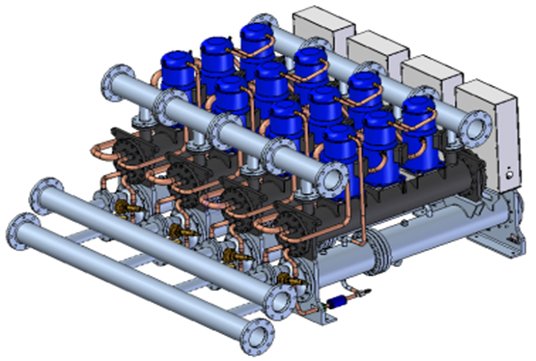

TopChiller can design and manufacture all types of water cooled scroll chillers for you

- Cooling capacity ranges from 5 Ton to 120 Ton

- Temperature control ranges from -15°C to 20°C

- Reliable brazed plate/tube type heat exchanger

- World-class brands efficient scroll compressor

- Water-cooled energy efficient SS condenser

- Ergonomic design and sturdy construction

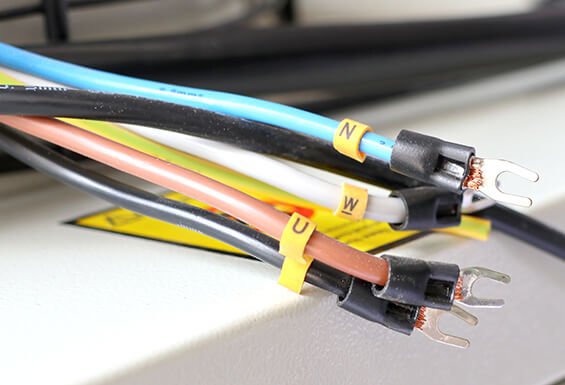

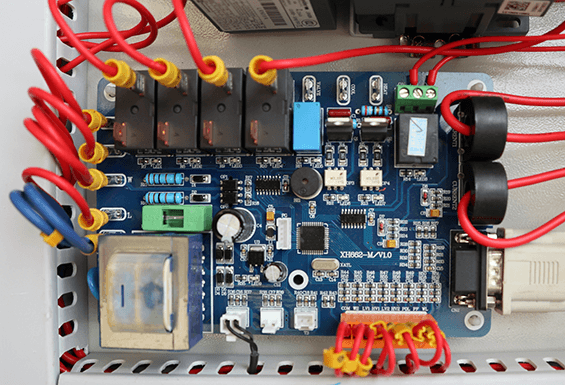

- MCS or PLC based microprocessor installation

- Pre-wiring and factory mounted full charging

Your Premier Water Cooled Scroll Chiller Manufacturer and Supplier in China Over 20 Years

Water Cooled Scroll Chiller is a cooling machine that executes the cooling effect for different industrial applications by using chilled water circulation proceeded by multiple scroll compressor interleaving compression on refrigerant.

TopChiller is the professional and the best leading manufacturer of Water Cooled Scroll Chiller in China working over the last twenty years of splendid experience and supplying it to all over the world to facilitate the customers with reliability and efficiency in performance.

TopChiller is keenly working for the manufacturing of a full line of Water Cooled Scroll Chiller models with different features and designs and supplying successfully to all over the world.

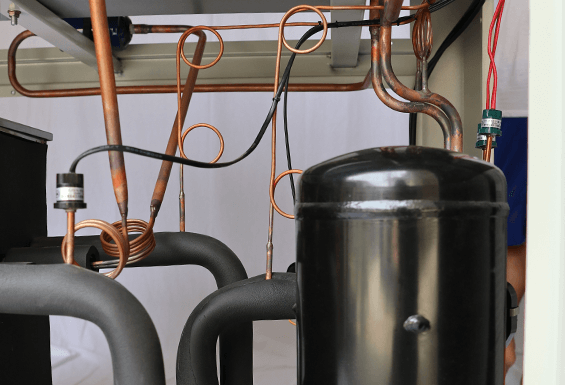

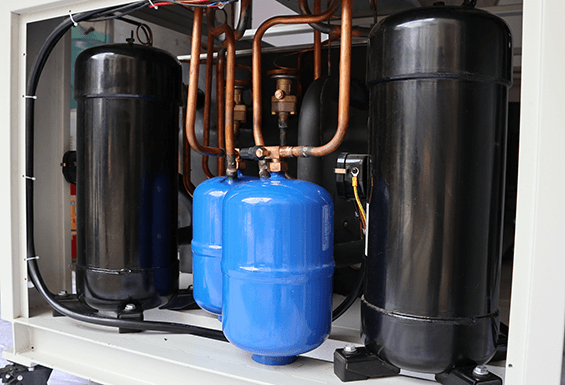

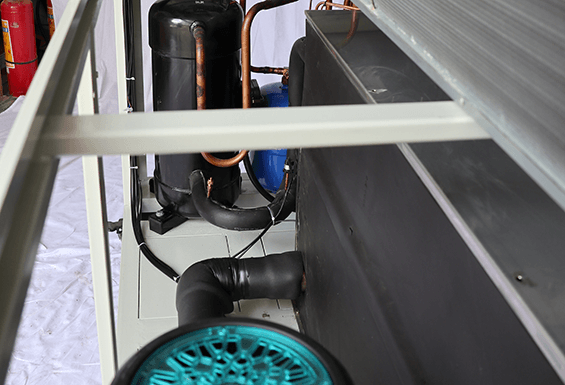

Water Cooled Scroll Chiller is featured with some basic components as a multiple scroll compressor, water tank, dual refrigeration circuit, electronic expansion valve, water-cooled condenser, brazed plate heat exchanger, cooling tower, control panel, and defensive devices.

TopChiller designed Water Cooled Scroll Chiller provides a variety of benefits to different industries that are using it as given below;

- Water Cooled Scroll Chiller is renowned for its energy-efficient performance featured by multiple scroll compressors with dual refrigeration circuits implementing high compression force on coolant for instant cooling.

- TopChiller branded Water Cooled Scroll Chiller is environment friendly with easy installation configured by the filling of the tank with refrigerant having no ozone depletion potential and prevents the environment from global warming by processing the heat collected from industrial application.

- TopChiller Water Cooled Scroll Chiller has a lower cost of maintenance and energy-efficient heat releasing from processing machines configured by use of city supply chilled water circulation having high heating capacity to absorb heat with again and again circulation, prevents the owner from high expanses.

- Water Cooled Scroll Chiller is easy to install for indoor applications requiring sound-free operation featured by scroll compressor rotation with lower moving parts ensuring quiet operation.

Water Cooled Scroll Chiller is used by different applications as given below:

Commercial applications as hypermarkets, supermarkets, water jets, injection and blow molding, medical labs, hospitals, beverage industry, vacuum coating, pharmaceutical industry, plastic industry, and construction industry.

Are you desiring to find an energy-efficient, noise-sensitive, and steadily working Water Cooled Scroll Chiller for your application?

Are you wandering over to find out a company manufacturing Water Cooled Scroll Chiller to get some beneficial guidelines to grow up your business?

TopChiller is a manufacturing company with years of experience. Come on, make contact with TopChiller sales and personnel to get the best optimal solutions for problems.

For getting purchasing guide first dictate your application specifications and requirements, our team will help in choosing the best Water Cooled Scroll Chiller for your application accordingly at affordable rates.

General Description:

Water Cooled Scroll Chiller is a premium quality cooling device that produces a cooling effect for various industrial and commercial applications by utilizing cold water for system heat accumulation.

Water Cooled Scroll Chiller, designed by TopChiller, is equipped with various branded components such as multi-scroll compressor, cooling tower, expansion valve, microprocessor controls, brazed plate heat exchanger, water cooled condenser, water tank, and control panel.

The most prominent applications of Water Cooled Scroll Chiller include injection molding, drilling, printing, food, beverages, additives, machine tools, industrial and commercial buildings semiconductors, and a lot more.

TopChiller is a trustworthy brand of China, having twenty years of outstanding experience in the industrial world, and known as a manufacturer and supplier of Water Cooled Scroll Chiller with standardized certifications.

Are you searching around to find the best Water Cooled Scroll Chiller manufacturer in China for making cooperation and getting ground-breaking technology to boost your business?

TopChiller is a matchless brand to rely on. We have hired trained engineers and professionals to hit the queries claimed by worldwide customers. So contact us without thinking twice and get your Water Cooled Scroll Chiller at a reasonable price. Our team will satisfy you with all aspects of its working and guarantee high efficiency.

Features and Advantages:

Water Cooled Scroll Chiller manufactured by TopChiller is fully integrated and furnished with a lot of features and benefits as given below:

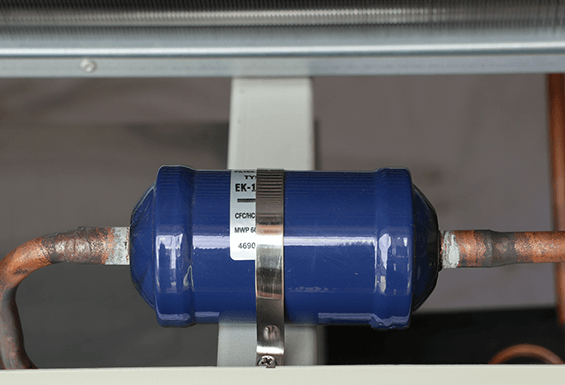

- Ergonomic design, latest technology, MCS microprocessor, and CFC-free refrigerant featuring makes it reliable and credible.

- Liquid injection for maximum compressor life, modular design, low input KW/TR required, robust construction, and implementation of modern technologies increase Water Cooled Scroll Chiller service life.

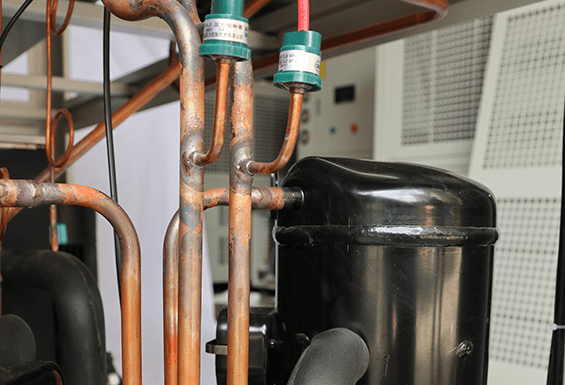

- It also consists of multiple scroll compressors with two cooling circuits that apply a high compressive force to the refrigerant to cool it instantly.

- It can be easily installed by pouring the refrigerant into a tank that does not have an ozone depletion potential preventing global warming in the surrounding area.

- Water Cooled Scroll Chiller has low maintenance costs and energy-efficient heat emissions from the system using cold water circulation.

- Data Sheet

- Image Gallery

- Main Parts

- Video

| Water Cooled Scroll Chiller Technical Specifications | |||||||||||

| Model Items | AW-3W | AW-4W | AW-5W | AW-6W | AW-8WD | AW-10WD | AW-12WD | AW-15WD | AW-15WT | AW-20WD | |

| Cooling Capacity | kcal/h 50HZ/60HZ | 8170 | 11266 | 14018 | 16340 | 22532 | 28036 | 32680 | 43172 | 42140 | 56760 |

| 9804 | 13519 | 16822 | 19608 | 27038 | 33643 | 39216 | 51806 | 50568 | 68112 | ||

| KW 50HZ/60HZ | 9.5 | 13.1 | 16.3 | 19 | 26.2 | 32.6 | 38 | 50.2 | 49 | 66 | |

| 11.4 | 15.72 | 19.56 | 22.8 | 31.44 | 39.12 | 45.6 | 60.24 | 58.8 | 79.2 | ||

| Input Power | KW | 3.07 | 3.87 | 5.3 | 5.95 | 7.75 | 10.6 | 11.9 | 16.25 | 15.85 | 19.71 |

| Max Current | A | 7.5 | 9.4 | 12.9 | 14.4 | 18,8 | 25.7 | 28.9 | 39.4 | 38.2 | 47.8 |

| power source | 3PH~380V/415V/480V~50HZ/60HZ(3PH~200V/220V 50HZ/60HZ) | ||||||||||

| Refrigerant | Type | R22/R407C/134a/404A/410A | |||||||||

| Control | Capillary / Thermostatic expansion valve | ||||||||||

| Compressor | Type | Hermetic scroll ( piston ) | |||||||||

| Power(KW) | 2.7 | 3.5 | 4.55 | 5.2 | 3.5×2 | 4.55×2 | 5.2×2 | 7×2 | 4.55×3 | 8.96×2 | |

| Condenser | Type | Shell and tube/ SS plate type heat exchanger | |||||||||

| Cooling water (m³/h) | 2.1 | 2.9 | 3.6 | 4.2 | 5.7 | 7.1 | 8.3 | 11 | 10.8 | 14.4 | |

| 2.4 | 3.3 | 4.1 | 4.8 | 6.6 | 8.3 | 9.6 | 12.8 | 12.5 | 16.7 | ||

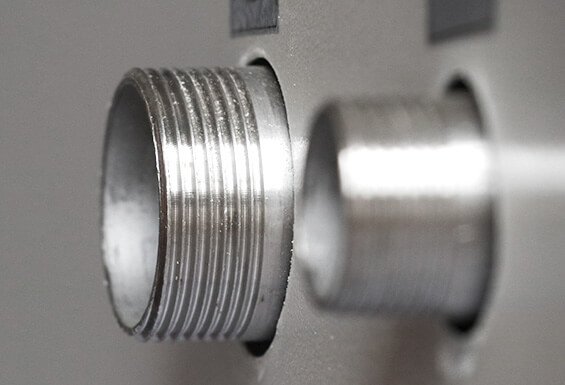

| Inlet/outlet pipe (inch) | 1 1/2″ | 1 1/2″ | 1 1/2″ | 1 1/2″ | 1 1/2″ | 1 1/2″ | 1 1/2″ | 2″ | 2″ | 2″ | |

| Evaporator | Type | SS Tank with cooper coil / Shell and tube/Plate heat exchanger | |||||||||

| Chilled water | 1.63 | 2.25 | 2.8 | 3.27 | 4.5 | 5.6 | 6.53 | 8.63 | 8.43 | 11.35 | |

| 1.96 | 2.7 | 3.36 | 3.92 | 5.4 | 6.73 | 7.84 | 10.36 | 10.1 | 13.62 | ||

| Water tank(L) | 60 | 60 | 60 | 90 | 150 | 200 | 200 | 330 | 330 | 330 | |

| inlet/outlet pipe (inch) | 1″ | 1″ | 1″ | 1″ | 1-1/2″ | 2″ | 2″ | 2″ | 2″ | 2″ | |

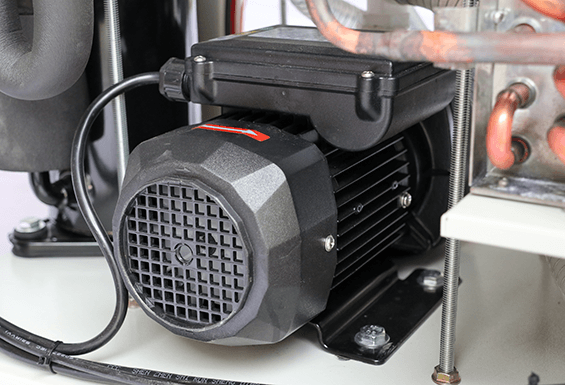

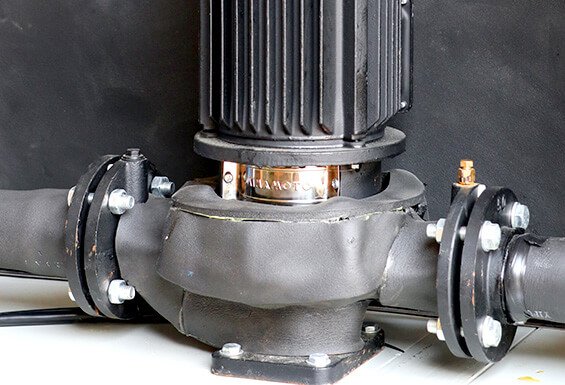

| Water pump | Power(kw) | 0.37 | 0.37 | 0.75 | 0.75 | 0.75 | 1.5 | 1.5 | 2.2 | 2.2 | 2.2 |

| Max lift(m) | 22 | 22 | 30 | 30 | 25 | 25 | 25 | 28 | 28 | 28 | |

| Max flow (m³) | 5.4 | 5.4 | 8.1 | 8.1 | 8.1 | 13.5 | 13.5 | 25.2 | 25.2 | 25.2 | |

| Safety protection | Compressor inner protection, over current protection, high/low pressure protection, over temperature protection, flow rate protection, phase sequence/phase missing protection, low level coolant protection, anti freezing protection, exhaust overheat protection | ||||||||||

| Dimension | L(mm) | 910 | 910 | 910 | 910 | 1250 | 1250 | 1250 | 1600 | 1600 | 1600 |

| W(mm)) | 480 | 480 | 480 | 480 | 680 | 680 | 680 | 750 | 750 | 750 | |

| H(mm)) | 1000 | 1000 | 1000 | 1000 | 1380 | 1380 | 1380 | 1600 | 1600 | 1600 | |

| Net weight(KG) | 125 | 135 | 160 | 180 | 230 | 260 | 330 | 420 | 420 | 460 | |

| Note: The above specifications are according to the following design conditions: 1, Chilled water inlet/outlet temperature 12℃/7℃. 2, Chiller temperature control range 5℃/35℃. We reserve the right to modify the specification without further notice. | |||||||||||

| Water Cooled Scroll Chiller Technical Specifications | |||||||||||

| Model Items | AW-20WF | AW-25WD | AW-25WF | AW-30WD | AW-30WT | AW-40WD | AW-40WF | AW-50WD | AW-50WF | AW-60WD | |

| Cooling capacity | kcal/h 50HZ/60HZ | 56072 | 66048 | 65360 | 83420 | 85140 | 114036 | 113520 | 134504 | 132096 | 169764 |

| 67286 | 79258 | 78432 | 100104 | 102168 | 136843 | 136224 | 161405 | 158515 | 203717 | ||

| KW 50HZ/60HZ | 65.2 | 76.8 | 76 | 97 | 99 | 132.6 | 132 | 156.4 | 153.6 | 197.4 | |

| 76.56 | 92.16 | 91.2 | 116.4 | 118.8 | 159.12 | 158.4 | 187.68 | 184.32 | 236.88 | ||

| Input power | KW | 20.4 | 23.8 | 23 | 30.99 | 30.63 | 41.31 | 39.59 | 52.7 | 48.7 | 59.3 |

| Max Current | A | 48.5 | 61.7 | 60 | 75.2 | 74.8 | 100.3 | 96.6 | 127.9 | 119.7 | 143.9 |

| Power Source | 3PH~380V/415V/480V~50HZ/60HZ(3PH~200V/220V 50HZ/60HZ) | ||||||||||

| Refrigerant | Type | R22/R407C/134a/404A/410A | |||||||||

| Control | Thermostatic expansion valve | ||||||||||

| Compressor | Type | Hermetic scroll ( piston ) | |||||||||

| Power(KW) | 4.55×4 | 10.8×2 | 5.2×4 | 13.62×2 | 8.96×3 | 18.78×2 | 8.96×4 | 23.6×2 | 10.8×4 | 26.9×2 | |

| Condenser | Type | Shell and tube/ SS plate type heat exchanger | |||||||||

| Cooling Water (m³/h) | 14.4 | 17 | 16.7 | 21.4 | 21.7 | 29.3 | 28.9 | 35 | 33.9 | 43.2 | |

| 16.6 | 19.6 | 19.3 | 24.7 | 25.1 | 33.8 | 34.4 | 40.4 | 39.1 | 50 | ||

| inlet/outlet pipe (inch) | 2″ | 2″ | 2 1/2″ | 2 1/2″ | 2 1/2″ | 3″ | 3″ | 3″ | 3″ | 4″ | |

| Evaporator | Type | SS Tank with cooper coil / Shell and tube/Plate heat exchanger | |||||||||

| Chilled Water (m³/h) | 11.21 | 13.21 | 13.1 | 16.68 | 17.02 | 22.8 | 22.7 | 26.9 | 26.41 | 33.95 | |

| 13.45 | 15.85 | 15.68 | 20.02 | 20.43 | 27.36 | 27.24 | 32.27 | 31.7 | 40.73 | ||

| Water Tank (L) | 330 | 350 | 350 | 450 | 450 | 580 | 580 | 620 | 620 | 620 | |

| inlet/outlet pipe (inch) | 2″ | 2″ | 2″ | 2-1/2″ | 2-1/2″ | 3″ | 3″ | 3″ | 3″ | 4″ | |

| Water pump | Power(kw) | 2.2 | 2.2 | 2.2 | 4 | 4 | 4 | 4 | 5.5 | 5.5 | 5.5 |

| Max lift(m) | 28 | 28 | 28 | 30 | 30 | 30 | 30 | 32 | 32 | 32 | |

| Max flow (m³) | 25.2 | 25.2 | 25.2 | 36 | 36 | 36 | 36 | 40 | 40 | 40 | |

| Safety protection | Compressor inner protection, over current protection, high/low pressure protection, over temperature protection, flow rate protection, phase sequence/phase missing protection, low level coolant protection, anti freezing protection, exhaust overheat protection | ||||||||||

| Dimension | L(mm) | 1600 | 1950 | 1950 | 1950 | 1950 | 2000 | 2000 | 2000 | 2000 | 2200 |

| W(mm) | 750 | 850 | 850 | 850 | 850 | 980 | 980 | 980 | 980 | 1100 | |

| H(mm) | 1600 | 1700 | 1700 | 1700 | 1700 | 1700 | 1700 | 1700 | 1700 | 1850 | |

| Net weight(KG) | 460 | 680 | 680 | 720 | 720 | 870 | 870 | 980 | 980 | 1120 | |

| Note: The above specifications are according to the following design conditions: 1, Chilled water inlet/outlet temperature 12℃/7℃. 2, Chiller temperature control range 5℃/35℃. We reserve the right to modify the specification without further notice. | |||||||||||

Why TopChiller is Your Reliable Water Cooled Scroll Chiller Manufacturer and Supplier In China?

Water Cooled Scroll Chiller-An Ultimate FAQ Guide by TopChiller.

- What is Water Cooled Scroll Chiller?

- What are the Excellent Features of Water Cooled Scroll Chiller?

- What are the Major Components of Water Cooled Scroll Chiller?

- How Does Water Cooled Scroll Chiller Work?

- What are the Applications of Water Cooled Scroll Chiller?

- Which Kind of Sensors are Used in Water Cooled Scroll Chiller?

- How Do Safety Devices Work in Water Cooled Scroll Chiller?

- What are the Advantages of Water Cooled Scroll Chiller for your Applications?

- How is Water Cooled Scroll Chiller Better than Air Cooled Scroll Chiller?

- How Does Microprocessor Controls Work in Water Cooled Scroll Chiller?

- What is the Function of Flow Switch and Freezing Protection in Water Cooled Scroll Chiller?

- Which Kind of Refrigerant is Used for Water Cooled Scroll Chiller?

- What is the Difference Between Water Cooled Scroll Chiller and Water Cooled Screw Chiller?

- How to Protect your Water Cooled Scroll Chiller from Low and High-Pressure Drop?

- What are the Important Points to Consider Before Selecting your Water Cooled Scroll Chiller?

- How to Install your Water Cooled Scroll Chiller?

- What are the Troubleshooting Guidelines for your Water Cooled Scroll Chiller?

- What are the Maintenance Tips for your Water Cooled Scroll Chiller?

What is Water Cooled Scroll Chiller?

A Water Cooled Scroll Chiller is an efficient cooling unit that decreases extra heat generated by several industrial machines. It is more potent than air cooled scroll chiller because water is better than air.

It consists of an evaporator, a water cooled shell and tube type condenser, and several sealed scroll compressors. Due to their high performance, it needs less power than air cooled scroll chillers.

The cooling module supplies the same amount of cold water all over time, regardless of changes in its environmental temperature. It also effectively supports cooling processes that demand a variety of temperature controls.

Water Cooled Scroll Chiller is known for its energy-efficient performance provided by multiple scroll compressors with two cooling circuits that instantly compress and cool the refrigerant.

It is equipped with unique functions such as compact design easy installation with a controller or cable.

Durable Water Cooled Scroll Chiller Designed by TopChiller

What are the Excellent Features of Water Cooled Scroll Chiller?

The Water Cooled Scroll Chiller has the following unique feature that is given below:

- It contains a reliable and energy-efficient scroll compressor and eco-friendly refrigerant R407C, R410A, and R134A

- Fully skid-mounted unit with one or more refrigeration circuits containing a liquid storage tank and pump.

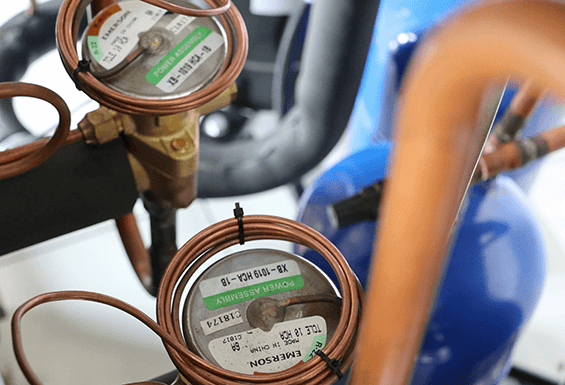

- It consists of a large-capacity electronic expansion valve for accurate temperature control and energy efficiency.

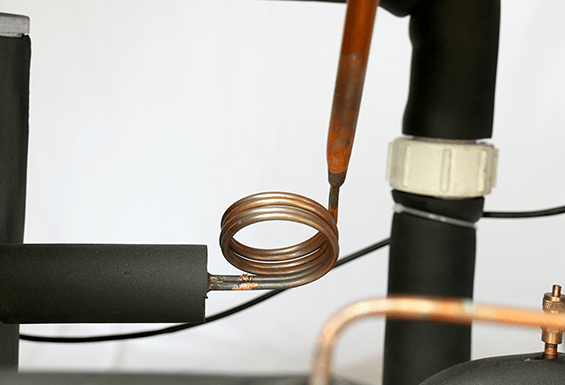

- Factory mounted tube-in-tube/ shell and tube type evaporator configuring efficient heat exchange.

- High flow rate design, enlarged condensing surface, and additional pipe thickness.

- Maximum energy efficiency, higher operational reliability, and easier maintenance

- Fully automated PLC-based unit with remote control and data logging service.

- Automatic step-by-step capacity controlling with several compressor operations

- The scroll compressor utilized in Water Cooled Scroll Chiller has modern technology with a deficient noise level of 72 dBA.

Water Cooled Scroll Chiller Eco-Friendly Refrigerant R134A

What are the Major Components of Water Cooled Scroll Chiller?

The major components of the Water Cooled Scroll Chiller are given below are:

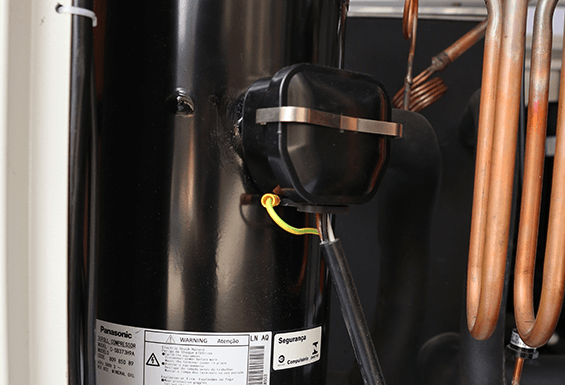

Scroll Compressor

The compressor is the central part that generates the pressure difference to flow the refrigerant throughout the system.

It is always placed between the condenser and evaporator. It is connected with an electric motor for taking driving force and is fixed inside or outside.

Condenser

The condenser is fixed behind the compressor and in front of the expansion valve. The condenser is responsible for extracting heat from the refrigerant absorbed by the evaporator.

The water repeatedly circulates between the water-cooled condenser and the cooling tower. The hot refrigerant that passes through the condenser transfers heat to circulating water over coils.

Ultimately hot water is carried to the cooling tower to discharge heat into the outer atmosphere.

Expansion Valve

The expansion valve is placed before the evaporator. Its primary function is to increase the volume, reduce the pressure of the refrigerant and permit it to absorb extra heat from building in the evaporator.

The most common valve utilized in Water Cooled Scroll Compressor is a thermal expansion valve.

Evaporator

The evaporator is placed before the compressor and after the expansion valve. It is used to absorb extra heat coming from the building through circulating refrigerant.

Water coolant gets cooled down in the evaporator and is sent back to the building for air conditioning.

Power Unit

The power unit could be fixed directly on the Water Cooled Scroll Chiller or separately on the wall of the system room with a power cable connected to the chiller.

The unit’s primary function is to regulate the flow of electricity to the chiller.

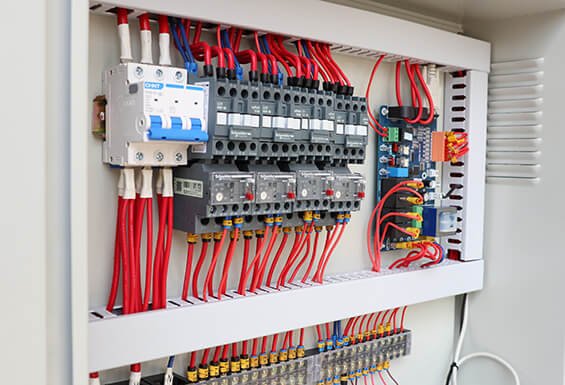

Controls Panel

The controls panel maintains the performance during operation. The control unit creates an alarm and safely shuts down in the system to protect damage to the device in the case of damage.

Water Boxes

The water box is attached to the condenser of the evaporator and Water Cooled Scroll Chiller.

Its function is to direct the flow and separate the inlet and outlet of water into evaporator and condenser.

Water Cooled Scroll Chiller Control Panel

How Does Water Cooled Scroll Chiller Work?

The Water Cooled Scroll Chiller operates according to the basic refrigeration cycle. It also acts as a refrigerator to cool the liquid and dehumidify the air in the area.

The working of it consists of four steps:

Step 1

The cycle begins at the evaporator, and the liquid refrigerant passes through the tubes that surround the evaporator.

The liquid refrigerant is a chemical that could take heat from the water flowing through a pipe. When the water reaches the boiling temperature of 100 ° C, water begins to turn into steam.

Step 2

This steam then passes through the compressor. After entering the moisture in the scroll compressor, it begins for action.

The compressor is integrated with a unique spiral design and two interlocking spirals for pumping, compressing, and pressurizing liquids. The primary function of the compressor is to increase the pressure of steam.

Step 3

The scroll compressor then begins to increase the pressure and temperature of the condenser by sending steam into the condenser.

The steam becomes liquid in the pipe by releasing heat to the cooling water that passes through the condenser.

Step 4

This high-pressure refrigerant in the form of liquid enters into the expansion valve to reduce both pressure and temperature.

In the expansion valve, whole steam is converted into liquid form and the cycle then again repeats itself.

What are the Applications of Water Cooled Scroll Chiller?

Water Cooled Scroll Chiller is a highly reliable cooling unit that discharges the system heat through chilled water coming from a water tank.

It is used to cope with the heating problems of various industrial applications as given below:

- Plastic Manufacturing

- Laser Industry

- Printing Press

- Injection Molding

- Drilling and Stamping

- Food and Beverage Industry

- Additives and Machine Tools

- Semiconductors

- Hospitals

- Shopping Malls

Water Cooled Scroll Chiller Applications

Which Kind of Sensors are Used in Water Cooled Scroll Chiller?

Pressure Sensor

Each circuit’s evaporation and condensation pressures are measured by utilizing two electronic sensors. The value of every sensor is visibly shown on the sensor housing.

Temperature Sensor

Water sensors for the evaporator and condenser are fixed into the inlet and outlet sides. In addition, a suction temperature sensor is integrated into each circuit to monitor the temperature of the superheated refrigerant.

Thermistor

Each compressor is furnished with a PTC thermistor immersed in the motor windings to protect the motor.

The thermistor shuts off to a high value when the motor temperature increases.

Water Cooled Scroll Chiller Pressure Sensor

How Do Safety Devices Work in Water Cooled Scroll Chiller?

Emergency Stop

The control panel consists of a push-button to turn off the working of the whole unit. By manually pressing the emergency stop button, all loads will stop spinning, and further accidents will be avoided.

The unit controller also triggers an alarm. Switch ON the chiller only after releasing the emergency stop button to clear the controller alarm.

Component Safety Devices

The Water Cooled Scroll Chiller’s components are also protected from damage by installing safety options. The safest option is turned off when it notices an unexpected working condition leading to irreversible destruction of chiller parts.

Below is a description of the protective device.

Over Current

The overload system protects the pump and compressor electric motors in a short circuit or overload.

Overcurrent protection is integrated into the electronic drive of the converter actuated motor. Circuit breakers or fuses fixed on each load or load group deliver additional short circuit protection.

Over Temperature Protections

The thermistor of the motor winding also prevents the compressor from overheating. The thermistor may trip and stop the motor if the winding temperature exceeds the specified value.

Phase Reversal, Under/Over Voltage, Ground Fault Protection

When any alarms ring, the Water Cooled Scroll Chiller automatically turns off. The warning will be cleared as soon as the problem is resolved.

This automatic system assists in recovering quickly if the input voltage crosses the lower or upper limit set in the safety system.

Manual adjustment of phase is required for setting the normal range to resolve the issue in the other two situations.

If you have a phase reversal warning, you need to reverse the two steps.

Water Cooled Scroll Chiller Emergency Stop Button

What are the Advantages of Water Cooled Scroll Chiller for your Applications?

Longer Lifespan

Water Cooled Scroll Chiller usually does not require to be replaced as often as air cooled scroll chiller. It is less vulnerable because it is not exposed to outdoor components such as snow, rain, heat, and dust.

Quiet Operation

The air cooled scroll chiller has noise-generating vents and ducts, but Water Cooled Scroll Chiller works quietly.

The water used in the condenser to remove heat from the system does not produce much noise compared to an air cooled scroll compressor that’s used fans to remove heat.

Energy Efficiency

The heat transfer coefficient of a Water Cooled Scroll Chiller is 10 to 100 times better than that of air cooled scroll chiller.

No Open Space Needed

The air cooled scroll chiller requires an outer environment with sufficiently fresh air. While the Water Cooled Scroll Chiller stays inside the building, making it perfect for applications that don’t have enough outdoor space.

Safety

Water Cooled Scroll Chiller utilizes CFC-free refrigerant instead of toxic chemicals. This makes it safer for the atmosphere.

How is Water Cooled Scroll Chiller Better than Air Cooled Scroll Chiller?

Water Cooled Scroll Chiller is more proficient than air cooled scroll chillers because it utilizes a cooling tower throughout the work.

It also offers condensation according to the ambient wet bulb temperature, which is lower than the ambient dry bulb temperature. It is more energy-efficient and highly sustainable than air cooled scroll chiller.

Water Cooled Scroll Compressor is more efficiently removes heat from the condenser because it utilized a water cooling tower to remove heat from the condenser.

On the other hand, an air cooled scroll compressor uses fans to remove heat from the condenser.

Air Cooled Scroll Chiller

How Does Microprocessor Controls Work in Water Cooled Scroll Chiller?

The entire Water Cooled Scroll Chiller range is equipped with integrated microprocessor control that offers several new working functions.

These features become a system more convenient and easy to use. These guarantee significant energy savings and reduce maintenance and downtime costs.

Digital Setting of Temperature Levels.

The digital setting of temperature permits you to set the required temperature level with accuracy as compared to manual control.

Manual temperature control has a much higher margin of error. The main advantages of these features are energy-saving and optimal cooling.

Built-in Time Delay

The compressor will take a few minutes to turn on again after it has been turned off or out of power.

The controller confirms that these time delays are automatically observed. The main advantage of this feature is that it extends the compressor’s life.

What is the Function of Flow Switch and Freezing Protection in Water Cooled Scroll Chiller?

Flow Switch

A flow switch is required to maintain the flow rate of the water coolant. When the water flow decreases below the minimum allowable flow rate, the flow switch turns OFF to stop the operation.

When the water flow is restored, the flow protection will automatically reset. If the flow switch opens with at least one compressor is running, you will need to remove the warning manually.

Freezing Protection

Antifreeze prevents the freezing of the water in the evaporator. It starts automatically when the evaporator’s water temperature decreases below the set limit.

When the device freezes in standby mode, the evaporator pump is activated to prevent freezing in the evaporator.

If a freeze occurs while the unit runs, the whole system will shut off alert while the pump works. If the freeze condition disappears, the alarm will be shut off immediately.

Water Cooled Scroll Chiller Flow Switch

Which Kind of Refrigerant is Used for Water Cooled Scroll Chiller?

If the capacity of the Water Cooled Scroll Chiller is medium, use R407C and R410A as the refrigerant. If it is more efficient, then utilize R123 and R134a.

These refrigerants have zero ozone depletion rate. These are environment-friendly refrigerants and more efficient for transferring heat throughout the whole system.

What is the Difference Between Water Cooled Scroll Chiller and Water Cooled Screw Chiller?

Water Cooled Scroll Chiller

The Water Cooled Scroll Chiller weighs 20-200 tons. In addition, it can be configured with two compressors for longer service life and durability.

In case if one compressor may damage, the other compressor can continue the operation. Scroll compressors are integrated with it for refrigerant compression.

It contains a water cooled condenser to cool down refrigerant by finally heat dissipation from the refrigeration cycle.

It is integrated with a screw compressor for noise-free refrigerant compression compared to a scroll compressor.

A water-cooled screw chiller has only one compressor, and its loss can disrupt the entire process.

The screw compressor consists of two rotary screw parts rotating over each other to pressurize the incoming refrigerant. It also makes the final heat dissipation through the water cooled condenser.

Water Cooled Screw Chiller

How to Protect your Water Cooled Scroll Chiller from Low and High-Pressure Drop?

Low-Pressure Protection

If the suction pressure of the circuit decreases below the set limit over a long time. The low-pressure switches of the circuit turn it off and generate a warning.

You must manually operate the microprocessor controller to reset the alarm. If the suction pressure drops below the safety level, it would only be reset.

High-Pressure Protection

If the discharge pressure elevates much high and crosses the upper limit associated with the compressor’s operating range.

Install high-pressure switches that will turn off by generating alarms and warning for prevention from fire.

Maintain the pressure at the required range. Manually operate the microprocessor controller to reset this alarm and turn on the switches for again working.

What are the Important Points to Consider Before Selecting your Water Cooled Scroll Chiller?

Some fundamental aspects should be kept in consideration while selecting your Water Cooled Scroll Chiller for your application, as given below:

Heat Load

It is necessary to calculate the heat load of the building to confirm that the selected chiller is not too large or too small for your desired application.

Type of Coolant and Flow Rate

Consider the heat load of your application. Then select the coolant with heat capacity ranged to your application. The Water Cooled Scroll Chiller flow rate should also be as per your requisites.

Ambient Temperature

Outdoor applications could be exposed to high and low ambient temperature and unclean environments. First, consider the site of installation for the Water Cooled Scroll Chiller and the ambient temperature of the surroundings.

Then select the chiller that feasibly relies on the ambient temperature. For muddy environments and outdoor applications, Water Cooled Scroll Chiller is preferred to choose.

How to Install your Water Cooled Scroll Chiller?

- Ensure that the foundation requirements are met before moving the Water Cooled Scroll Chiller to the installation site.

- The details and requirements of the chiller foundation must correspond to the drawings of the approved workshop drawing.

- Make a concrete bed for the placement of chiller or non-wrapping pads.

- Make sure the foundation can bear the operating weight of the chiller.

- After confirming the foundation use a forklift to move the chiller to the correct position.

- Make sure the lifting cable can support the total weight of the chiller.

- Failure to properly lift the chiller can result in severe injury or damage to the device before lowering the unit to its foundation.

- Hire a technician and electrician to connect the Water Cooled Scroll Chiller to the main power supply. Please turn it on in the presence of a technician and wait for 2 hours. After confirming its proper working, you can enjoy its working.

What are the Troubleshooting Guidelines for your Water Cooled Scroll Chiller?

- If the water entering the condenser is too hot, or the flow rate is inadequate, test the cooling tower, water pump, and each water valve.

- Sometimes Water Cooled Scroll Chiller generates air or non-condensable gas obstructing operation. These gases could be removed according to the fault

- Wash out copper tanks if there is terrible scaling of the condenser.

- Excessive refrigerant must be removed if the filling is above the set limit.

- The problem can also occur in complete heat dissipation from the condenser. Troubleshoot the problem by checking the inlet valve of the condenser. If it is not fully open, find it and open it completely.

- Check the suction pressure. If it is above the set limits, fix it as soon as possible.

- Reduce the opening of the valve if the pressure of water in the condenser is too high to sort out the problem.

- Change out the fan velocity or the number of fans in the cooling tower if the inlet of water entering the condenser is cold.

- If the compressor is not properly working, then check out voltage and leaks of refrigerant piping.

Water Cooled Scroll Chiller Troubleshooting

What are the Maintenance Tips for your Water Cooled Scroll Chiller?

Check the Display Screen

Check the display screen of the microprocessor unit after a specific duration to verify that you do not receive any error messages. If you find any error, amend it on time to avoid whole chiller damage.

Refrigerant Leaks and Compressor Oil Level

Check the compressor, condenser, cooler, and piping for damage or gas leaks. If the compressor is not working correctly, check out the level of oil of the compressor. The oil level in the oil sight glass must be between 0.5 and 0.75.

Compressor Oil Quality and Refrigerant Charge

If the oil colour of a compressor is pale yellow or becomes dark, it may indicate that the compressor oil has impurities.

In this case, you can take an oil sample and analyze it. The machine should be cleaned in the presence of contaminants to avoid compressor failure.

Bubble flow may be seen in the glass of the liquid line during capacity adjustment. The bubbles should disappear after some time of constant activity so that only the liquid refrigerant is left behind.

In addition to the above scans, you should regularly check to ensure that the chiller is working correctly. Machine looseness, component behaviour, mysterious noise, and other issues must be tested and resolved as soon as possible.

Regular Inspection of Microprocessor

Check the safety of the microprocessor control and the sensor’s calibration to ensure the compressor’s efficient working.

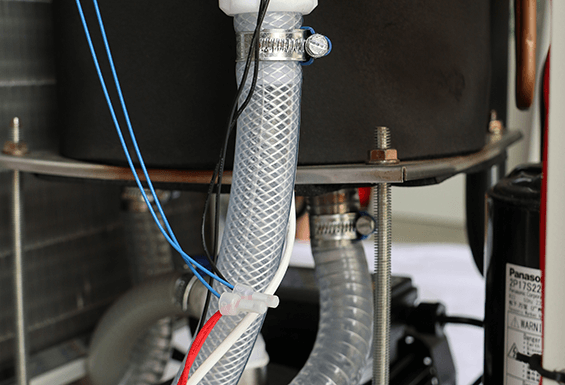

Monitor the Piping and Wiring

Check the ground resistance of the motor wiring to avoid poor insulation—repair damages for the proper working of the Water Cooled Scroll Chiller.

Water Cooled Scroll Chiller Maintenance