TopChiller can design and manufacture all types of air cooled screw chillers for you

- Cooling capacity ranges from 50 Ton – 200 Ton

- Temperature control ranges from 5℃ to 25℃

- Highly reliable top branded screw compressor

- High-efficiency tube type loading evaporator

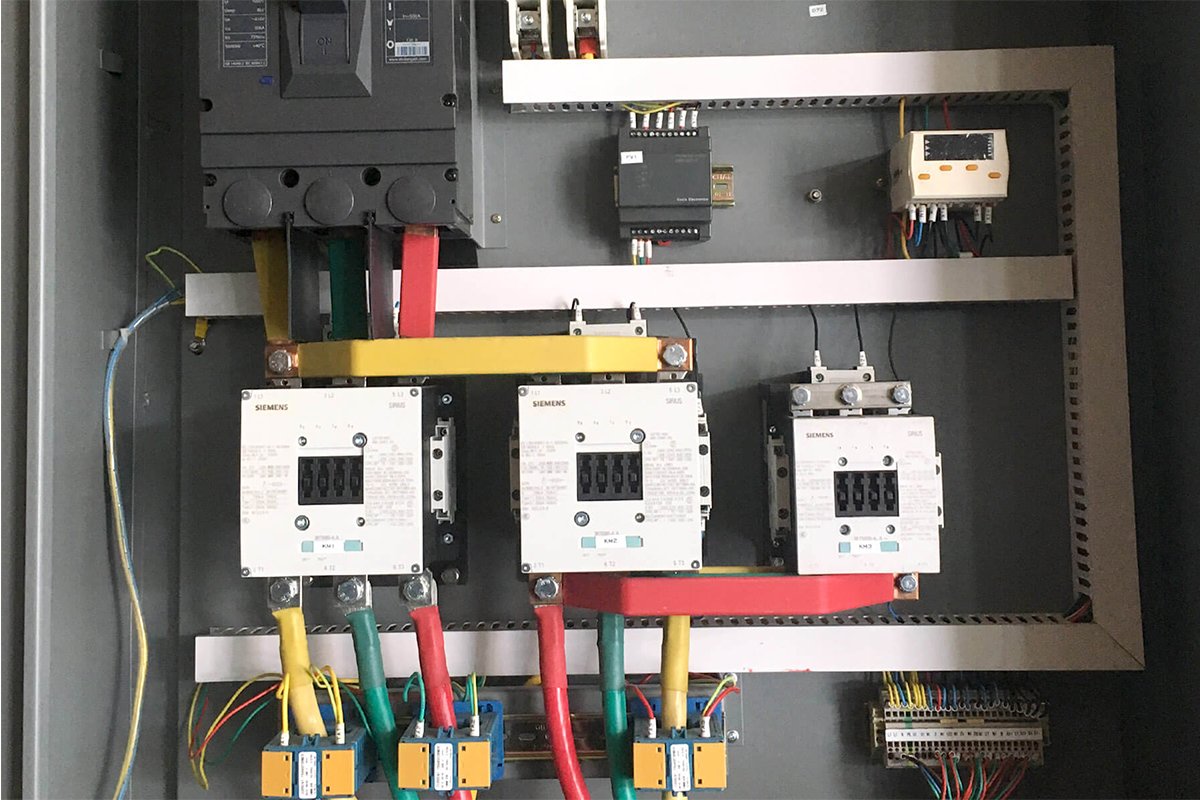

- ACP and AC control solutions for monitoring

- Ice thermal storage system for indoor cooling

- Flexible design, quiet operation & easy installation

- Modular design adoption with high cooling capacity

Your Premier Air Cooled Screw Chiller Manufacturer and Supplier in China

Air Cooled Screw Chiller is a water cooling device that produced a chilling effect by using compression pressure and releases out heat from the system by chilled air circulation in different commercial and industrial applications.

TopChiller is the leading manufacturer and supplier of China servicing the whole world industries with energy efficient and steadfast Air Cooled Screw Chiller for over last twenty years with a worldwide reputation.

TopChiller has introduced itself among the global world by establishing powerful distribution networking ensuring the supply and easy access of diverse ranged Air Cooled Screw Chiller for all our customers, retailers, and stakeholders with a standard credential.

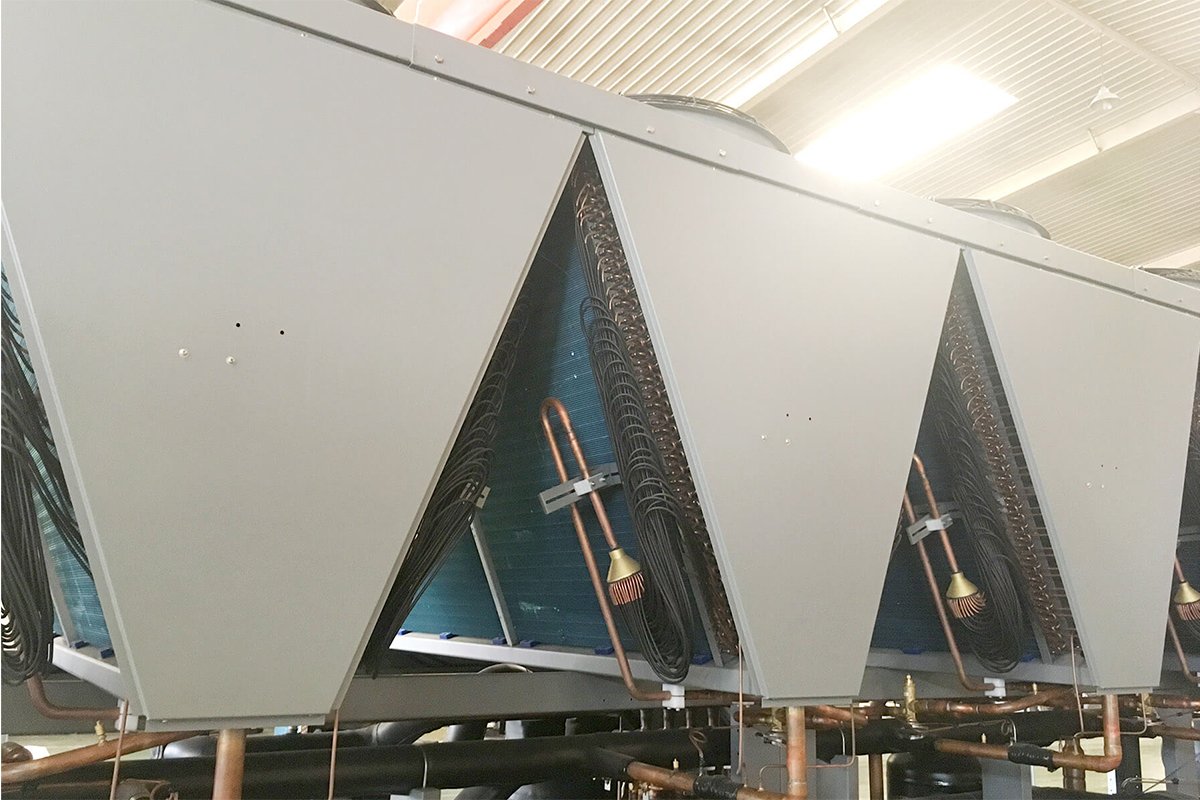

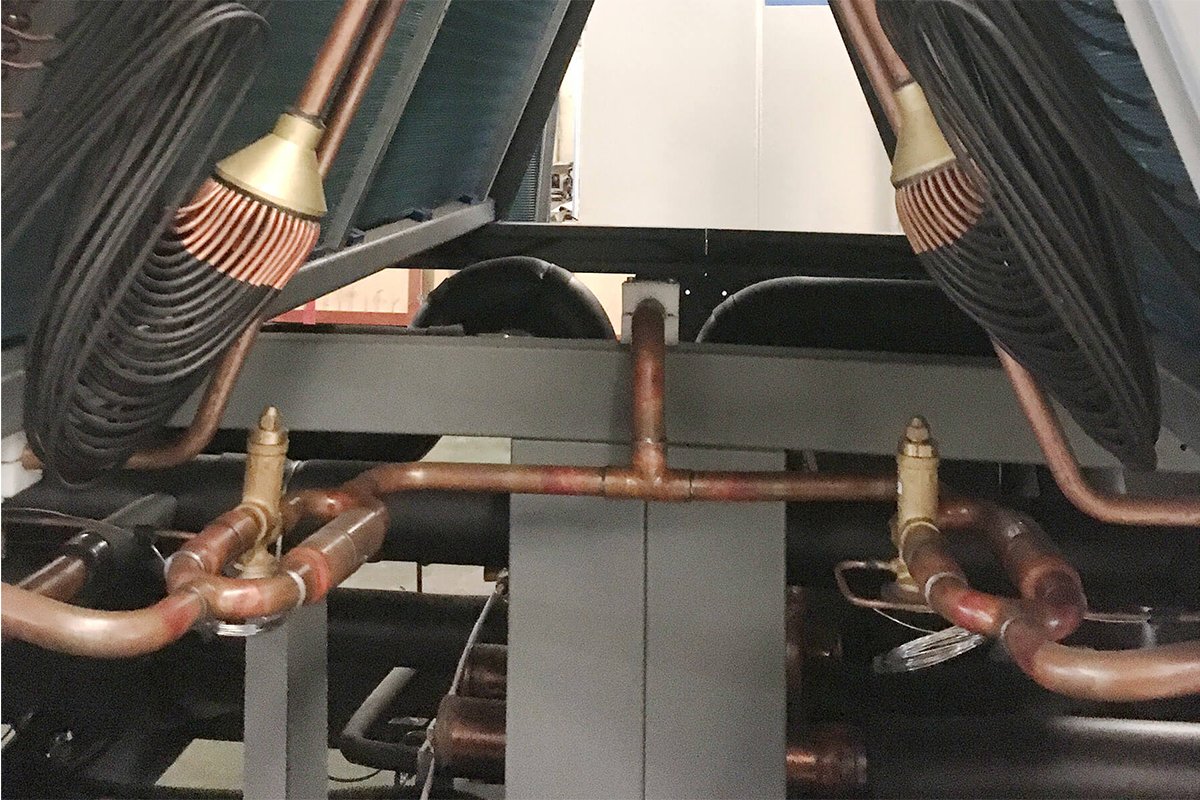

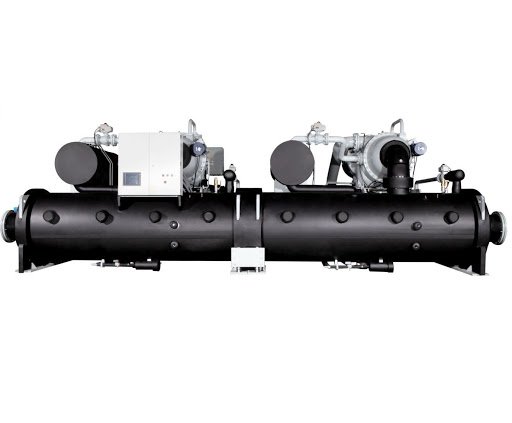

Air Cooled Screw Chiller manufactured by TopChiller consist of a screw compressor, air-cooled condenser, ice thermal storage unit, condenser fan, AC control system, refrigerant tank, expansion valves, tube type evaporator, and protection devices for efficient operation.

TopChiller brand Air Cooled Screw Chiller has its outstanding benefits supporting different industrial processing as given below:

- Air Cooled Screw Chiller is steadfast and fluent in its cooling operation configured by the installation of a screw chiller with automatic scheduling that ensures compression force on refrigerant and analyzes the cooling load to maintain a set point.

- TopChiller designed Air Cooled Screw Chiller is featured with expansion valve and economizer that increase the cooling capacity of compressor preventing the unit from any damaging effect by high pressure.

- Air Cooled Screw Chiller enables noise-free operation configured by the use of twin-screw compressor rotation in such a wised way producing little vibration or no voice.

- TopChiller engineered Air Cooled Screw Chiller has outstanding reliability and is durably configured by factory testing of all units before installation as well control panel controlling temperature and pressure inside the unit.

- Air Cooled Screw Chiller provides a cooling effect for different commercial applications by using chilled air that circulates over the condenser for efficient heat exchange.

Air Cooled Screw Chiller steadily works and provides chilling effect to different applications as:

Commercial areas, hospitals, supermarkets, plastic and steel manufacturing, medical industries, food, and beverage industry, pharmaceutical industry, and chemicals processing, etc.

If you are sourcing for a durable and high cooling capacity Air Cooled Screw Chiller for your application?

If you are focusing over to find a trustworthy company as Air Cooled Screw Chiller manufacturer in China to get help and instructions about your business establishment?

No need to go way around. TopChiller is a trustworthy company available from form 24 hours of servicing and best to choose.

Make contact with TopChiller experts and technocrats for sizing the best Air Cooled Screw Chiller for your application at suitable charges. TopChiller team is intended to provide aftermarket servicing and technical assistance for either installation or working of the unit.

General Description:

An Air Cooled Screw Chiller is a closed refrigeration system based on a screw-type compressor that uses air to lower the temperature of the industrial process. It efficiently removes heat from a process and discharges it into the atmosphere using air as a cooling medium.

It essentially contains an evaporator, a screw compressor, a condenser, an expansion valve, a control unit, along a lubrication system.

Air Cooled Screw Chiller manufactured by TopChiller contains a branded screw compressor. It comes with several innovative features that have made it preferable for many specific applications. It is a wide choice for many applications due to its long-lasting performance even under harsh environmental conditions.

Air Cooled Screw Chiller designed by TopChiller has been excessively used in manufacturing plastics, electronics, electroplating, pharmaceutical industries, food processing, chemical processes. It is also being used in other areas to maintain the internal conditions of industrial plants under optimized conditions.

If you are wondering for a reliable manufacturer that could meet your chilling requirements by providing Air Cooled Screw Chiller to your industrial processes, the TopChiller brand would be a smart choice.

TopChiller is a well-known manufacturer introducing a highly efficient Air Cooled Screw Chiller with incredible performance. It is durable, easy to install, and lightweight that operates calmly without producing irritating noises.

Contact our sales engineer today to get a high-duty Air Cooled Screw Chiller at very affordable costs.

Features and Advantages:

The premium quality Air Cooled Screw Chiller by TopChiller is being highlighted among others with its following distinctive features.

- It has a compact, stable and lightweight structure with the advancement of continuous operation without making noises. Along with easy maintenance, the installation has been made easy.

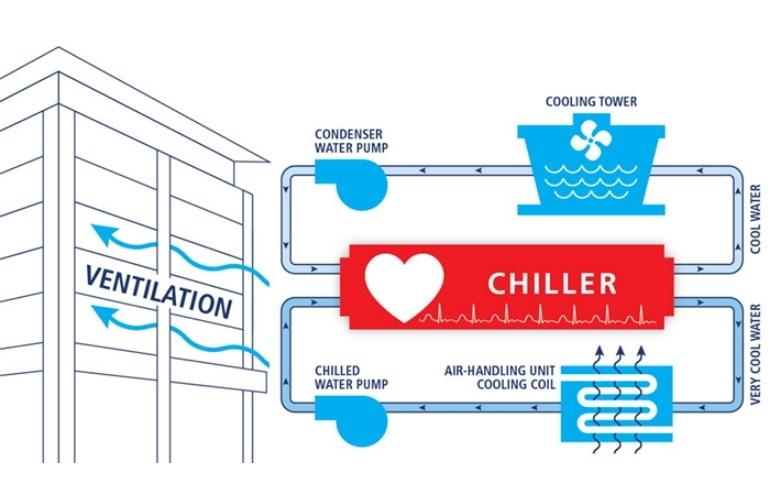

- The unit is devised to release heat directly into the air. Thereby, the cooling tower and cooling water pump complications have been abolished; thus, it can be installed even in water-deficient areas.

- An Air Cooled Screw Chiller is marked by flexible adjustments and a low failure rate. It contains multiple refrigeration circuits. In case of any malfunctioning in a circuit, another circuit keeps on working normally. Multiple compressors help in increasing and balancing the load.

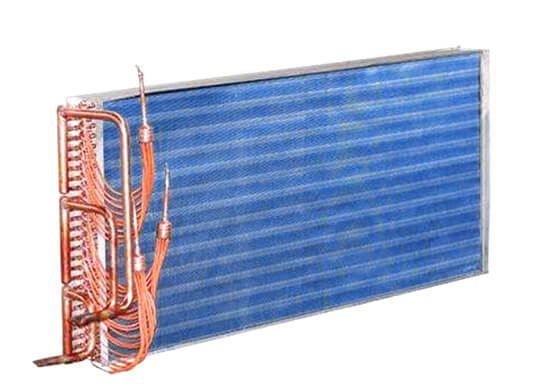

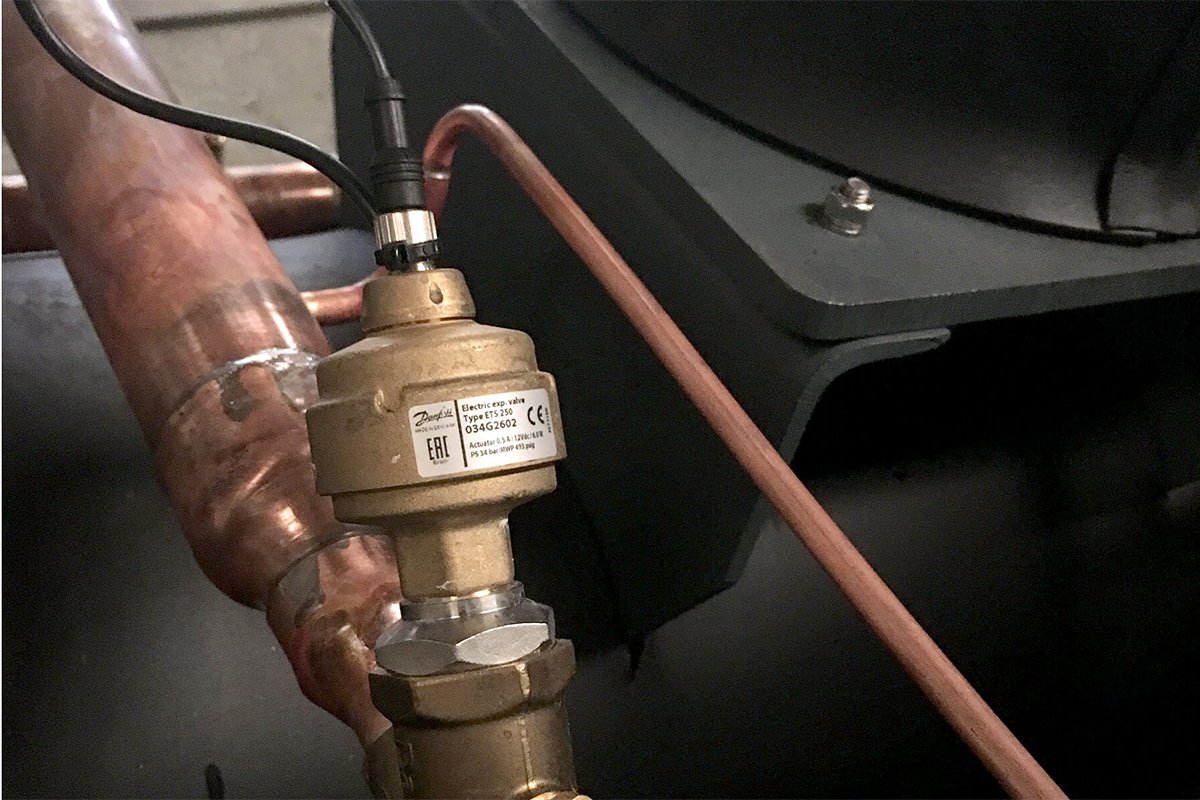

- The heat exchanger contains internally grooved copper tubes that provide a larger surface area for high ambient conditions. According to the system’s load, an electronic expansion valve is used for a regular refrigerant flow in the evaporator.

- Our highly effective Air Cooled Screw Chiller adjusts its capacity as per its requirements. Thus, it is highly energy-efficient. Moreover, it doesn’t cause any adverse effects on the environment; it is eco-friendly.

- Data Sheet

- Image Gallery

- Main Parts

- Video

| Air Cooled Screw Chiller Technical Specifications | ||||||||||||||

| Model Items | TPAS-80ASH | TPAS-110ASH | TPAS-140ASH | TPAS-160ASH | TPAS-190ASH | TPAS-210ASH | TPAS-250ASH | TPAS-290ASH | TPAS-310ASH | TPAS-340ASH | TPAS-400ASH | TPAS-430ASH | ||

| Cooling capacity | kcal/h | 68800 | 94600 | 122980 | 135020 | 164260 | 180600 | 212420 | 245100 | 266600 | 292400 | 348300 | 369800 | |

| KW | 80 | 110 | 143 | 157 | 191 | 210 | 247 | 285 | 310 | 340 | 405 | 430 | ||

| Input power | KW | 32.5 | 43.6 | 54.7 | 59.7 | 73.6 | 79.6 | 88.2 | 101.2 | 112.8 | 123.8 | 145 | 155 | |

| Max Current | A | 57 | 75 | 95 | 103 | 125 | 135 | 151 | 173 | 191 | 211 | 246 | 263 | |

| Power source | 3PH~380V/415V/480V~50HZ/60HZ(3PH~200V/220V 50HZ/60HZ) | |||||||||||||

| Refrigerant | Type | R22(R134a/R407c/R404A) | ||||||||||||

| Charge | kg | 21 | 28 | 35 | 42 | 49 | 56 | 63 | 70 | 77 | 84 | 98 | 112 | |

| Control | Thermostatic expansion valve | |||||||||||||

| Compressor | Type | Semi-hermetic screw | ||||||||||||

| Power | KW | 30 | 40 | 50 | 55 | 67 | 73 | 82 | 95 | 104 | 115 | 134 | 142 | |

| Start mode | Y-△ | |||||||||||||

| Capacity control | % | 0-33-66-100 | 0-25-50-75-100 | |||||||||||

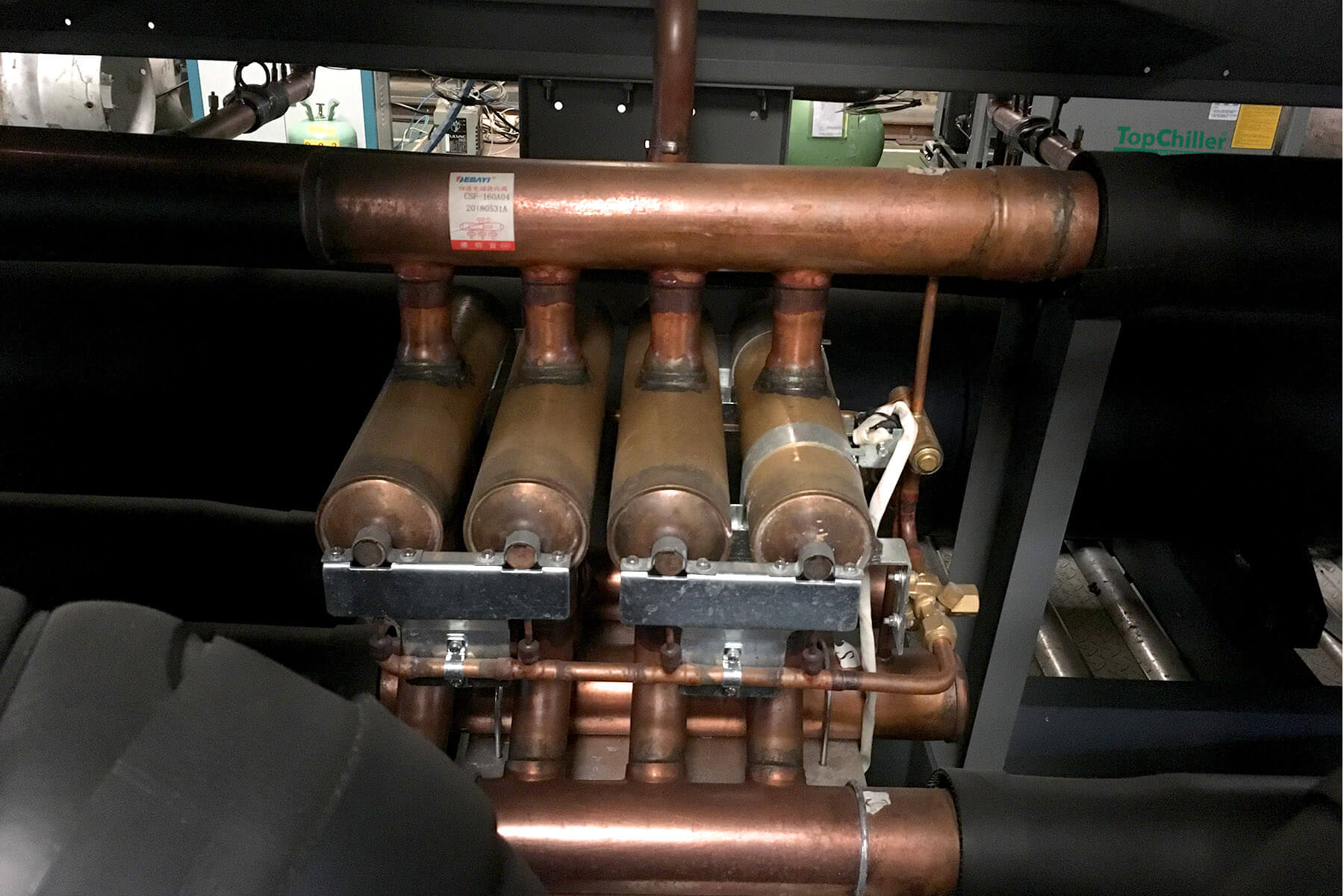

| Evaporator | Type | Shell and tube (SS plate heat exchanger) | ||||||||||||

| Chilled water | m³/h | 13.8 | 18.9 | 24.6 | 27.0 | 32.8 | 36.1 | 42.5 | 49.0 | 53.3 | 58.4 | 70.0 | 74.0 | |

| Water pressure | KPa | 32 | 32 | 35 | 38 | 42 | 42 | 45 | 43 | 43 | 43 | 41 | 43 | |

| Pipe connection | Inch | 3″ | 3″ | 3″ | 4″ | 4″ | 4″ | 4″ | 4″ | 5″ | 5″ | 6″ | 6″ | |

| Condenser | Type | Air cooled type high efficiency finned cooper tube | ||||||||||||

| Fan | Type | m³/h | Big volume & low noise axil fan | |||||||||||

| Power | KW | 0.42×6 | 0.6×6 | 0.78×6 | 0.78×6 | 1.1×6 | 1.1×6 | 0.78×8 | 0.78×8 | 1.1×8 | 1.1×8 | 1.1×10 | 1.1×12 | |

| Air volume | m³/h | 30000 | 40000 | 50000 | 60000 | 70000 | 80000 | 90000 | 100000 | 110000 | 116000 | 145000 | 165000 | |

| Safety protection devices | Inner thermostat for compressor motor, unit overload relay,high and low pressure switch, freeze protection thermostat, reverse phase protection relay, discharge gas thermostat, flow switch | |||||||||||||

| Dimension | Length | mm | 2200 | 2350 | 2600 | 2600 | 2650 | 2650 | 3400 | 3400 | 3800 | 3800 | 4800 | 5800 |

| Width | mm | 1150 | 1350 | 1500 | 1500 | 1900 | 1900 | 1700 | 1700 | 1900 | 1900 | 1900 | 1900 | |

| Height | mm | 1980 | 2000 | 2100 | 2100 | 2200 | 2200 | 2200 | 2200 | 2200 | 2200 | 2200 | 2200 | |

| Net weight | kg | 1100 | 1300 | 1600 | 1900 | 2200 | 2350 | 2550 | 2800 | 2850 | 2950 | 3200 | 3550 | |

| Running weight | kg | 1300 | 1500 | 1840 | 2200 | 2530 | 2700 | 2950 | 3250 | 3350 | 3560 | 3650 | 3950 | |

| The above specifications are according to the following design conditions: 1, Chilled water inlet/outlet temperature 12℃/7℃. 2, Cooling air inlet/outlet temperature 30℃/38℃. We reserve the right to modify the specifications without further notice. | ||||||||||||||

| Air Cooled Screw Chiller Technical Specifications | ||||||||||||||

| Model Items | TPAS-160ADH | TPAS-220ADH | TPAS-285ADH | TPAS-315ADH | TPAS-380ADH | TPAS-420ADH | TPAS-495ADH | TPAS-570ADH | TPAS-620ADH | TPAS-680ADH | TPAS-810ADH | TPAS-860ADH | ||

| Cooling capacity | kcal/h | 137600 | 189200 | 245960 | 270040 | 328520 | 361200 | 424840 | 490200 | 533200 | 584800 | 696600 | 739600 | |

| KW | 160 | 220 | 286 | 314 | 382 | 420 | 494 | 570 | 620 | 680 | 810 | 860 | ||

| Input power | KW | 64.7 | 86.6 | 106.2 | 118.8 | 145 | 159.2 | 177.2 | 207.6 | 225.6 | 247.6 | 290 | 310.4 | |

| Max Current | A | 114 | 149 | 185 | 205 | 250 | 274 | 308 | 358 | 388 | 428 | 500 | 533 | |

| Power Source | 3PH~380V/415V/480V~50HZ/60HZ(3PH~200V/220V 50HZ/60HZ) | |||||||||||||

| Refrigerant | Type | R22(R134a/R407c/R404A) | ||||||||||||

| Charge | kg | 21×2 | 28×2 | 35×2 | 42×2 | 49×2 | 56×2 | 63×2 | 70×2 | 77×2 | 84×2 | 98×2 | 112×2 | |

| Control | Thermostatic expansion valve | |||||||||||||

| Compressor | Type | Semi-hermetic screw | ||||||||||||

| Power | KW | 30×2 | 40×2 | 50×2 | 55×2 | 67×2 | 73×2 | 82×2 | 95×2 | 104×2 | 115×2 | 134×2 | 142×2 | |

| Start mode | Y-△ | |||||||||||||

| Capacity control | % | 0-33-66-100 | 0-25-50-75-100 | |||||||||||

| Evaporator | Type | Shell and tube (SS plate heat exchanger) | ||||||||||||

| Chilled water | m³/h | 27.5 | 37.8 | 49.1 | 54 | 65.7 | 72.2 | 85 | 98 | 106.6 | 117 | 139.3 | 147.9 | |

| Water pressure | KPa | 32 | 32 | 35 | 38 | 42 | 42 | 45 | 43 | 43 | 43 | 41 | 43 | |

| Pipe connection | Inch | 4″ | 4″ | 4″ | 5″ | 6″ | 6″ | 6″ | 6″ | 8″ | 8″ | 8″ | 10″ | |

| Condenser | Type | Air cooled type high efficiency finned cooper tube | ||||||||||||

| Fan | Type | m³/h | Big volume & low noise axil fan | |||||||||||

| Power | KW | 0.78×6 | 1.1×6 | 0.78×8 | 1.1×8 | 1.1×10 | 1.1×12 | 1.1×12 | 1.1×16 | 1.1×16 | 1.1×16 | 1.1×20 | 1.1×24 | |

| Air volume | m³/h | 60000 | 80000 | 100000 | 116000 | 145000 | 165000 | 180000 | 205000 | 225000 | 242000 | 285000 | 325000 | |

| Safety protection devices | Inner thermostat for compressor motor, unit overload relay, high and low pressure switch, freeze protection thermostat, reverse phase protection relay, discharge gas thermostat, flow switch | |||||||||||||

| Dimension | Length | mm | 2600 | 2650 | 3400 | 3800 | 4800 | 5800 | 5800 | 7800 | 7800 | 8000 | 9800 | 11600 |

| Width | mm | 1500 | 1900 | 1700 | 1900 | 1900 | 1900 | 2200 | 2000 | 2200 | 2200 | 2200 | 2200 | |

| Height | mm | 2100 | 2200 | 2200 | 2200 | 2200 | 2200 | 2300 | 2250 | 2250 | 2300 | 2350 | 2350 | |

| Net weight | kg | 2050 | 2520 | 2980 | 3180 | 3420 | 3730 | 3950 | 4330 | 4650 | 4930 | 5450 | 5850 | |

| Running weight | kg | 2360 | 2870 | 3420 | 3690 | 3780 | 4180 | 4380 | 4650 | 4920 | 5360 | 5830 | 6530 | |

| The above specifications are according to the following design conditions: 1, Chilled water inlet/outlet temperature 12℃/7℃. 2, Cooling air inlet/outlet temperature 30℃/38℃. We reserve the right to modify the specifications without further notice. | ||||||||||||||

Why TopChiller is Your Reliable Air Cooled Screw Chiller Manufacturer and Supplier In China?

Air Cooled Screw Chiller-An Ultimate FAQ Guide by TopChiller.

- What is an Air Cooled Screw Chiller?

- What are the Unique Features of the Air Cooled Screw Chiller?

- What are the Important Parts of an Air Cooled Screw Chiller?

- What is the Working Mechanism of an Air Cooled Screw Chiller?

- What are the Applications of an Air Cooled Screw Chiller?

- What are the Advantages of an Air Cooled Screw Chiller for your Applications?

- What are the Electrical Requirements of Air Cooled Screw Chiller?

- Which Refrigerant is Used in Air Cooled Screw Chiller?

- What are the Control Features of an Air Cooled Screw Chiller?

- How Do the Screw Compressors in an Air Cooled Screw Chiller Work?

- What are the Technological Alternatives for the Air Cooled Screw Chiller?

- What is the Estimated Cost of an Air Cooled Screw Chiller?

- What are Safety Tips for your Air Cooled Screw Chiller?

- What is the Efficient Energy Control Mechanism of an Air Cooled Screw Chiller?

- How to Troubleshoot your Air Cooled Screw Chiller?

- How to Size a Suitable Air Cooled Screw Chiller for your Industry?

- How to Monitor and Adjust your Air Cooled Screw Chiller Operation?

- How to Increase Efficiency of your Air Cooled Screw Chiller?

What is an Air Cooled Screw Chiller?

An Air Cooled Screw Chiller is, in fact, a cooling system that uses air to cool the temperature of the application unit. It contains a screw compressor that increases its ability to remove heat efficiently from an industrial process.

It doesn’t involve the complications of installing an immense water-cooling system but stays easy to install. Despite having a compact structure, it is lightweight that operates quietly without producing noises.

The essential components include an evaporator, a condenser, an expansion valve, a control unit, and, peculiarly, a screw compressor.

It circulates cooled water through the process that gets warmer after absorbing heat. The heat is exhausted from the process to the atmosphere employing exhaust fans.

Air Cooled Screw Chiller can withstand harsh climatic conditions thus, widely used in various industrial plants to maintain the temperature.

It is being excessively used in manufacturing plastics, food processing, pharmaceutical, chemical industries, and many more.

Air Cooled Screw Chiller Manufactured by TopChiller

What are the Unique Features of the Air Cooled Screw Chiller?

The following unique features mark an Air Cooled Screw Chiller:

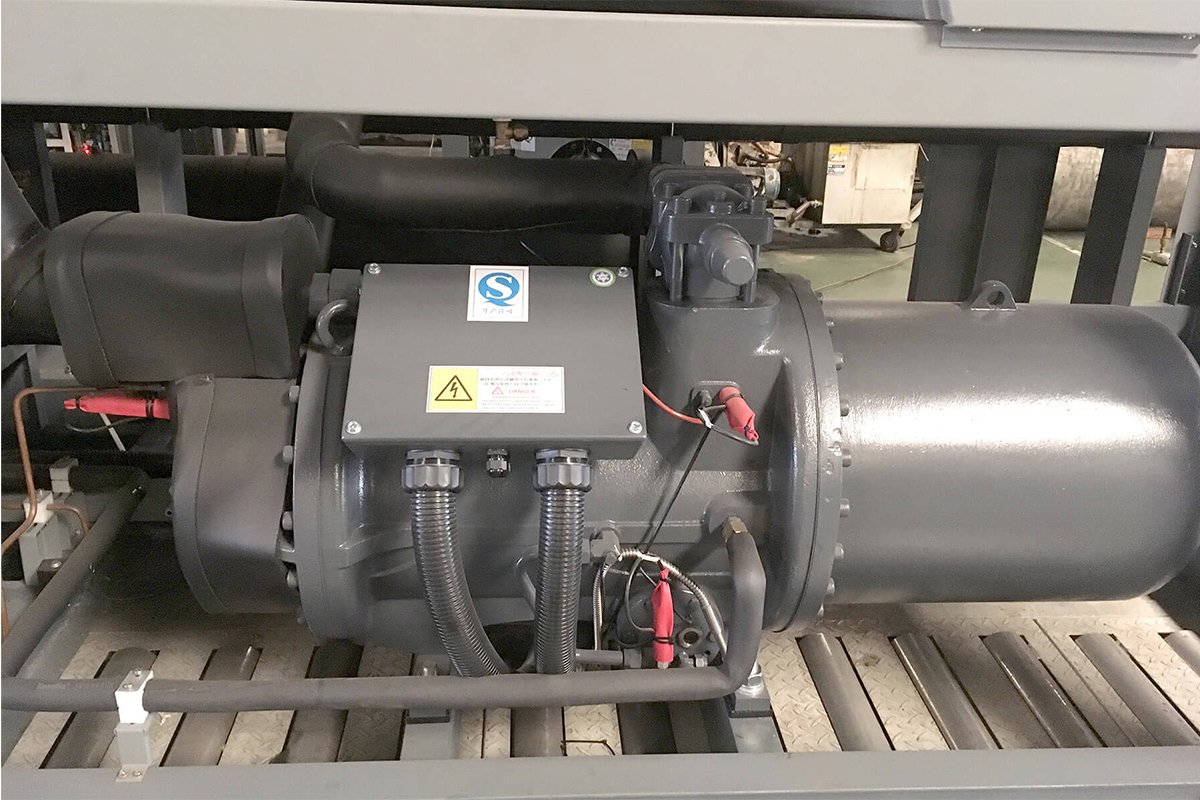

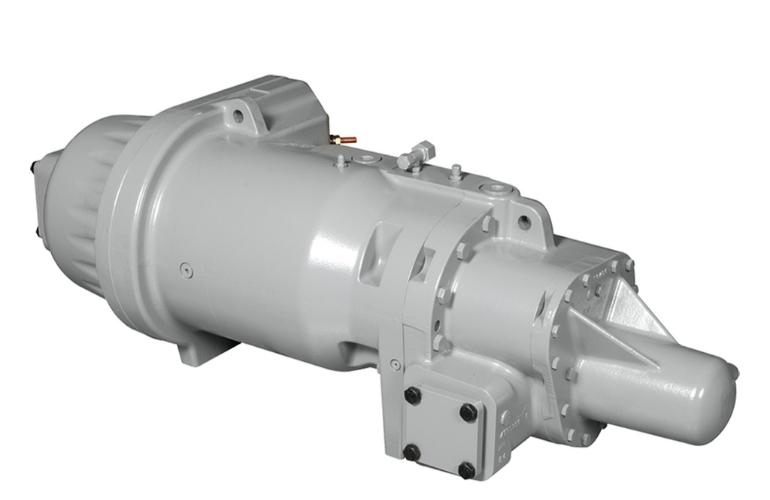

Screw Compressor

It contains a twin-rotor, semi-hermetic screw compressor that improves the overall performance of your chiller. It contains only three moving parts increasing its reliability.

A refrigerant dispersing device is located internal to the compressor for motor cooling. The slide valve possesses a unique profile that is optimized for part-load conditions.

Corrosion Free Structure

All chilled water contact surfaces are made up of stainless steel, copper, or other non-ferrous material for protection against corrosion.

Configuration

An Air Cooled Screw Chiller has a stable and compact configuration. It is lightweight, easier to maintain, and simple to install. It has reduced energy consumption and has been designed environmentally friendly.

Protection Devices

It contains various components that ensure the safety, reliability, and long-term functioning of an Air Cooled Screw Chiller.

These include a high and low-pressure switch, thermal protection switch, phase sequence, overload relay, anti-freeze protection, compressor overload protection, oil level protection, and more.

High Efficient Condenser

The condenser contains high-efficiency heat transfer tubes. It can adjust the capacity corresponding with the load change to increase the efficiency of the compressor, reducing the energy consumption and increasing the unit’s service life.

Intelligent Control

It is controlled by a microcontroller with the automatic controlling functions of energy management, fault diagnosis, and anti-freezing monitoring, which ensures the high-efficiency operation of the unit.

Air Cooled Screw Chiller Semi-Hermetic Screw Compressor

What are the Important Parts of an Air Cooled Screw Chiller?

An Air Cooled Screw Chiller has contained the following major components:

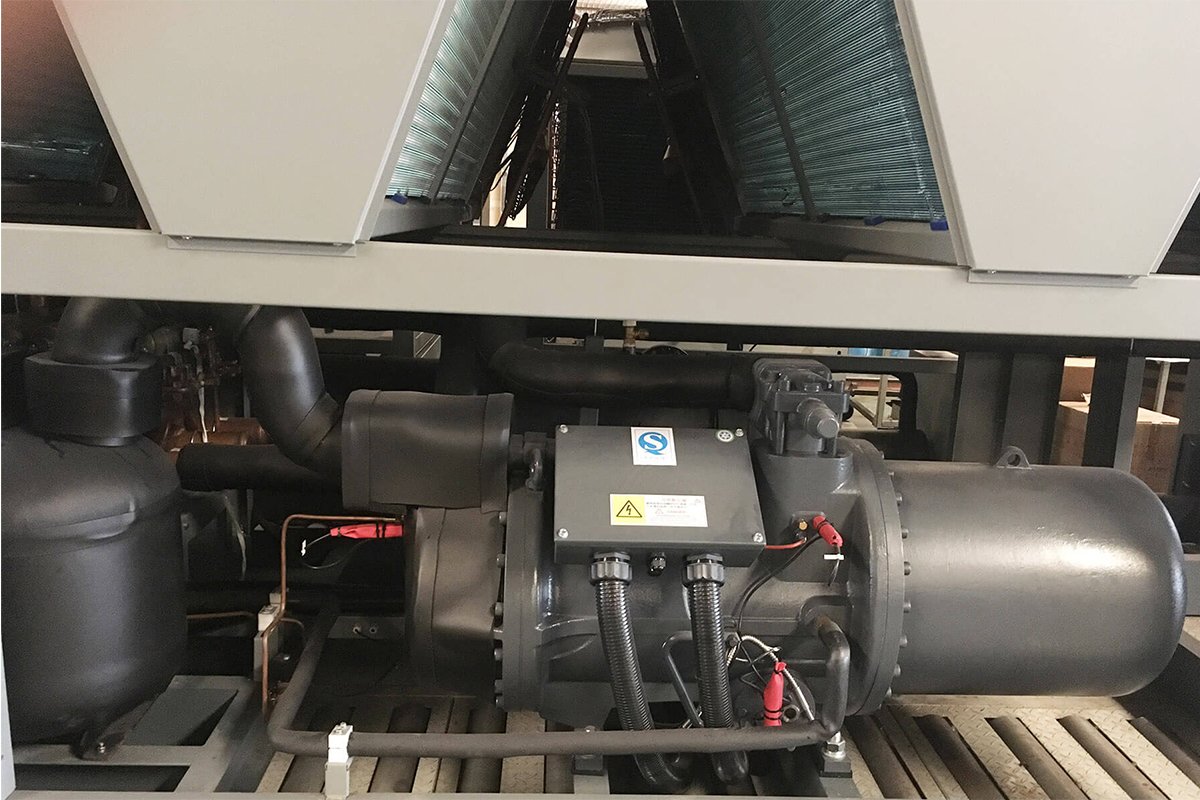

Screw Compressor

The screw compressor is of crucial importance among all others. It converts refrigerant vapors from low temperature and pressure to high temperature and pressure vapors.

It then transfers the highly pressurized vapors into a tube condenser.

A screw compressor is a rotatory compressor with one or two screws. It is highly efficient and continually compresses air by its screw action.

An Air Cooled Screw Chiller is composed of semi-hermetic double screw compressors that the controller can handle to modulate the capacity.

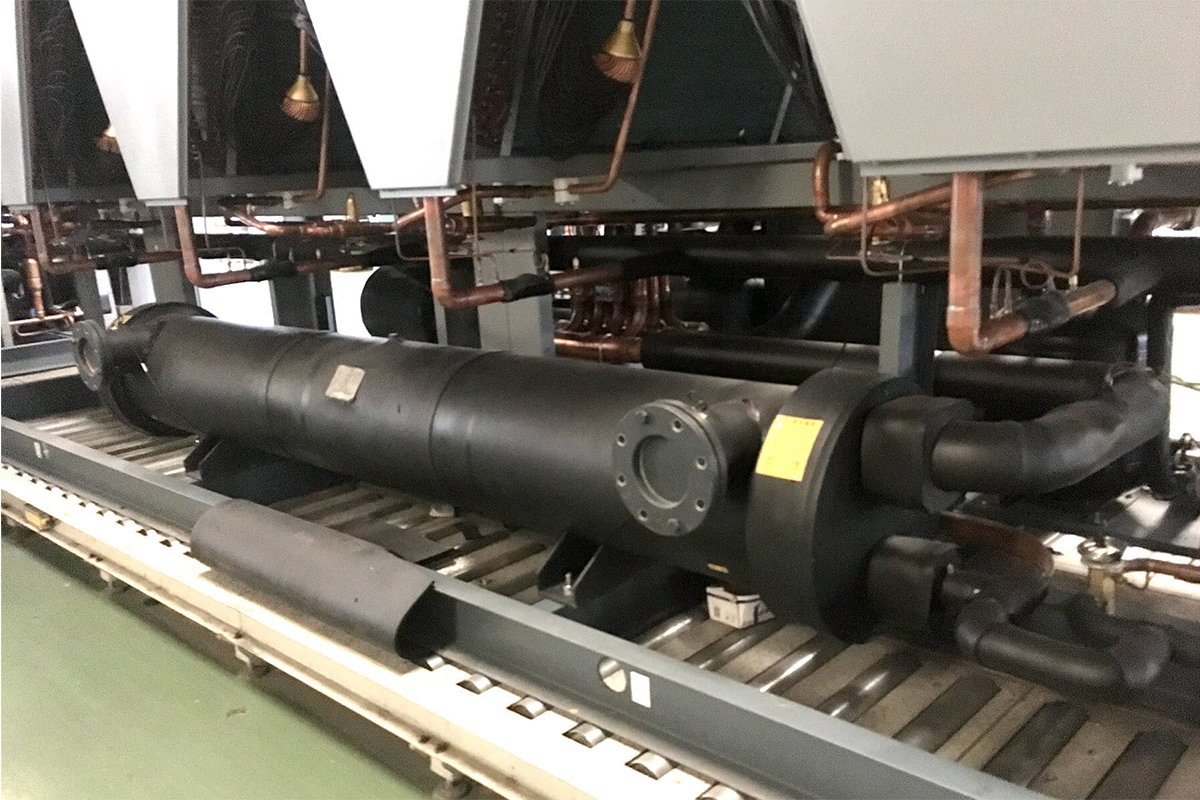

Evaporator

The evaporator is typically present between the compressor and expansion valve. The refrigeration cycle initiates with an evaporator that is a site for gas exchange.

The liquid refrigerant at low pressure absorbs heat from warmer water flowing through the evaporator.

As a result, the refrigerant converts into vapors. Meanwhile, the temperature of the water drops down.

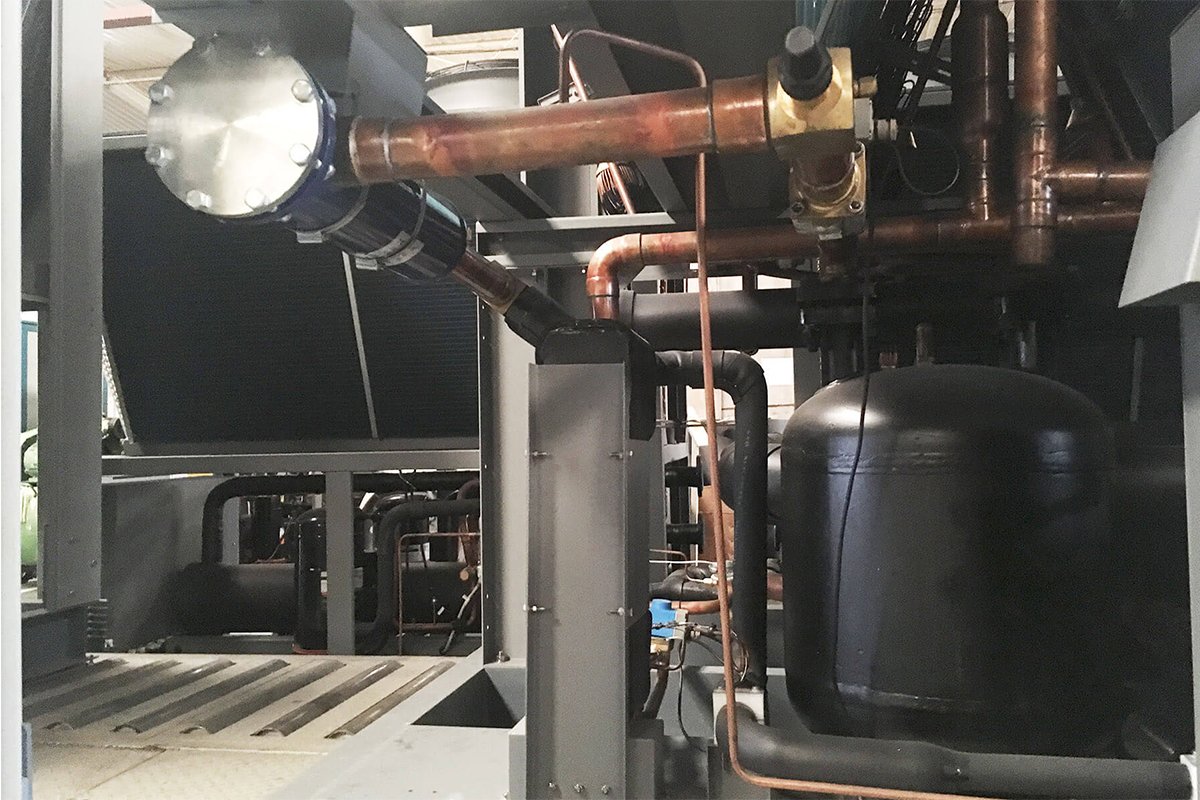

Condenser

The condenser coils are generally made of aluminum fins and copper tubes.

In an Air Cooled Screw Chiller, the condenser shrinks the high-pressure warmer refrigerant vapor flowing to a liquid.

It lowers the temperature of the refrigerant, which enhances the refrigeration effect.

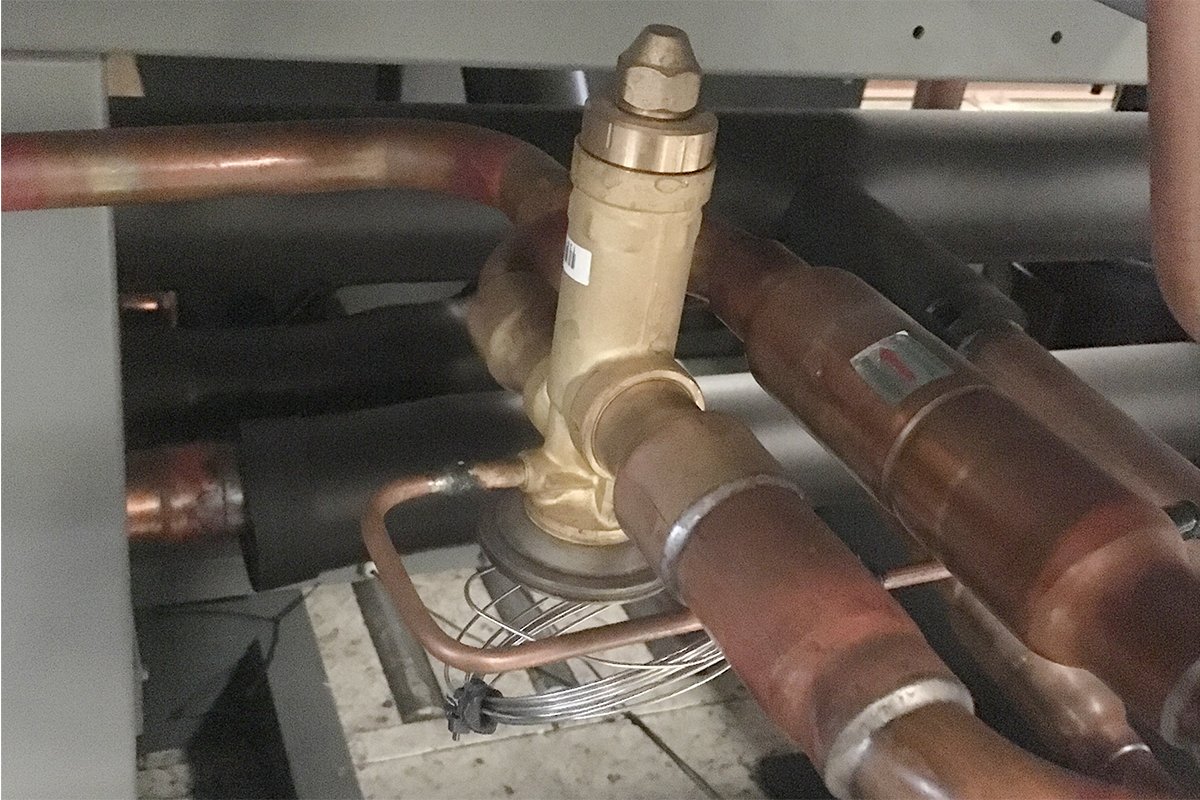

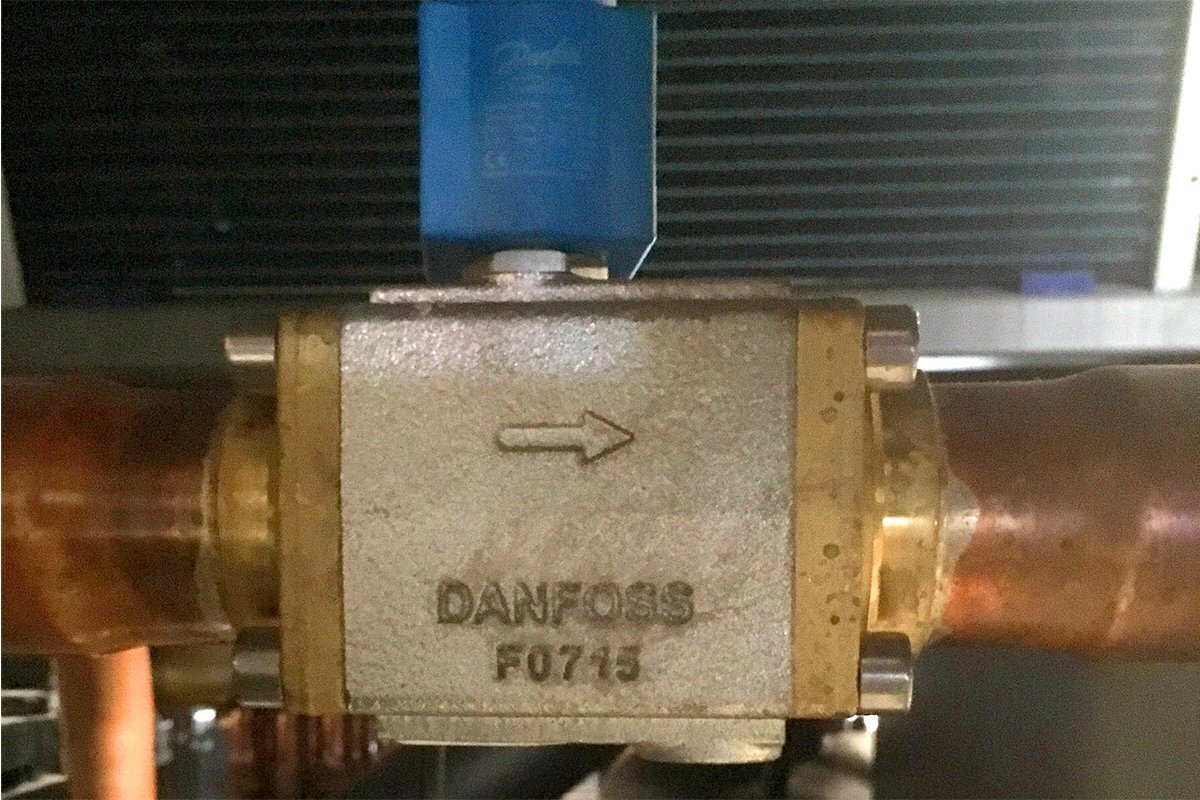

Expansion Valve

The expansion valve functions to decrease the liquid refrigerant’s pressure and lower the temperature of the liquid.

The refrigerant gets colder under reduced pressure and move towards the evaporator.

Cooling fan

An Air Cooled Screw Chiller essentially contains a cooling fan. It extracts the heat out to the atmosphere. A high-quality cooling fan increases the overall installation efficiency.

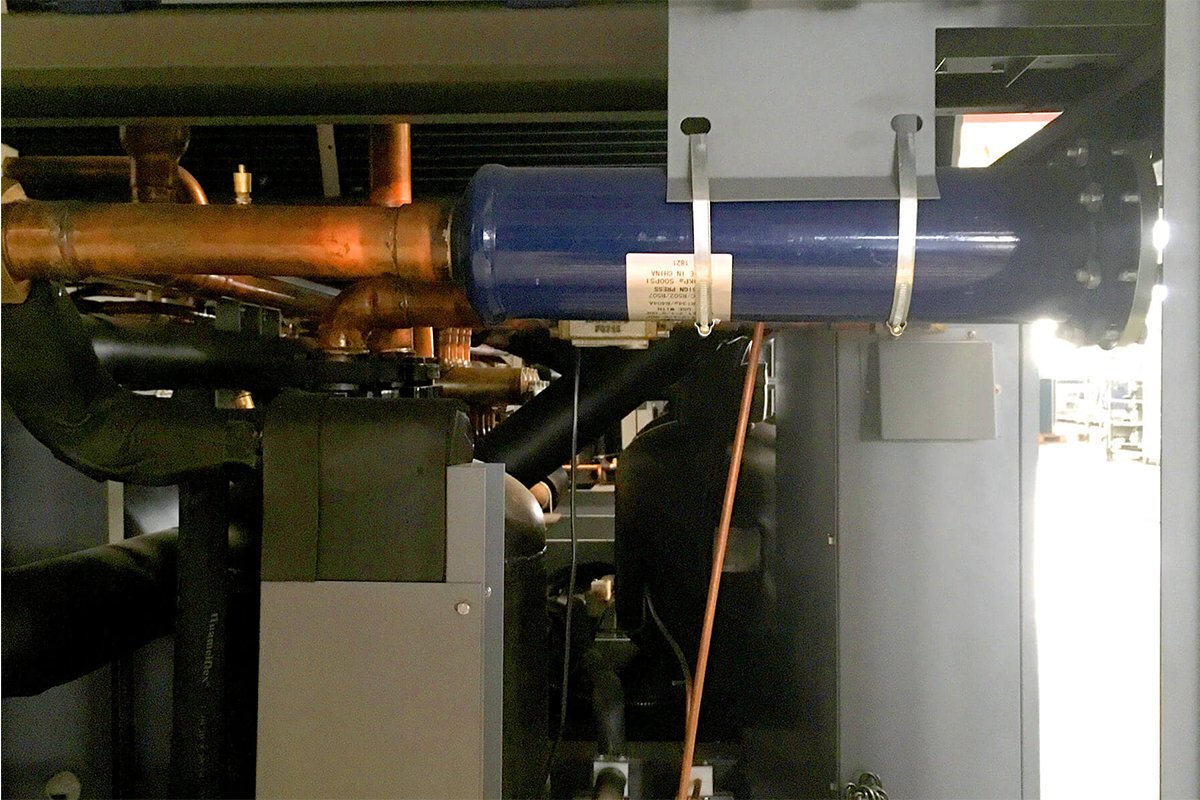

Oil Separator

When the refrigerant passes by a compressor, a certain amount of oil is released. The oil can hinder the flow of refrigerant; may impact the efficient performance of your chiller.

In order to overcome these circumstances, an oil separator is introduced as a significant component.

It separates the oil from the refrigerant and minimizes oil flow in the cooling system.

Air Cooled Screw Chiller Oil Separator

What is the Working Mechanism of an Air Cooled Screw Chiller?

An Air Cooled Screw Chiller is named after the screw compressor used as a significant component.

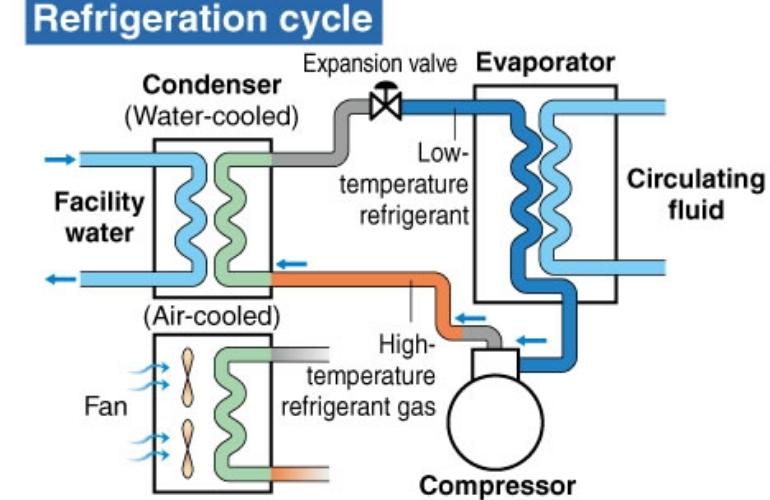

Its working principle is based on a refrigeration cycle that revolves around absorption and compression.

In the refrigeration cycle, the refrigerant passes by different components where it interchanges its state from liquid to gas and vice versa, forming a closed loop.

The screw compressor consisting of male and female compressors rotate in helical movement and convert the low-pressure refrigerant vapors into high-pressure, high-temperature refrigerant vapors.

As soon as the refrigerant becomes pressurized, they are released into a finned tube condenser. It condenses the refrigerant vapors radiating heat energy into the ambient and eventually getting liquified.

The high-pressure liquid has become cooled and is passed by an expansion valve. The expansion valve will decrease the pressure of the liquid refrigerant.

Ultimately, it will reach the shell and tube evaporator, where it will vaporize by absorbing heat within the evaporator.

Here, a refrigerant cycle has been completed. The refrigerant vapors turn back towards the screw compressor.

What are the Applications of an Air Cooled Screw Chiller?

An Air Cooled Screw Chiller operates efficiently under harsh environmental conditions. It conserves energy consumption and is easy to install and maintain.

That is why it is being excessively used in commercial units, residential buildings, and public service spots.

It has a wider range of applications from industrial processes to hospitals, research areas, hotels, educational institutes, offices, and many other projects that need a continuous supply of cooling.

Most prominently, Air Cooled Screw Chiller has been broadly used at industrial scales. Followings are a few of its major applications:

- Chemical Processing and Pharmaceuticals

- Food and Beverage Processing

- Energy and Power Project

- Printing Plants

- Pet Food Manufacturing Industry

- Construction Industry

- Central Air Conditioning HVAC Systems

- Telecommunications

- Welding Engineering

- Laser Technology

- Dye and Pigment Manufacturing

- Factory Furnaces

- Induction Hardening Machine

- Aeronautical Testing Facility

- Electroplating Industry

- Automobile Factories

- Plastic Processing

- Cement Industries

- Plasma Cutting

- Injection Molding Machines

- Anodizing Plants

- Plasma Spray Machines

- Defense Laboratory Testing Facility

- Blow Mold Machines

- Computer Chip Manufacturing

Applications of Air Cooled Screw Chiller

What are the Advantages of an Air Cooled Screw Chiller for your Applications?

An Air Cooled Screw Chiller has various advantages of its use. Its heavy-duty performance, stability, reliability, quiet operation, easy installation, durability, and multiple control systems are advanced.

These certain advantages of an Air Cooled Screw Chiller are detailed below.

Solid Structure and Steady Operation

The dry evaporator and condenser hold a heat transfer tube; the primary motor contains a semi-hermetic screw compressor advancing the unit with a compact structure, lightweight, and lower volume.

The screw compressor operates continuously without pulsation, characterized by stable performance, slight vibration, and low noise.

High-Efficiency Levels

The unit can absorb heat excessively at a high rate with efficiency and operates equally well in harsh climate conditions.

Environmentally Friendly

The operation of an Air Cooled Screw Chiller does not have any adverse effect on the environment. Since it uses R134a refrigerant that is eco-friendly and harmless to the ozone layer.

Energy Control System

A self-regulating Air Cooled Screw Chiller is energy efficient that gets a start and stops according to the load change.

The computer control system can adjust the energy gain according to the control of change of heat load during operation.

Easy Operation

It comes with a modern control system, a microcomputer programmable controller (PLC), and a screen display, which allows you to control the operation easily as per your requirements.

Protection Features

The unit possesses a compressor’s internal protection elements to provide overload, lack of phase, overpressure, and other protection features that protect the compressor.

In addition, it holds the pressure and temperature control features and other devices of the refrigeration system to make the unit operate without any failure.

Independent Operation

A large capacity Air Cooled Screw Chiller encloses multiple independent refrigeration circuits.

They allow the unit to work typically using another circuit if one fails. It enables you to keep your industrial processes going on without shutting down.

Easy Installation Process

The unit carries all the essential components upon shipment. It comes after operation tests by the manufacturers and is charged fully with refrigerant and refrigeration oil.

The installation process is quite simple and only involves connecting water pipe water and circuit connection.

Air Cooled Screw Chiller Refrigeration Circuit

What are the Electrical Requirements of Air Cooled Screw Chiller?

An Air Cooled Screw Chiller requires the following electrical conditions.

- The chiller must operate on three-phase power at the voltage specified in the equipment plan.

- The primary electrical power supply must be insured to work at an ambient temperature of 125 degrees Fahrenheit (52 degrees Celsius).

- You can use terminal blocks to access the control points. Factory control and power wiring will be scaled after the unit is delivered.

- The primary electrical supply must enter via a single point. However, voltage and size combinations need two power supplies in some units.

Which Refrigerant is Used in Air Cooled Screw Chiller?

An Air Cooled Screw Chiller primarily uses CFC-free refrigerants that work with a higher frequency. The quantity of these refrigerants depends on the unit’s weight and size.

The most common refrigerants used are R134a, R407c, R410a, and R404a. Their usage relies on the working conditions of an Air Cooled Screw Chiller, application requirements, and ambient temperature.

However, R134a refrigerant is widely used because of its non-toxic nature. It is environment-friendly, does not harm the ozone layer, and protects the environment.

Refrigerant for Air Cooled Screw Chiller

What are the Control Features of an Air Cooled Screw Chiller?

An Air Cooled Screw Chiller is possessed with numerous control features. These control features increase the precision and reliability of the unit.

They help in the regulation of energy and control of operating conditions as per cooling load.

A few of the advanced control features are discussed below:

- A control switch toggles between OFF and ON.

- Suction, discharge, oil pressures, and intermediate economizer are measured employing pressure sensors and transducers.

- Power and control supplies and terminal blocks are separate.

- A separate 220-volt power supply is needed for all relays, controllers, and control components.

- Thermistors are installed to track the temperature of the fluid when it enters and leaves the system and the ambient temperature as well.

- The electrical control system regulates the cooling system through the thermal sensor.

- You can replace the solid-state controllers.

- Various electrical protection devices and alarm systems serve to protect, monitor, and alarm.

- The unit holds high automatic management with various features to monitor the start-up and shut down, water pump control, timing control, malfunction alarm, and other self-diagnosis features.

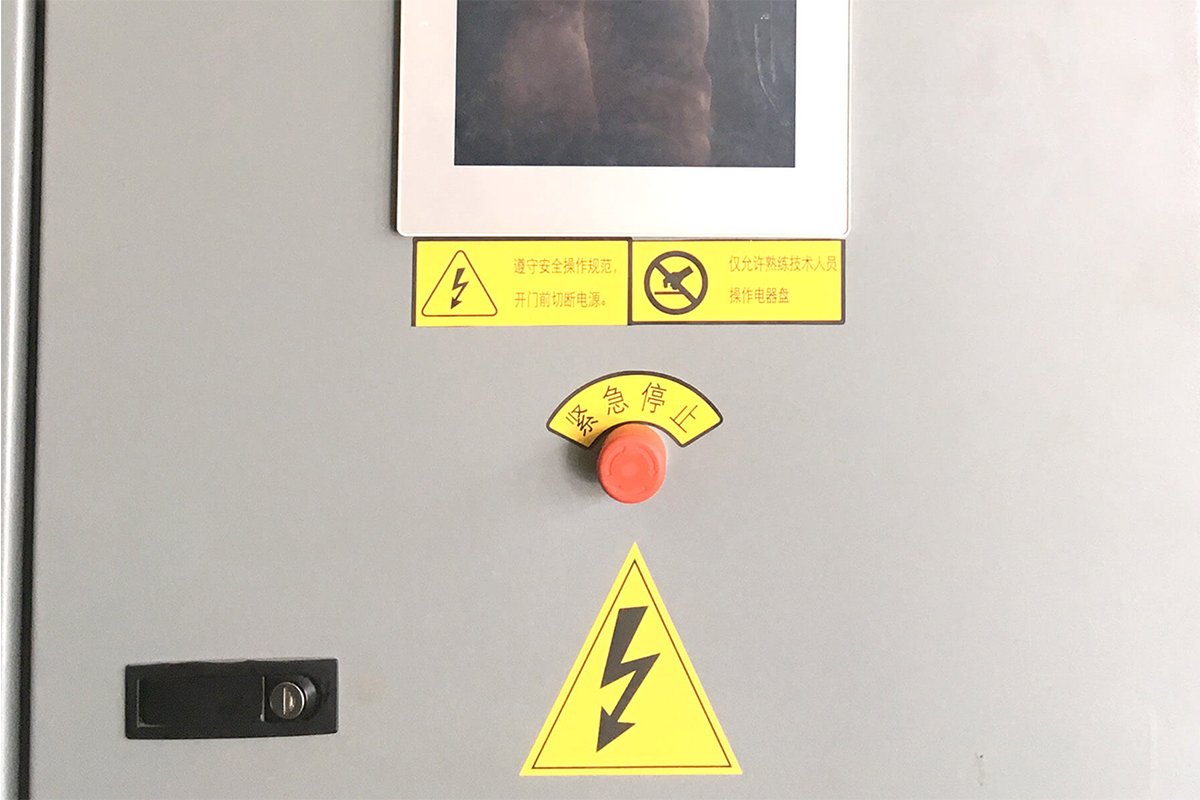

Air Cooled Screw Chiller Emergency Stop Button

How Do the Screw Compressors in an Air Cooled Screw Chiller Work?

A screw compressor is used to compress the refrigerant with low temperature and pressure. It converts it into the refrigerant with high temperature and pressure and transfers it into the finned tube condenser.

A semi-hermetic type screw compressor is used in an Air Cooled Screw Chiller containing an electric motor.

Temperature sensors covered by coil winding are present inside the motor that continuously monitors its temperature.

A screw compressor is composed of a male and female rotor. The male rotor directly connects to the motor, whereas the female rotor will be driven.

The refrigerant will flow into the compressor through the suction port.

The rotors rotate, and the volume between the teeth of female and male rotors gets connected. The teeth mesh with each other, the volume gradually falls, and eventually, the refrigerant compresses.

The refrigerant will exit the compressor through the exhaust port at extremely high pressure.

This is how a screw compressor works with high efficiency.

What are the Technological Alternatives for the Air Cooled Screw Chiller?

There are specific improvements made in Air Cooled Screw Chiller for better performance and efficient operation.

A few of the technological alternatives are discussed below:

Gas Driven Systems

The latest technology has been introduced in an Air Cooled Screw Chiller that enables it to operate by consuming driving power from gas rather than electricity.

It is ideal for areas where the power is not sufficiently available or has very high costs.

Increased Energy Efficiency

Variable frequency drives are advanced in the unit that enables you to save a lot of energy when the cooling load is low.

When the cooling load is decreased, the variable frequency drives reduce the energy output and increase it with the increased cooling loads.

Two-Phase Turbines

This feature allows you to replace the expansion valve with the 2-phase turbines in larger-scale applications.

It will help you maintain the chiller’s energy potential that often gets lost by using an expansion valve.

Larger Size

Various technological advancements have been made in an Air Cooled Screw Chiller with a larger size that has increased the capacity and overall efficiency of the chiller.

What is the Estimated Cost of an Air Cooled Screw Chiller?

An Air Cooled Screw Chiller has a wider range of choices depending upon the price.

Typically an Air Cooled Screw Chiller costs somewhere between 3000 and 50,000 US dollars according to the unit type.

The prices vary significantly according to the size and quality.

Size

A larger unit will cost you higher than a smaller one. You should select the size of your unit by considering the cooling requirements of your application area.

Quality

The quality determines the rates of a unit. Better is the quality, and higher will be the costs.

What are Safety Tips for your Air Cooled Screw Chiller?

Ensure the safety of your Air Cooled Screw Chiller by considering the following tips:

- Install an air detector to monitor whether the refrigerant vapor concentration in the air is appropriate or not.

- Ensure the regular inspection of the controller.

- Inappropriate earthling can cause a sudden electric shock.

- Ensure the proper ventilation of the unit. If necessary, you may use a piece of additional ventilation equipment to remove the refrigerant vapor induced by an accidental leak.

- Do not pull or distort the contact wires and power supply.

- The solid and weak electricity must be piped separately. Make sure that the wiring must precisely follow the wiring diagrams. Ensure the accuracy of voltage input of the isolating transformer.

- Interpret the safety directions and ensure that all of the specifications are fulfilled. Save the manual for future use.

- Avoid using the machine in a potentially explosive setting.

- Do not use acid or alkaline drugs to clean the dust on the machine. Instead, use a soft cloth dampened with clean water.

Air Cooled Screw Chiller Ventilation Diagram

What is the Efficient Energy Control Mechanism of an Air Cooled Screw Chiller?

An efficient energy control mechanism retains an Air Cooled Screw Chiller, one of its mostunique and beneficial features.

It is based on 25%, 50%, 75%, and 100% of the four-stage capacity control mechanism.

This energy control mechanism works by two methods.

First, you can customize the required capacity of your Air Cooled Screw Chiller and provide enough energy as per the requirements. It saves energy from being leaked or overused.

Secondly, the unit contains an automatic load switching mechanism. You can set the direction of operation, and it will automatically switch to one of the four capacities according to the conditions of the process.

These methods are highly efficient in reducing the energy consumption of the system. They lower your energy costs.

How to Troubleshoot your Air Cooled Screw Chiller?

An Air Cooled Screw Chiller helps you adjust your commercial area’s atmosphere according to your specifications.

Besides its advantages, one may have to overcome some problems with it. Some of the widespread problems and their quick solutions are given below:

Blown Fuses

Fuses may blow off if the wires, motor, or compressor are shortened or over-amped. The problem can be fixed by looking for shorts or grounds and repairing them as required.

Compressor Malfunctioning

Sometimes due to the power cut off, current overload, low pressure, circuit power fuse burnt out may cause the failure of the compressor.

You can fix the issue by checking power sources, finding out the reason for the current overload, and applying accurate pressure.

Oil Failure

A refrigerant leak induces low oil caused when there is low superheat or the oil pump is impaired. Fix these issues to avoid oil failure.

Freeze Stat

It mainly happens when the thermostat is set below the requirements or weak water flow.

Low Discharge Pressure

Insufficient refrigerant, extremely low ambient temperature, and low suction pressure are the primary causes of low discharge pressure.

You can fix them by adding the refrigerant and checking the ambient temperature, and turning off some fans if required.

High Discharge Pressure

The unit may suffer from high discharge pressure if the refrigerant is highly increased, the incondensable refrigerant enters, the fin heat exchanger is dirty, or due to the high temperature of the fin heat exchanger.

You can resolve the issue by drawing out excessive refrigerant, incondensable exhaust gas, cleaning the heat exchanger, or checking its ambient temperature.

Air Cooled Screw Chiller Troubleshooting

How to Size a Suitable Air Cooled Screw Chiller for your Industry?

The sizing of a chiller is the crucial factor to get the fullest desirous cooling for your application.

You can size a suitable Air Cooled Screw Chiller for your industrial plant by considering the following measures.

- Estimate the required cooling capacity for your application in tons.

- Calculate the process cooling load. It can be done by dividing the cooling capacity by unit time.

- Determine your operating load range. It generally ranges from 50% to 75%.

How to Monitor and Adjust your Air Cooled Screw Chiller Operation?

You should follow the following guidelines to monitor and adjust your Air Cooled Screw Chiller to ensure its proper functioning.

- Monitor the pressure and temperature of the chilled water that passes through the evaporator.

- Inspect the flow rate of refrigerants regularly.

- Check the electrical voltage and current of the primary motor.

- Examine the pressure, the inlet, and outlet temperature of the condenser.

- Monitor the lubricant temperature, density, and pressure daily.

- Look for any kind of abnormal noise or vibration in the unit.

How to Increase Efficiency of your Air Cooled Screw Chiller?

The following factors will help to increase the working efficiency of your Air Cooled Screw Chiller:

Analyze Compressor Oil

High moisture levels in compressor oil can suggest a problem with the unit that can reduce its efficiency.

Reduce Entering Water Temperature

If the water temperature entering the system is lower, it will take less energy to cool it to its average operating temperature.

Maintain Proper Water Flow Rate

A lower flow rate of water decreases the efficiency of your Air Cooled Screw Chiller.

At the same time, a flow rate can cause tube corrosion, vibration, and noise. It is essential to maintain an optimized flow rate of water.

Keep the Tubes Clean

Dirty tubes can adversely affect the efficiency of your unit. Thus, it is recommended to keep the tubes clean to ensure adequate heat transfer.

Proper Insulation on Chilled Water Pipeline

If the insulation is insufficient, heat loss may occur that lowers the overall efficiency of your chilling plant.

Proper Insulation on Chilled Water Pipeline of Air Cooled Screw Chiller