TopChiller can design and manufacture all types of industrial water chillers for you

- Cooling capacity ranges from 5 Ton to 200 Ton

- Temperature control ranges -25°C to 25°C

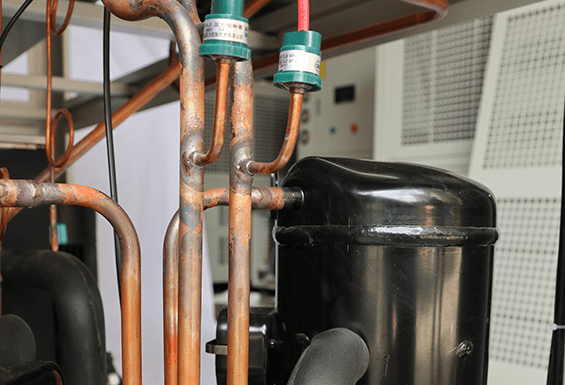

- Famous brand Scroll & screw compressor

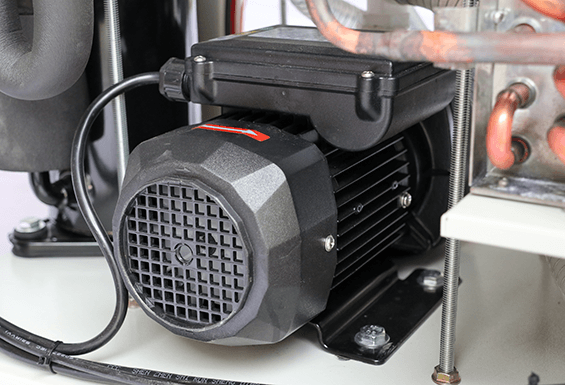

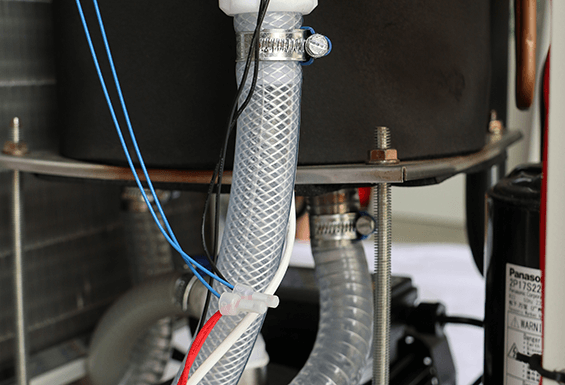

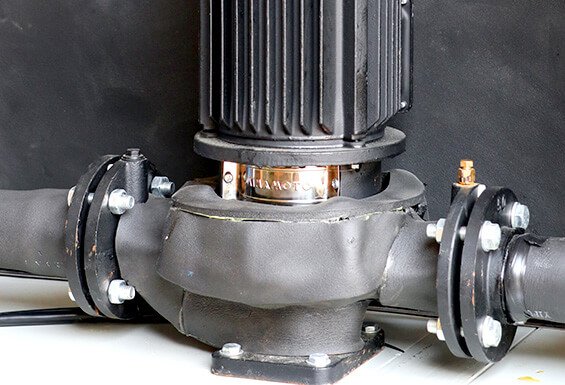

- Stainless steel reliable water pump and tank

- Job-specific evaporator & hot gas bypass

- Secondary coolant loops & LCD screen display

- Multiple alarms for overcurrent/temperature

- Durable design with steel frames & covers

Your Premier Industrial Water Chiller Manufacturer and Supplier

Industrial Water Chiller is a peculiar designed cooling machine that configures the chilling effect for industrial processing machines by transferring heat from processing equipment to outside air by using chilled water circulation.

TopChiller is the foremost manufacturing company in China that was established in 1999. Within twenty years’ time span TopChiller has expanded our product line around the world to accommodate assorted application requirements with appreciating fame and name.

By keeping in view the different requirements claimed by the customers, TopChiller is manufacturing a full stock of Industrial Water Chiller with simple designs, preventing the customers from facing any difficulties and profoundly supplying to the whole world marketplace.

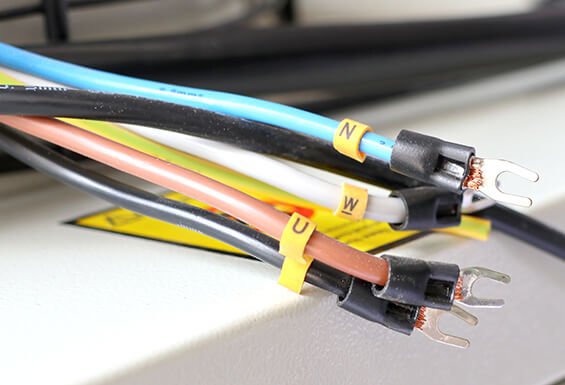

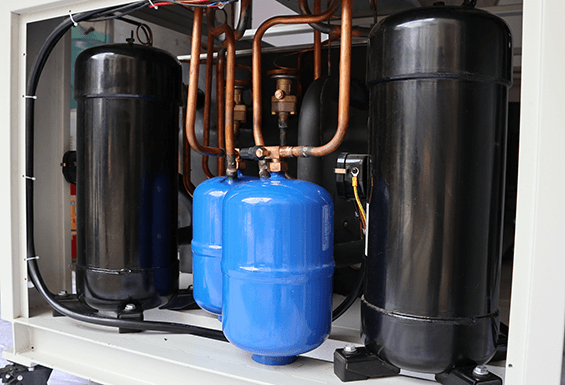

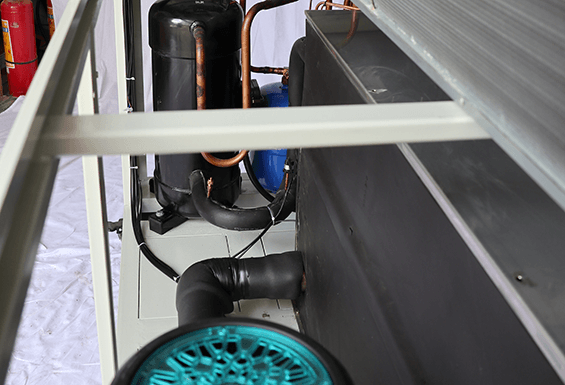

Industrial Water Chiller is designed with different branded spare parts as scroll/screw compressor, hot gas bypass, multiple protecting alarms, heat exchanger, secondary loops, screen display, reliable condenser, cooling tower, refrigerant tank, PID temperature controller, and power supply.

TopChiller engineered Industrial Water Chiller has a large number of marvelous benefits for different industrial machines as given below:

- Industrial Water Chiller ensures durable operation even dealing with continuous heat processing equipment configured by a steel frame, covers, and removable steel panel preventing the whole unit from damaging.

- TopChiller designed Industrial Water Chiller is capable of regulating minus temperature for a processing machine by releasing a high amount of heat from equipment featured by the use of secondary coolant loops as an extra heat exchanger.

- Industrial Water Chiller is configured with job evaporator that increases the unit versatility by its different featuring according to application requirement as the high-efficiency evaporator, low flow evaporator, and space-saving evaporator for heating discharge.

- TopChiller brand Industrial Water Chiller is an energy conservative and steadfast unit in its working featured by hot gas bypass that prevents the compressor from energy consumption by continuous on/off due to coolant level fluctuations by regulating it at normal set point.

Industrial Water Chiller is widely used for different industrial applications requiring continuous heat discharge from the system as:

Laser machines, plastic industry, semi-conductors, die-cutting, medical industry, hospitals, food, and beverage industry, chemical synthesis, rubber industry, pharmaceutical industry, metalwork, nuclear sciences biotechnology, etc.

If you are searching for a highly accurate and precise heat discharging Industrial Water Chiller for your application?

If you are running your own business and desiring to come in collaboration with a worldwide Industrial Water Chiller manufacturing company in China for getting key points and assistance to explore your business.

Stay here and stop looking way around. TopChiller is the most preferred company among the best choices.

Make contact with TopChiller engineers and staff for getting buying guide, quote for sizing the best Industrial Water Chiller for your application.

TopChiller team is committed to getting satisfy our customers with every perspective of Industrial Water Chiller operational efficacy.

General Description:

An Industrial Water Chiller is a heavy-duty cooling machine that provides cooling to the various industrial equipment by removing the extra heat produced by different mechanical processes.

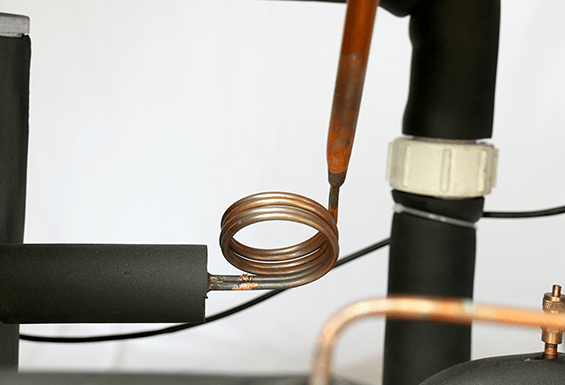

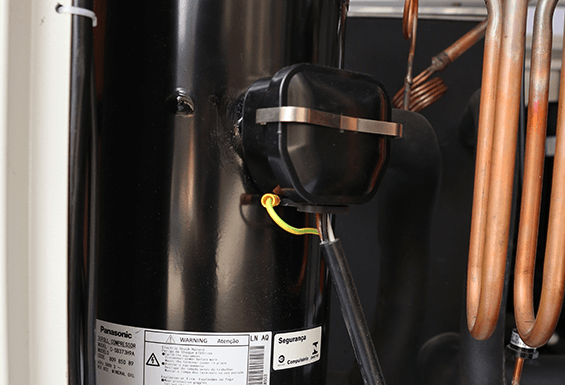

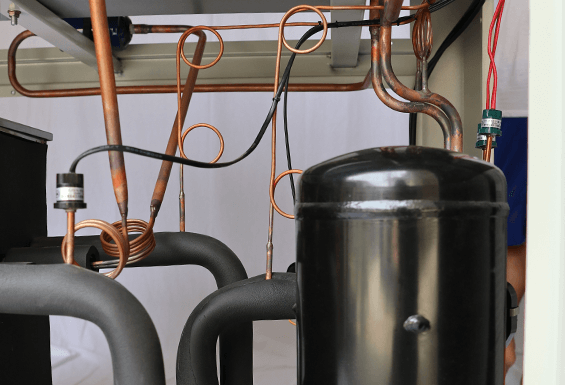

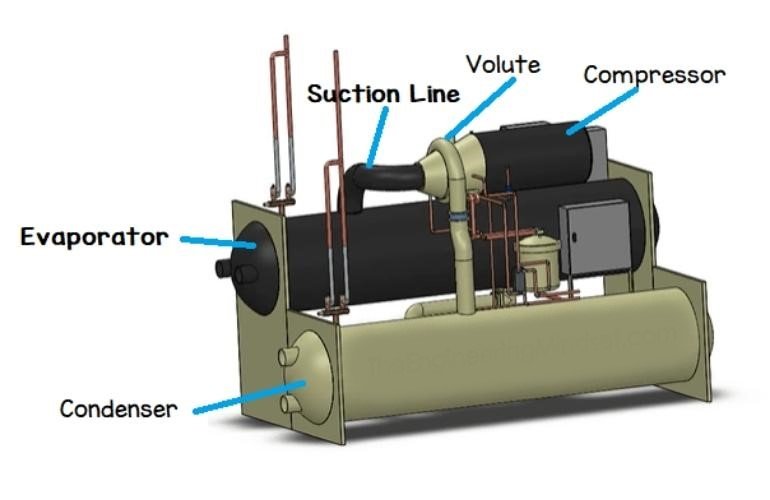

An Industrial Water Chiller consists of reliable branded spare parts, including an evaporator, condenser, compressor, control panel, drier filter, cooling tower, and a water storage tank that collectively work together to remove extra heat.

Industrial Water Chiller designed by TopChiller consists of multiple outstanding features that assist in its efficient and optimum functioning. It is being used in several industries such as medicine, pharmaceutical, laser, plastic manufacturing, food manufacturing, and other health zones to eliminate excessive harmful heat produced from heavy machines.

With over 20 years of rich experience in designing and manufacturing Industrial Water Chiller, TopChiller provides the most efficient and premium quality water cooling systems.

Other than the standard dimensional unit, depending upon your space availability and cooling requirement, at TopChiller, you can get a customizable Industrial Water Chiller according to your industrial requirements.

If you desire to establish an associative relationship with a reliable brand, get key tips and guidelines about Industrial Water Chiller? Contact us, and our team will undoubtedly help you to choose a water cooling system at an affordable price.

Features and Advantages:

An Industrial Water Chiller manufactured by TopChiller is filled with multiple features and excellent benefits such as:

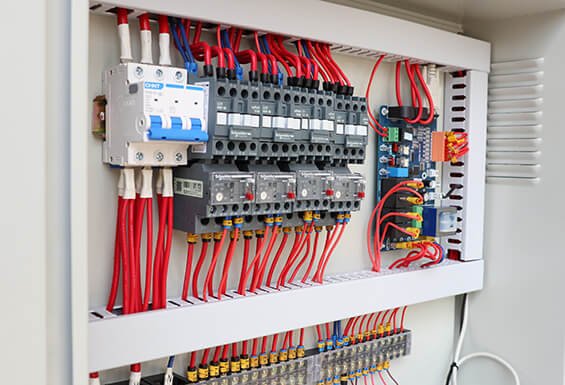

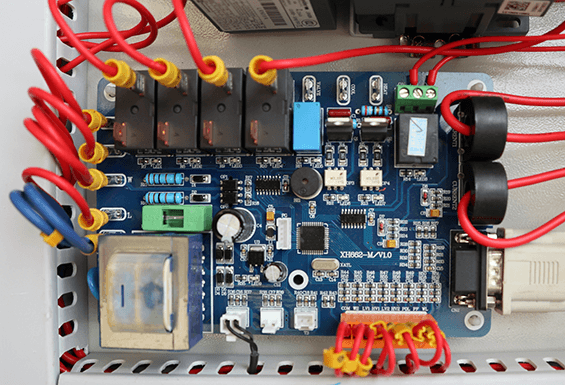

- It is equipped with an advanced electronic PLC controlling system that can notify about the safety alarms, system faults, maintenance notifications, power status, and other alerts.

- Industrial Water Chiller has a shell and tube condenser, durable construction, and long life, ensuring efficient heat exchanging, simple maintenance, easy cleaning, and longevity.

- Along with the standard stainless steel tank with coils, it offers multiple choices in the evaporator. You can get the shell and tube and the brazed plate heat exchangers depending upon your cooling requirement and the size of the equipment.

- It has an efficient and fine-quality hermetic scroll compressor featuring high internal volume, and this scroll design is suitable in the radial and axial directions.

- For increased safety against liquid transfer, it comes with compressor crankcase heaters.

- Data Sheet

- Image Gallery

- Main Parts

- Video

| Industrial Water Chiller Technical Specifications | |||||||||||

| Model Items | AW-3W | AW-4W | AW-5W | AW-6W | AW-8WD | AW-10WD | AW-12WD | AW-15WD | AW-15WT | AW-20WD | |

| Cooling Capacity | kcal/h 50HZ/60HZ | 8170 | 11266 | 14018 | 16340 | 22532 | 28036 | 32680 | 43172 | 42140 | 56760 |

| 9804 | 13519 | 16822 | 19608 | 27038 | 33643 | 39216 | 51806 | 50568 | 68112 | ||

| KW 50HZ/60HZ | 9.5 | 13.1 | 16.3 | 19 | 26.2 | 32.6 | 38 | 50.2 | 49 | 66 | |

| 11.4 | 15.72 | 19.56 | 22.8 | 31.44 | 39.12 | 45.6 | 60.24 | 58.8 | 79.2 | ||

| Input Power | KW | 3.07 | 3.87 | 5.3 | 5.95 | 7.75 | 10.6 | 11.9 | 16.25 | 15.85 | 19.71 |

| Max Current | A | 7.5 | 9.4 | 12.9 | 14.4 | 18,8 | 25.7 | 28.9 | 39.4 | 38.2 | 47.8 |

| power source | 3PH~380V/415V/480V~50HZ/60HZ(3PH~200V/220V 50HZ/60HZ) | ||||||||||

| Refrigerant | Type | R22/R407C/134a/404A/410A | |||||||||

| Control | Capillary / Thermostatic expansion valve | ||||||||||

| Compressor | Type | Hermetic scroll ( piston ) | |||||||||

| Power(KW) | 2.7 | 3.5 | 4.55 | 5.2 | 3.5×2 | 4.55×2 | 5.2×2 | 7×2 | 4.55×3 | 8.96×2 | |

| Condenser | Type | Shell and tube/ SS plate type heat exchanger | |||||||||

| Cooling water (m³/h) | 2.1 | 2.9 | 3.6 | 4.2 | 5.7 | 7.1 | 8.3 | 11 | 10.8 | 14.4 | |

| 2.4 | 3.3 | 4.1 | 4.8 | 6.6 | 8.3 | 9.6 | 12.8 | 12.5 | 16.7 | ||

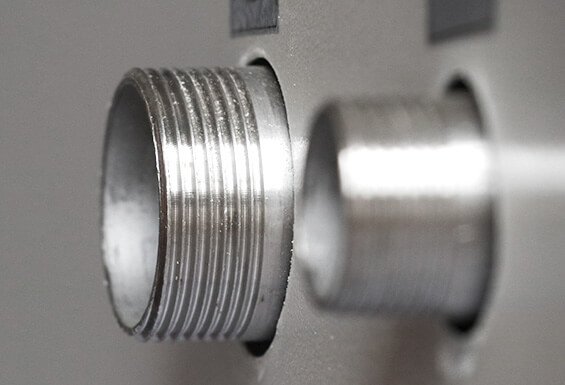

| Inlet/outlet pipe (inch) | 1 1/2″ | 1 1/2″ | 1 1/2″ | 1 1/2″ | 1 1/2″ | 1 1/2″ | 1 1/2″ | 2″ | 2″ | 2″ | |

| Evaporator | Type | SS Tank with cooper coil / Shell and tube/Plate heat exchanger | |||||||||

| Chilled water | 1.63 | 2.25 | 2.8 | 3.27 | 4.5 | 5.6 | 6.53 | 8.63 | 8.43 | 11.35 | |

| 1.96 | 2.7 | 3.36 | 3.92 | 5.4 | 6.73 | 7.84 | 10.36 | 10.1 | 13.62 | ||

| Water tank(L) | 60 | 60 | 60 | 90 | 150 | 200 | 200 | 330 | 330 | 330 | |

| inlet/outlet pipe (inch) | 1″ | 1″ | 1″ | 1″ | 1-1/2″ | 2″ | 2″ | 2″ | 2″ | 2″ | |

| Water pump | Power(kw) | 0.37 | 0.37 | 0.75 | 0.75 | 0.75 | 1.5 | 1.5 | 2.2 | 2.2 | 2.2 |

| Max lift(m) | 22 | 22 | 30 | 30 | 25 | 25 | 25 | 28 | 28 | 28 | |

| Max flow (m³) | 5.4 | 5.4 | 8.1 | 8.1 | 8.1 | 13.5 | 13.5 | 25.2 | 25.2 | 25.2 | |

| Safety protection | Compressor inner protection, over current protection, high/low pressure protection, over temperature protection, flow rate protection, phase sequence/phase missing protection, low level coolant protection, anti freezing protection, exhaust overheat protection | ||||||||||

| Dimension | L(mm) | 910 | 910 | 910 | 910 | 1250 | 1250 | 1250 | 1600 | 1600 | 1600 |

| W(mm)) | 480 | 480 | 480 | 480 | 680 | 680 | 680 | 750 | 750 | 750 | |

| H(mm)) | 1000 | 1000 | 1000 | 1000 | 1380 | 1380 | 1380 | 1600 | 1600 | 1600 | |

| Net weight(KG) | 125 | 135 | 160 | 180 | 230 | 260 | 330 | 420 | 420 | 460 | |

| Note: The above specifications are according to the following design conditions: 1, Chilled water inlet/outlet temperature 12℃/7℃. 2, Chiller temperature control range 5℃/35℃. We reserve the right to modify the specification without further notice. | |||||||||||

| Industrial Water Chiller Technical Specifications | |||||||||||

| Model Items | AW-20WF | AW-25WD | AW-25WF | AW-30WD | AW-30WT | AW-40WD | AW-40WF | AW-50WD | AW-50WF | AW-60WD | |

| Cooling capacity | kcal/h 50HZ/60HZ | 56072 | 66048 | 65360 | 83420 | 85140 | 114036 | 113520 | 134504 | 132096 | 169764 |

| 67286 | 79258 | 78432 | 100104 | 102168 | 136843 | 136224 | 161405 | 158515 | 203717 | ||

| KW 50HZ/60HZ | 65.2 | 76.8 | 76 | 97 | 99 | 132.6 | 132 | 156.4 | 153.6 | 197.4 | |

| 76.56 | 92.16 | 91.2 | 116.4 | 118.8 | 159.12 | 158.4 | 187.68 | 184.32 | 236.88 | ||

| Input power | KW | 20.4 | 23.8 | 23 | 30.99 | 30.63 | 41.31 | 39.59 | 52.7 | 48.7 | 59.3 |

| Max Current | A | 48.5 | 61.7 | 60 | 75.2 | 74.8 | 100.3 | 96.6 | 127.9 | 119.7 | 143.9 |

| Power Source | 3PH~380V/415V/480V~50HZ/60HZ(3PH~200V/220V 50HZ/60HZ) | ||||||||||

| Refrigerant | Type | R22/R407C/134a/404A/410A | |||||||||

| Control | Thermostatic expansion valve | ||||||||||

| Compressor | Type | Hermetic scroll ( piston ) | |||||||||

| Power(KW) | 4.55×4 | 10.8×2 | 5.2×4 | 13.62×2 | 8.96×3 | 18.78×2 | 8.96×4 | 23.6×2 | 10.8×4 | 26.9×2 | |

| Condenser | Type | Shell and tube/ SS plate type heat exchanger | |||||||||

| Cooling Water (m³/h) | 14.4 | 17 | 16.7 | 21.4 | 21.7 | 29.3 | 28.9 | 35 | 33.9 | 43.2 | |

| 16.6 | 19.6 | 19.3 | 24.7 | 25.1 | 33.8 | 34.4 | 40.4 | 39.1 | 50 | ||

| inlet/outlet pipe (inch) | 2″ | 2″ | 2 1/2″ | 2 1/2″ | 2 1/2″ | 3″ | 3″ | 3″ | 3″ | 4″ | |

| Evaporator | Type | SS Tank with cooper coil / Shell and tube/Plate heat exchanger | |||||||||

| Chilled Water (m³/h) | 11.21 | 13.21 | 13.1 | 16.68 | 17.02 | 22.8 | 22.7 | 26.9 | 26.41 | 33.95 | |

| 13.45 | 15.85 | 15.68 | 20.02 | 20.43 | 27.36 | 27.24 | 32.27 | 31.7 | 40.73 | ||

| Water Tank (L) | 330 | 350 | 350 | 450 | 450 | 580 | 580 | 620 | 620 | 620 | |

| inlet/outlet pipe (inch) | 2″ | 2″ | 2″ | 2-1/2″ | 2-1/2″ | 3″ | 3″ | 3″ | 3″ | 4″ | |

| Water pump | Power(kw) | 2.2 | 2.2 | 2.2 | 4 | 4 | 4 | 4 | 5.5 | 5.5 | 5.5 |

| Max lift(m) | 28 | 28 | 28 | 30 | 30 | 30 | 30 | 32 | 32 | 32 | |

| Max flow (m³) | 25.2 | 25.2 | 25.2 | 36 | 36 | 36 | 36 | 40 | 40 | 40 | |

| Safety protection | Compressor inner protection, over current protection, high/low pressure protection, over temperature protection, flow rate protection, phase sequence/phase missing protection, low level coolant protection, anti freezing protection, exhaust overheat protection | ||||||||||

| Dimension | L(mm) | 1600 | 1950 | 1950 | 1950 | 1950 | 2000 | 2000 | 2000 | 2000 | 2200 |

| W(mm) | 750 | 850 | 850 | 850 | 850 | 980 | 980 | 980 | 980 | 1100 | |

| H(mm) | 1600 | 1700 | 1700 | 1700 | 1700 | 1700 | 1700 | 1700 | 1700 | 1850 | |

| Net weight(KG) | 460 | 680 | 680 | 720 | 720 | 870 | 870 | 980 | 980 | 1120 | |

| Note: The above specifications are according to the following design conditions: 1, Chilled water inlet/outlet temperature 12℃/7℃. 2, Chiller temperature control range 5℃/35℃. We reserve the right to modify the specification without further notice. | |||||||||||

Why TopChiller is Your Reliable Industrial Water Chiller Manufacturer and Supplier In China

Industrial Water Chiller-An Ultimate FAQ Guide by TopChiller.

- What is an Industrial Water Chiller?

- What are the Major Parts of an Industrial Water Chiller?

- What is the Working Principle of an Industrial Water Chiller?

- What are the Applications of an Industrial Water Chiller?

- What are the Benefits of an Industrial Water Chiller for your Industry?

- How is an Industrial Water Chiller Better than Industrial Air Chiller?

- What are the Common Refrigerants Suitable for an Industrial Water Chiller?

- How to Select the Suitable Size of an Industrial Water Chiller for your Applications?

- What is the Average Energy Consumption of an Industrial Water Chiller?

- What are the Safety Features of an Industrial Water Chiller?

- What Types of Evaporator is Present in an Industrial Water Chiller?

- Why is it Important to Install a Drier Filter in your Industrial Water Chiller?

- What is the Purpose of the Cooling Tower for an Industrial Water Chiller?

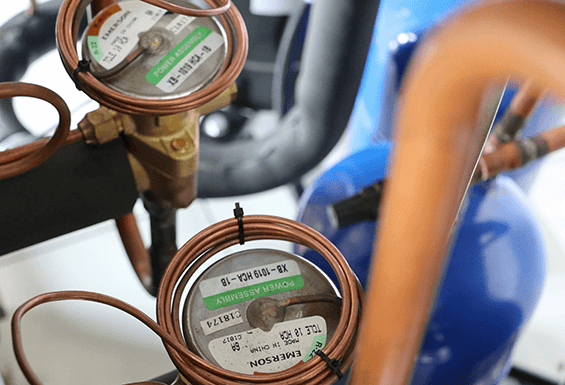

- What is the Role of an Expansion Valve in an Industrial Water Chiller?

- How to Solve Different Alarm Conditions of your Industrial Water Chiller?

- How to Install your Industrial Water Chiller?

- What are the Troubleshooting Tips for your Industrial Water Chiller?

- How to Increase the Efficiency of your Industrial Water Chiller?

What is an Industrial Water Chiller?

An Industrial Water Chiller is cooling equipment used to deal with the excessive heat production from various industrial machinery for maintaining the overall atmosphere suitable for work.

It works by grabbing the internal high heat from the building and shifting it to the outside environment.

It is implied in plastic manufacturing, food and beverage, metal forming, laser, and medical sectors to combat extra heat produced due to high mechanical procedures being performed.

Water and other refrigerants are used to achieve the cooling function, and it is preferred over the industrial air chillers for their noise-free working and enhanced safety features.

Industrial Water Chiller needs effortless maintenance, easy cleaning, trouble-free operation, durable construction, and affordable pricing to ensure the convenience and comfort of the user.

TopChiller Designed Industrial Water Chiller

What are the Major Parts of an Industrial Water Chiller?

Different parts present in an Industrial Water Chiller that work together to exhibit excellent cooling include:

Compressors

Compressors generate a significant pressure differential that forces refrigerants toward the condenser.

Compressors come in various configurations, including screw, centrifugal, scroll, and reciprocal.

Condensers

The condenser plays a significant role in eliminating the refrigerant’s heat from heavy industrial equipment.

A water-cooled condenser is used in this chiller, which works using water as the primary cooling source.

Evaporator

The evaporator will transfer surplus heat through industrial machinery to the refrigerants.

It is cooled by water moving across the system, which accumulates heat as the refrigerant removes it.

Power Unit

It is in charge of regulating the electricity supply to the Industrial Water Chiller operations.

It is composed of several components that regulate the device’s quantity, velocity, and flow of electrical charge.

Control Panel

The function of the control panel is to monitor and control different factors of this chiller’s working. It will activate alarms in different safety conditions.

Also, it powers off the system to save it from any technical damage in case of any technical problem. It incorporates technology breakthroughs that enable remote management of critical operations of the unit.

Industrial Water Chiller Major Parts

What is the Working Principle of an Industrial Water Chiller?

To start, you must set the Industrial Water Chiller to meet your individual operating parameters.

When the unit is turned on, the process begins with water circulation through the evaporator. The water will continually circulate inside the evaporator and gather heat from the industrial application.

As the water absorbs additional heat through industrial use, its temperature rises. As heated water returns to the evaporator, it comes into contact with reduced pressure and refrigeration.

The refrigerant absorbs the heat and transports it directly to the condenser, keeping the water cold. Compressing the refrigerant increases its pressure and velocity of movement.

The refrigerant shall move rapidly through the compressor into the condenser. The condenser here will remove the heat of the refrigerant, reverting it to liquid form.

Following this, the chiller would utilize water to remove heat from the water reservoirs and dispose of it. After that, the liquid refrigerant flows to the expansion valve, which increases the volume while decreasing the pressure.

Eventually, this will start flowing to the evaporator, where the process will be repeated.

What are the Applications of an Industrial Water Chiller?

Industrial Water Chiller is widely used in given industries to meet the extraordinary demands of eliminating extra heat generated from heavy machinery:

Metal Forming Industry

It is being used to chill various machinery in the forming metal sector. Resistive welding, rolling mills, welding, presses, extruders, machine tools profiling, plating, and polishing machinery are among the equipment that will be cooled.

Chemical and Pharmaceutical Industry

It is widely used in the chemical and pharmaceutical industries.

Industrial Water Chiller helps cool down lab equipment, encased containers, natural gas, polyurethane foam mixers, industrial cleaning, paints, and solvents.

Food and Drinks Industry

In the foods and beverage business, an Industrial Water Chiller is used to chill a variety of devices.

Wineries, breweries, distilleries, bottling, dairy, bakeries, carbonation, food storage, and confectionery equipment are among the machinery you can chill using this cooling equipment.

Laser Machines

It will help chill several laser devices, including diode/solid-state lasers, CO2 lasers, and yage lasers.

Plastic and Rubber Industry

An Industrial Water Chiller is used to cool various machinery in the rubber and plastic industries.

Presses, PET, injection moulding, extrusion, thermoforming, sheet profile, and blow moulding machines are only a few of the machinery.

Medical Industry

It is frequently used in the medical sector to chill medical devices.

CT scanner, MRI, X-ray, laboratory, linear accelerator, and health technologies are just a few of the required instruments.

What are the Benefits of an Industrial Water Chiller for your Industry?

The following are among the numerous advantages of using an Industrial Water Chiller for your industry:

Improved Productivity

You may experience decreased interruption and increased production with industrial goods.

It will result in minimal wastage and minimal disruptions throughout the manufacturing procedure of various items.

Equipment Protection

Industrial Water Chiller will shield sensitive industrial machines against the damaging impact of excessive temperatures or extreme heat.

It will assist in preventing your expenditures from being destroyed, hence extending the lifespan of the devices.

Optimized Operating Limits and Process Controls

You may invest a significant amount of money in current, extremely advanced technology so that you will increase manufacturing performance.

Additionally, you will decrease interruption, therefore increasing the financial viability of industrial manufacturing operations.

Reduction in Maintenance and Operation Costs

Additionally, you will save money on maintenance costs for various machinery.

This results in a decrease in the total expense of creating various items, hence improving revenues.

Saves Water

This technology recycles water, hence decreasing environmental water waste.

Additionally, it will assist in reducing the expense of water which you already pay to water suppliers.

Flexible

An Industrial Water Chiller is adaptable and customized to meet your specific usage needs. This way, you can add or modify different features to achieve your desirable or required application.

How is an Industrial Water Chiller Better than Industrial Air Chiller?

Several factors make an Industrial Water Chiller stand ahead of the Industrial Air Chiller:

Longer Lifespan

It generally requires maintenance less frequently than industrial air-cooled chillers. Because it is not subjected to external conditions like rainfall, snowfall, frost, or heat, it is least susceptible to frequent exterior damage.

Quiet Operation

Industrial Water Chiller functions silently while air-cooled chillers generate sound through ducting and venting.

The movement of water across the device does not produce a similar level of noise associated with air-cooled chillers.

Quiet operation is critical in schools and hospitals, wherein sound can be a source of discomfort for people.

Energy Efficiency

Industrial Water Chiller has a coating coefficient 10 to 100 times greater than air-cooled chillers.

This implies that it is very effective in transferring heat. As a consequence, you can save money on your high energy bills.

No Open Space Needed

To work correctly, air-cooled chillers must be located outside in an open area with enough clean air.

However, an Industrial Water Chiller is installed within buildings that lack adequate outside area.

Safety

Rather than harmful substances, it employs water as a coolant. This increases the safety of anyone who comes into touch with them.

What are the Common Refrigerants Suitable for an Industrial Water Chiller?

Among the refrigerants that may be used in Industrial Water Chiller are the following:

- Hydrochlorofluorocarbons (HFCs)

- Chlorofluorocarbons (CFCs)

- Natural Refrigerants

- Freons

- Halocarbons

Refrigerant Suitable for Industrial Water Chiller

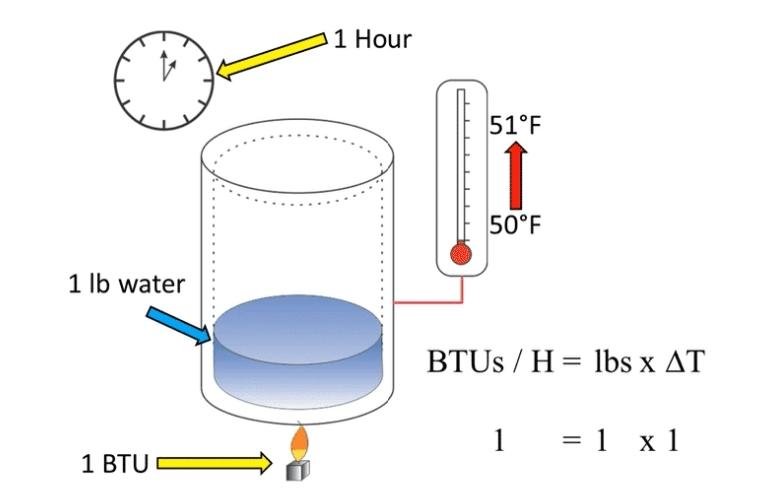

How to Select the Suitable Size of an Industrial Water Chiller for your Applications?

It would be best to choose the appropriate Industrial Water Chiller. It’s because a small-sized chiller may be incapable of adequately chilling the equipment.

On the other hand, big chillers may not operate at peak efficiency or waste resources. You’ll need to use the size calculator to determine the proper dimension in that scenario.

You will need the following information to use the device sizing calculator.

- Temperature Difference

- Gallons of Water Per Minute

- Estimate the BTU Consumption Per Hour

- Estimate the Cooling Tonnage Needed

To prevent under or extra Industrial Water Chiller size, you should have reliable information for such analyses.

The calculator will automatically determine the appropriate capacity of the Industrial Water Chiller for your application.

BTU Consumption Formula for Industrial Water Chiller

What is the Average Energy Consumption of an Industrial Water Chiller?

The quantity of energy consumed by an Industrial Water Chiller varies according to its kind. It frequently consumes over 40% of the overall energy required in industrial applications.

Compared to a small chiller, a large one consumes considerable energy.

Modern technical breakthroughs have resulted in the development of energy-conserving technologies. Try utilizing a unit that effectively preserves and saves energy, lowering operating costs.

What are the Safety Features of an Industrial Water Chiller?

Before running your Industrial Water Chiller, you must read all operating instructions. These guidelines offer a list of instructions that you must obey for your protection and the protection of the device.

Besides that, the chiller is provided with a sensor system that may identify impending danger. The protection monitors will alert you to impending danger by sending alerts to the control display screen.

Additionally, you may rely on the detectors to instantly power off the whole system. This occurs whenever the equipment is at grave risk, and doing more procedures would put it in grave danger.

Additionally, it occurs if you’re in severe danger of injury if the equipment continues to operate.

Industrial Water Chiller Water Temperature Sensor

What Types of Evaporator is Present in an Industrial Water Chiller?

Depending upon your requirements, you can decide anyone most suitable type that will be compatible with your Industrial Water Chiller:

- Brazed Plate Heat Exchanger

- Shell and Tube Type Heat Exchanger

The primary function of both these evaporators is similar, and the difference occurs in the construction and design. You can get good results only if you keep them cleaned and maintained.

Brazed Plate Heat Exchanger of Industrial Water Chiller

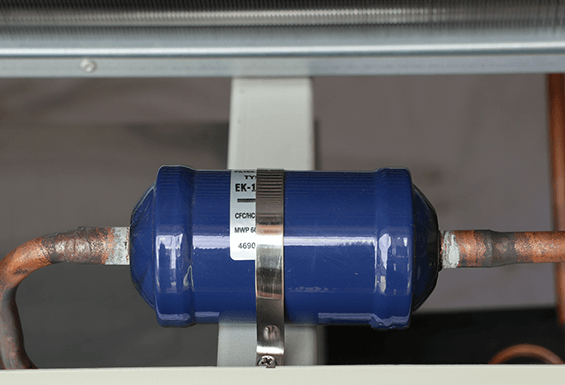

Why is it Important to Install a Drier Filter in your Industrial Water Chiller?

It is required to avoid the intrusion of humidity and debris (grease, iron, copper scraps, etc.) during the Industrial Water Chiller cooling cycle.

Moisture is derived chiefly from the trace quantity of water included in recently introduced refrigeration and lubrication and from the air generated by the inspection system.

If moisture is not removed from the system when refrigerant moves across the throttle nozzle (thermal expansion valve). In that case, the water solidifies into ice because of the temperature and pressure drop.

It can cause obstruct the pathway and interfere with its standard operating condition. As a result, this equipment should be equipped with a dryer filter.

Industrial Water Chiller Filter Drier

What is the Purpose of the Cooling Tower for an Industrial Water Chiller?

Your Industrial Water Chiller should function with a cooling tower to ensure optimal cooling performance.

A cooling tower is a structure that employs water as a flowing coolant to gather heat off a system and release it into the atmosphere to cool the water.

The cooling source exchanges coldness and heat with air and water to produce steam, then volatilized. Remove heat via convective heat transfer, evaporative heat dissipation, and radiation heat transfer to disperse waste heat created in the industry.

You can also go for air conditioning and refrigeration to lower the water temperature of the evaporative heat dropping. A cooling tower ensures the regular operation of the cooling water system.

Industrial Water Chiller Cooling Tower

What is the Role of an Expansion Valve in an Industrial Water Chiller?

In addition to the evaporator, condenser, and other essential parts, it also relies on the expansion valve for proper operation.

The thermal expansion valve is a flow controlling valve and a throttle valve in the refrigeration system of your Industrial Water Chiller.

Evaporation encases an expansion valve’s temperature sensor package, which is located across the drying filter as well as the evaporator of a refrigeration unit.

As it passes via the thermal expansion valve, it reduces the force of the intense, normal-temperature refrigerant fluid.

This will turn it into low-temperature, low-pressure refrigerant steam vaporized by the evaporator.

Industrial Water Chiller Expansion Valve

How to Solve Different Alarm Conditions of your Industrial Water Chiller?

Flow Alarm

Two leading failure causes for this alarm include blockage in water circulation pipes and deficient water level in the water storage tank of your Industrial Water Chiller.

First, the most suitable approach is to fill the water tank with appropriate water content until it reaches the green area. The other thing is to check and clean the water circulation pipes to clear and clog.

Ultra-High Temperature Alarm

Bad thermolysis, unstable voltage, poor ventilation, and high heat load are some of the failure causes for the activation of this alarm.

This can be resolved by using a voltage regulator, improving inlet and outlet ventilation, and decreasing the heat load.

How to Install your Industrial Water Chiller?

Installing the Industrial Water Chiller is easy if you consider and follow the given steps accurately:

- Open the packaging and ensure that the machine is in good condition and that all essential accessories are included.

- Allow cooling water to be injected through the injection port. (take care not to let the water overflow!), Keep an eye on the water level indicator and gradually add water; take care not to let the water overflow.

An adequate volume of cooling water additives should be added to the water (anti-corrosion water aqua) to cool carbon steel equipment.

When working in the frigid north, utilizing noncorrosive antifreeze fluid for your Industrial Water Chiller is preferable.

- Try connecting the water input and output pipes properly according to the system circumstances.

- Connect the power cord and put on the power button of your Industrial Water Chiller. (Don’t turn the key if there is no water in the storage tank!)

- When the power switch is switched on, the circulation pump of the device begins to operate.

The first operation may increase bubbling in the tube, resulting in an occasional startling flow, but it will return to normal after a few minutes.

- Immediately following the initial startup, check for breaks in the water pipe.

- When the power is turned or when the water temperatures drop below the specified value, it is common for the machine’s fans and other components to fail to operate.

The temperature sensor will dynamically regulate the operating parameters of the compressor, magnetic valve, fans, and other components based on the control settings that have been established.

Because it consumes more time to start the compressor and various components, the time varies between seconds and minutes depending on the conditions. Do not turn off and on the power often.

- Now inspect the water tank’s water level.

The first starting of the modern chiller expels air from the water pipe, resulting in a bit of drop in the water level, but sufficient water may be added to maintain the water standard in the green region.

- Please monitor and record the present water level in your Industrial Water Chiller, and re-inspect it after the device has been running for a long time; if the water level lowers significantly, carefully recheck the water pipeline leaking.

- Now adjust the temperature controller’s specifications.

Typically, users are not required to make any adjustments.

Kindly direct to the controller operating condition and parameter modification section if this is essential.

What are the Troubleshooting Tips for your Industrial Water Chiller?

Some problems commonly experienced by the users and the tips which can help solve these problems are explained below:

Filling the Refrigerant

Whenever gas/refrigerant leaks, you can tell by the low-pressure gauge’s function. Additionally, it can generate a low-pressure alarm.

Whether this occurs, we will need to refresh your Industrial Water Chiller with refrigerant. Just follow these instructions to refill a refrigerant:

- Attach the vacuum pump’s air tube to the fluid ejector valve and remove the fluid thimble valve’s cover.

- Just over an hour and a half is needed for this procedure. To start this process, vacuum the Industrial Water Chiller and ensure that the liquid adding ejector valve is linked to a refrigerant line.

- Then the refrigerant is pumped into the returning pipe to keep track of weight changes on an electronic balance (the fluid refrigerant is severely forbidden when the power is on).

- When the power is turned on, the high-pressure gauge reads about 13-15 bar, and the low-pressure gauge reads around 3-5 bar, which is standard operating behaviour.

A Blocked Condenser

Sometimes, the overall functioning of your equipment slows down, consuming a lot of extra time to provide cooling. A significant cause is the blockage of the condenser with trapped dirt.

A shell-type condenser is used in the Industrial Water Chiller. Scale builds up inside heat transfer tubes over time, reducing heat transfer efficiency.

Cleaning the condensers is necessary to keep your Industrial Water Chiller operating at its peak efficiency.

Any unnecessary object should be removed from its pipeline, and the rear side should be lifted. Also, its condenser must be discharged when it is not in operation or maintained at a temperature below 0° Fahrenheit.

Clean the evaporator regularly to keep the Industrial Water Chiller running smoothly.

Water Quality

Using hydrogen peroxide to eliminate the bath before using the cooling water is advised if the purification procedure has previously been carried out.

The water-free scale should be checked following the high-pressure water gun has been washed. It has to be passivated once it’s been pickled. Purchase of the passivating agent is possible.

How to Increase the Efficiency of your Industrial Water Chiller?

To increase the efficiency of your Industrial Water Chiller, the following points will surely be helpful if implemented properly:

Maintaining Daily Operation Logs

Throughout 24 hours of operation, you should keep logs of your daily activities and the device’s performance.

An analysis of daily returns will assist you in determining if there has been a drop in efficiency of your Industrial Water Chiller and thus in the time required for service.

Keeping the Tubes Clean

Keeping the Industrial Water Chiller tubing clean to maximize heat transfer efficiency would be best.

This will ensure that refrigerants and water flow appropriately through the tubing, reducing time and enhancing performance.

Ensuring Leak Free Units

Additionally, you will ensure that all devices are free of leakages, preventing resource waste throughout the cooling operation.

It would be best to evaluate the chiller quarterly to determine whether there is any leakage in the system.

Sustain Treatment of Water

Additionally, you will guarantee that the water purification program is maintained to guarantee that the water is constantly pure and free of contaminants.

Toxins in the water might create difficulties inside the device, lowering the system’s total effectiveness.

Analysis of Refrigerants and the Oil

Additionally, you should examine the refrigerants and lubricants over a specific period to ensure their condition.

In such a situation, you will be permitted to perform necessary adjustments and replacements before the expiration of refrigerants and lubricants.