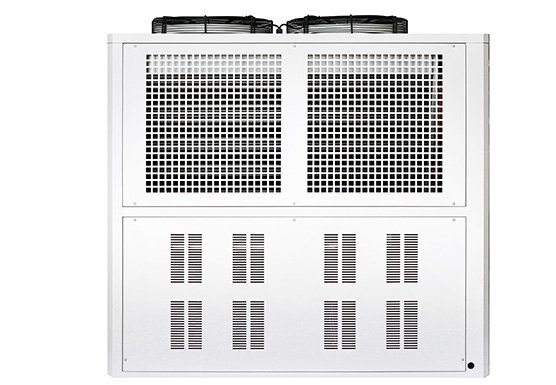

TopChiller can design and manufacture all types of air cooled water chillers for you

- Cooling capacity ranges from 5 Ton to 200 Ton

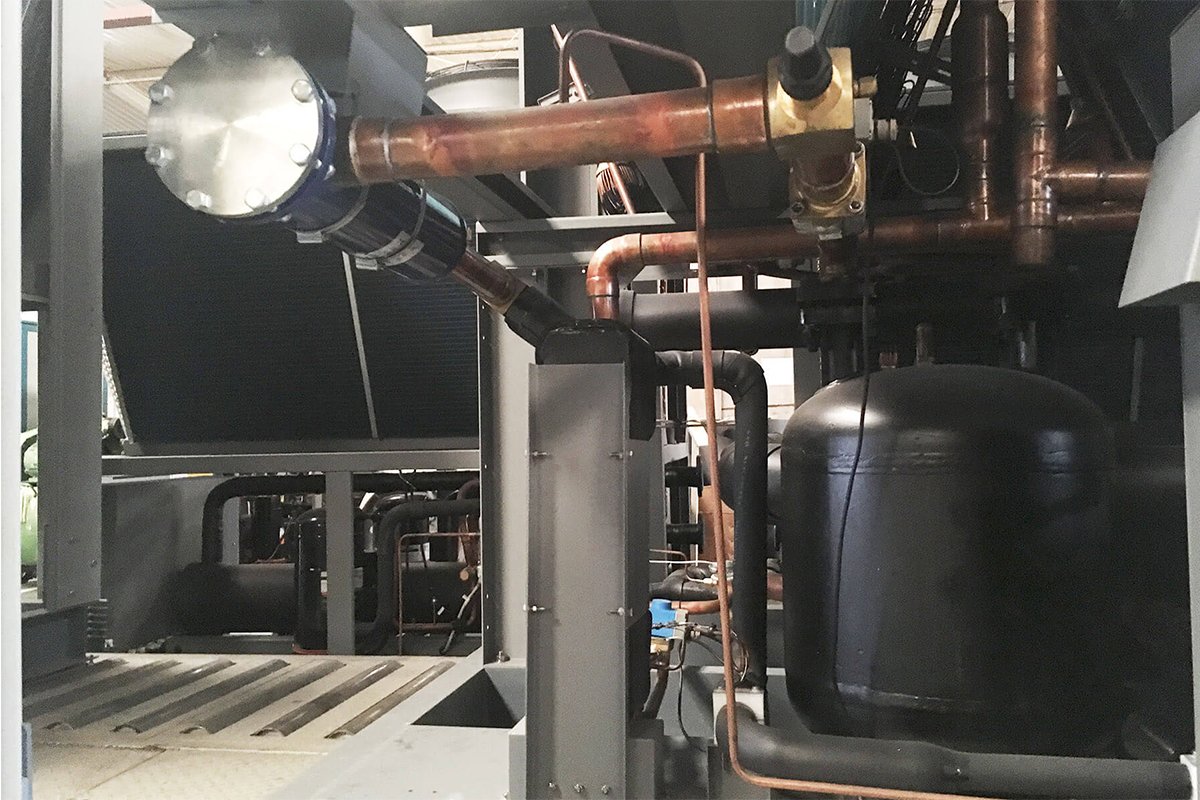

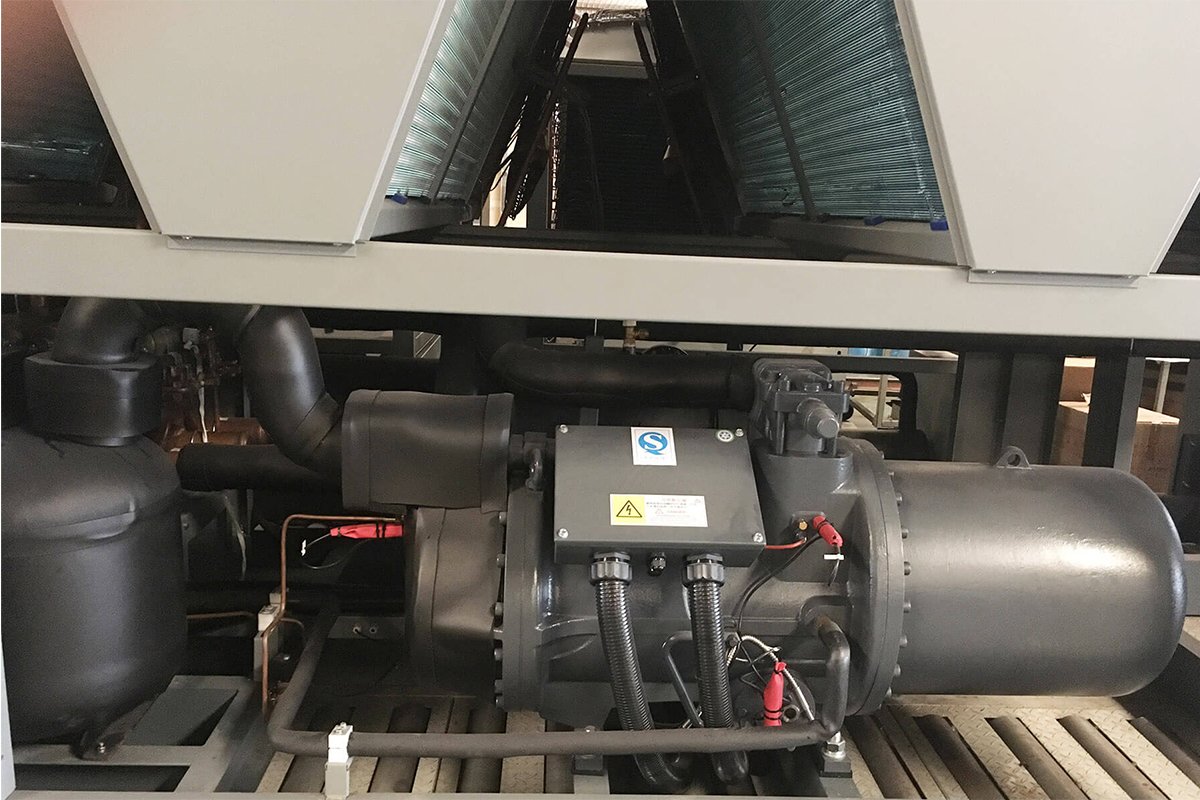

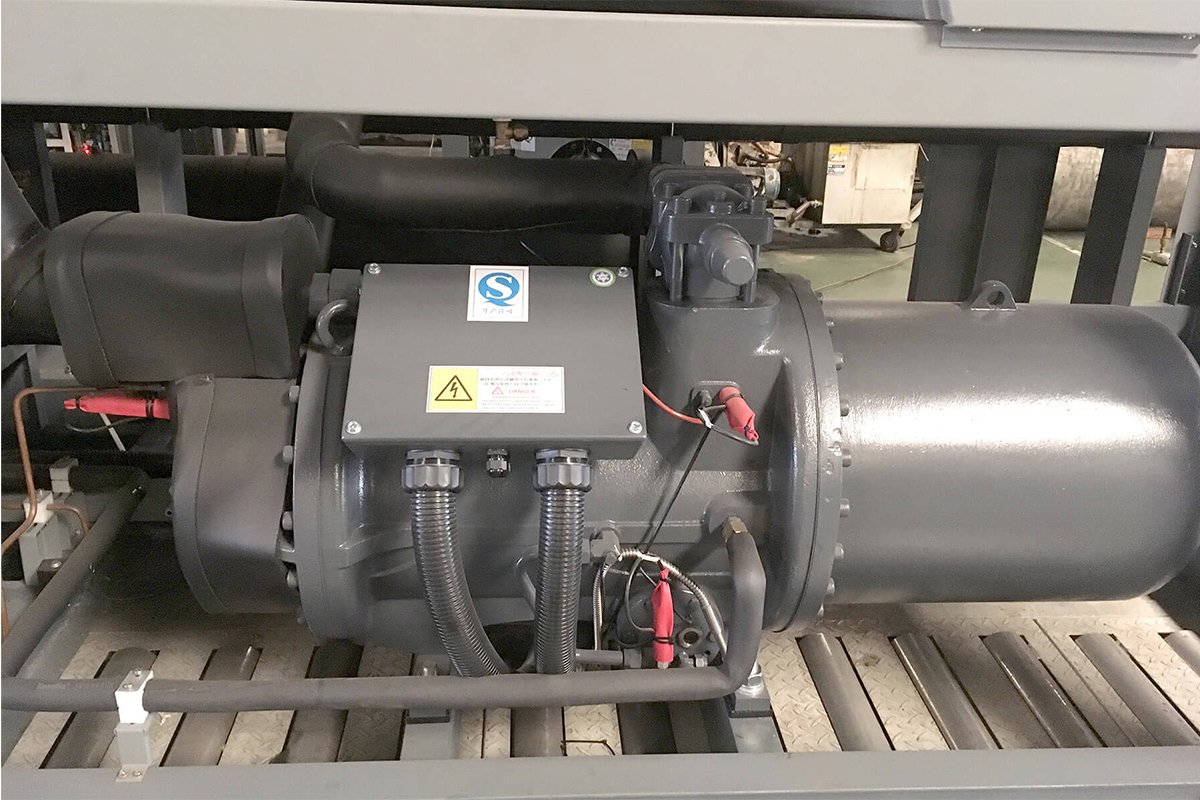

- Top branded scroll & screw type compressor

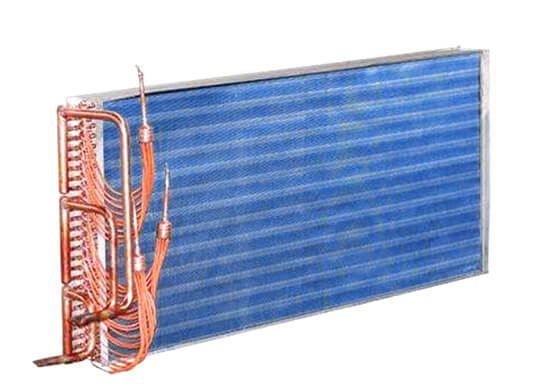

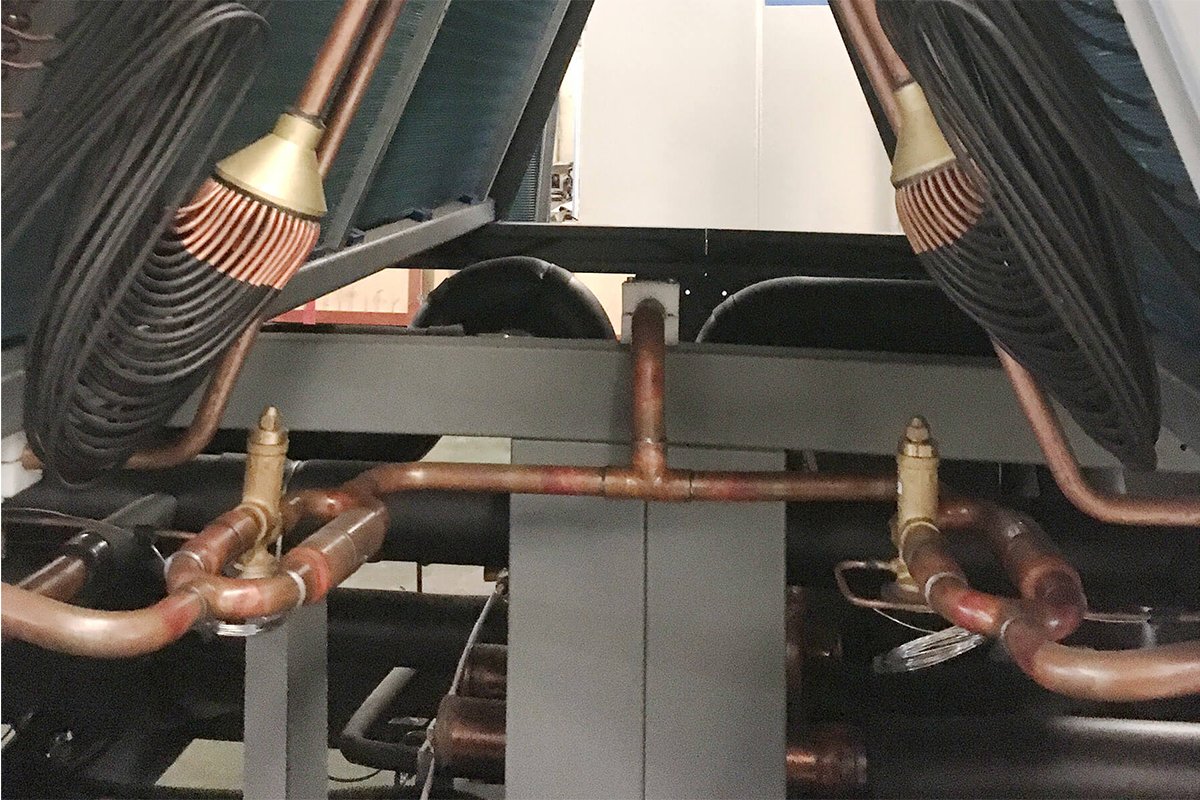

- Air-cooled energy-efficient copper condenser

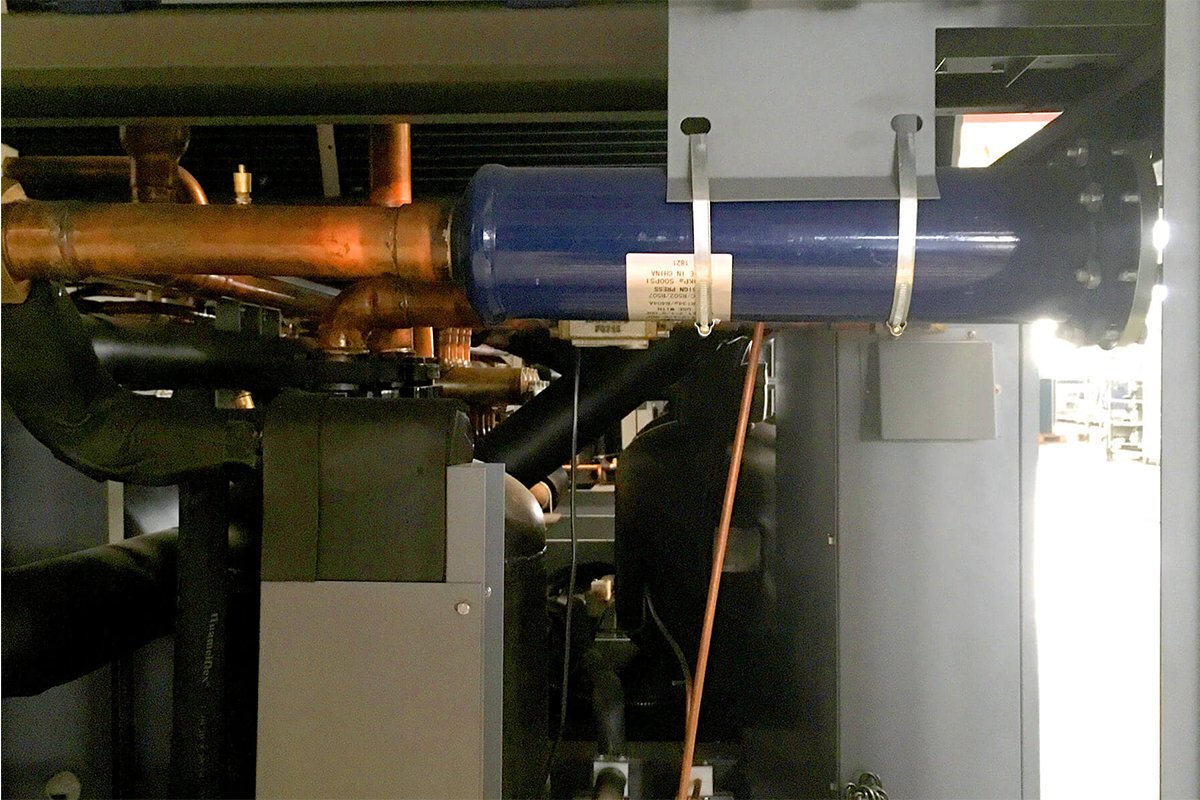

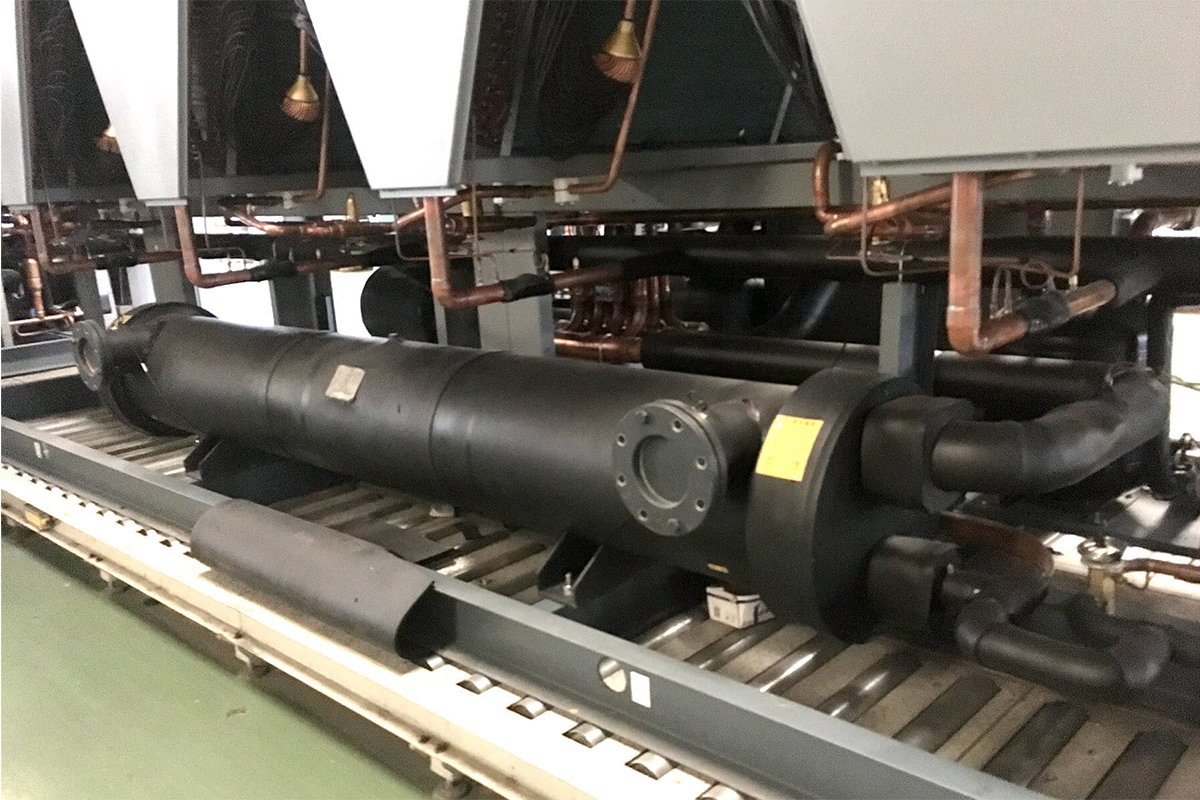

- Closed-loop shell and tube type evaporator

- Condenser fans, with no external cooling tower

- Non-ozone depleting refrigerant, air filter

- SS water tank, shell & tube type evaporator

- Easy maintenance, repairing & compact design

Your Premier Air Cooled Water Chiller Manufacturer and Supplier

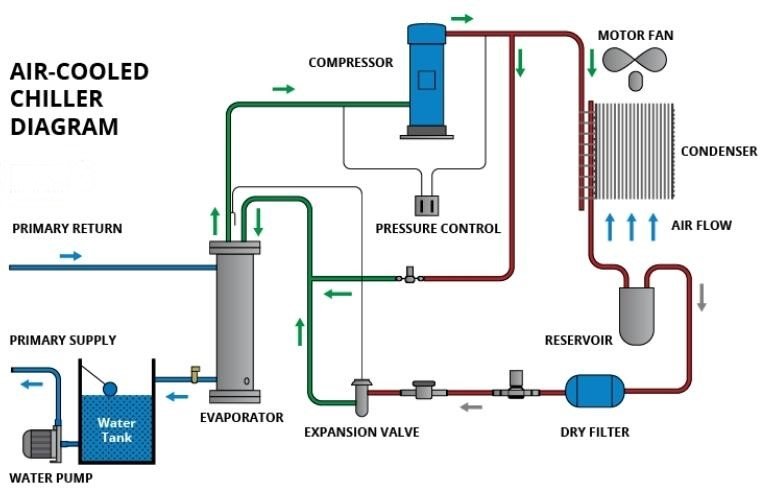

Air Cooled Water Chiller is an energy-efficient water cooling machine the executes cooling effect on processing machines by absorbing heat through chilled water and dissipating it out by air surrounding the condenser unit.

TopChiller is a most appreciated manufacturing company of China that was established in 1999 and working over years to avail the world retailers and manufacturing industries with energy conserving and efficient Air Cooled Water Chiller.

By diligent hardworking over years, TopChiller has manufactured an assorted number of Air Cooled Water Chiller models and earned a name over the world by its worldwide products portfolio, best reviews from customers, and 24 hours active servicing to clients.

Air Cooled Water Chiller is designed by different primary components as scroll/screw compressors, air-cooled condenser, temperature controlling unit, condenser fan, shell and tube type evaporator, water pump, air filter, and power supply.

TopChiller brand Air Cooled Water Chiller has a variety of distinctive benefits for different industrial applications as given below:

- Air Cooled Water Chiller is constructed as a stand-alone unit configured with pipes to connect with pump and external reservoir ensuring reliable performance and easy installation.

- TopChiller designed Air Cooled Water Chiller has lower costs of maintenance for its self-contained featuring preventing all units from direct contact to air dust and no water tank installation inside the unit.

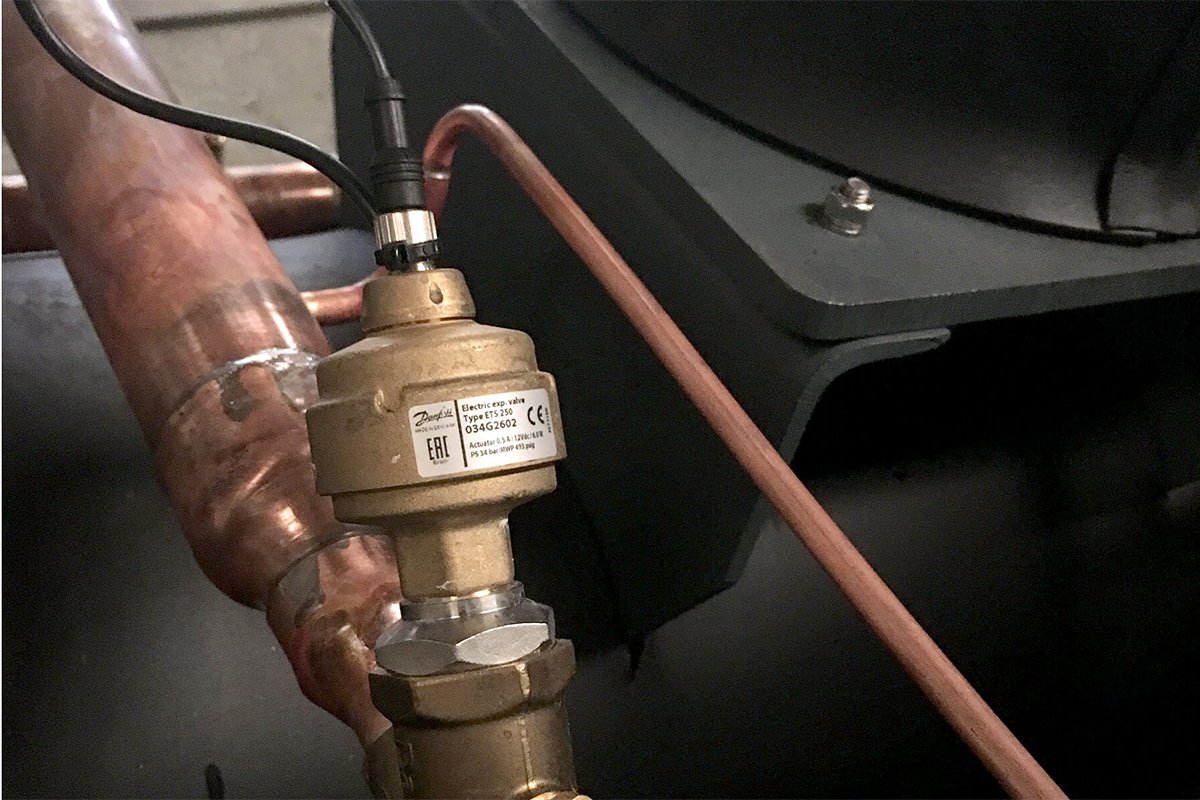

- Air Cooled Water Chiller efficiently discharges the heat where water is not in easy excess by using expansion valves that mitigate pressure on refrigerant and make an easy discharge of heat towards the ambient air.

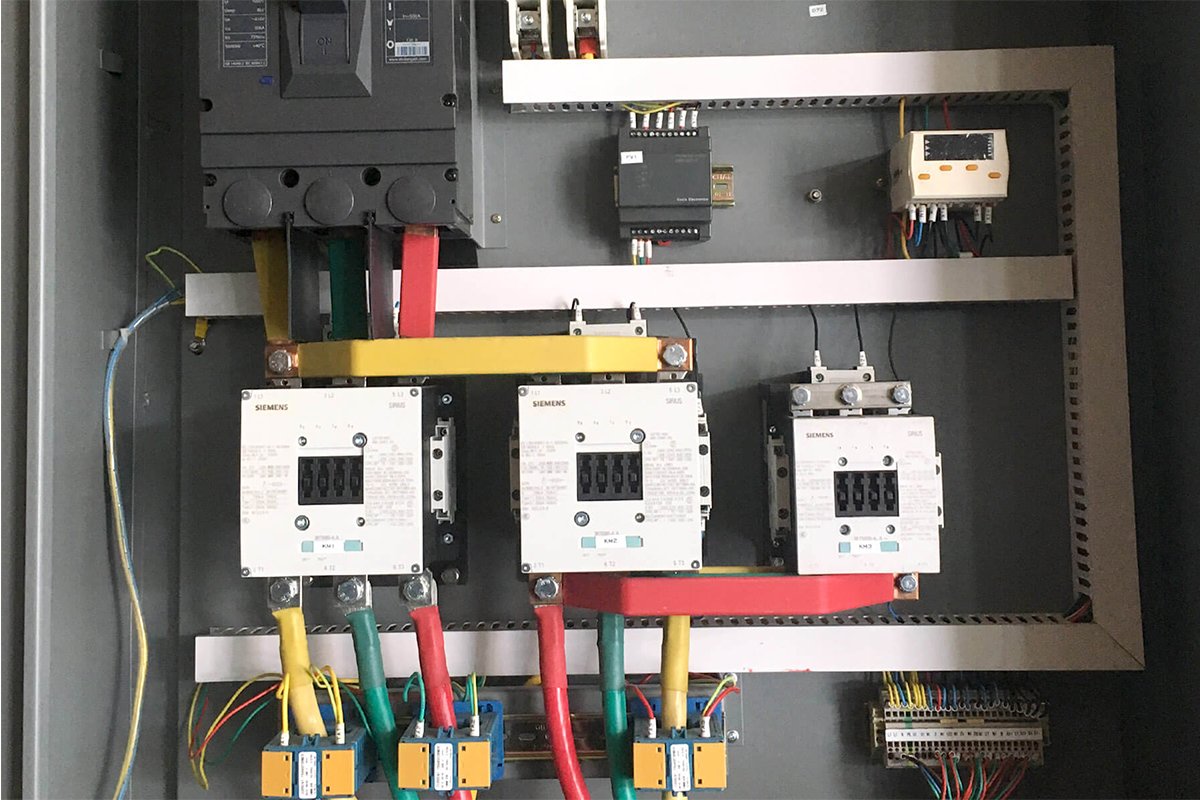

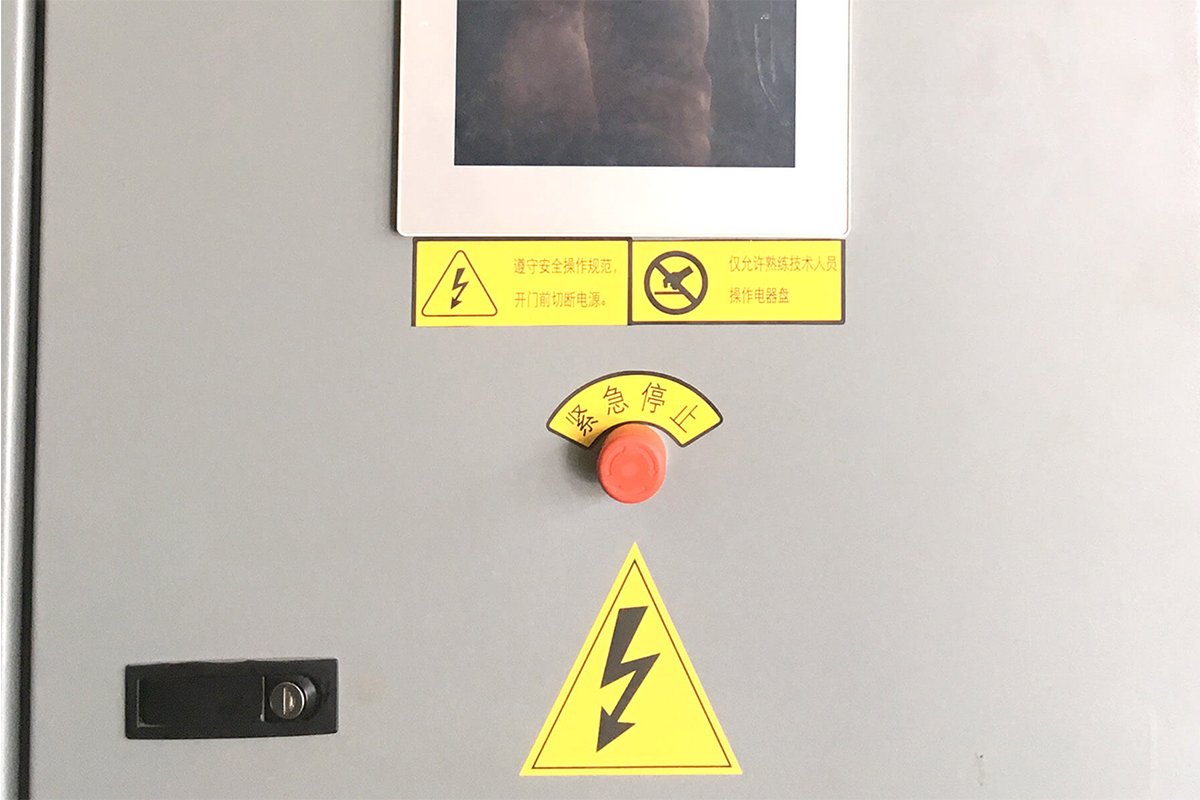

- TopChiller brand Air Cooled Water Chiller has separate electric wires connected to single power control ensuring a unit long service life preventing the unit from overcurrent in emergencies by switching off the main power circuit.

- Air Cooled Water Chiller releases out the heat from the heated system by cooling air circulation from processed water and sometimes recirculates the heated air around the machine to accommodate cooling weather.

Air Cooled Water Chiller is famous among different applications due to its steadfast and reliable performance as:

Metalwork, injection molding, blow molding, supermarkets, hypermarkets, medical laboratories, R&D institutes, large buildings, offices, fermentation industry, refineries, plastic industry, pharmaceutical industry, and die casting, etc.

Are you considering buying an energy-efficient, reliable, and précised working Air Cooled Water Chiller to deal with your application for enhancing product growth?

Are you wandering around to find the best Air Cooled Water Chiller manufacturing company in China for making collaboration and getting innovative technology updates to enhance your business?

TopChiller is a superlative company to rely on. TopChiller has hired trained engineers and professional experts to hit the queries claimed by customers.

Make contact today with the TopChiller team to get updates, technical assistance, and quotes for purchasing Air Cooled Water Chiller at affordable rates.

General Description:

Air Cooled Water Chiller is a reliable and famous water cooling unit that produces chilled water to remove extra heat from commercial and industrial applications by using a mechanical refrigeration cycle.

Air Cooled Water Chiller manufactured by TopChiller is integrated with scroll/screw compressor, air-cooled condenser, evaporator, water pump, water tank, expansion device, and control system as its leading components.

Air Cooled Water Chillers are renowned wide applications in pharmaceuticals, beverage industries, CNC machines, anodizing, fermentation process, distilleries, printing, and cold storage rooms.

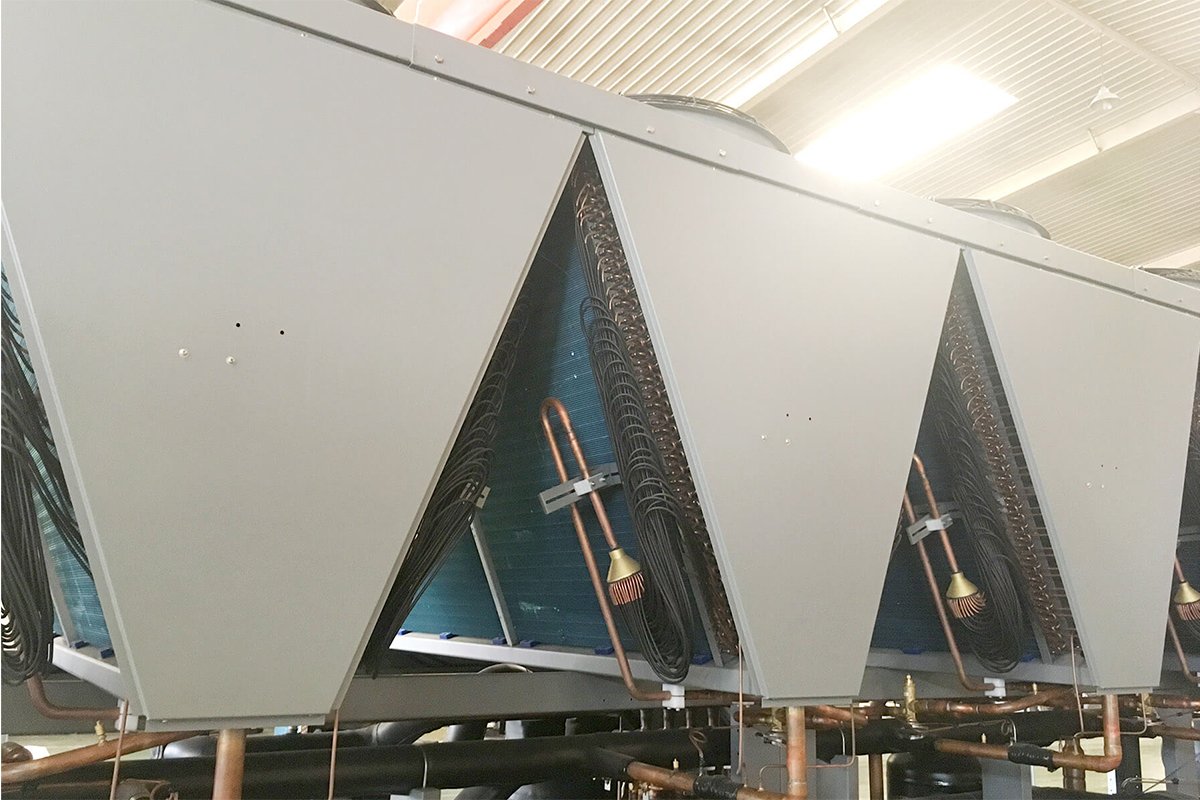

Industrial and commercial application’s heat is rejected by ambient air circulating over air-cooled condensers, hence Air Cooled Water Chiller is called crucial for cooling in water-cooled air conditioning applications.

TopChiller is a leading manufacturer and supplier of Air Cooled Water Chiller for the reliability of its cooling systems.

Under more than twenty years, TopChiller has proudly designed a full line of prime quality Air Cooled Water Chiller to avail the customers of the world with its endless list of options.

If you are desiring an environment-friendly and chilled water-producing Air Cooled Water Chiller for your applications, you will find TopChiller as a top rating company in China.

So commence us a call today for placing your order at a reasonable price. Our personnel and staff engineers will assist you to select the suitable Air Cooled Water Chiller for your applications.

Features and Advantages:

Air Cooled Water Chiller manufactured by TopChiller is famous for its diverse number of features and advantages as given below:

- Self-contained single or split chiller configuration assists to meet the needs of indoors and outdoors applications.

- Heat is dissipated out from the system directly through ambient air present over the condenser configuring ultimate cooling of refrigerant.

- The environment-friendly behavior of the chiller ensures the reliability and working efficiency featured by good quality refrigerant installation and SS compact design.

- Water tank separately connected to the unit through water pipes and control unit ensuring the protection of the whole unit from any damage.

- Copper coils and aluminum fins of condenser coils protect the condenser from corrosion ensuring high durability of the unit.

- Chilled water collects the heat from the system and ultimately transfers it to the circulating air that spreads around to provide the heating effecting in winter.

- Data Sheet

- Image Gallery

- Main Parts

- Video

| Air Cooled Water Chiller Technical Specifications | ||||||||||||||

| Items Model | AC-0.5A | AC-1A | AC-1.5A | AC-2A | AC-2.5A | AC-3A | AC-4A | AC-5A | AC-6A | AC-8AD | AC-10AD | AC-12AD | AC-15AD | |

| Cooling capacity | Kcal/h 50HZ/60HZ | 1419 | 2451 | 3182 | 4833 | 5848 | 7181 | 9288 | 11988 | 14534 | 18576 | 23994 | 29068 | 38270 |

| 1703 | 2941 | 3784 | 5800 | 7018 | 8617 | 11146 | 14386 | 17441 | 22291 | 28793 | 34882 | 45924 | ||

| KW 50HZ/60HZ | 1.65 | 2.85 | 3.7 | 5.62 | 6.8 | 8.35 | 10.8 | 13.94 | 16.9 | 21.6 | 27.9 | 33.8 | 44.5 | |

| 1.98 | 3.42 | 4.4 | 6.74 | 8.2 | 10.02 | 12.96 | 16.73 | 20.28 | 25.92 | 33.48 | 40.56 | 53.4 | ||

| Input power | KW | 0.88 | 1.35 | 2 | 2.25 | 2.66 | 3.27 | 4.07 | 5.75 | 6.45 | 8.25 | 11.5 | 12.9 | 17.45 |

| Max Current | A | 5.4 | 8.2 | 12 | 13.6 | 6.6 | 8.2 | 10.1 | 13.8 | 15.5 | 20 | 27.9 | 31.3 | 42.4 |

| Power source | 1PH~220V/3PH~220V/380V 50HZ/60HZ | 3PH~380V/415V/480V~50HZ/60HZ(3PH~200V/220V 50HZ/60HZ) | ||||||||||||

| Refrigerant | Type | R22/R407C/134a/404A/410A | ||||||||||||

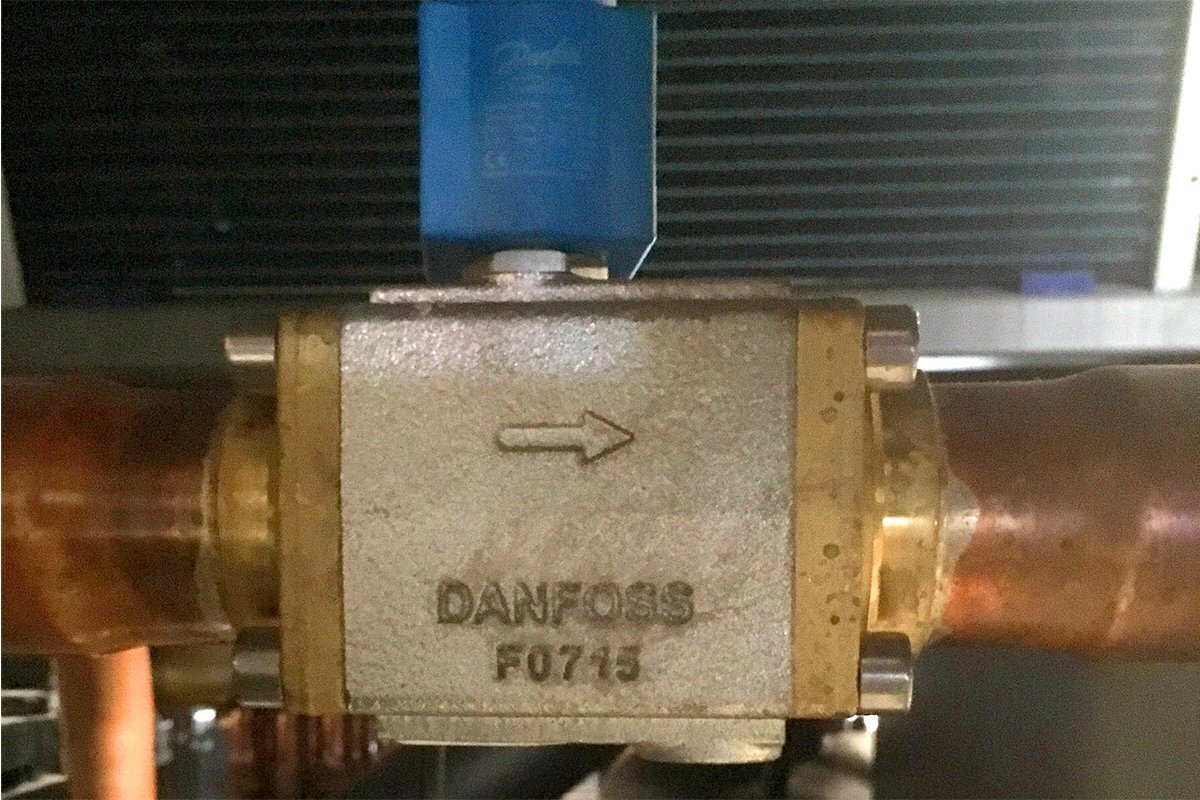

| Control | Capillary / thermostatic expansion valve | |||||||||||||

| Compressor | Type | Hermetic Rotary | Hermetic scroll ( piston ) | |||||||||||

| Power(KW) | 0.45 | 0.89 | 1.3 | 1.73 | 2.1 | 2.7 | 3.5 | 4.55 | 5.25 | 3.5×2 | 4.55×2 | 5.25×2 | 7×2 | |

| Condenser | Type | Efficient finned copper tube with aluminum+low noise external rotor fan | ||||||||||||

| Air flow (m3/h) | 750 | 1000 | 1500 | 2000 | 2500 | 3000 | 4000 | 5000 | 6000 | 8000 | 10000 | 12000 | 15000 | |

| Air blower(KW) | 0.06 | 0.09 | 0.15 | 0.15 | 0.19 | 0.14×2 | 0.14×2 | 0.19×2 | 0.19×2 | 0.25×2 | 0.45×2 | 0.45×2 | 0.6×2 | |

| Evaporator | Type | SS Tank coil / shell and tube type / Plate type heat exchanger | ||||||||||||

| Chilled water (m3/h) | 0.28 | 0.49 | 0.64 | 0.97 | 1.12 | 1.44 | 1.86 | 2.4 | 2.91 | 3.71 | 4.8 | 5.81 | 7.65 | |

| 0.34 | 0.59 | 0.76 | 1.16 | 1.4 | 1.72 | 2.23 | 2.88 | 3.49 | 4.46 | 5.76 | 7 | 9.18 | ||

| Water tank(L) | 10.6 | 18.3 | 27 | 27 | 50 | 50 | 60 | 60 | 110 | 120 | 200 | 200 | 270 | |

| Inlet/outlet pipe (inch) i | 1/2″ | 1/2″ | 1/2″ | 1/2″ | 1″ | 1″ | 1″ | 1″ | 1″ | 1-1/2″ | 2″ | 2″ | 2″ | |

| Water pump | Power (kw) | 0.37 | 0.37 | 0.37 | 0.37 | 0.37 | 0.37 | 0.37 | 0.75 | 0.75 | 0.75 | 1.5 | 1.5 | 2.2 |

| Max lift(m) | 22 | 22 | 22 | 22 | 22 | 22 | 22 | 30 | 30 | 25 | 25 | 25 | 28 | |

| Max flow (m3) | 5.4 | 5.4 | 5.4 | 5.4 | 5.4 | 5.4 | 5.4 | 8.1 | 8.1 | 8.1 | 13.5 | 13.5 | 25.2 | |

| Safety protection | Compressor inner protection, over current protection, high/low pressure protection, over temperature protection, flow rate protection, phase sequence/phase missing protection, low level coolant protection, anti freezing protection, exhaust overheat protection | |||||||||||||

| Dimension | L(mm) | 550 | 550 | 600 | 600 | 720 | 980 | 980 | 1150 | 1150 | 1350 | 1500 | 1500 | 1860 |

| W(mm) | 350 | 450 | 500 | 500 | 550 | 520 | 520 | 560 | 560 | 680 | 760 | 760 | 850 | |

| H(mm) | 695 | 845 | 985 | 985 | 1350 | 1170 | 1170 | 1215 | 1215 | 1530 | 1660 | 1660 | 1900 | |

| Net weight(KG) | 45 | 62 | 85 | 95 | 125 | 152 | 175 | 185 | 215 | 283 | 345 | 382 | 580 | |

| Note: The above specifications are according to the following design conditions: 1, 12℃/7℃.Chilled water inlet/outlet temperature 12℃/7℃. 2, 33℃/38℃.Cooling air inlet/outlet temperature 33℃/38℃. We reserve the right to modify the specification without further notice. | ||||||||||||||

| Air Cooled Water Chiller Technical Specifications | |||||||||||||

| Items Model | AC-15AT | AC-20AD | AC-20AF | AC-25AD | AC-25AF | AC-30AD | AC-30AT | AC-40AD | AC-40AF | AC-50AD | AC-50AF | AC-60AD | |

| Cooling capacity | Kcal/h 50HZ/60HZ | 36120 | 49966 | 47988 | 58480 | 58136 | 74734 | 74922 | 98040 | 99760 | 119024 | 116960 | 144996 |

| 43344 | 59959 | 57586 | 70176 | 69763 | 89681 | 89990 | 117648 | 119712 | 142829 | 140352 | 173995 | ||

| KW 50HZ/60HZ | 42 | 58.1 | 55.8 | 68 | 67.6 | 86.9 | 87.2 | 114 | 116 | 138.4 | 136 | 168.6 | |

| 50.4 | 69.72 | 66.96 | 81.6 | 81.12 | 104.28 | 104.64 | 136.8 | 139.2 | 166.08 | 163.2 | 202.3 | ||

| Input power | KW | 17.1 | 21.73 | 22 | 25.4 | 24.8 | 33.39 | 33.1 | 44.91 | 43.3 | 57.3 | 54 | 65 |

| Max Current | A | 43.2 | 52.7 | 53.3 | 63.7 | 61.3 | 81 | 80.2 | 109 | 106 | 135.5 | 128.5 | 135 |

| Power source | 3PH~380V/415V/480V~50HZ/60HZ(3PH~200V/220V 50HZ/60HZ) | ||||||||||||

| Refrigerant | Type | R22/R407C/134a/404A/410A | |||||||||||

| Control | Capillary / Thermostatic expansion valve | ||||||||||||

| Compressor | Type | Hermetic scroll ( piston ) | |||||||||||

| Power(KW) | 4.55×3 | 8.96×2 | 4.55×4 | 10.8×2 | 5.25×4 | 13.62×2 | 8.96×3 | 18.78×2 | 8.96×4 | 23.6×2 | 10.8×4 | 27.4×2 | |

| Condenser | Type | Efficient finned copper tube with aluminum+low noise external rotor fan | |||||||||||

| Air flow (m3/h) | 15000 | 20000 | 20000 | 25000 | 25000 | 30000 | 30000 | 40000 | 40000 | 50000 | 50000 | 60000 | |

| Air blower(KW) | 0.6×2 | 0.78×2 | 0.78×2 | 0.78×2 | 0.78×2 | 0.42×6 | 0.42×6 | 0.6×6 | 0.6×6 | 0.78×6 | 0.78×6 | 0.78×6 | |

| Evaporator | Type | SS Tank coil/ shell and tube type/Plate type heat exchanger | |||||||||||

| Chilled water (m3/h) | 7.22 | 10 | 9.6 | 11.69 | 11.62 | 14.94 | 15 | 19.6 | 19.95 | 23.8 | 23.4 | 29 | |

| 8.67 | 11.99 | 11.51 | 14.03 | 13.95 | 17.93 | 18 | 23.52 | 23.94 | 28.6 | 28.1 | 34.8 | ||

| Water tank(L) | 270 | 350 | 350 | 350 | 350 | 420 | 420 | 580 | 580 | 580 | 580 | 580 | |

| inlet/outlet pipe (inch) | 2″ | 2″ | 2″ | 2-1/2″ | 2-1/2″ | 2-1/2″ | 2-1/2″ | 3″ | 3″ | 3″ | 3″ | 3″ | |

| Water pump | Power(kw) | 2.2 | 2.2 | 2.2 | 2.2 | 2.2 | 4 | 4 | 4 | 4 | 5.5 | 5.5 | 5.5 |

| Max lift(m) | 28 | 28 | 28 | 28 | 28 | 30 | 30 | 30 | 30 | 32 | 32 | 32 | |

| Max flow (m3) | 25.2 | 25.2 | 25.2 | 25.2 | 25.2 | 36 | 36 | 36 | 36 | 40 | 40 | 40 | |

| Safety devices | Compressor inner protection, over current protection, high/low pressure protection, over temperature protection, flow rate protection, phase sequence/phase missing protection, low level coolant protection, anti freezing protection, exhaust overheat protection | ||||||||||||

| Dimension | L(mm) | 1860 | 2020 | 2020 | 2020 | 2020 | 2200 | 2200 | 2350 | 2350 | 2600 | 2600 | 2600 |

| W(mm) | 850 | 950 | 950 | 950 | 950 | 1150 | 1150 | 1350 | 1350 | 1500 | 1500 | 1500 | |

| H(mm) | 1900 | 2000 | 2000 | 2000 | 2000 | 1980 | 1980 | 2000 | 2000 | 2100 | 2100 | 2100 | |

| Net weight(KG) | 580 | 650 | 650 | 810 | 810 | 890 | 890 | 1112 | 1112 | 1320 | 1320 | 1320 | |

| Note: The above specifications are according to the following design conditions: 1, Chilled water inlet/outlet temperature 12℃/7℃. 2, Cooling air inlet/outlet temperature 33℃/38℃. We reserve the right to modify the specification without further notice. | |||||||||||||

| Air Cooled Water Chiller Technical Specifications | ||||||||||||||

| Model Items | TPAS-80ASH | TPAS-110ASH | TPAS-140ASH | TPAS-160ASH | TPAS-190ASH | TPAS-210ASH | TPAS-250ASH | TPAS-290ASH | TPAS-310ASH | TPAS-340ASH | TPAS-400ASH | TPAS-430ASH | ||

| Cooling capacity | kcal/h | 68800 | 94600 | 122980 | 135020 | 164260 | 180600 | 212420 | 245100 | 266600 | 292400 | 348300 | 369800 | |

| KW | 80 | 110 | 143 | 157 | 191 | 210 | 247 | 285 | 310 | 340 | 405 | 430 | ||

| Input power | KW | 32.5 | 43.6 | 54.7 | 59.7 | 73.6 | 79.6 | 88.2 | 101.2 | 112.8 | 123.8 | 145 | 155 | |

| Max Current | A | 57 | 75 | 95 | 103 | 125 | 135 | 151 | 173 | 191 | 211 | 246 | 263 | |

| Power source | 3PH~380V/415V/480V~50HZ/60HZ(3PH~200V/220V 50HZ/60HZ) | |||||||||||||

| Refrigerant | Type | R22(R134a/R407c/R404A) | ||||||||||||

| Charge | kg | 21 | 28 | 35 | 42 | 49 | 56 | 63 | 70 | 77 | 84 | 98 | 112 | |

| Control | Thermostatic expansion valve | |||||||||||||

| Compressor | Type | Semi-hermetic screw | ||||||||||||

| Power | KW | 30 | 40 | 50 | 55 | 67 | 73 | 82 | 95 | 104 | 115 | 134 | 142 | |

| Start mode | Y-△ | |||||||||||||

| Capacity control | % | 0-33-66-100 | 0-25-50-75-100 | |||||||||||

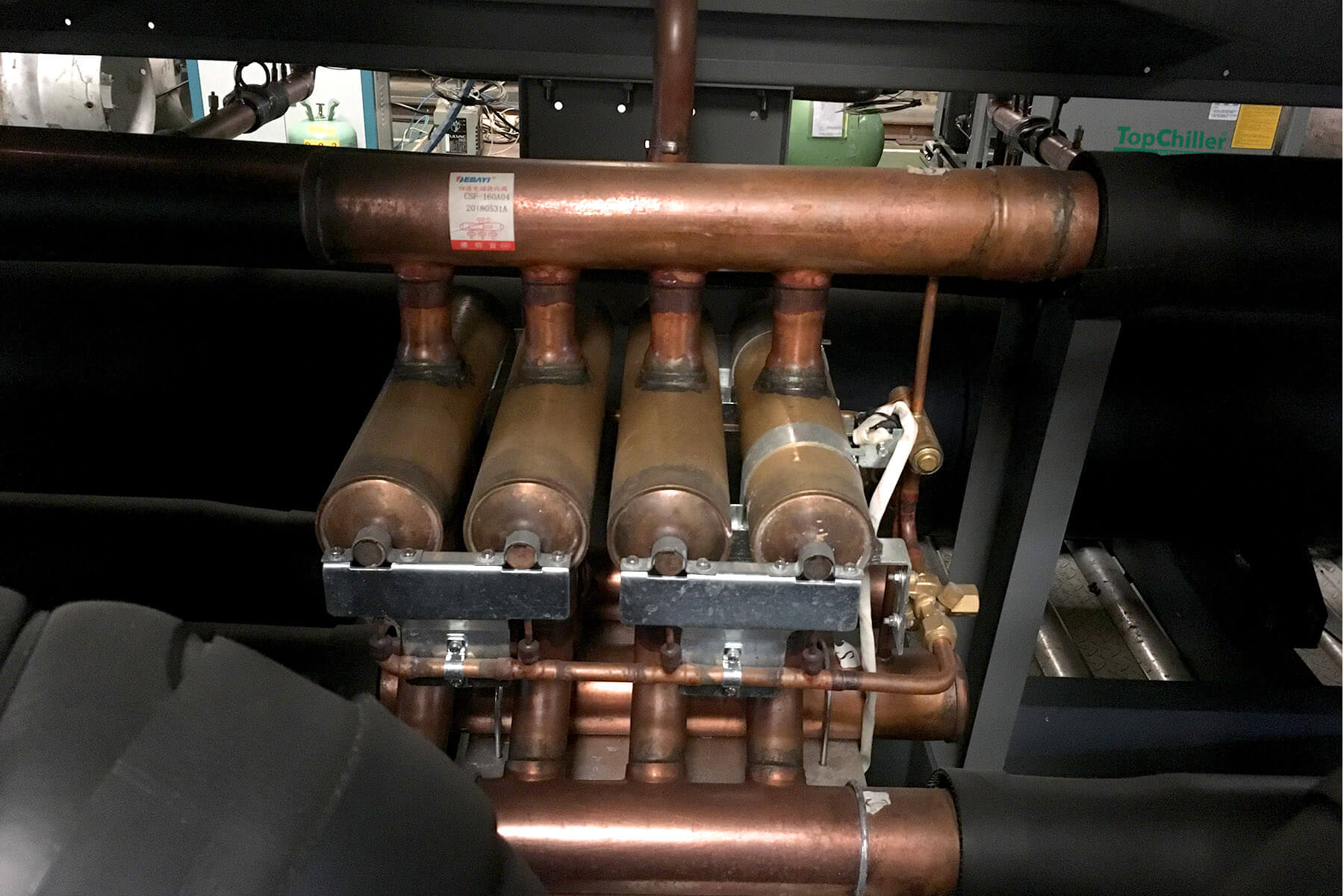

| Evaporator | Type | Shell and tube (SS plate heat exchanger) | ||||||||||||

| Chilled water | m³/h | 13.8 | 18.9 | 24.6 | 27.0 | 32.8 | 36.1 | 42.5 | 49.0 | 53.3 | 58.4 | 70.0 | 74.0 | |

| Water pressure | KPa | 32 | 32 | 35 | 38 | 42 | 42 | 45 | 43 | 43 | 43 | 41 | 43 | |

| Pipe connection | Inch | 3″ | 3″ | 3″ | 4″ | 4″ | 4″ | 4″ | 4″ | 5″ | 5″ | 6″ | 6″ | |

| Condenser | Type | Air cooled type high efficiency finned cooper tube | ||||||||||||

| Fan | Type | m³/h | Big volume & low noise axil fan | |||||||||||

| Power | KW | 0.42×6 | 0.6×6 | 0.78×6 | 0.78×6 | 1.1×6 | 1.1×6 | 0.78×8 | 0.78×8 | 1.1×8 | 1.1×8 | 1.1×10 | 1.1×12 | |

| Air volume | m³/h | 30000 | 40000 | 50000 | 60000 | 70000 | 80000 | 90000 | 100000 | 110000 | 116000 | 145000 | 165000 | |

| Safety protection devices | Inner thermostat for compressor motor, unit overload relay,high and low pressure switch, freeze protection thermostat, reverse phase protection relay, discharge gas thermostat, flow switch | |||||||||||||

| Dimension | Length | mm | 2200 | 2350 | 2600 | 2600 | 2650 | 2650 | 3400 | 3400 | 3800 | 3800 | 4800 | 5800 |

| Width | mm | 1150 | 1350 | 1500 | 1500 | 1900 | 1900 | 1700 | 1700 | 1900 | 1900 | 1900 | 1900 | |

| Height | mm | 1980 | 2000 | 2100 | 2100 | 2200 | 2200 | 2200 | 2200 | 2200 | 2200 | 2200 | 2200 | |

| Net weight | kg | 1100 | 1300 | 1600 | 1900 | 2200 | 2350 | 2550 | 2800 | 2850 | 2950 | 3200 | 3550 | |

| Running weight | kg | 1300 | 1500 | 1840 | 2200 | 2530 | 2700 | 2950 | 3250 | 3350 | 3560 | 3650 | 3950 | |

| The above specifications are according to the following design conditions: 1, Chilled water inlet/outlet temperature 12℃/7℃. 2, Cooling air inlet/outlet temperature 30℃/38℃. We reserve the right to modify the specifications without further notice. | ||||||||||||||

| Air Cooled Water Chiller Technical Specifications | ||||||||||||||

| Model Items | TPAS-160ADH | TPAS-220ADH | TPAS-285ADH | TPAS-315ADH | TPAS-380ADH | TPAS-420ADH | TPAS-495ADH | TPAS-570ADH | TPAS-620ADH | TPAS-680ADH | TPAS-810ADH | TPAS-860ADH | ||

| Cooling capacity | kcal/h | 137600 | 189200 | 245960 | 270040 | 328520 | 361200 | 424840 | 490200 | 533200 | 584800 | 696600 | 739600 | |

| KW | 160 | 220 | 286 | 314 | 382 | 420 | 494 | 570 | 620 | 680 | 810 | 860 | ||

| Input power | KW | 64.7 | 86.6 | 106.2 | 118.8 | 145 | 159.2 | 177.2 | 207.6 | 225.6 | 247.6 | 290 | 310.4 | |

| Max Current | A | 114 | 149 | 185 | 205 | 250 | 274 | 308 | 358 | 388 | 428 | 500 | 533 | |

| Power Source | 3PH~380V/415V/480V~50HZ/60HZ(3PH~200V/220V 50HZ/60HZ) | |||||||||||||

| Refrigerant | Type | R22(R134a/R407c/R404A) | ||||||||||||

| Charge | kg | 21×2 | 28×2 | 35×2 | 42×2 | 49×2 | 56×2 | 63×2 | 70×2 | 77×2 | 84×2 | 98×2 | 112×2 | |

| Control | Thermostatic expansion valve | |||||||||||||

| Compressor | Type | Semi-hermetic screw | ||||||||||||

| Power | KW | 30×2 | 40×2 | 50×2 | 55×2 | 67×2 | 73×2 | 82×2 | 95×2 | 104×2 | 115×2 | 134×2 | 142×2 | |

| Start mode | Y-△ | |||||||||||||

| Capacity control | % | 0-33-66-100 | 0-25-50-75-100 | |||||||||||

| Evaporator | Type | Shell and tube (SS plate heat exchanger) | ||||||||||||

| Chilled water | m³/h | 27.5 | 37.8 | 49.1 | 54 | 65.7 | 72.2 | 85 | 98 | 106.6 | 117 | 139.3 | 147.9 | |

| Water pressure | KPa | 32 | 32 | 35 | 38 | 42 | 42 | 45 | 43 | 43 | 43 | 41 | 43 | |

| Pipe connection | Inch | 4″ | 4″ | 4″ | 5″ | 6″ | 6″ | 6″ | 6″ | 8″ | 8″ | 8″ | 10″ | |

| Condenser | Type | Air cooled type high efficiency finned cooper tube | ||||||||||||

| Fan | Type | m³/h | Big volume & low noise axil fan | |||||||||||

| Power | KW | 0.78×6 | 1.1×6 | 0.78×8 | 1.1×8 | 1.1×10 | 1.1×12 | 1.1×12 | 1.1×16 | 1.1×16 | 1.1×16 | 1.1×20 | 1.1×24 | |

| Air volume | m³/h | 60000 | 80000 | 100000 | 116000 | 145000 | 165000 | 180000 | 205000 | 225000 | 242000 | 285000 | 325000 | |

| Safety protection devices | Inner thermostat for compressor motor, unit overload relay, high and low pressure switch, freeze protection thermostat, reverse phase protection relay, discharge gas thermostat, flow switch | |||||||||||||

| Dimension | Length | mm | 2600 | 2650 | 3400 | 3800 | 4800 | 5800 | 5800 | 7800 | 7800 | 8000 | 9800 | 11600 |

| Width | mm | 1500 | 1900 | 1700 | 1900 | 1900 | 1900 | 2200 | 2000 | 2200 | 2200 | 2200 | 2200 | |

| Height | mm | 2100 | 2200 | 2200 | 2200 | 2200 | 2200 | 2300 | 2250 | 2250 | 2300 | 2350 | 2350 | |

| Net weight | kg | 2050 | 2520 | 2980 | 3180 | 3420 | 3730 | 3950 | 4330 | 4650 | 4930 | 5450 | 5850 | |

| Running weight | kg | 2360 | 2870 | 3420 | 3690 | 3780 | 4180 | 4380 | 4650 | 4920 | 5360 | 5830 | 6530 | |

| The above specifications are according to the following design conditions: 1, Chilled water inlet/outlet temperature 12℃/7℃. 2, Cooling air inlet/outlet temperature 30℃/38℃. We reserve the right to modify the specifications without further notice. | ||||||||||||||

Why TopChiller is Your Reliable Air Cooled Water Chiller Manufacturer and Supplier In China?

Air Cooled Water Chiller-An Ultimate FAQ Guide by TopChiller.

- What is Air Cooled Water Chiller?

- What are the General Features of Air Cooled Water Chiller?

- What are the Main Components of Air Cooled Water Chiller?

- How Does an Air Cooled Water Chiller Work?

- What is the Refrigeration Cycle of Air Cooled Water Chiller?

- What are the Advantages of an Air Cooled Water Chiller?

- What are the Basic Configurations of an Air Cooled Water Chiller?

- What is the Cooling Capacity of Air Cooled Water Chiller?

- Which Types of Compressors are Featured With Air Cooled Water Chiller?

- What are the Applications of Air Cooled Water Chiller?

- Which Accessories can be Integrated With your Air Cooled Water Chiller?

- Which Type of Condenser is Used for Air Cooled Water Chiller?

- Which Type of Heat Exchangers is Configured With Air Cooled Water Chiller?

- How is an Air Cooled Water Chiller Different from Water Cooled Water Chiller?

- How is Stationary Air Cooled Water Chiller Different from Portable Air Cooled Water Chiller?

- Which Refrigerant is Installed in an Air Cooled Water Chiller?

- What are Capacity Control Methods of Air Cooled Water Chiller?

- How to Size an Air Cooled Water Chiller for your Applications?

- What are the Installation Steps of Air Cooled Water Chiller?

- What are the Maintenance Guidelines for your Air Cooled Water Chiller?

- How to Troubleshoot your Air Cooled Water Chiller?

What is Air Cooled Water Chiller?

An Air Cooled Water Chiller is a reliable and environment-friendly cooling unit that dissipates the system heat by air-cooled condensers.

Water tanks are filled with chilled water that circulates in the system through ducts for collecting heat.

Air acts as a condenser medium and helps in the final discharge of heat from the system.

R-410A is the most commonly used refrigerant for water cooling. Long service life, easy installation, high reliability, and maintenance are the key features that make the unit reliable to use.

Air Cooled Water Chiller Manufactured by TopChiller

What are the General Features of Air Cooled Water Chiller?

An Air Cooled Water Chiller configures the chilling effect for different industrial applications under its some basic features as given below:

- Shell and tube type/brazed plate evaporator for water cooling

- Scroll/screw-type compressors for refrigerant compression

- Environmental friendly refrigerant installation

- Air-cooled condenser for cooling refrigerant

- Impeller fans for air spread over coils

- Controlled unit and energy-saving working efficiency

- Compact design and easy repairing of the unit

- Prime quality SS water tank and water pump

- Easy installation and maintenance

What are the Main Components of Air Cooled Water Chiller?

An Air Cooled Water Chiller is a cooling device that uses chilled water to generate a cooling effect in a processing application.

It has some main components as given below:

Compressor

A scroll compressor or screw compressor is configured to the unit for refrigerant compression.

Evaporator

Brazed plate or shell and tube type evaporator are installed for chilling water.

Condenser

Air-cooled condensers with impeller fans dissipate the system heat in the outside environment.

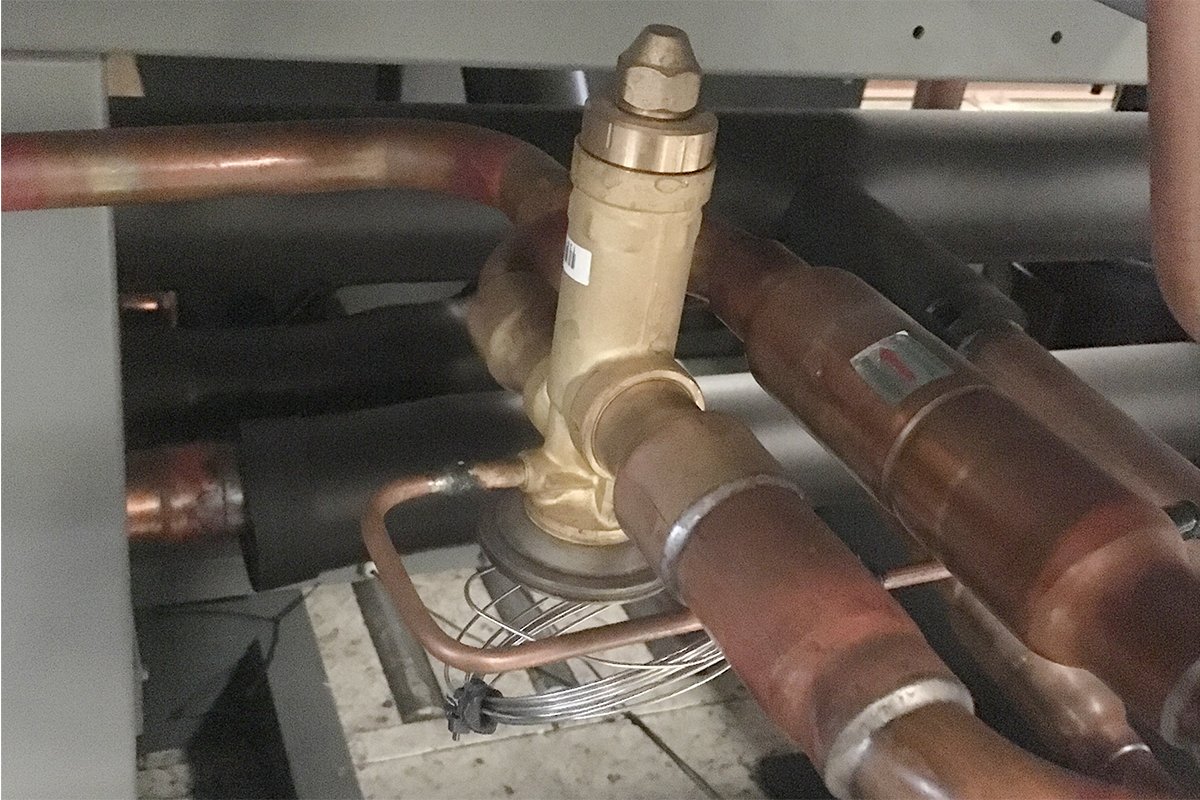

Expansion Unit

The expansion valve lowers the temperature and pressure of the refrigerant before entering the evaporator.

Control Unit

Display screen and control unit for regulating Air Cooled Water Chiller operation.

Air Cooled Water Chiller Major Parts

How Does an Air Cooled Water Chiller Work?

An Air Cooled Water Chiller is a highly reliable cooling device that collects heat from the system by chilled water and dissipates it through air circulation.

This working process of the chiller is given below:

Step 1

Chilled water from the water tank circulates through the duct system in the required application or building for heat absorption.

Water coolant gets hot after heat absorption from the system and enters into evaporator/heat exchanger.

Step 2

The heat exchanger consists of a tubing system in which the chilled refrigerant circulates. The hot water circulated over the refrigerant. The heat is transferred from coolant to refrigerant.

After heat absorption, the liquid refrigerant evaporates. The gaseous refrigerant with low pressure leaves the evaporator and enters the compressor.

Step 3

The scroll/screw compressor of the Air Cooled Water Chiller receives the low pressured refrigerant and mediates compression force over the refrigerant.

Refrigerant with high pressure and temperature leaves the compressor and enters into the condenser.

Step 4

The air-cooled condenser receives the coming refrigerant and dissipates heat by air circulating over condenser coils.

The air is released into the environment and the refrigerant condenses into a liquid state.

Step 5

After condensation, the refrigerant enters into an expansion device that lowers the pressure and temperature on the refrigerant.

Step 6

The refrigerant then enters again into the evaporator to repeat the refrigeration cycle.

What is the Refrigeration Cycle of Air Cooled Water Chiller?

The refrigeration cycle of an Air Cooled Water Chiller consists of a compressor, air-cooled condenser, evaporator, and expansion valve through which the refrigerant circulates.

Two processes take place in the refrigeration cycle:

1 Evaporation Process

The liquid refrigerant changes from the liquid phase to the gaseous phase inside the evaporator after heat absorption comes from the system.

2 Condensation Process

The gaseous refrigerant condenses back into a liquid state in an air-cooled condenser after heat discharging in the outside environment.

Refrigeration Cycle

- In Air Cooled Water Chiller, the heated water coming from buildings or processing applications gets enter inside the evaporator.

- The chilled refrigerant of the evaporator again cools down the water to circulate back in buildings. The gaseous refrigerant moves towards the compressor.

- The compressor puts compression force over the refrigerant. The pressurized refrigerant discharged from the compressor enters the air-cooled condenser for the final heat dissipation.

- After that refrigerant enters again in the evaporator to start up the next cycle. This is called the refrigeration cycle.

What are the Advantages of an Air Cooled Water Chiller?

There are a large number of advantages to using an Air Cooled Water Chiller as given below:

Easy Installation

The unit has easy installation, lower costs of repairing and maintenance.

Energy-Efficient Operation

The scroll compressors/screw compressors are configured with the chiller to make an energy-efficient and cost-effective operation.

Environment-Friendly Behavior

The refrigerant that is installed has environmentally-friendly behavior having no negative impact on the ozone layer.

Compact Unit

Compact designed stainless steel unit and copper coils of condensers make the unit corrosion resistive and high protective from weather extremities.

Easy Heat Discharging

Ambient air helps the discharge of air from the condenser without making a substantial investment as in a water-cooled condenser.

Compact Design Portable Air Cooled Water Chiller

What are the Basic Configurations of an Air Cooled Water Chiller?

An Air Cooled Water Chiller is available with different configurations. Different configurations depend upon the application requirements as well as environmental conditions.

The basic configuration is given below:

Single Piece/Packaged Chiller Unit

The single packaged unit consists of all of its refrigeration components together in a single unit for easy installation and maintenance.

The main advantage of Packaged Air Cooled Water Chiller is that it is factory mounted. All validation tests are performed in a factory with refrigeration pipe assembly and power connections etc.

It can be installed outdoors under controlled environmental conditions.

Split System for Air Cooled Water Chiller

Alternatively to the packaged unit, a split system configuration is also adopted for chiller designing.

In the split system, all of the refrigeration components are not configured inside a single unit but instead, the compressor and condenser are installed outdoors.

While the evaporators/heat exchanger component of the refrigeration system is placed indoors.

Both indoor and outdoor components of Air Cooled Water are connected by refrigeration piping.

Its primary advantage is that during winter when the ambient temperature reaches to lower level, the evaporator indoor installation prevents the refrigerant from freezing.

Condenserless Chiller

The Air Cooled Water Chiller configuration consists of all refrigeration components together except for the condenser unit that is placed outdoor while compressor, evaporator, and control units are placed indoors.

The advantage to use this type of configuration is easy installation, maintenance, and troubleshooting in case of any extremity in weather.

What is the Cooling Capacity of Air Cooled Water Chiller?

An Air Cooled Water Chiller can meet the cooling requirements of different applications as it is available with cooling capacity ranges 2.7KW to 168KW with temperature control ranges 7˚C to 30˚C.

Which Types of Compressors are Featured With Air Cooled Water Chiller?

Three types of compressors can be integrated with Air Cooled Water Chiller as given below:

Scroll Compressor

Scroll compressors are highly efficient as compared to the reciprocating compressor because it contains 60% moveable components.

The compression ability of the scroll compressor is highly reliable as it contains one fixed scroll unit and the other is a moveable/ rotary unit.

When rotary scroll moves coupled with fixed scroll, pressure is exerted over circulating gas. In the end, gas is discharged from the scroll compressor with high pressure.

These compressors are available hermetically with up to 25 Ton capacity. More than one compressor can also be integrated to increase capacity.

Screw Compressor

Screw compressors are commonly used for Air Cooled Water Chiller. One or more than one screw compressor is attached to meet needs ranges 70 Ton to 500 Ton.

It consists of more than one rotor for gas compression. A screw compressor is also considered better as compared to a reciprocating compressor because of its rotary parts.

It can compress the fixed amount of refrigerant entering because of its positive displacement feature.

Reciprocating Compressor

Reciprocating compressors are mediated to receive a fixed amount of refrigerant for compression under its positive displacement featuring.

It consists of rods, intake valves as well as discharge valve and piston.

The valves act to control the suction pressure as well as discharge pressure. It is also available in hermetic or semi-hermetic and can be configured with a single compact unit.

Air Cooled Water Chiller Scroll Compressor

What are the Applications of Air Cooled Water Chiller?

Air Cooled Water Chiller is a specifically designed cooling machine that is used to get the chilling effect for an assorted number of processing applications as given below:

- X-Rays Spectrometry

- Distilleries

- Fermentation

- Nitrogen Liquid Plants

- Pharmaceutical Industry

- Anodizing

- Printing

- CNC Machines

- Poultry

- Cold Storage Rooms

- Semiconductors

- Food And Beverage Industry

- Laboratories

- Water Jet Cutting

Which Accessories can be Integrated With your Air Cooled Water Chiller?

An Air Cooled Water Chiller is configured to cool different processing applications. Different accessories can be integrated with the unit to increase the working efficiency as given below:

- Wind Baffles

- Condenser Head Pressure Controlling Unit

- Volume Tank

- Expansion Tank

- High-Pressure Gauge

- Fan Speed Controlling Unit

Air Cooled Water Chiller Expansion Tank

Which Type of Condenser is Used for Air Cooled Water Chiller?

Air Cooled Condenser

For Air Cooled Water Chiller, the air-cooled condensers are used for system heat dissipation.

Air-cooled condensers consist of circulating coils in which the refrigerant enters coming from the compressor.

The condenser is featured with a cooler that is air circulating over condenser coils. All of the heat from the hot refrigerant is transferred to the condenser.

The continuous air is drawn over the condenser by impeller fans.

The condenser coils of air-cooled condensers are designed differently to protect them from corrosion effects as:

The condenser has copper coils and aluminum fins or the entire unit is designed with copper that ensures condenser protection from corrosion effects.

Finally, the condenser lowers the temperature of the refrigerant and converts it again into a liquid state.

Which Type of Heat Exchangers is Configured With Air Cooled Water Chiller?

Three different types of heat exchangers are integrated with Air Cooled Water Chiller assuring the availability of a various number of chiller designs as given below:

Flooded Shell and Tube Type Heat Exchanger

This type of evaporator/heat exchanger consists of tubing covered with a shell. The tubing always entailed water flooding.

While the refrigerant present in shell flowing over water coolant coming from processing unit.

It is a less efficient heat exchanger. When it is installed for Air Cooled Water Chiller, the number of tubing is increased to level up the chiller working efficiency.

The chiller containing a centrifugal compressor is featured with this flooded type heat exchanger.

Expanded Shell and Tube Type Heat Exchanger

This type of heat exchanger also contains tubes and a shell as its basic components. The refrigerant flows inside tubes of the heat exchanger, while the water coolants flow over tubes, present in the shell.

After heat transfer from hot water, the refrigerant gets evaporated and moves out from the heat exchanger at low temperature and pressure.

Air Cooled Water Chiller containing reciprocating compressor or scroll compressor is preferred to integrate with direct expansion shell and tube type heat exchanger.

Brazed Plate Heat Exchanger

This type of heat exchanger is efficient in its working as compared to other types of heat exchangers.

It consists of multiple plate facings to which the tubing is attached. The fluid flows inside tubes. One tube contains refrigerant. While the other tube contains water circulation.

On one side hot water and chilled refrigerant enter inside tubes. While on the outlet evaporated refrigerant and chilled water flows out.

The efficiency of the brazed plate heat exchanger increased under a small cross-sectional area of plates and fluted design that increase the turbulence in the fluid.

It also occupies lower space in Air Cooled Water Chiller ensuring turbulence in fluid for part-load applications.

Air Cooled Water Chiller Brazed Plate Heat Exchanger

How is an Air Cooled Water Chiller Different from Water Cooled Water Chiller?

Air Cooled Water Chiller and water cooled water chiller differ from each other based on their refrigerant cooling process as soon as it comes out from compressors as:

Air Cooled Water Chiller

This type of chiller is featured with air-cooled condensers for the cooling of refrigerants. Condenser coils are surrounded by ambient air as a condenser medium for heat dissipation.

While condenser fans mediate the air circulation over coils. The condenser capacity depends on airflow rate, refrigerant temperature, and surface area.

A water cooled water chiller contains water-cooled condensers to cool the refrigerant.

The water employ over condenser coils as condenser medium. Pumps assist water circulation over coils. As the refrigerant passes from copper coils heat is transferred to water circulation.

In this way, heat discharges from the refrigerant. While heated water moves back to the cooling tank for getting cooling back to the recycling process.

How is Stationary Air Cooled Water Chiller Different from Portable Air Cooled Water Chiller?

Stationary Air Cooled Water Chiller

A specific type of chiller that does not have a water pump and tank integrated inside the unit.

The tank is connected to the chiller with separate piping is called a stationary Air Cooled Water Chiller.

This type of chiller has separate electrical connections as well as a control system.

Portable Air Cooled Water Chiller

A precise type of chiller containing all of its basic components together and can easily be moved from one position to another is called Portable Air Cooled Water Chiller.

Compressor, pump, evaporator, and condenser are integrated for overall operation. Electrical connections and control system is configured with the unit for controlling overall function.

Stationary Air Cooled Water Chiller

Which Refrigerant is Installed in an Air Cooled Water Chiller?

R-410A and R-407C refrigerant is installed in the Air Cooled Water Chiller as it is environment-friendly and efficient refrigerant for heat transfer.

R-22 refrigerant is also used in some models. But now its usage has been stopped as it contains chlorine that is hazardous for the environment.

The chlorine radicles effects on ozone layer causing global warming. Therefore R-410A and R-407C refrigerants are widely used as compared to R-22.

Air Cooled Water Chiller Environmental Friendly Refrigerant

What are Capacity Control Methods of Air Cooled Water Chiller?

The Air Cooled Water Chiller is configured to work at full capacity based on application load. So its capacity can be controlled by the following methods:

Compressor Unloading

The capacity can be controlled by unloading the compressor. The scroll compressor has not the capability to be unloaded.

The screw compressor and reciprocating compressor undergo this process. The suction valves of the reciprocating compressor are opened by the unloader resulting in a reduction of compression over the refrigerant.

While the side valves of the screw compressor cover the suction valves reducing screws length as well as compression over the refrigerant.

In this way, the capacity of the compressor is being controlled.

Cycling of Compressor

When multiple compressors are organized within the chiller, the cycling compressor method is commonly chosen.

It is an energy-efficient and highly reliable capacity controlling method. But one drawback is that by its continuous use, the motor of the compressor can be damaged.

In multiple compressors, when the load will be at peak, the refrigeration cycle will run in all integrated compressors.

But if there is a lighter load, the individual compressors are cycled-off to reduce the load or capacity.

Hot Gas Bypass

This method is also suitable for capacity control. The highly pressurized refrigerant that discharges from the compressor should be entered into a condenser for heat discharge. But the refrigerant is reversed back towards the evaporator.

In this way, some of the refrigerants lose while moving back towards the compressor and capacity reduces at hot gas bypass.

But it is not considered a reliable method because of the continuous operation requisite for the compressor to complete the refrigeration cycle.

Air Cooled Water Chiller Hot Gas Bypass

How to Size an Air Cooled Water Chiller for your Applications?

An Air Cooled Water Chiller is available with different sizes and cooling capacities. Different applications require chiller of different cooling capacities.

So it can be sized in the following way:

- First checkout the cooling requirements of your application and then select the chiller accordingly.

- If further expansion is required, install another unit to meet additional needs.

- Also, inspect environmental conditions to select your Air Cooled Water Chiller.

- Select the split chiller system if there is lower space for installation.

- Also, keep in mind your budget while selecting a chiller.

- Prefer to select that can meet the needs of your application with reliability.

What are the Installation Steps of Air Cooled Water Chiller?

An Air Cooled Water Chiller is available with different configurations as per application requisites as a single unit or split unit etc.

The installation steps are given below:

Transport and Handling

- After receiving the cooling equipment, make sure a precised inspection.

- Check out the outer surface of the chiller for any damage or scratches.

- Also, check that all accessories that you have ordered safely arrive at the site of installation.

Unit Lifting and Installation

- Call the technicians with sound knowledge and experience for unit installation.

- The electric current, chiller pressure, and refrigerant charge are some peculiar aspects that must consider while unit lifting.

- Follow the instructions available on the catalog for unit lifting to protect the frame, condenser coils from jolting.

- Install it in a place where obstructions through ambient air would be less.

- For lower temperature, and frosting environments select the concrete designed base for chiller installation instead of ground.

- Sufficient spacing should be available around the site of installation for feasible air discharging from the condenser.

Water Connections

- The tank should be installed upstream so that positive pressure remains maintained for the evaporator and condenser.

- The water pipes are fitted in such a way that no radial force acts on the evaporator through water circulation.

- Drain connections, valves, and flexible connections are made for controlling water flow and vibrations.

Flow Switches

- These are integrated with evaporators to determine the water flow in the heat exchanger before the start-up Air Cooled Water Chiller.

Electric Connections

- Connect the power supply from the building to the chiller.

- Also, connect the control unit with the power supply used for an electric panel.

- Connect the isolator switch between the chiller and power supply.

- Test all connections, startup the unit, and starts working.

What are the Maintenance Guidelines for your Air Cooled Water Chiller?

For long service life and efficient working of an Air Cooled Water Chiller, the following maintenance guidelines should be followed as given below:

- Make sure the regular inspection and servicing of the unit at least one time per year

- Clean out the whole unit on regular basis.

- Also, monitor all pipes and valves. Then clean out the condenser coils as well as filters for proper operation.

- Repaint the surface where paint is diminished for corrosion protection.

- Also check the water pump, piping leaks, and cleanout water pump filters.

- Top-up water with an anti-freezing agent if the level goes down from requisites.

Seasonal servicing by shutting down or restarting the whole system for:

1-Checking control system and motor work.

2-To analyze compressor oil and change the oil if required.

3-Electrical connections analysis for the smooth operation of the unit.

Air Cooled Water Chiller Maintenances

How to Troubleshoot your Air Cooled Water Chiller?

An Air Cooled Water Chiller can face some problems while operation that can be troubleshot as explained below:

- If the compressor is not working, the refrigerant charge can be below. To troubleshoot the problem check out the refrigerant charge and refill it.

- In case the water flow rate is slow down then inspect the water pump and clean it to sort out the problem.

- If motor windings are not cooled properly then measure superheating of heat exchanger and adjust it if needed.

- Check if the compressor is taking the time or turning on with difficulty, any mechanical problem or faulty windings can occur. This problem can be troubleshot by replacing the compressor.

- The compressor is making vibrations and noise, the fault can be by blockage of expansion valve or rupturing of suction valve. The problem can be troubleshot by replacing valves with a new one.

- Abnormally heating of condenser can be due to the high refrigerant charge. This is sorted out by recovering the refrigerant charge.

- If water is too cold at the condenser, the problem can be due to tube fouling. Clean the tubes for the sorting problem.