quality of all its unit components to build up your business?

Feel free and make contact with TopChiller personnel and trained employees to get optimal solutions for technical requirements for Screw Chiller customization at the best rates.

TopChiller sales are committed to satisfying our customers with a selection of a Screw Chiller best adjustable to your application without taking much time.

General Description:

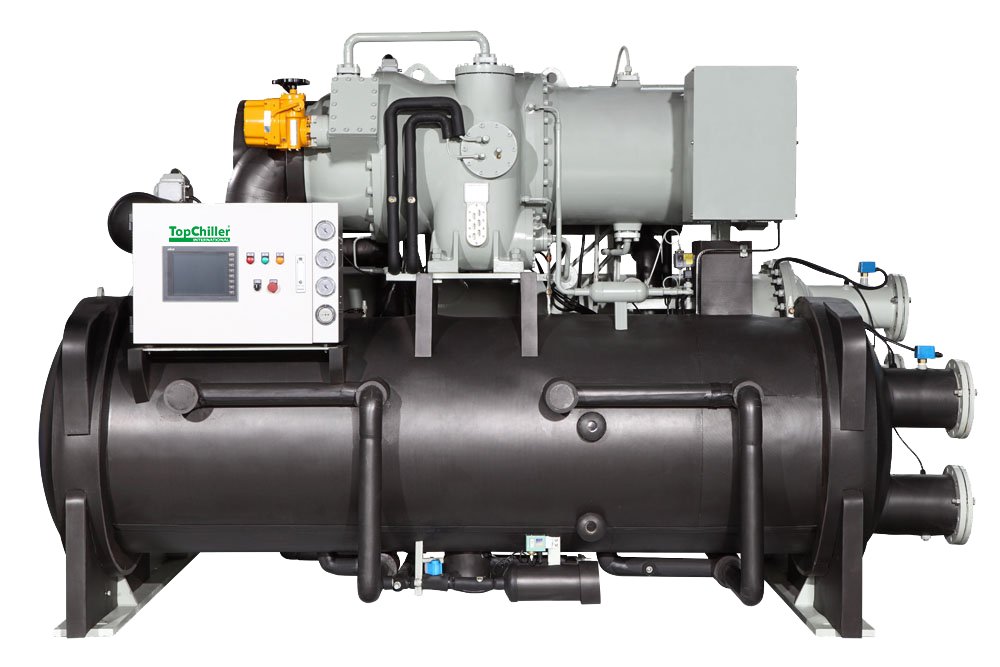

A Screw Chiller is a closed cooling mechanism that resolves all the heating problems in commercial and industrial lines of work. It is configured with a screw compressor and has several innovative and unique features, thus being an ideal cooling unit for various applications.

Like the rest of the chillers system, Screw Chiller designed by TopChiller consists of a branded screw compressor, evaporator, expansion valve, and controls.

Having common expertise in all major industries, the utility of Screw Chiller has a wide range of advantages in multiple applications like shopping malls, warehouses, factories, food processing, electroplating, chemical plants, restaurants, hotels, hospitals, printing plants, automobile factories, and far more.

TopChiller is a leading manufacturer and supplier of China that has developed long-term relationships with worldwide customers. We manufacture energy-efficient Screw Chiller at a large scale to meet the basic requirements claimed by clients over the last twenty years.

If you are looking for a reliable and trusted source that provides you with prime quality Screw Chillers with peak efficiency and less power consumption, your search ends here. TopChiller features it with outstanding advantages and little to almost no cons.

Contact our sales engineer to get your desired Screw Chiller at your doorstep, considering your budget and industrial requirements.

Features and Advantages:

TopChiller brand brings you a Screw Chiller that is not only efficient but it is also long-lasting.

- Best known for its quality, Screw Chiller comprises branded screw compressor with single and twin screw arrangements and an automatic capacity control system.

- It consists of secondary components that avert any operation failure. They may include compressor protection design timer, temperature sensor, over-current relay, sight glass, safety valve, oil heater, and so on.

- It can use air and water to fuel the condenser and get the cooling done. Therefore, it has been categorized into air cooled and water cooled Screw Chiller.

- Screw Chiller manufactured by TopChiller has completed all of its installation and performance tests, thereby reducing the commissioning time. It is already filled with refrigerant.

- It is robust in construction and has smooth operation. The compressor, evaporator, and expansion valve work in harmony to get the desired cooling in the system. They eliminate as much heat as possible.

- Data Sheet

- Image Gallery

- Main Parts

- Video

| Screw Chiller Technical Specifications | Screw Chiller Technical Specifications | |||||||||||||||||||||||

| Model Items | TPW-100WSH | TPW-135WSH | TPW-175WSH | TPW-190WSH | TPW-230WSH | TPW-255WSH | TPW-300WSH | TPW-350WSH | TPW-375WSH | TPW-415WSH | Model Items | TPW-470WSH | TPW-500WSH | TPW-560WSH | TPW-590WSH | TPW-610WSH | TPW-720WSH | TPW-790WSH | TPW-840WSH | TPW-940WSH | ||||

| Cooling Capacity | kcal/h | 86000 | 116100 | 150500 | 163400 | 197800 | 219300 | 258000 | 301000 | 322500 | 356900 | Cooling Capacity | kcal/h | 425700 | 447200 | 490200 | 533200 | 550400 | 645000 | 705200 | 756800 | 851400 | ||

| KW | 100 | 135 | 175 | 190 | 230 | 255 | 300 | 350 | 375 | 415 | KW | 495 | 520 | 570 | 620 | 640 | 750 | 820 | 880 | 990 | ||||

| Input Power | KW | 22 | 30 | 37 | 42 | 51 | 56 | 65 | 75 | 80 | 90 | Input Power | KW | 103 | 109 | 118 | 127 | 131 | 151 | 167 | 177 | 199 | ||

| Max Current | A | 40 | 53 | 67 | 73 | 89 | 97 | 109 | 126 | 137 | 153 | Max Current | A | 177 | 187 | 203 | 218 | 225 | 260 | 288 | 306 | 345 | ||

| Power Source | 3PH~380V/415V/480V~50HZ/60HZ(3PH~200V/220V 50HZ/60HZ) | Power Source | 3PH~380V/415V/480V~50HZ/60HZ(3PH~200V/220V 50HZ/60HZ) | |||||||||||||||||||||

| Refrigerant | Type | R22(R134a/R407c/R404A) | Refrigerant | Type | R22(R134a/R407c/R404A) | |||||||||||||||||||

| Charge | kg | 17 | 22 | 27 | 33 | 38 | 43 | 50 | 55 | 60 | 66 | Charge | kg | 82 | 88 | 94 | 100 | 110 | 121 | 132 | 143 | 165 | ||

| Control | Thermostatic expansion valve | Control | Thermostatic Expansion Valve | |||||||||||||||||||||

| Compressor | Type | Semi-hermetic screw | Compressor | Type | Semi-hermetic Screw | |||||||||||||||||||

| Power | KW | 22 | 30 | 37 | 42 | 51 | 56 | 65 | 75 | 80 | 90 | Power | KW | 103 | 109 | 118 | 127 | 131 | 151 | 167 | 177 | 199 | ||

| Start mode | Y-△ | Start Mode | Y-△ | |||||||||||||||||||||

| Capacity control | % | 0-33-66-100 | 0-25-50-75-100 | Capacity Control | % | 0-25-50-75-100 | ||||||||||||||||||

| Evaporator | Type | Shell and tube (SS plate heat exchanger) | Evaporator | Type | Shell and tube (SS plate heat exchanger) | |||||||||||||||||||

| Chilled water | m³/h | 17.2 | 23.2 | 30 | 32.7 | 40 | 43.9 | 51.6 | 60.2 | 64.5 | 71.4 | Chilled Water | m3/h | 85.1 | 89.4 | 98 | 106.6 | 110 | 129 | 141 | 151.3 | 170.4 | ||

| Water pressure | KPa | 35 | 35 | 35 | 38 | 40 | 42 | 42 | 45 | 45 | 43 | Water Pressure | KPa | 40 | 41 | 43 | 45 | 45 | 45 | 45 | 43 | 45 | ||

| Pipe connection | Inch | 3″ | 3″ | 3″ | 3″ | 4″ | 4″ | 4″ | 4″ | 4″ | 4″ | Pipe Connection | Inch | 5″ | 5″ | 5″ | 6″ | 6″ | 8″ | 8″ | 10″ | 10″ | ||

| Condenser | Type | Water cooled type shell and tube | Condenser | Type | water cooled type Shell and tube | |||||||||||||||||||

| Cooling water | m³/h | 21 | 28.4 | 36.6 | 40 | 48.3 | 53.5 | 62.8 | 73 | 78.2 | 86.8 | Cooling Water | m3/h | 102.8 | 108.2 | 118.3 | 128.5 | 132.6 | 155 | 169.7 | 181.8 | 204.5 | ||

| Water pressure | KPa | 42 | 42 | 42 | 43 | 42 | 43 | 43 | 45 | 45 | 45 | Water Pressure | KPa | 48 | 45 | 46 | 48 | 46 | 48 | 48 | 45 | 47 | ||

| Pipe connection | Inch | 3″ | 3″ | 3″ | 4″ | 4″ | 4″ | 4″ | 4″ | 5″ | 5″ | Pipe Connection | Inch | 5″ | 5″ | 6″ | 6″ | 6″ | 8″ | 8″ | 10″ | 10″ | ||

| Safety protection devices | Inner thermostat for compressor motor, unit overload relay, high and low pressure switch, freeze protection thermostat, reverse phase protection relay, discharge gas thermostat, flow switch | Safety protection devices | Inner thermostat for compressor motor, unit overload relay,high and low pressure switch, freeze protection thermostat, reverse phase protection relay, discharge gas thermostat, flow switch | |||||||||||||||||||||

| Dimension | Length | mm | 2150 | 2350 | 2450 | 2600 | 2750 | 2800 | 2800 | 2900 | 2900 | 3000 | Dimension | Length | mm | 3000 | 3100 | 3300 | 3500 | 3800 | 3900 | 4100 | 4300 | 4500 |

| Width | mm | 560 | 620 | 650 | 680 | 780 | 950 | 950 | 950 | 950 | 1200 | Width | mm | 1200 | 1250 | 1380 | 1380 | 1380 | 1380 | 1450 | 1480 | 1480 | ||

| Height | mm | 1550 | 1650 | 1650 | 1650 | 1650 | 1800 | 1950 | 1950 | 1950 | 1580 | Height | mm | 1580 | 1630 | 1630 | 1750 | 1750 | 1750 | 1780 | 1780 | 1780 | ||

| Net weight | kg | 650 | 900 | 1050 | 1200 | 1550 | 1800 | 1900 | 2050 | 2050 | 2350 | Net weight | kg | 2500 | 2500 | 2650 | 2850 | 3150 | 3350 | 3620 | 3850 | 4160 | ||

| Running weight | kg | 820 | 1050 | 1200 | 1400 | 1800 | 2100 | 2200 | 2350 | 2380 | 2530 | Running weight | kg | 2700 | 3000 | 3100 | 3350 | 3750 | 4000 | 4300 | 4600 | 5000 | ||

| The above specifications are according to the following design conditions: 1, Chilled water inlet/outlet temperature 12℃/7℃. 2, Cooling water inlet/outlet temperature 25℃/30℃. We reserve the right to modify the specifications without further notice. | The above specifications are according to the following design conditions: 1, Chilled water inlet/outlet temperature 12℃/7℃. 2, Cooling water inlet/outlet temperature 25℃/30℃. We reserve the right to modify the specifications without further notice. | |||||||||||||||||||||||

| Screw Chiller Technical Specifications | Screw Chiller Technical Specifications | |||||||||||||||||||||||

| Model Items | TPW-200WDH | TPW-270WDH | TPW-350WDH | TPW-380WDH | TPW-460WDH | TPW-510WDH | TPW-600WDH | TPW-700WDH | TPW-750WDH | TPW-830WDH | Model Items | TPW-990WDH | TPW-1040WDH | TPW-1140WDH | TPW-1240WDH | TPW-1280WDH | TPW-1500WDH | TPW-1640WDH | TPW-1760WDH | TPW-1980WDH | ||||

| Cooling Capacity | kcal/h | 172000 | 232200 | 301000 | 326800 | 395600 | 438600 | 516000 | 602000 | 645000 | 713800 | Cooling Capacity | kcal/h | 851400 | 894400 | 980400 | 1066400 | 1100800 | 1290000 | 1410400 | 1513600 | 1702800 | ||

| KW | 200 | 270 | 350 | 380 | 460 | 510 | 600 | 700 | 750 | 830 | KW | 990 | 1040 | 1140 | 1240 | 1280 | 1500 | 1640 | 1760 | 1980 | ||||

| Input Power | KW | 44 | 60 | 74 | 84 | 102 | 112 | 130 | 150 | 160 | 180 | Input Power | KW | 206 | 218 | 236 | 254 | 262 | 302 | 334 | 354 | 398 | ||

| Max Current | A | 40 | 53 | 67 | 73 | 89 | 97 | 109 | 126 | 137 | 153 | Max Current | A | 354 | 374 | 406 | 436 | 450 | 520 | 576 | 612 | 490 | ||

| Power Source | 3PH~380V/415V/480V~50HZ/60HZ(3PH~200V/220V 50HZ/60HZ) | Power Source | 3PH~380V/415V/480V~50HZ/60HZ(3PH~200V/220V 50HZ/60HZ) | |||||||||||||||||||||

| Refrigerant | Type | R22 (R134a / R407c / R404A) | Refrigerant | Type | R22 (R134a / R407c / R404A) | |||||||||||||||||||

| Charge | kg | 17×2 | 22×2 | 27×2 | 33×2 | 38×2 | 43×2 | 50×2 | 55×2 | 60×2 | 66×2 | Charge | kg | 82×2 | 88×2 | 94×2 | 100×2 | 110×2 | 121×2 | 132×2 | 143×2 | 165×2 | ||

| Control | Thermostatic expansion valve | Control | Thermostatic expansion valve | |||||||||||||||||||||

| Compressor | Type | Semi-hermetic screw | Compressor | Type | Semi-hermetic screw | |||||||||||||||||||

| Power | KW | 22×2 | 30×2 | 37×2 | 42×2 | 51×2 | 56×2 | 65×2 | 75×2 | 80×2 | 90×2 | Power | KW | 103×2 | 109×2 | 118×2 | 127×2 | 131×2 | 151×2 | 167×2 | 177×2 | 199×2 | ||

| Start mode | Y-△ | Start mode | Y-△ | |||||||||||||||||||||

| Capacity Control | % | 0-33-66-100 | 0-25-50-75-100 | Capacity control | % | 0-25-50-75-100 | ||||||||||||||||||

| Evaporator | Type | Shell and tube (SS plate heat exchanger) | Evaporator | Type | Shell and tube (SS plate heat exchanger) | |||||||||||||||||||

| Chilled Water | m3/h | 34 | 46 | 60 | 65 | 79 | 88 | 103 | 120 | 120 | 143 | Chilled water | m³/h | 170 | 179 | 196 | 213 | 220 | 258 | 282 | 303 | 340 | ||

| Water Pressure | KPa | 35 | 35 | 35 | 38 | 40 | 42 | 42 | 45 | 45 | 43 | Water pressure | KPa | 40 | 41 | 43 | 45 | 45 | 45 | 45 | 43 | 45 | ||

| Pipe Connection | Inch | 4″ | 4″ | 4″ | 5″ | 5″ | 6″ | 6″ | 6″ | 8″ | 8″ | Pipe connection | Inch | 8″ | 8″ | 8″ | 8″ | 10″ | 10″ | 10″ | 12″ | 12″ | ||

| Condenser | Type | Water cooled type shell and tube | Condenser | Type | Water cooled type shell and tube | |||||||||||||||||||

| Cooling Water | m3/h | 42 | 57 | 73 | 80 | 97 | 107 | 126 | 146 | 156 | 174 | Cooling water | m³/h | 206 | 216 | 237 | 257 | 265 | 310 | 339 | 364 | 409 | ||

| Water Pressure | KPa | 42 | 42 | 42 | 43 | 42 | 43 | 43 | 45 | 45 | 45 | Water pressure | KPa | 48 | 45 | 46 | 48 | 46 | 48 | 48 | 45 | 47 | ||

| Pipe Connection | Inch | 4″ | 4″ | 4″ | 5″ | 6″ | 4″×2 | 4″×2 | 4″×2 | 5″×2 | 5″×2 | Pipe connection | Inch | 5″×2 | 5″×2 | 6″×2 | 6″×2 | 6″×2 | 8″×2 | 8″×2 | 10″×2 | 10″×2 | ||

| Safety protection devices | Inner thermostat for compressor motor, unit overload relay,high and low pressure switch, freeze protection thermostat, reverse phase protection relay, discharge gas thermostat, flow switch | Safety Protection Devices | Inner thermostat for compressor motor, unit overload relay,high and low pressure switch, freeze protection thermostat, reverse phase protection relay, discharge gas thermostat, flow switch | |||||||||||||||||||||

| Dimension | Length | mm | 2750 | 2800 | 2800 | 2950 | 2950 | 3150 | 3480 | 3480 | 3480 | 3650 | Dimension | Length | mm | 3650 | 3650 | 3750 | 3750 | 4230 | 4230 | 4350 | 4350 | 4420 |

| Width | mm | 750 | 780 | 780 | 810 | 810 | 850 | 875 | 875 | 895 | 1120 | Width | mm | 1120 | 1220 | 1300 | 1450 | 1380 | 1480 | 1450 | 1560 | 1650 | ||

| Height | mm | 1650 | 1650 | 1650 | 1650 | 1750 | 1750 | 1850 | 1850 | 1850 | 1950 | Height | mm | 1950 | 1950 | 2100 | 2150 | 2150 | 2250 | 2250 | 2300 | 2450 | ||

| Net weight | kg | 1650 | 1800 | 1850 | 2200 | 2450 | 2650 | 2800 | 2800 | 3450 | 3750 | Net weight | kg | 3950 | 4100 | 4450 | 4700 | 5000 | 5250 | 5500 | 5750 | 6000 | ||

| Running weight | kg | 1950 | 2180 | 2240 | 2660 | 2960 | 3200 | 3380 | 3580 | 4160 | 4360 | Running weight | kg | 4760 | 4770 | 5270 | 5460 | 5800 | 6100 | 6400 | 6680 | 6970 | ||

| The above specifications are according to the following design conditions: 1, Chilled water inlet/outlet temperature 12℃/7℃. 2, Cooling water inlet/outlet temperature 25℃/30℃. We reserve the right to modify the specifications without further notice. | The above specifications are according to the following design conditions: 1, Chilled water inlet/outlet temperature 12℃/7℃. 2, Cooling water inlet/outlet temperature 25℃/30℃. We reserve the right to modify the specifications without further notice. | |||||||||||||||||||||||

| Screw Chiller Technical Specifications | ||||||||||||||

| Model Items | TPAS-80ASH | TPAS-110ASH | TPAS-140ASH | TPAS-160ASH | TPAS-190ASH | TPAS-210ASH | TPAS-250ASH | TPAS-290ASH | TPAS-310ASH | TPAS-340ASH | TPAS-400ASH | TPAS-430ASH | ||

| Cooling capacity | kcal/h | 68800 | 94600 | 122980 | 135020 | 164260 | 180600 | 212420 | 245100 | 266600 | 292400 | 348300 | 369800 | |

| KW | 80 | 110 | 143 | 157 | 191 | 210 | 247 | 285 | 310 | 340 | 405 | 430 | ||

| Input power | KW | 32.5 | 43.6 | 54.7 | 59.7 | 73.6 | 79.6 | 88.2 | 101.2 | 112.8 | 123.8 | 145 | 155 | |

| Max Current | A | 57 | 75 | 95 | 103 | 125 | 135 | 151 | 173 | 191 | 211 | 246 | 263 | |

| Power source | 3PH~380V/415V/480V~50HZ/60HZ(3PH~200V/220V 50HZ/60HZ) | |||||||||||||

| Refrigerant | Type | R22(R134a/R407c/R404A) | ||||||||||||

| Charge | kg | 21 | 28 | 35 | 42 | 49 | 56 | 63 | 70 | 77 | 84 | 98 | 112 | |

| Control | Thermostatic expansion valve | |||||||||||||

| Compressor | Type | Semi-hermetic screw | ||||||||||||

| Power | KW | 30 | 40 | 50 | 55 | 67 | 73 | 82 | 95 | 104 | 115 | 134 | 142 | |

| Start mode | Y-△ | |||||||||||||

| Capacity control | % | 0-33-66-100 | 0-25-50-75-100 | |||||||||||

| Evaporator | Type | Shell and tube (SS plate heat exchanger) | ||||||||||||

| Chilled water | m³/h | 13.8 | 18.9 | 24.6 | 27.0 | 32.8 | 36.1 | 42.5 | 49.0 | 53.3 | 58.4 | 70.0 | 74.0 | |

| Water pressure | KPa | 32 | 32 | 35 | 38 | 42 | 42 | 45 | 43 | 43 | 43 | 41 | 43 | |

| Pipe connection | Inch | 3″ | 3″ | 3″ | 4″ | 4″ | 4″ | 4″ | 4″ | 5″ | 5″ | 6″ | 6″ | |

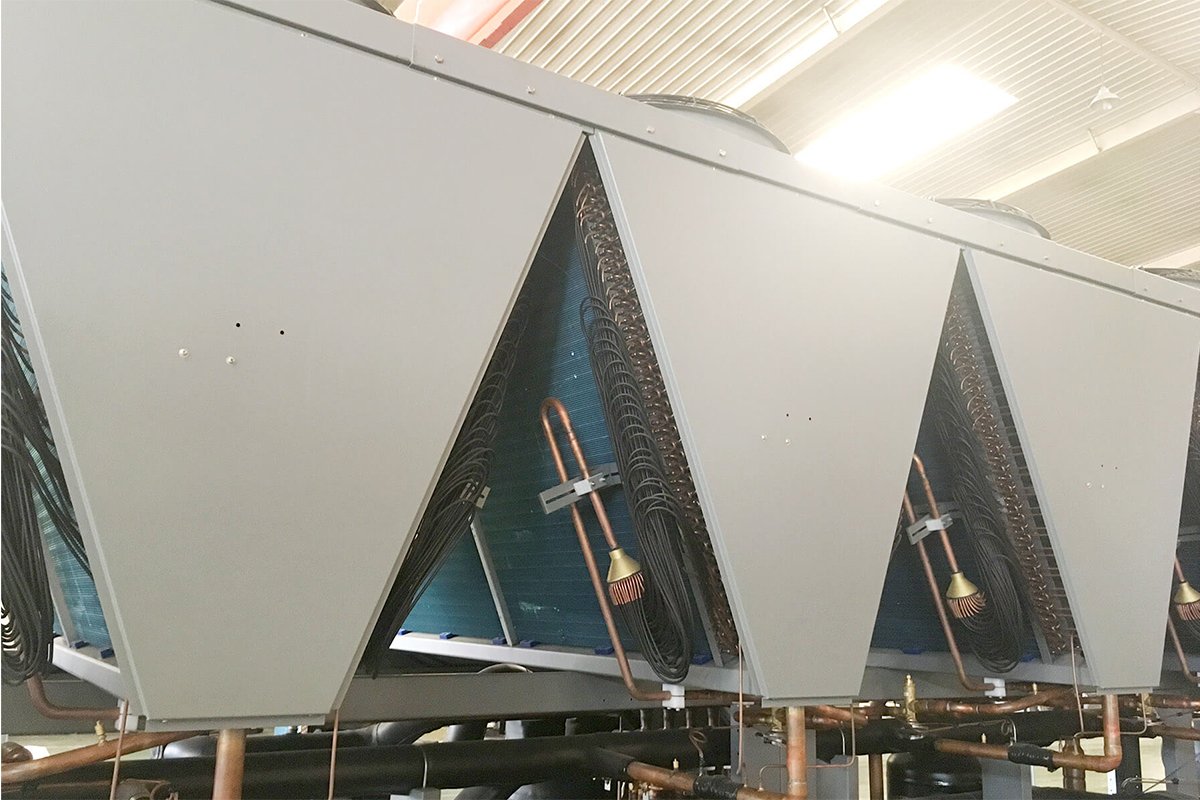

| Condenser | Type | Air cooled type high efficiency finned cooper tube | ||||||||||||

| Fan | Type | m³/h | Big volume & low noise axil fan | |||||||||||

| Power | KW | 0.42×6 | 0.6×6 | 0.78×6 | 0.78×6 | 1.1×6 | 1.1×6 | 0.78×8 | 0.78×8 | 1.1×8 | 1.1×8 | 1.1×10 | 1.1×12 | |

| Air volume | m³/h | 30000 | 40000 | 50000 | 60000 | 70000 | 80000 | 90000 | 100000 | 110000 | 116000 | 145000 | 165000 | |

| Safety protection devices | Inner thermostat for compressor motor, unit overload relay,high and low pressure switch, freeze protection thermostat, reverse phase protection relay, discharge gas thermostat, flow switch | |||||||||||||

| Dimension | Length | mm | 2200 | 2350 | 2600 | 2600 | 2650 | 2650 | 3400 | 3400 | 3800 | 3800 | 4800 | 5800 |

| Width | mm | 1150 | 1350 | 1500 | 1500 | 1900 | 1900 | 1700 | 1700 | 1900 | 1900 | 1900 | 1900 | |

| Height | mm | 1980 | 2000 | 2100 | 2100 | 2200 | 2200 | 2200 | 2200 | 2200 | 2200 | 2200 | 2200 | |

| Net weight | kg | 1100 | 1300 | 1600 | 1900 | 2200 | 2350 | 2550 | 2800 | 2850 | 2950 | 3200 | 3550 | |

| Running weight | kg | 1300 | 1500 | 1840 | 2200 | 2530 | 2700 | 2950 | 3250 | 3350 | 3560 | 3650 | 3950 | |

| The above specifications are according to the following design conditions: 1, Chilled water inlet/outlet temperature 12℃/7℃. 2, Cooling air inlet/outlet temperature 30℃/38℃. We reserve the right to modify the specifications without further notice. | ||||||||||||||

| Screw Chiller Technical Specifications | ||||||||||||||

| Model Items | TPAS-160ADH | TPAS-220ADH | TPAS-285ADH | TPAS-315ADH | TPAS-380ADH | TPAS-420ADH | TPAS-495ADH | TPAS-570ADH | TPAS-620ADH | TPAS-680ADH | TPAS-810ADH | TPAS-860ADH | ||

| Cooling capacity | kcal/h | 137600 | 189200 | 245960 | 270040 | 328520 | 361200 | 424840 | 490200 | 533200 | 584800 | 696600 | 739600 | |

| KW | 160 | 220 | 286 | 314 | 382 | 420 | 494 | 570 | 620 | 680 | 810 | 860 | ||

| Input power | KW | 64.7 | 86.6 | 106.2 | 118.8 | 145 | 159.2 | 177.2 | 207.6 | 225.6 | 247.6 | 290 | 310.4 | |

| Max Current | A | 114 | 149 | 185 | 205 | 250 | 274 | 308 | 358 | 388 | 428 | 500 | 533 | |

| Power Source | 3PH~380V/415V/480V~50HZ/60HZ(3PH~200V/220V 50HZ/60HZ) | |||||||||||||

| Refrigerant | Type | R22(R134a/R407c/R404A) | ||||||||||||

| Charge | kg | 21×2 | 28×2 | 35×2 | 42×2 | 49×2 | 56×2 | 63×2 | 70×2 | 77×2 | 84×2 | 98×2 | 112×2 | |

| Control | Thermostatic expansion valve | |||||||||||||

| Compressor | Type | Semi-hermetic screw | ||||||||||||

| Power | KW | 30×2 | 40×2 | 50×2 | 55×2 | 67×2 | 73×2 | 82×2 | 95×2 | 104×2 | 115×2 | 134×2 | 142×2 | |

| Start mode | Y-△ | |||||||||||||

| Capacity control | % | 0-33-66-100 | 0-25-50-75-100 | |||||||||||

| Evaporator | Type | Shell and tube (SS plate heat exchanger) | ||||||||||||

| Chilled water | m³/h | 27.5 | 37.8 | 49.1 | 54 | 65.7 | 72.2 | 85 | 98 | 106.6 | 117 | 139.3 | 147.9 | |

| Water pressure | KPa | 32 | 32 | 35 | 38 | 42 | 42 | 45 | 43 | 43 | 43 | 41 | 43 | |

| Pipe connection | Inch | 4″ | 4″ | 4″ | 5″ | 6″ | 6″ | 6″ | 6″ | 8″ | 8″ | 8″ | 10″ | |

| Condenser | Type | Air cooled type high efficiency finned cooper tube | ||||||||||||

| Fan | Type | m³/h | Big volume & low noise axil fan | |||||||||||

| Power | KW | 0.78×6 | 1.1×6 | 0.78×8 | 1.1×8 | 1.1×10 | 1.1×12 | 1.1×12 | 1.1×16 | 1.1×16 | 1.1×16 | 1.1×20 | 1.1×24 | |

| Air volume | m³/h | 60000 | 80000 | 100000 | 116000 | 145000 | 165000 | 180000 | 205000 | 225000 | 242000 | 285000 | 325000 | |

| Safety protection devices | Inner thermostat for compressor motor, unit overload relay, high and low pressure switch, freeze protection thermostat, reverse phase protection relay, discharge gas thermostat, flow switch | |||||||||||||

| Dimension | Length | mm | 2600 | 2650 | 3400 | 3800 | 4800 | 5800 | 5800 | 7800 | 7800 | 8000 | 9800 | 11600 |

| Width | mm | 1500 | 1900 | 1700 | 1900 | 1900 | 1900 | 2200 | 2000 | 2200 | 2200 | 2200 | 2200 | |

| Height | mm | 2100 | 2200 | 2200 | 2200 | 2200 | 2200 | 2300 | 2250 | 2250 | 2300 | 2350 | 2350 | |

| Net weight | kg | 2050 | 2520 | 2980 | 3180 | 3420 | 3730 | 3950 | 4330 | 4650 | 4930 | 5450 | 5850 | |

| Running weight | kg | 2360 | 2870 | 3420 | 3690 | 3780 | 4180 | 4380 | 4650 | 4920 | 5360 | 5830 | 6530 | |

| The above specifications are according to the following design conditions: 1, Chilled water inlet/outlet temperature 12℃/7℃. 2, Cooling air inlet/outlet temperature 30℃/38℃. We reserve the right to modify the specifications without further notice. | ||||||||||||||

Why TopChiller is Your Reliable Screw Chiller Manufacturer and Supplier In China?

Screw Chiller-An Ultimate FAQ Guide by TopChiller

- What is a Screw Chiller?

- What are the Features of the Screw Chiller?

- What are the Main Components of a Screw Chiller?

- What is the Working Principle of a Screw Chiller?

- What is the Difference Between Air Cooled Screw Chiller and Water Cooled Screw Chiller?

- Which Industrial and Commercial Applications Require Screw Chiller?

- What are the Benefits of a Screw Chiller for your Applications?

- What is the Difference Between Screw Chiller Chiller and Scroll Chiller?

- What is the Cooling Capacity of a Screw Chiller?

- What is the Difference Between a Screw Chiller and a Centrifugal Chiller?

- What is the Role of Screw Compressors in a Screw Chiller?

- What are the Three Major Types of Evaporators Used in a Screw Chiller?

- What are the Electrical Requirements of the Screw Chiller?

- What is the Advanced Control Unit System of the Screw Chiller?

- What is the Multi-Level Protection Feature of a Screw Chiller?

- How to Choose the Right Type of Screw Chiller for your Applications?

- How to Install your Screw Chiller?

- What is the Common Fault Analysis of Screw Chiller?

- What are the Reasons and Treatment of Irregular Vibration your Screw Chiller?

- How to Increase the Performance of your Screw Chiller?

What is a Screw Chiller?

A Screw Chiller is a heat-removing source that drives the vapour-compression refrigeration process and thus offers cooling solutions to the essential applications.

Its refrigeration system uses two interlocking rotating helical rotors to propel and compress the refrigerant vapor. Rotary motion and few moving parts make it durable and less noisy.

The Screw Chiller also consists of a high and low voltage protector that ensures the safety and protection of the unit in case of sudden voltage changes.

The easy maintenance and installation processes make it an absolute steal for users looking for a device that meets all their commercial and industrial needs.

Screw Chiller Fabricated by TopChiller

What are the Features of the Screw Chiller?

Some of Screw Chiller’s distinctive features are mentioned as under:

- The evaporator and condenser are carefully integrated inside the unit, thus saving additional space in the machine room area.

- Thanks to its compact size and structure, it doesn’t need a sound foundation. You can even place it on every floor because it produces fewer vibrations than its alternatives.

- Having the highest ambient temperature at 50°C, it works just fine even in summer.

- It is composed of a few parts; it saves you installation time.

- Screw Chiller is also equipped with the feature of multiple refrigeration circuits. The cycle control installed in the various compressors balances the load efficiently.

- There is always a back circuit in the unit if any circuits need maintenance.

- Some of the features make it an environment-friendly and energy-saving machine. The Artificial Intelligence Technology makes sure the capacity is adjusted with the need. So that energy can be saved, and the environment is also protected from the contamination of particles.

- In addition to the features mentioned above, it also outshines the other products because of its simple design, few to none exhausting parts, reduced failure rate, and easy adjustment methods.

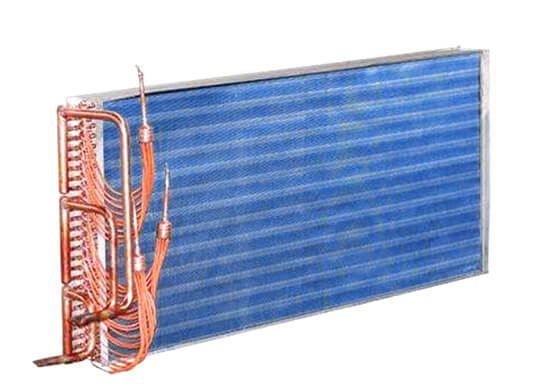

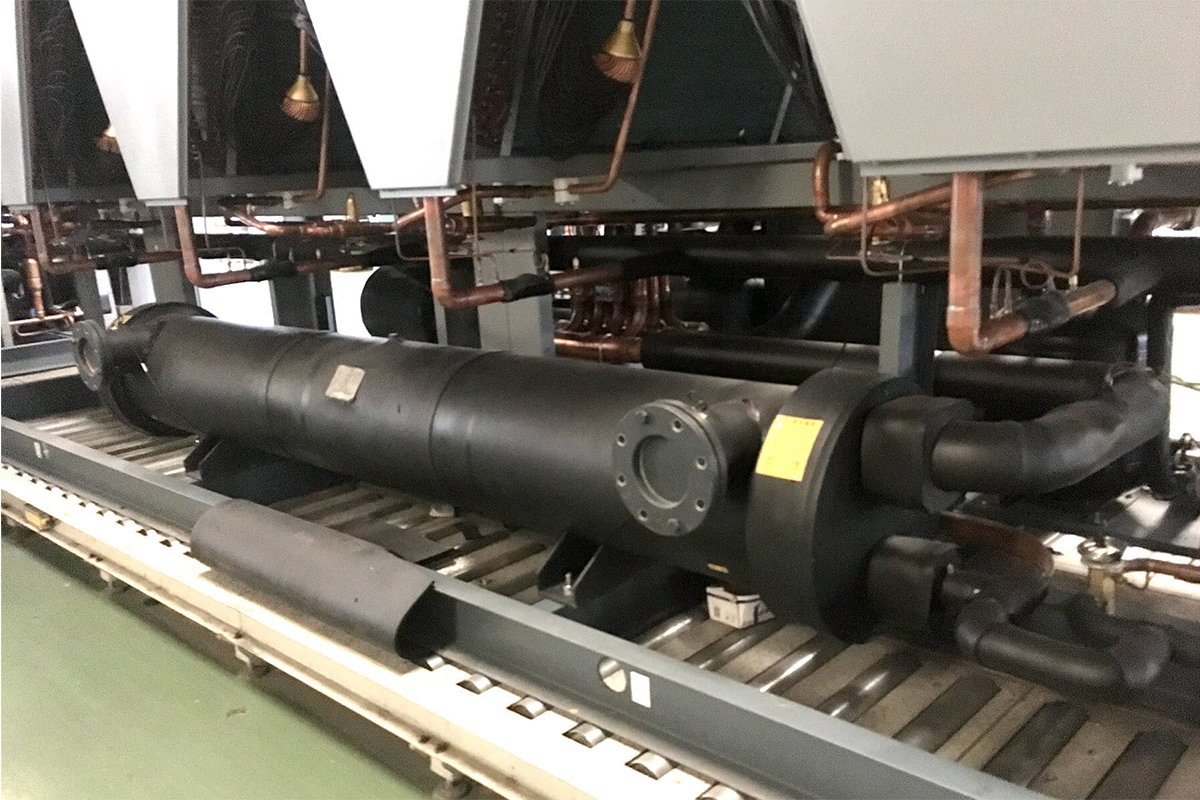

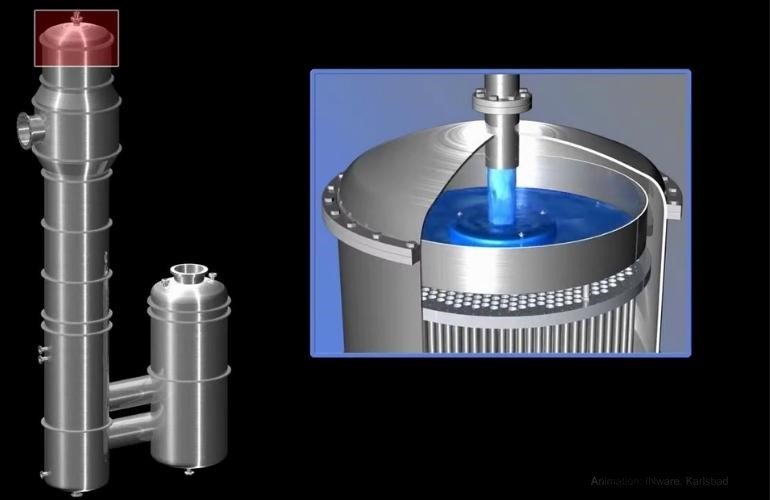

Screw Chiller Evaporator

What are the Main Components of a Screw Chiller?

Like every other chiller system, the main components of a Screw Chiller include compressor, evaporator, expansion valve, and controls.

Compressor

The compressor is the key component that differentiates the Screw Chiller from the rest of the chiller system. The two spiral rotors have a role in driving and compressing the refrigerant into vapor.

Situated in the stationary casing of the unit, the screw compressor rotates the refrigerant and increases the pressure from low to high.

The compressor also provides the medium load for the medium application.

Evaporator

The evaporator, also termed ‘heat exchanger’, gets rid of the unwanted heat from the liquid, thus cooling the water.

It is expensive to get the water cool, so the evaporator is insulated to keep the water from absorbing heat from the surrounding.

Expansion Valve

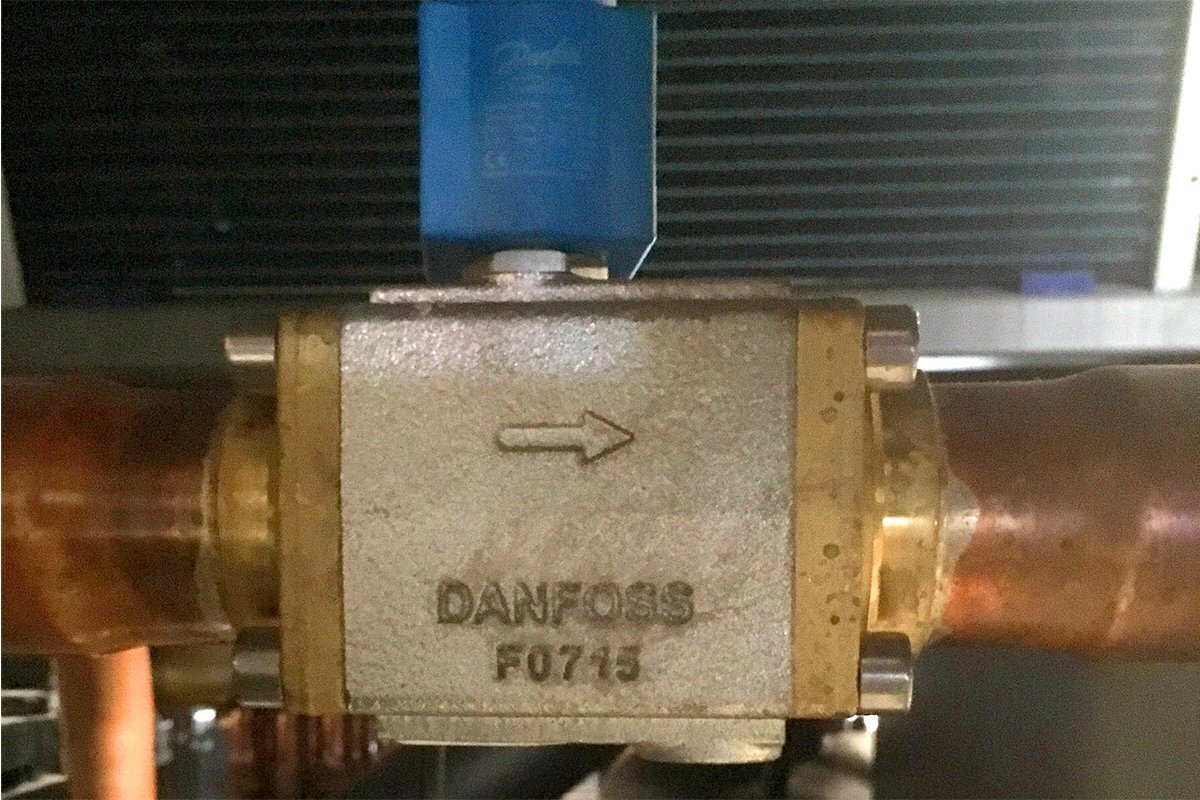

The flow of refrigerants to the refrigeration is controlled by the expansion valve, which is another important component of the Screw Chiller.

The expansion valve performs the task of transitioning the liquid refrigerant with high pressure in the condenser to the refrigerant with low pressure in an evaporator.

Besides, it also controls the flow rate and helps the unit get the desired load for the application.

Controls

The necessary controls of the unit include the control for the cooling capacity, the control for the flow rate of liquid, and the control for indicating any fault in the system.

In addition to this, the required temperature can also be set on the control system.

Screw Chiller Expansion Valve

What is the Working Principle of a Screw Chiller?

Screw Chiller operates readily only when all of its components work simultaneously in the following steps:

Step 1

The compressor converts the refrigerant into high pressure and high-temperature state.

Later, the compressed refrigerant cools down. The condenser does its job by condensing under constant pressure. Lastly, the refrigerant turns into a liquid refrigerant.

Step 2

The expansion valve expands the liquid refrigerant to the low pressure, which becomes a mixture of gas and liquid.

Under low temperature and pressure, heat absorption by liquid takes place. After the heat is absorbed, the evaporator cools the liquid.

Step 3

The cooling turns the refrigerant into a gas again. The final step is when the gas state of the refrigerant reaches the compressor, and the cycle goes back to the start.

What is the Difference Between Air Cooled Screw Chiller and Water Cooled Screw Chiller?

Air Cooled Screw Chiller is a cooling mechanism that cools the ambient air using compression pressure.

It removes the unnecessary heat from the system by circulating that chilled air in different commercial and industrial applications.

The automatic scheduling feature installed in the unit makes the cooling operation very smooth and fluent.

It controls the refrigerant’s compression force and monitors the cooling load for balancing the set point.

The expansion valve and economizer enhance the unit’s cooling capacity and protect it from all kinds of damaging effects resulting from high pressure.

During the cooling operation, there is almost little to no noise because the twin-screw compressor rotation produces the least vibrations possible.

Air Cooled Screw Chiller is perfectly reliable and functional as the factory thoroughly tests all the components before installation.

A control panel is also installed to analyze the unit’s temperature and pressure.

Water Cooled Screw Chiller is a cooling device that works on the compression and refrigeration principle.

It uses chilled water running inside the unit coils to remove the wasted heat from the environment.

It consists of a screw compressor, pressure gauge, temperature controller, condenser, heat exchanger, water tank, Emerson filter, valve, electric box, etc.

The energy-efficient screw compressor discharges the heat steadily and instantly by enforcing a compression force on the chilled water so that it can circulate fast without freezing.

The air filters remove all the impurities from the water before it enters the main circulation.

Water Cooler Screw Chiller is easily installed for large capacity applications because of its stainless steel compact body and fewer moving parts.

Which Industrial and Commercial Applications Require Screw Chiller?

Screw Chiller is used in several industrial and commercial fields. Some of them are mentioned as under:

- Hospitals

- Supermarkets

- Shopping Malls

- Hotels

- Labs

- Rubber Manufacturing

- Beverage Industry

- Automobile Industry

- Chemical Processing

- Pharmaceutical Industry

- Plastic And Steel Manufacturing

- Medical Industry

- Electronic Production

- Ultrasonic Cooling

- Electroplating

- Printing

Industrial Applications of Screw Chiller

What are the Benefits of a Screw Chiller for your Applications?

The advanced technology used in the making of Screw Chiller places it in the top position for being used in your daily life applications.

- The only component of the chiller that consumes space is the compressor. It doesn’t require huge space for installation.

- Screw Chiller is highly efficient and provides the right amount of cooling for the required application as over cooling can affect production.

- The latest technology installed in the unit prevents it from producing a disturbing amount of vibrations and noise. Besides, the motor is also functional to control the sound from coming outside the system.

- Although a regular check-up after intervals is necessary, it doesn’t require high maintenance.

- Whether you are at a high altitude or have wider applications, it can meet your needs. It has long pipes that can be extended to a great application area. The operation of the compressor is trouble-free and efficient too.

- The whole unit is flexible enough to be adjusted wherever it works perfectly.

What is the Difference Between Screw Chiller Chiller and Scroll Chiller?

The difference between a Screw Chiller and a scroll chiller mostly lies in their compressor. It is known fact compressors are the most important component of a cooling system.

The compressor’s quality is directly effective on the performance of the unit. In a scroll compressor, the two scrolls, an orbital scroll, and a fixed scroll, give a continuous compression of refrigerant.

The scroll chillers find a wide area of applications in buildings, offices, industries, etc.

On the other hand, a screw compressor increases the refrigerant pressure from low to high by using two rotors. First, it traps the gas into a casing and then processes it.

Many medium-load cooling applications like double-storey buildings, clinics, and surgical centres use Screw Chillers for their cooling tasks.

The evaporators, condensers, and expansion valves of the scroll chiller and the Screw Chiller are the same. They just differ in the working principle of their compressors.

Prime Quality Scroll Chiller

What is the Cooling Capacity of a Screw Chiller?

Cooling capacity can be defined as the ability of the cooling mechanism to remove heat from the refrigerated space over time.

The cooling capacity of the Screw Chiller ranges from 50 Ton – 250 Ton. However, it’s different for an Air Cooled Screw Chiller.

It can fluctuate from 50 Ton – 200 Ton. For Water Cooled Screw Chiller, it increases from 50 Ton and catches up to 500 Ton.

The difference in the cooling capacities of the chillers, as mentioned earlier, is because of their different working principles and mechanisms.

What is the Difference Between a Screw Chiller and a Centrifugal Chiller?

Although both the Screw Chiller and centrifugal chiller are used to provide cooling to commercial and industrial applications, they may differ in many ways.

Some of their differences are mentioned as under:

Screw Chiller

- The main components of the units, like the screw compressor and expansion valve, are small than centrifugal.

- It has less cooling capacity than the centrifugal chiller and ranges from 30 RT-500 RT.

- Speed is 2950 r/min.

- The noise produced is as much as 75 dB.

- The multi-compressor feature keeps the unit going even if one of the compressors is out of work and needs maintenance. It can meet the load of the application even in times of emergency.

Centrifugal Chiller

- Centrifugal Chiller has a complex structure and more components than its alternative. It includes the compressor, condenser, evaporator, throttle, lubrication system, suction recovery device, and electronic panel.

- It comes with a higher cooling capacity of 150 RT-3000 RT.

- It has a higher speed of 9000 to 4000 r/min.

- The noise production by centrifugal chiller is also higher, i.e. 80db.

- As it has a single compressor, if it goes down, working will be stopped. Besides, maintenance is also costly for the owners.

Centrifugal Chiller

What is the Role of Screw Compressors in a Screw Chiller?

A screw compressor is the crucial component of a Screw Chiller that compresses the gas with the help of two spiral screws (rotors).

The Screw Chiller even gets its name from the screw compressor it possesses. The compression chamber traps the given quantity of gas and simultaneously increases the pressure resulting from the decreased volume before discharge.

The air is condensed due to the pressurization built in the compressor. The increased pressure triggers the valve to open and let the pressurized air enter the other holding tank.

The air is compressed and transported to downstream equipment to remove contamination in the final step.

What are the Three Major Types of Evaporators Used in a Screw Chiller?

A Screw Chiller has three types of evaporators installed in the unit. It cannot work at its best unless all of its evaporators are completely functional.

Dry Shell and Tube Evaporator

In a dry evaporator, cold water runs outside the heat exchanger tube. On the other hand, the refrigerant passes through the tube. However, the evaporator has a low heat exchange efficiency.

Comparing the heat transfer coefficient of the dry evaporator with the light tube, you see that the former gives double output.

The bright side has simple control, and it is also easy to return oil.

Flooded Evaporator

The working mechanism and principle of operation of the flooded evaporator are contrary to that of the dry evaporator.

The heat exchange tube has cold water passing through it while the refrigerant runs outside the tube.

The heat transfer tube has numerous needle-shaped holes and spiral protrusions on the inner surface to promote heat exchange on the cold waterside.

The heat transfer coefficient is five times that of the light tubes.

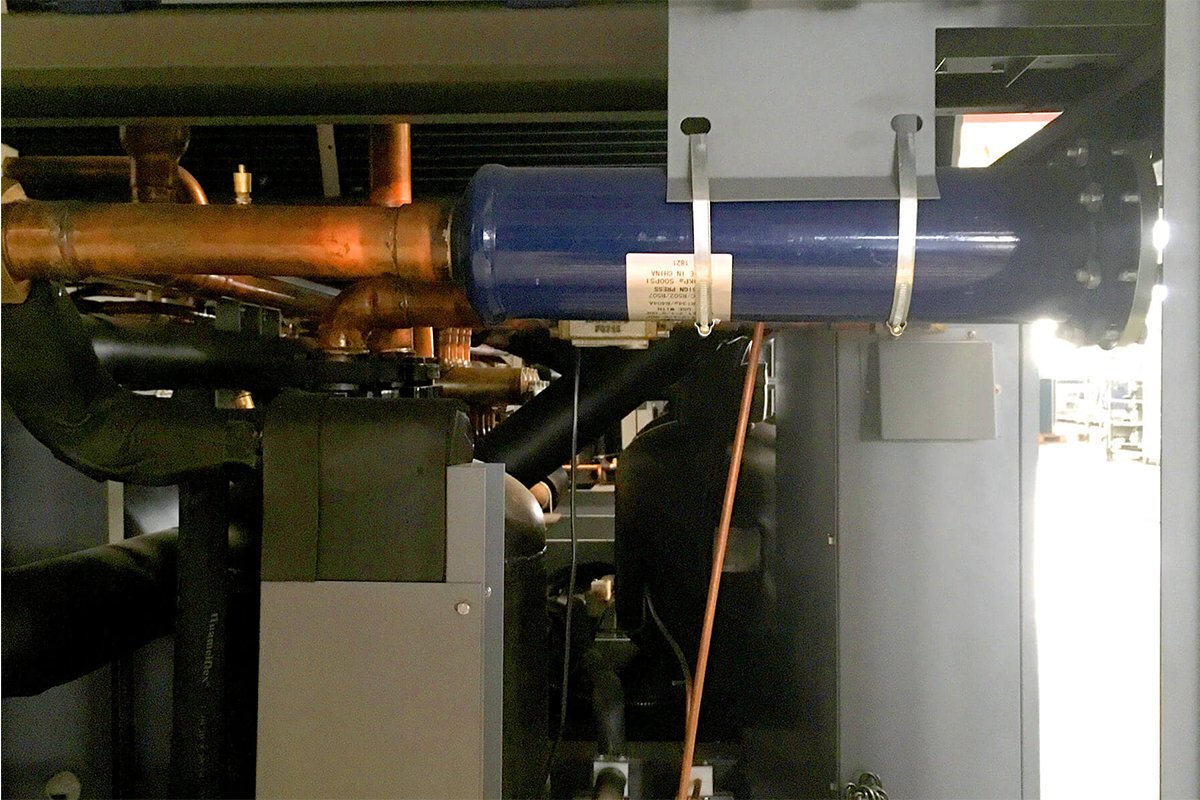

Falling Film Evaporator

A falling film evaporator, also termed a spray evaporator, involves the refrigerant sprayed to the heat exchanger tube from the upper part of the heat exchanger.

The refrigerant is reduced in boiling evaporation as it forms a thin film of cold liquid on the surface of the heat exchange tube.

The static liquid level pressure raises the heat exchange efficiency by about 5-6 times that of the full flooded evaporator.

Screw Chiller Falling Film Evaporator Inside View

What are the Electrical Requirements of the Screw Chiller?

The motors, pumps, and the compressor installed in the Screw Chiller consume as much as 51% of the total electrical energy for different percentages of loadings.

The whole unit is more energy-efficient than any other refrigeration and cooling equipment. So it consumes only 480 volts maximum.

What is the Advanced Control Unit System of the Screw Chiller?

Screw Chiller is equipped with certain innovative features of the control unit that make it an advanced control unit system.

These features are explained as under:

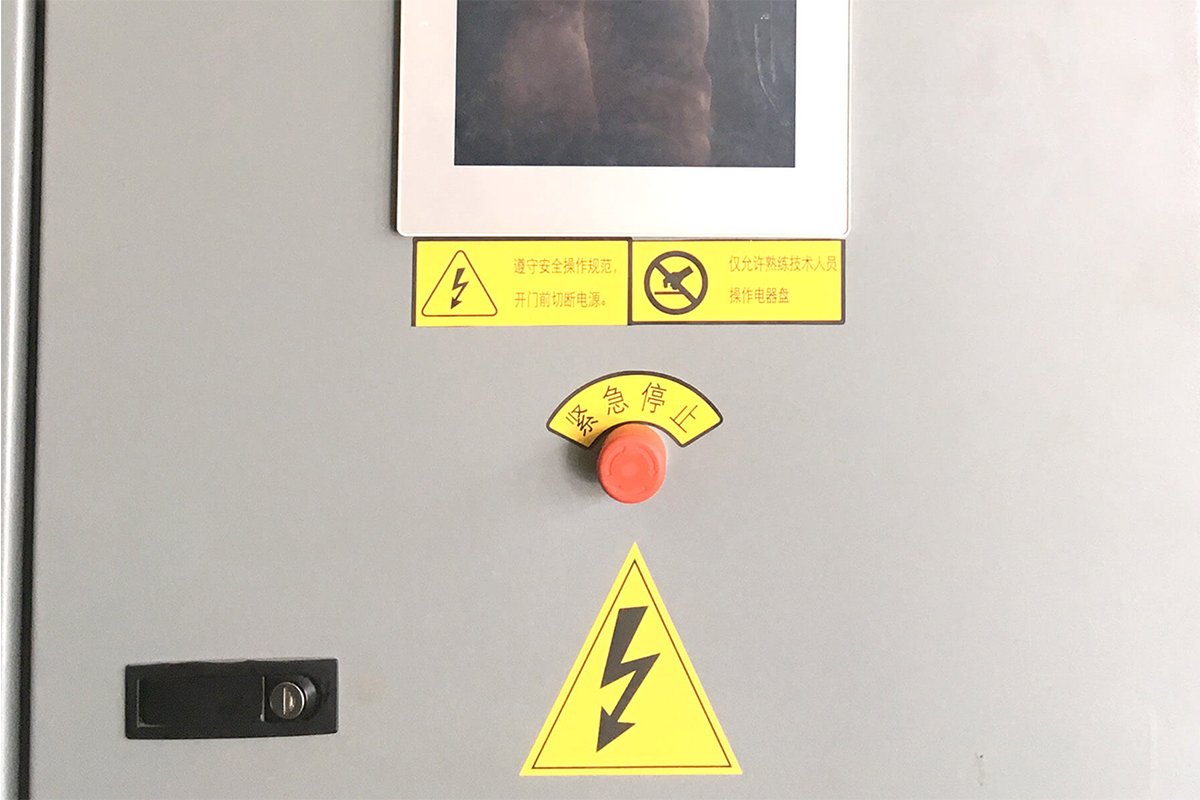

- The technology used in making PLC-based controllers is truly exceptional as it controls every operation to the highest possible accuracy and perfection.

- You can handle the control unit better, as it has a big sensitive touch screen.

- The control unit is simple and easy to operate. Anyone with a little training can go through it in no time and proceed to the operations.

Screw Chiller PLC-Based Controller

What is the Multi-Level Protection Feature of a Screw Chiller?

The multi-level protection feature is one of the most unique and beneficial features of the Screw Chiller. It is described as under:

- The internal protective layer system ensures the longevity of the unit. The two layers offer protection to the compressor and keep it from rusting.

- The material used in the construction of the unit is highly resistant to corrosion, accumulation of dust, chemical reactive agents, and spills.

- The surface of the Screw Chiller is compact enough to withstand any kind of wear and tear resulting from sharp and heavy items.

- The automatic loading switch feature keeps the maintenance safe and sound from extreme temperature fluctuations and thermal expansions.

How to Choose the Right Type of Screw Chiller for your Applications?

Some factors must be considered before selecting the Screw Chiller for your applications. They are mentioned as follows:

- There is a huge variety of the desired equipment you are looking for, and it varies based on size, shape, and capacity. You must take into account which one suits your application the best.

- A small Screw Chiller is usually maintenance-free, so go for a small size. It can save you space issues too.

- The range of cooling capacity should be equivalent to your required range. There is no use in purchasing a chiller whose cooling capacity is less than you need.

- The screw compressors offer power from 38Kw to 178Kw, so you must select the compressor while keeping your load in mind.

- The unit’s performance is efficient when the temperature difference between the inlet and outlet of the refrigerant is optimum. Too much temperature difference can bring down the chilling efficiency.

- Analyze the cooling you are looking for and how many hours the unit will have to operate to deliver that cooling range.

- The flow rate of your system should also be considered as it pairs with the right temperature and increases overall production.

- Always purchase the Screw Chiller with the most advanced control system.

How to Install your Screw Chiller?

You might want to look at the following tips before installing your Screw Chiller.

- No matter the chiller’s size, it always needs to be installed carefully, so it is better to move it with a forklift and avoid any possible damage.

- Foundation is an important factor; therefore, you can use a forklift for short distances.

- All vibrations and noise can be avoided by placing an anti-vibration pad between the foundation and the chiller unit.

- In the case of outdoor installation, choose a place where it doesn’t hit monsoon rains, and the process of heat exchange is trouble-free.

- If the installation is carried on the rooftop, you can use a spring isolator as a sound absorber.

- Always leave some extra space around the unit for air circulating and maintenance.

- Make a proper alignment between the water sources. Set the piped in a safe and secure place.

- Set an installation of the manual valve shutoff system. The purpose of this system is to ease your maintenance tasks.

- Keep a check on the quality standard of water. The area where you install the unit must have fresh water flowing. The contaminated water gave rise to algae and decreased the working efficiency.

What is the Common Fault Analysis of Screw Chiller?

Screw Chiller can keep on working with maximum efficiency for years. However, it may develop some problems after considerable periods.

The chiller’s problems can be identified with the help of proper troubleshooting procedures. Some of the common fault analyses of the Screw Chiller are given below:

High and Low-Pressure Alarms

The high-pressure alarm goes off when the pressure within the system is higher than usual. The low-pressure alarm starts beeping when the system pressure is less than the required pressure.

The control panel has pressure systems that you can manually control in an emergency.

Compressor Overheat

Sometimes, the temperature reaches its peak within the compressor system, and it can be brought under control by activating the thermal protection module installed in the unit.

Screw Chiller Inspection

What are the Reasons and Treatment of Irregular Vibration your Screw Chiller?

Sometimes a Screw Chiller may start giving unusual vibrations. The causes and solutions for such disturbance are given below:

Loose Bolts and Joints:

Unusual vibrations and unbearable sounds may result from the loosened parts of machinery, i.e. joints and bolts. You can fix this problem in no time by tightening these parts firmly.

The Improper Flow Rate of Refrigerant:

The pipes and the condenser start giving strong vibrations when the flow rate of the refrigerant is too high. Setting the flow rate to an optimum value can solve this problem.

How to Increase the Performance of your Screw Chiller?

The life span and efficiency of your Screw Chiller can be extended with the right maintenance.

However, it doesn’t have costly maintenance as it comes with spare parts.

- Keep a check on the rotors and make sure their speed is high. Their contact with the surface can result in decreased efficiency.

- It is also important to see for the leakages in the capacity control. If there are any leakages, seal them immediately.

- The unit’s efficiency is maintained only when the solenoid valves of the capacity control are fully operational.

- The oil being used must be in a proper grade, and its level shouldn’t exceed the recommended limits.

- It is always better to let the experts do the maintenance to avoid all sorts of mishandling.

Screw Chiller Routine Maintenance