TopChiller can design and manufacture all types of portable chillers for you

- Cooling capacity ranges from 1 ton to 50 ton

- Temperature control from ranges 0°F to 80° F

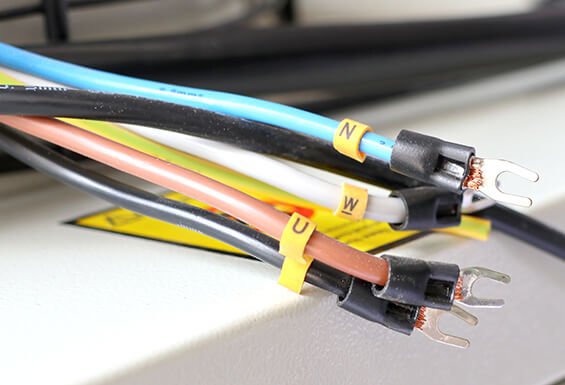

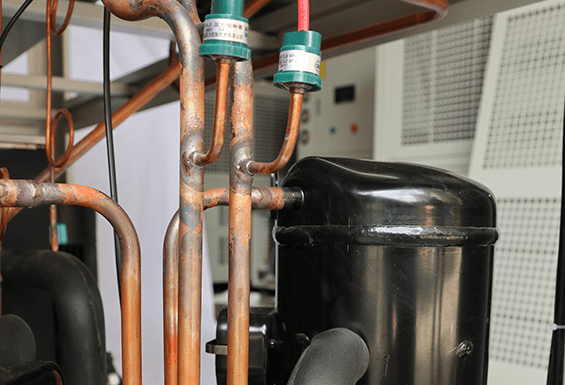

- Reliable and high-quality scroll compressor

- Air-cooled /water-cooled v-type condenser

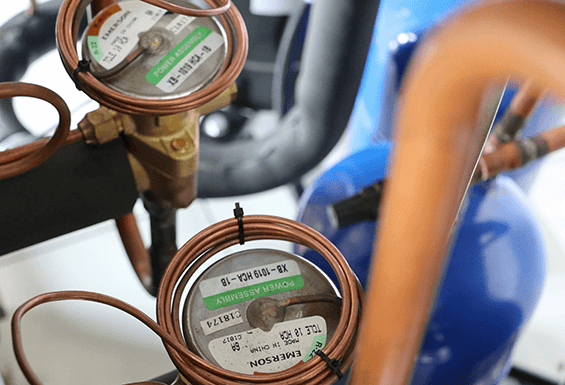

- Thermostatic expansion valves & flow switches

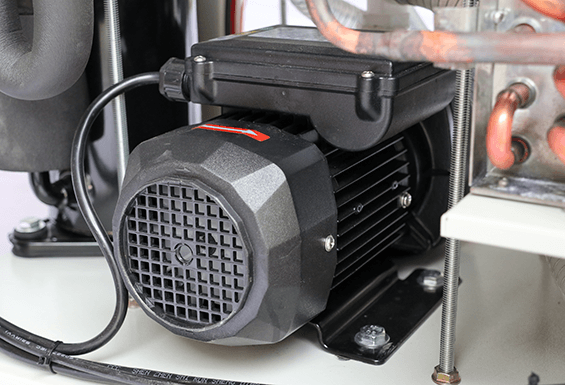

- Brazed plate heat exchanger & SS water pump

- Three type refrigerator with different circulation

- Data logging, temperature & pressure logging

Your Premier Portable Chiller Manufacturer and Supplier in China

Portable Chiller is a water cooling unit featured with wheels or casters for easy installation and provides a cooling effect to different applications by using chilled water or air circulation around the condenser unit.

TopChiller is the popular manufacturing company of China that is supplying worldwide fabulous Portable Chiller to our clients with pride by accommodating queries from our manufacturing facility since 1999.

As a professional manufacturer and supplier, TopChiller is servicing the global markets with an assorted number of Portable Chiller with different specifications and customization capabilities for over the last twenty years.

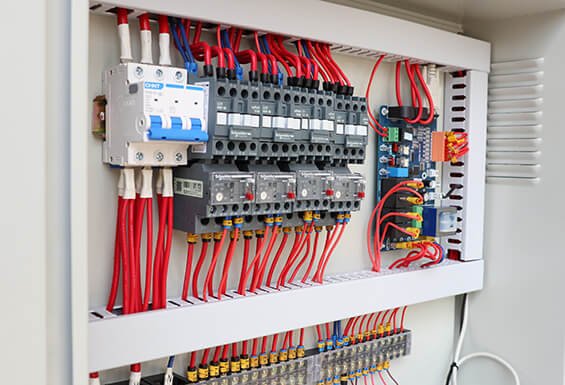

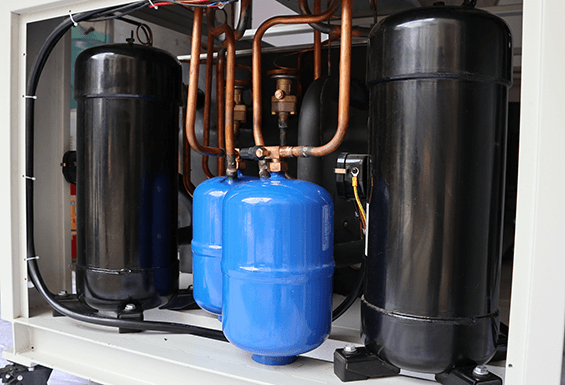

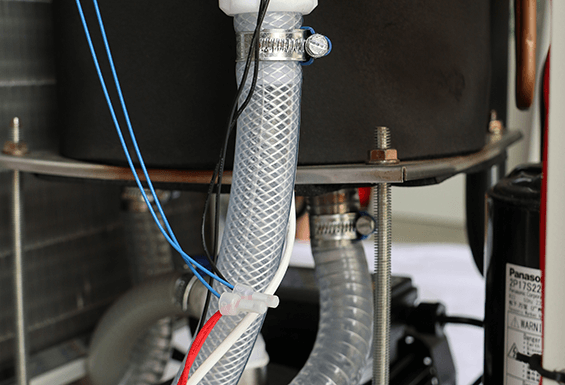

Portable Chiller is designed with different reliable components as scroll Compressor, v-type condenser, thermostatic expansion valve, wheeling caster, SS water tank, flow-switches, multiple evaporator, PLC controller, brazed plate heat exchanger, and electric box.

TopChiller brand Portable Chiller has easy installation and a wide range of other advantages as given below:

- Portable Chiller is featured with compact design, stainless steel body, and wheeling casters that enable the unit easy installation, movement, and sizes for different industrial applications.

- TopChiller designed Portable Chiller steadily performs its function ensuring long service life featured by an automated temperature and pressure logging system that records the fluctuation in set points and gives an alarm for adjustment and ultimately safe the unit from damage.

- Portable Chiller is constructed with flow switches and H.P/L.P detecting protecting devices configuring the maintenance of change in refrigerant pressure by switching off the unit and preventing coils from leakage or any other disturbance.

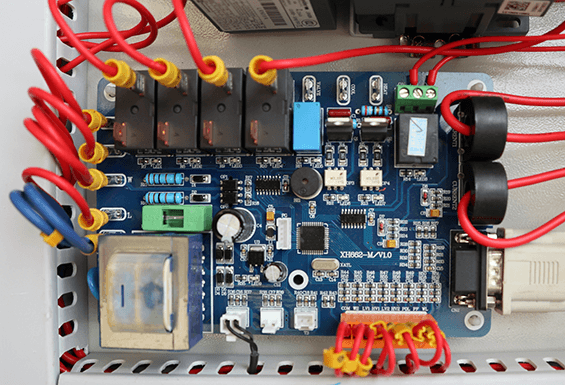

- PLC-based temperature controller in Portable Chiller diagnoses temperature of coolant before entering in compressor and regulates it accordingly as per the requirement of the unit.

- Portable Chiller configures cooling effect for different industrial applications featured by energy-efficient v-type condenser that collects the heat from the machine and dissipates out by chilled air or water circulating in coils around the condenser.

Portable Air Cooled Chiller is renowned for different industrial applications as:

Food & beverage industry, meat processing, carbonation, electroplating-ray spectrometer, liquid nitrogen plant, power generation, concrete mixing plant, anodizing plating, printing, chemical processing, paint cooling, distilleries, pharmaceutical industry, and wineries.

If you are searching for a reliable and easily movable Portable Chiller for your application?

If you are interested to collaborate with a company manufacturing Portable Chiller for getting updated and innovative instructions to promote your business?

TopChiller is the best company providing excellent customer care and updates about chilling operations. Faithfully you can trust it. Make a decision and come in contact with TopChiller collaborative team and discuss all your queries without hesitancy.

Get a buying guide or quote for sizing a Portable Chiller optimally best adjustable to your application at a reasonable price with the support of TopChiller expertise.

General Description:

Portable Chiller is a mobile cooling device that typically works to remove excessive heat produced by the equipment and cools down industrial machines using various mediums. It can be easily dragged from one place to another owing to its small size.

Conventionally, Portable Chiller comprises a high-quality compressor, evaporator, condenser, and expansion valve; besides, it is essentially equipped with castors or wheels that make it easy to drag. It is easy to install using flexible hoses.

Portable Chiller manufactured by TopChiller has a compact design configuration that comprises all the fundamental components in a movable size that includes refrigeration circuit, controlling system, process pump, and reservoir.

It has a vast area of applications in commercial plants that include food and beverage industries, chemical processing, dairy, printing, welding, plastic industries, and far more.

If your chiller demand is confined to a smaller scale or looking for a temporary choice before making a final purchase, you will find TopChiller a definite solution to your relevant problems.

TopChiller is a well-known chiller brand that uses its twenty years of experience and introduces a wide variety of highly efficient Portable Chillers and their incredible features.

Contact our sales engineer today, and you get your highly efficient Portable Chiller at a very affordable price.

Features and Advantages:

The following distinctive features essentially characterize a remarkably efficient Portable Chiller manufactured by TopChiller:

- The caster wheels facilitate easy transportation from one place to another. It has a simple configuration that makes it easy to pack and carry to another application unit.

- It provides a higher degree of flexibility for your cooling requirements. It can be operated at varying temperature conditions. You can easily customize the operation of your Portable Chiller under specific temperature requirements.

- It possesses microchannel aluminum condenser coils. The evaporator is constructed of a stainless-steel blazed plate. It has a microprocessor-based PID controller for automatic control of functions.

- Refrigerant suction and discharge pressure transducers enable the compressor to adjust the speed in order to adapt to the best efficient conditions.

- Highly efficient Portable Chiller designed by TopChiller does not contain any pollutants. In contrast, it helps dispose of contaminated particles and improves air quality in the atmosphere.

- Data Sheet

- Image Gallery

- Main Parts

- Video

| Portable Chiller Technical Specifications | ||||||||||||||

| Items Model | AC-0.5A | AC-1A | AC-1.5A | AC-2A | AC-2.5A | AC-3A | AC-4A | AC-5A | AC-6A | AC-8AD | AC-10AD | AC-12AD | AC-15AD | |

| Cooling capacity | Kcal/h 50HZ/60HZ | 1419 | 2451 | 3182 | 4833 | 5848 | 7181 | 9288 | 11988 | 14534 | 18576 | 23994 | 29068 | 38270 |

| 1703 | 2941 | 3784 | 5800 | 7018 | 8617 | 11146 | 14386 | 17441 | 22291 | 28793 | 34882 | 45924 | ||

| KW 50HZ/60HZ | 1.65 | 2.85 | 3.7 | 5.62 | 6.8 | 8.35 | 10.8 | 13.94 | 16.9 | 21.6 | 27.9 | 33.8 | 44.5 | |

| 1.98 | 3.42 | 4.4 | 6.74 | 8.2 | 10.02 | 12.96 | 16.73 | 20.28 | 25.92 | 33.48 | 40.56 | 53.4 | ||

| Input power | KW | 0.88 | 1.35 | 2 | 2.25 | 2.66 | 3.27 | 4.07 | 5.75 | 6.45 | 8.25 | 11.5 | 12.9 | 17.45 |

| Max Current | A | 5.4 | 8.2 | 12 | 13.6 | 6.6 | 8.2 | 10.1 | 13.8 | 15.5 | 20 | 27.9 | 31.3 | 42.4 |

| Power source | 1PH~220V/3PH~220V/380V 50HZ/60HZ | 3PH~380V/415V/480V~50HZ/60HZ(3PH~200V/220V 50HZ/60HZ) | ||||||||||||

| Refrigerant | Type | R22/R407C/134a/404A/410A | ||||||||||||

| Control | Capillary / thermostatic expansion valve | |||||||||||||

| Compressor | Type | Hermetic Rotary | Hermetic scroll ( piston ) | |||||||||||

| Power(KW) | 0.45 | 0.89 | 1.3 | 1.73 | 2.1 | 2.7 | 3.5 | 4.55 | 5.25 | 3.5×2 | 4.55×2 | 5.25×2 | 7×2 | |

| Condenser | Type | Efficient finned copper tube with aluminum+low noise external rotor fan | ||||||||||||

| Air flow (m3/h) | 750 | 1000 | 1500 | 2000 | 2500 | 3000 | 4000 | 5000 | 6000 | 8000 | 10000 | 12000 | 15000 | |

| Air blower(KW) | 0.06 | 0.09 | 0.15 | 0.15 | 0.19 | 0.14×2 | 0.14×2 | 0.19×2 | 0.19×2 | 0.25×2 | 0.45×2 | 0.45×2 | 0.6×2 | |

| Evaporator | Type | SS Tank coil / shell and tube type / Plate type heat exchanger | ||||||||||||

| Chilled water (m3/h) | 0.28 | 0.49 | 0.64 | 0.97 | 1.12 | 1.44 | 1.86 | 2.4 | 2.91 | 3.71 | 4.8 | 5.81 | 7.65 | |

| 0.34 | 0.59 | 0.76 | 1.16 | 1.4 | 1.72 | 2.23 | 2.88 | 3.49 | 4.46 | 5.76 | 7 | 9.18 | ||

| Water tank(L) | 10.6 | 18.3 | 27 | 27 | 50 | 50 | 60 | 60 | 110 | 120 | 200 | 200 | 270 | |

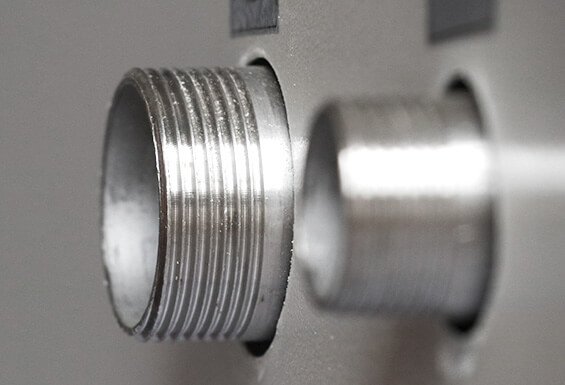

| Inlet/outlet pipe (inch) i | 1/2″ | 1/2″ | 1/2″ | 1/2″ | 1″ | 1″ | 1″ | 1″ | 1″ | 1-1/2″ | 2″ | 2″ | 2″ | |

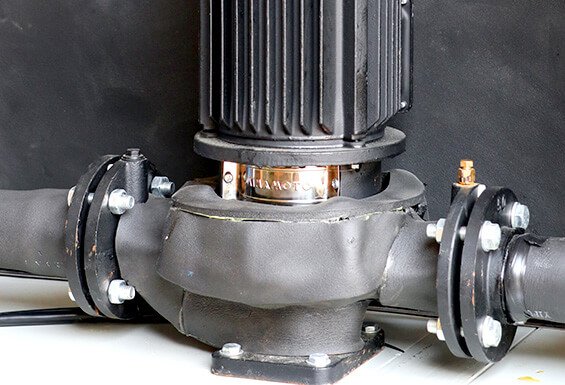

| Water pump | Power (kw) | 0.37 | 0.37 | 0.37 | 0.37 | 0.37 | 0.37 | 0.37 | 0.75 | 0.75 | 0.75 | 1.5 | 1.5 | 2.2 |

| Max lift(m) | 22 | 22 | 22 | 22 | 22 | 22 | 22 | 30 | 30 | 25 | 25 | 25 | 28 | |

| Max flow (m3) | 5.4 | 5.4 | 5.4 | 5.4 | 5.4 | 5.4 | 5.4 | 8.1 | 8.1 | 8.1 | 13.5 | 13.5 | 25.2 | |

| Safety protection | Compressor inner protection, over current protection, high/low pressure protection, over temperature protection, flow rate protection, phase sequence/phase missing protection, low level coolant protection, anti freezing protection, exhaust overheat protection | |||||||||||||

| Dimension | L(mm) | 550 | 550 | 600 | 600 | 720 | 980 | 980 | 1150 | 1150 | 1350 | 1500 | 1500 | 1860 |

| W(mm) | 350 | 450 | 500 | 500 | 550 | 520 | 520 | 560 | 560 | 680 | 760 | 760 | 850 | |

| H(mm) | 695 | 845 | 985 | 985 | 1350 | 1170 | 1170 | 1215 | 1215 | 1530 | 1660 | 1660 | 1900 | |

| Net weight(KG) | 45 | 62 | 85 | 95 | 125 | 152 | 175 | 185 | 215 | 283 | 345 | 382 | 580 | |

| Note: The above specifications are according to the following design conditions: 1, 12℃/7℃.Chilled water inlet/outlet temperature 12℃/7℃. 2, 33℃/38℃.Cooling air inlet/outlet temperature 33℃/38℃. We reserve the right to modify the specification without further notice. | ||||||||||||||

Why TopChiller is Your Reliable Portable Chiller Manufacturer and Supplier In China?

Portable Chiller-An Ultimate FAQ Guide by TopChiller.

- What is a Portable Chiller?

- What are the Excellent Features of a Portable Chiller?

- What are the Types of a Portable Chiller?

- What are the Major Components of a Portable Chiller?

- How Does a Portable Chiller Work?

- What are the Prominent Applications of a Portable Chiller?

- What is the Cooling Capacity of a Portable Chiller?

- How to Calculate the Cooling Capacity of a Portable Chiller?

- How Does a Portable Chiller Different from a Central Chiller?

- Why Does a Portable Chiller Not Suitable for Larger Scale Applications?

- What are the Safety Features of a Portable Chiller?

- What are the new Technologies of a Portable Chiller?

- What Factors Should you Consider While Buying your Portable Chiller?

- How Much Does a Portable Chiller Cost?

- What are the Common Problems of a Portable Chiller?

- When Should you Change Filters in your Portable Chiller?

- How Do you Troubleshoot your Portable Chiller?

- How to Maintain your Portable Chiller?

- What are the Factors Should you Consider While Installing your Portable Chiller?

- How to Increase the Working Efficiency of your Portable Chiller?

What is a Portable Chiller?

A Portable Chiller is a cooling system that eradicates unwanted heat from the industrial unit through a refrigeration cycle. It circulates various mediums such as water, air, or glycol solution through the heat exchangers.

Caster wheels are hooked below it for easy movement from one application unit to another. It has a small, movable size.

It possesses a simple overall configuration and has lower installation costs. The overall heat exchange is regulated by a single circuit incorporated in it. It is simple to connect through flexible hoses and easy to power up.

A Portable Chiller is usually optimized to provide a fixed amount of heat transfer capacity measured in tons. Thus, it is suitable for the cooling requirements that remain relatively constant.

It is widely used in industries to maintain the temperature of industrial processes and is an ideal choice for smaller-scale commercial applications.

High Quality Portable Chiller Fabricated by TopChiller

What are the Excellent Features of a Portable Chiller?

The following exhilarating features characterize a Portable Chiller.

Durability

It is featured by an automatic temperature and pressure logging system that ensures its long life.

It detects any fluctuation in set points and gives an alarm for adjustment. This is how it eventually saves the unit from damage.

Configuration

Portable Chiller has a compact design and stainless steel body mounted by casters enabling easy installation and movement from one place to another.

Temperature Controller

PLC-based temperature controller detects the temperature of the coolant and proceeds to regulate it according to the requirements.

Protection Devices

Various flow switches and pressure detecting protection devices configure the maintenance of refrigerant pressure. It prevents the coils from leakage and other problems.

Energy Efficient Condenser

The Portable Chiller consists of an energy-efficient condenser that collects heat from the system. Later, it dissipates through air or water circulating in coils around the condenser.

What are the Types of a Portable Chiller?

A Portable Chiller can be of two types viz. Portable Water Cooled Chiller and Portable Air Cooled Chiller.

They oppose each other primarily based on the medium used to remove heat from the refrigerant in the condensers.

A Portable Water Cooled Chiller is a mobile cooling device that dissipates heat from the system using water as a cooling medium.

It circulates water through the heat exchangers and efficiently lowers the temperature of the application unit.

It does not encounter outdoor factors thus, has a longer life span. Along with highly efficient performance, it works quietly without producing nasty noises. It has lower electricity consumption.

A Portable Air Cooled Chiller is a portable chilling machine that eradicates excessive heat from the system and disposes it to the environment employing a fan. It uses air as a condensing medium.

It cools down the temperature of the system through a refrigeration cycle. The refrigeration circuit, pumps, and reservoir are fundamental components for the proper functioning of a Portable Air Cooled Chiller.

It is energy efficient with optimum performance. It is composed of materials that can withstand extreme weather conditions, ensuring durability.

What are the Major Components of a Portable Chiller?

A Portable Chiller consists of the following major components:

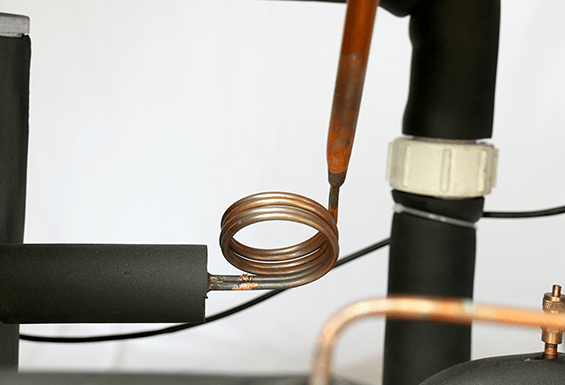

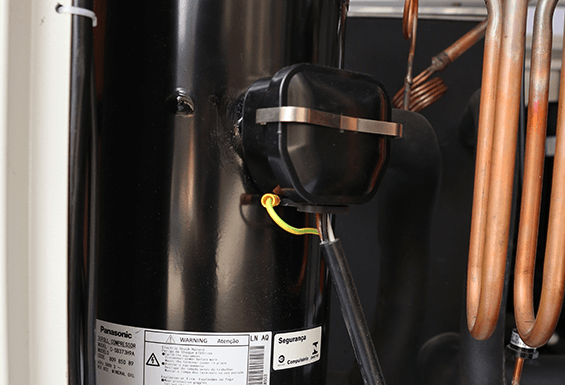

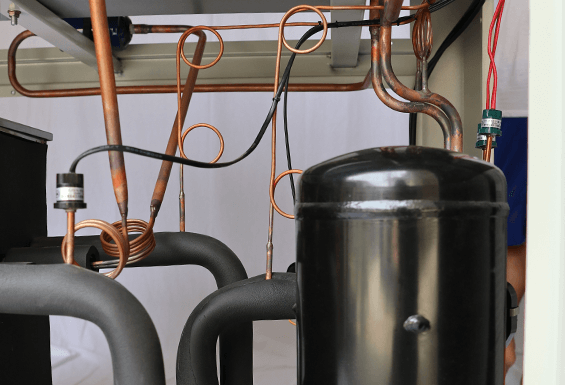

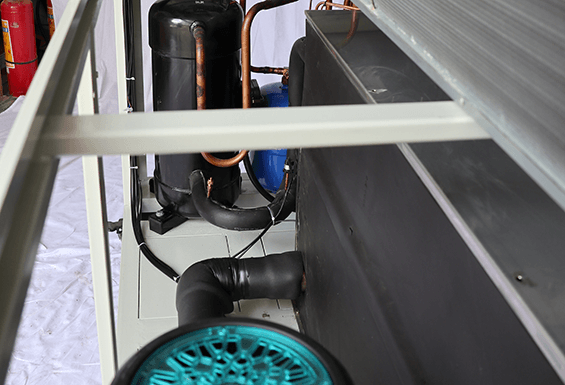

Compressor

A compressor converts the low-temperature refrigerant vapors into high-temperature vapors. It provides refrigeration power to a Portable Chiller.

Screw, scroll, reciprocating, and centrifugal are the four main types of compressors.

Evaporator

An evaporator converts refrigerant into vapors and absorbs the heat from the cooling medium producing a cooling effect.

Direct expansion, brazed-plate, and flooded shell-and-tube are the main types of the evaporator.

Condenser

The condenser eliminates heat from the refrigerant and converts it to a liquid state from a gaseous state.

Expansion Valve

The expansion valve leads the refrigerant from the compressor to the evaporator. It controls the amount of refrigerant that passes between the evaporator and the condenser.

Exhaust Fan

A Portable Chiller contains an exhaust fan to eliminate heat from the system, releasing it into the atmosphere.

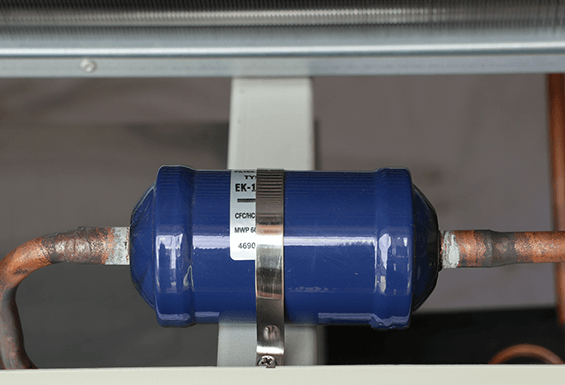

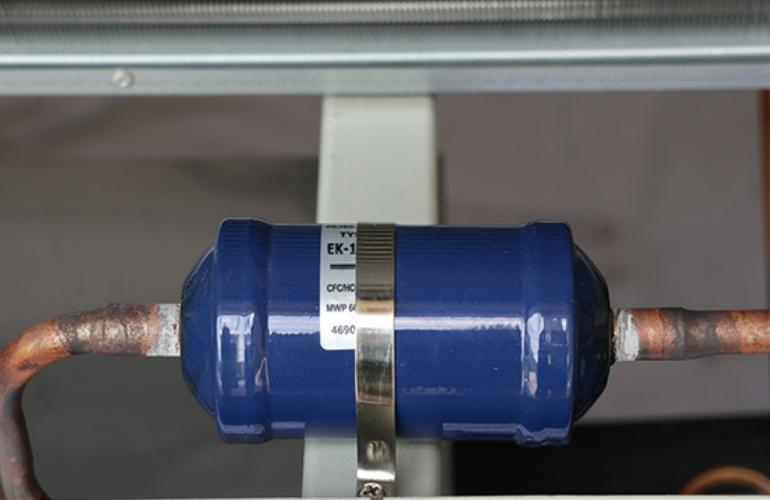

Filter Drier

A filter drier functions to remove dust particles and prevent them from entering the fluid.

Portable Chiller Filter Drier

How Does a Portable Chiller Work?

A Portable Chiller is based on the principle of compression and absorption through the refrigeration cycle.

Both portable air cooled and water cooled chiller works on the same principle.

However, an air cooled chiller uses the current of ambient air for eliminating heat, while the water cooled chiller uses water as a cooling medium in the condenser.

The refrigeration cycle initiates with an evaporator. The evaporator is responsible for absorbing heat from the chilled circulating water. The heat is transferred to the refrigerant and vaporizes it.

The vaporized refrigerant then passes by a compressor. The compressor’s low temperature and pressure refrigerant vapors are converted into high temperature and pressure vapors.

The highly pressurized refrigerant vapors are then directed to the condenser that acts as a heat exchanger. It removes heat from the refrigerant.

In the case of water cooled chiller, the heat of the refrigerant is transferred to the water in the condenser; consequently, the refrigerant cools down and converts into a liquid state.

On the other hand, the exchange of gases occurs in the condenser in an air cooled chiller. Warm air is blown out while the fresh air is drawn in through the fans. It condenses the vapors into a high-pressure liquid.

The refrigerant returns the evaporator passing by expansion valves. The expansion valve converts refrigerant into a low-pressure, low-temperature liquid.

It then enters into the next cycle. This is how the whole process keeps going on.

What are the Prominent Applications of a Portable Chiller?

A Portable Chiller has fewer installation costs and can be easily shifted from one place to another. Thus, it is extensively used for a wider range of applications.

It is primarily used in industrial plants to prevent the system from overheating.

Rather, it is not confined to commercial areas but is extensively used in residential buildings, schools, offices, hotels, and hospitals to cool down the environment.

However, it is prominently used for the following applications.

- Beverage Industry

- Laser Industry

- Glass Manufacturing

- Thermoforming

- Injection Molding

- Extrusion Industry

- Blow Molding

- Plating

- Optical Coating

- Machine Tooling

- Die Casting Industry

- Pharmaceutical Industry

- Welding

- Semiconductor

What is the Cooling Capacity of a Portable Chiller?

A Portable Chiller features a compact design that provides reliable and accurate process cooling control with high efficiency for small capacity process applications.

It is thought to have a lower cooling capacity between 0.5 and 30 tons of refrigeration.

However, the modern Portable Chiller has a wide cooling capacity range from 1 ton to 50 tons with a 5°C to 35°C temperature cooling range.

How to Calculate the Cooling Capacity of a Portable Chiller?

You can calculate the cooling capacity of a Portable Chiller employing the following method:

- Calculate the volume of flow rate (V).

- Measure the density of water(ρ).

- Note down the specific heat capacity (Cp).

- Calculate the temperature difference (ΔT) in degrees Fahrenheit.

ΔT = Incoming Water Temperature (°F) – Required Chill Water Temperature

- Determine the cooling capacity for your chiller using the formula:

Q = (V × ρ) Cp (ΔT)

Cooling capacity can also be determined in terms of heat load.

Heat load can be calculated by multiplying the coolant flow in gallons per minute, the change in temperature, and the specific gravity. Multiply it to 499.8 to convert pounds to gallons.

Eventually, to find the cooling load (in tons) that is required to control your heat production, divide the heat load by 12,000.

In this way, you can determine the tonnage of a Portable Chiller that will be appropriate for your specific application.

How Does a Portable Chiller Different from a Central Chiller?

A Portable Chiller is usually small and simple in an overall configuration, having lower installation costs. It is equipped with casters making it easy to move.

It is optimized to deliver a fixed amount of heat transfer capacity. It is suitable for processing equipment that needs cooling steam at a considerably different temperature from other equipment.

Portable Chiller is ideal for small load applications or temporary use. Its capacity ranges typically from 1 to 30 tons of cooling.

On the other hand, a central chiller is generally larger with a complex design. It has higher installation costs.

It can handle large cooling loads with outstanding efficiency. The capacity of the central chiller ranges from 10 to 250+ tons.

The central chiller requires more complex controls and an immense pumping system to circulate coolant throughout the process. It is primarily suitable for larger-scale applications.

It is designed to control a wide range of temperatures, from the lowest to the highest, while a Portable Chiller is used for specific or extreme cooling needs.

Why Does a Portable Chiller Not Suitable for Larger Scale Applications?

A Portable Chiller is best suited for smaller cooling loads and temporary usage.

However, it is not designed for larger scale applications, as demonstrated by the following points:

- It has a simple configuration; it does not involve an immense pumping system.

- The capacity has a lower range between 1 to 30 tons of refrigeration.

- It is optimized to provide a fixed amount of heat transfer capacity.

- The overall heat exchange is regulated by a single circuit incorporated in it.

- Portable Chiller is suitable for processing equipment that needs cooling steam at a considerably different temperature from other equipment.

What are the Safety Features of a Portable Chiller?

A Portable Chiller is equipped with numerous protection devices to ensure the safety and durability of the chiller.

Some of the notable safety features are listed below:

- The refrigerant flow controller controls the flow of refrigerant and protects the compressor.

- The capacity controller that maintains the temperature of your chiller.

- Mechanical controls cause the system to shut off in any failure or emergency.

- Power circuits contain fuses that protect the system in case of any defect in the regular flow of current.

- Compressors contain thermal overloads.

- It is equipped with anti-freeze thermostats.

- All fan and pump motors also contain thermal overloads.

- Compressors are equipped with high-pressure and low-pressure switches.

- Compressors are also provided with oil pressure protection.

- Receivers are equipped with pressure relief devices and fusible plugs.

- The condenser and chilled water lines equip flow switches.

- Motors are provided with over-temperature protectors.

- Temperature control devices and alarms are installed in the application area.

- The Portable Chiller also possesses high and low pressure control systems.

Portable Chiller Temperature Controller Unit

What are the new Technologies of a Portable Chiller?

Many latest technologies are introduced in a Portable Chiller that has broadened its applications.

Some of these are mentioned below:

- Quiet operation

- Low maintenance

- Reduced carbon emissions

- Energy efficiency

- Smaller size

- Mobility

- Easing the transition to lower-GWP refrigerants.

- More efficient

- Advances in oil-free chiller technology

Portable Chiller Caster Wheel

What Factors Should you Consider While Buying your Portable Chiller?

Portable Chiller has a wide variety based on features, size, and cooling capacity.

Before making a selection, you must be well versed about the cooling requirements of the application for which you are purchasing your chiller.

Besides these, while choosing a Portable Chiller, you must consider the following factors to pick the best one for your application:

Heat Load

Heat load is the amount of heat that your process generates. If the heat load is higher, you must need a more powerful chiller to remove the excess heat from the process.

It is measured in British Thermal Units (BTUs) per hour.

Coolant Temperature

The coolant temperature helps in defining the amount of heat it can absorb. It refers to the measurement of the coldness of the coolant in the chiller.

In the process, the cooling liquid warms by absorbing heat from the surrounding air.

Coolant Flow and Pressure

Pressure and the rate of coolant flow affect the ability of the coolant to remove heat.

The coolant flow rate can be measured by the heat load divided by the change in temperature and the coolant’s specific gravity.

Condenser Heat Dissipation

The condenser of the portable water cooled chiller passes out the excess heat into the cooling towers. It is more effective in cooling the system down.

However, the portable air-cooled chiller condenser blows out excess heat directly into the atmosphere through fans.

It is better for colder climates since there is no problem of water freezing in cooling towers.

How Much Does a Portable Chiller Cost?

An average Portable Chiller typically costs somewhere from $600 to $7,000. But the price varies greatly according to model, tonnage, and power supply voltage.

Various factors affect the price of a Portable Chiller.

- Type of Cooling System

- Cooling Method

- Maximum Ambient Temperature

- Minimum Ambient Temperature

- Selected Voltage

- Noise Level

- Maximum R.H

A high-quality Portable Chiller uses superior materials that make its cost higher than a low-quality chiller.

It may cost as low as $400 and as high as $500000 depending on the quality and the factors mentioned above.

What are the Common Problems of a Portable Chiller?

A Portable Chiller may suffer from various problems. Some of them are:

Flow fault

It refers to low process fluid flow at the pump discharge. It occurs when the water level in the tank is low.

High Discharge Pressure

A clogged condenser causes it or if it is overcharged with refrigerant.

Pump Overload

It is caused if the overload is set incorrectly or possibly due to low supply voltage.

Compressor Overload

The low supply voltage primarily causes it.

Low Suction Pressure

If the evaporator is fouled or the compressor suction valve is closed.

Refrigerant leakage, incorrect wiring, or a too cold condenser medium may also cause a low suction pressure.

Portable Chiller Micro Cooling System and Compressor

When Should you Change Filters in your Portable Chiller?

Filters in a Portable Chiller can last long, even for a year, provided that it is repeatedly serviced and well maintained.

However, you may need to change them after every three months at least. They should be changed more frequently if:

- There is some fireplace or any source of smoke inside the application unit.

- A large working farm or ranch around the area.

- If there is some ongoing construction near the area of application.

Filters should be immediately replaced in case of any damage.

How Do you Troubleshoot your Portable Chiller?

If your Portable Chiller suffers a problem, firstly, you need to analyze the causes behind the problem.

After which, locate the area of the problem and look for the solution.

There are some most common problems with it. You can troubleshoot these problems as given below.

Power Up Failure

Your Portable Chiller may fail to power up due to losing connections and irregular power flow.

It may be caused due to blow fuse, circuit breaker, and incorrect phase connections. You can solve the problem by establishing proper connections on the circuit.

Ensure that the power flowing is sufficient to power your Portable Chiller.

Insufficient Pumping and Fluid Flow

Sometimes, the refrigerant fails to flow through the pumps due to insufficient fluid in the reservoir.

It may also be caused due to poor pump conditions, process restrictions, power failure, blocked filters, and small passage sizes.

The process line may also get pinched or blocked temporarily. In this case, check for closed valves, failed flow switches, or plugged pipes.

You should maintain your chiller and clean filters regularly to avoid such problems.

Insufficient Cooling

The Portable Chiller may fail to provide sufficient cooling due to an improper power supply or clogged condenser and filters.

Sometimes, it may also be caused if the refrigerant has languished or due to any leakage.

Portable Chiller Troubleshooting

How to Maintain your Portable Chiller?

Maintaining your Portable Chiller frequently improves your chiller’s overall performance and durability.

Following should be part of your regular chiller maintenance activities.

- Turn off your chiller.

- A complete survey of each component of your chiller to ensure its proper functioning.

- Check all the setpoints to ensure the proper settings and function.

- Conduct a test to address any leakage in relief valves, compressor fittings, and pump joints.

- Maintain an optimal flow rate.

- Check the control functioning.

- Measure condenser and evaporator pressures.

- Check the refrigerant charge.

- Analyze the voltage and current flow.

- Check all the electrical connections and terminals once a year.

- Analyze the compressor oil system. Change necessary oil pumps.

- Inspect the valve, filters, oil heater, and thermostat.

- Provide proper lubrication to the moving components when needed.

- Maintain the optimized climate conditions.

Portable Chiller Maintenances

What are the Factors Should you Consider While Installing your Portable Chiller?

You should keep the following factors in your mind while installing your Portable Chiller:

Inspection of packaging

A Portable Chiller comes in a single crate that contains all the essentials. The casters must be attached to it to make them functional.

Inspection of Each Component

Carefully inspect all the components. Select an appropriate location for your chiller. Try to position it as nearer to the process machine as possible.

Plumbing Connection

The pipe threads should be clean. Wrap them with Teflon or pipe dope. Connect the valves present at the back of the chiller from process tubing.

It should be tightened enough to prevent any leakage.

Coolant Temperature

Fill the coolant in your Portable Chiller manually during installation. The temperature of the water coolant should be 40°F (4°C).

Coolant Level

As soon as the chiller turns on, the coolant level falls as the coolant starts to circulate. Inspect the coolant level.

Refrigerant Charge

A Portable Chiller is fully charged during manufacturing. Check out the refrigerant charge while the chiller is running.

Main Power Source

Connect the power wires to the terminals. Ensure the connection of the ground wire to the grounding lug.

How to Increase the Working Efficiency of your Portable Chiller?

To increase the efficiency of your Portable Chiller, you must keep on maintaining your chiller by cleaning and lubricating it frequently after regular intervals.

Besides this, the following are the ways by which you can increase efficiency:

Maintaining refrigerant charge

Its cooling capability depends on the refrigerant level. Thus, maintaining the refrigerant charge can increase the energy efficiency of your chiller.

Inspecting and cleaning condenser coils

Heat directly impacts the system of a Portable Chiller. Thus, cleaning the condenser coils frequently and regular inspection of condenser coilsfor clogging can help you boost the energy efficiency of your chiller.

Maintaining condenser water

Condenser water must ensure regular flow to maintain working efficiency.

Filtration

Inspect the proper functioning of filters to ensure the disposal of contaminants. Keep on changing filters at regular intervals.

Optimization

It works more efficiently at lower speeds than being operated to its fullest. Operate multiple parallel devices at a time to optimize the efficiency of your Portable Chiller.