TopChiller can design and manufacture all types of water cooled water chillers for you

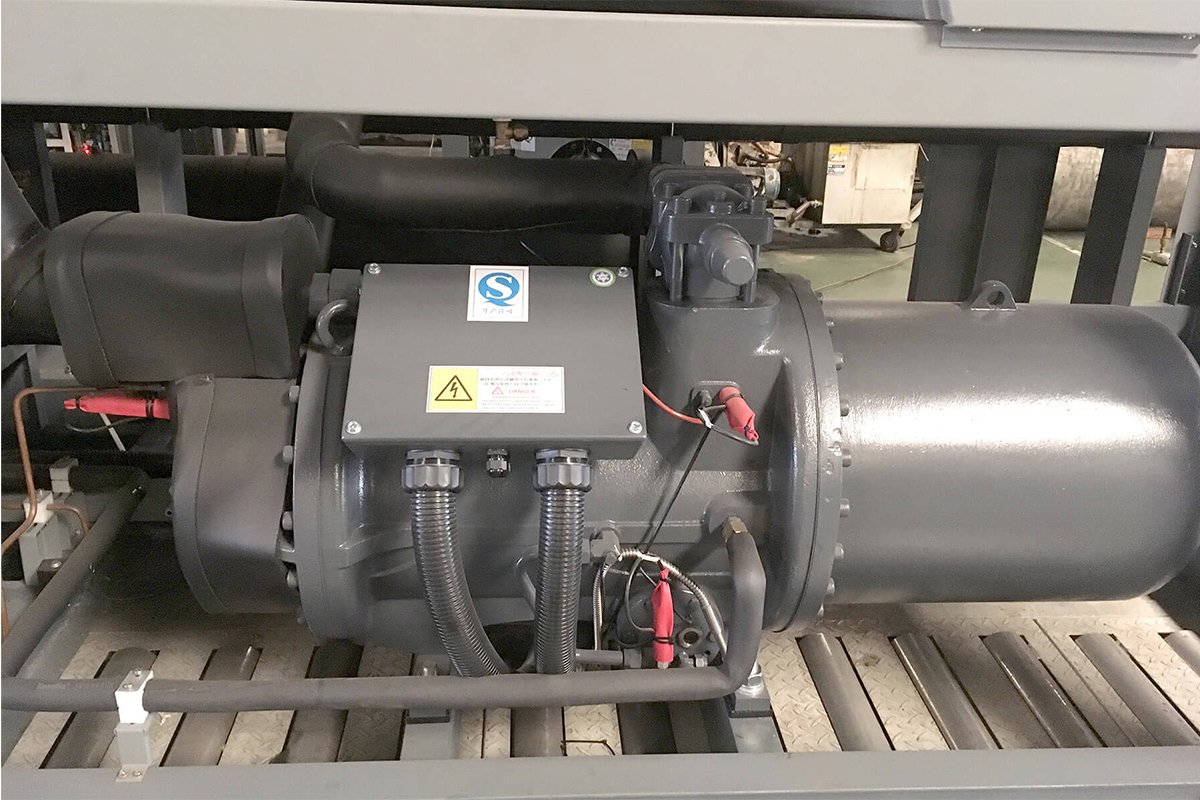

- Scroll/screw/ centrifugal type branded compressor

- Non-ozone depleting refrigerant & reliable fan motors

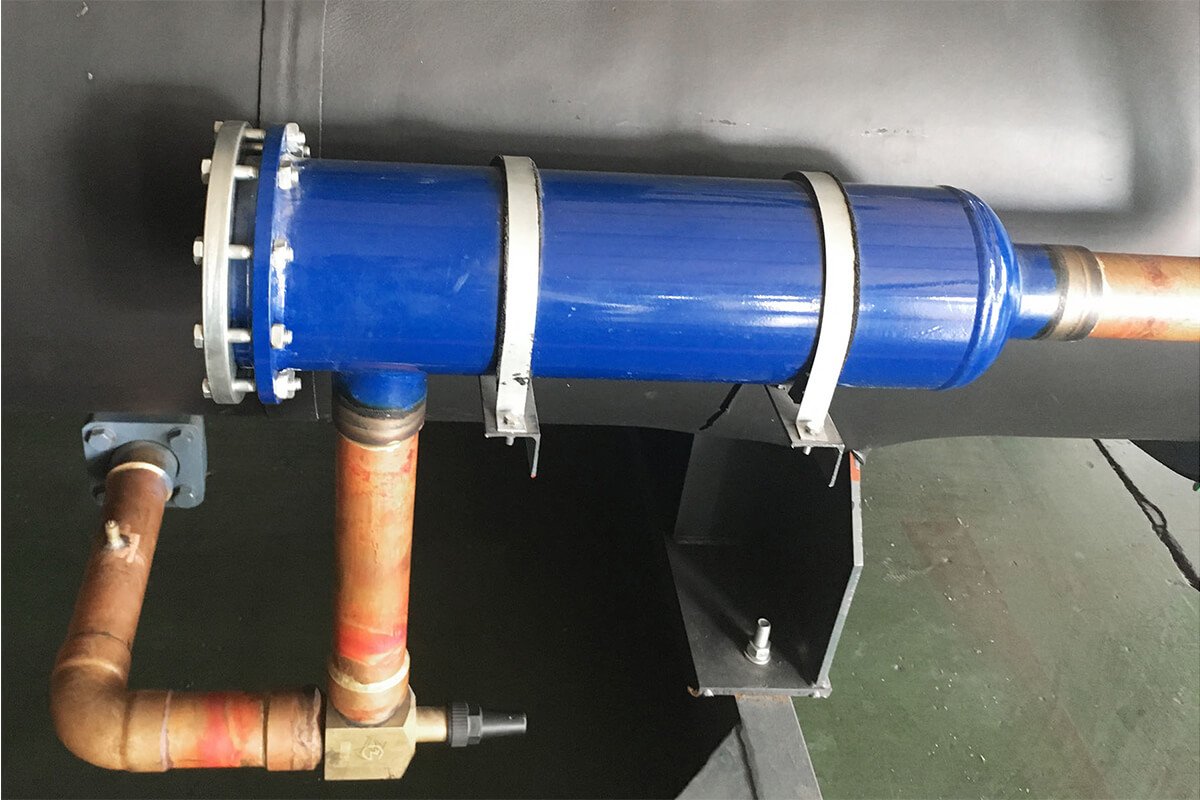

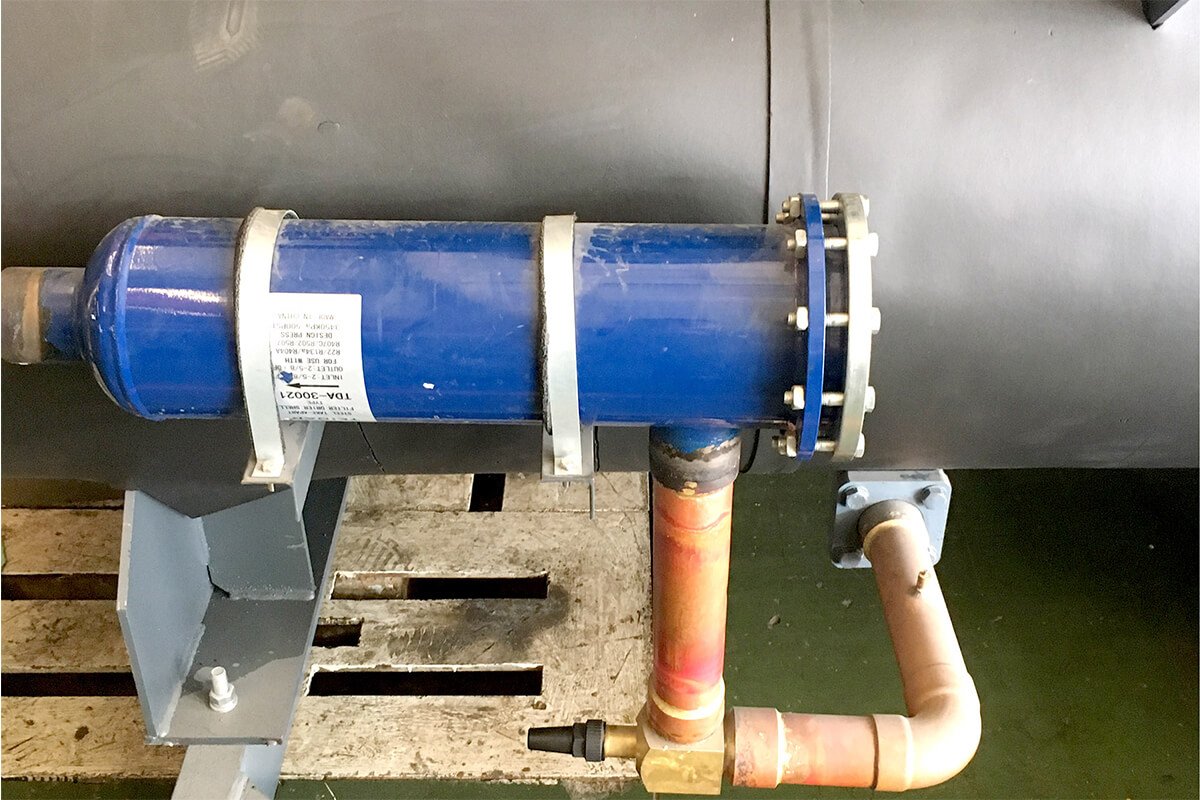

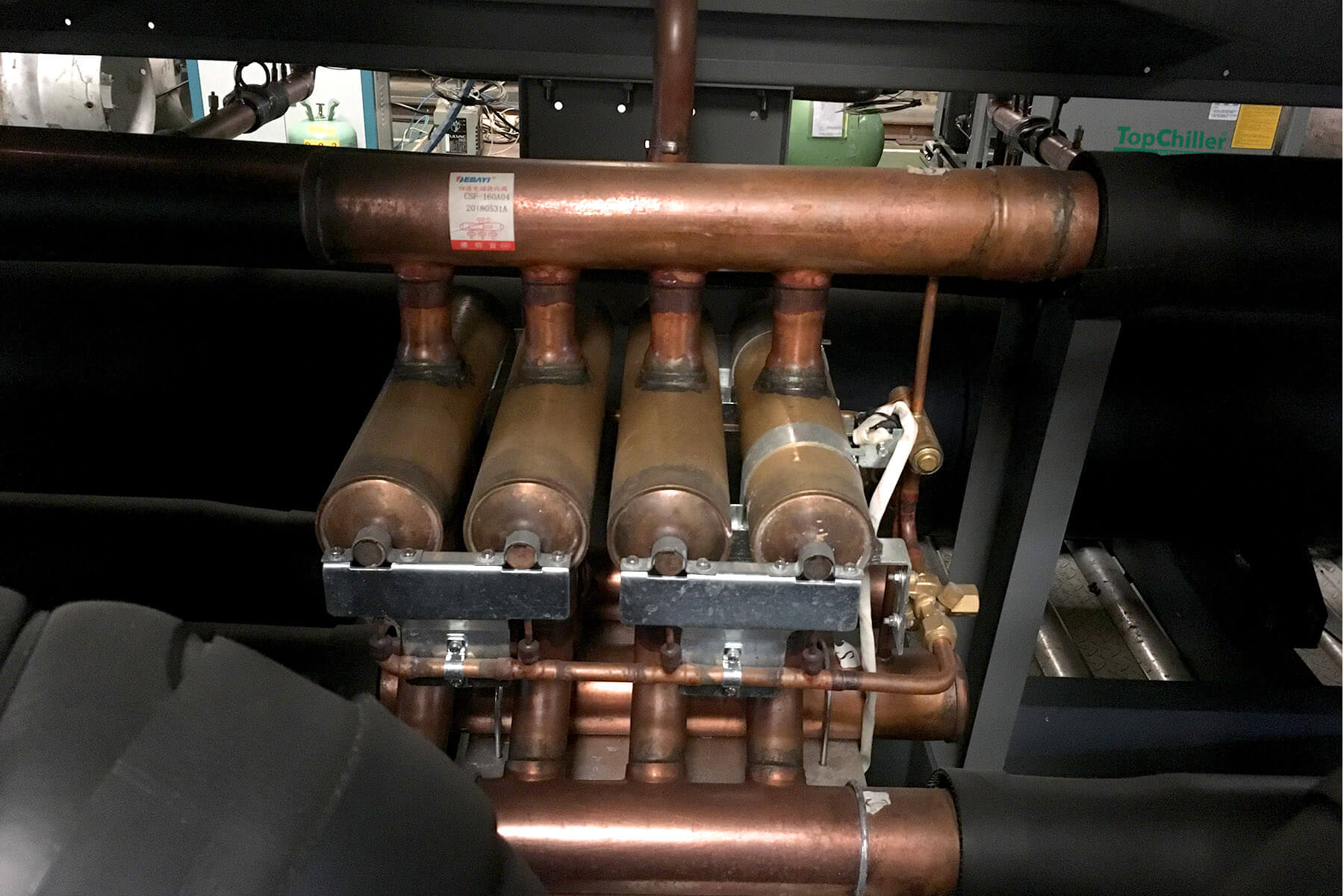

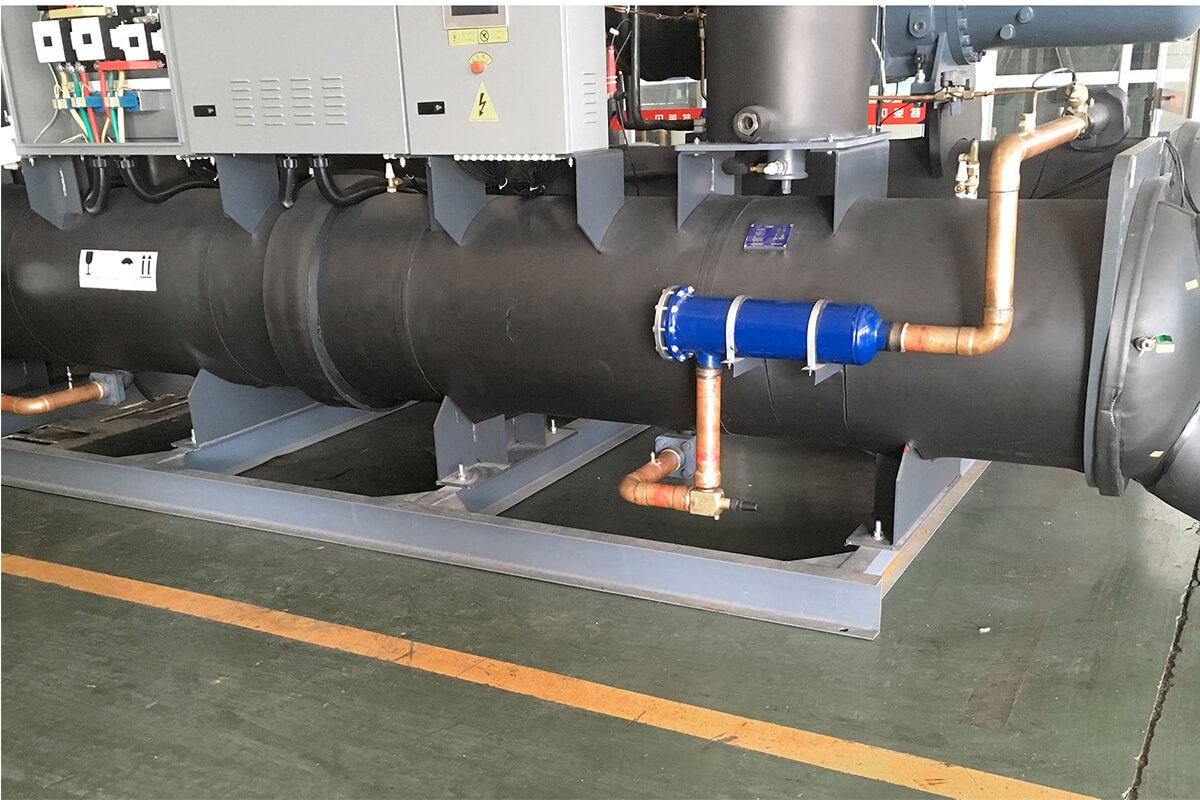

- Shell and tube type efficient condenser & evaporator

- Electronic water level indicator & rust treatment system

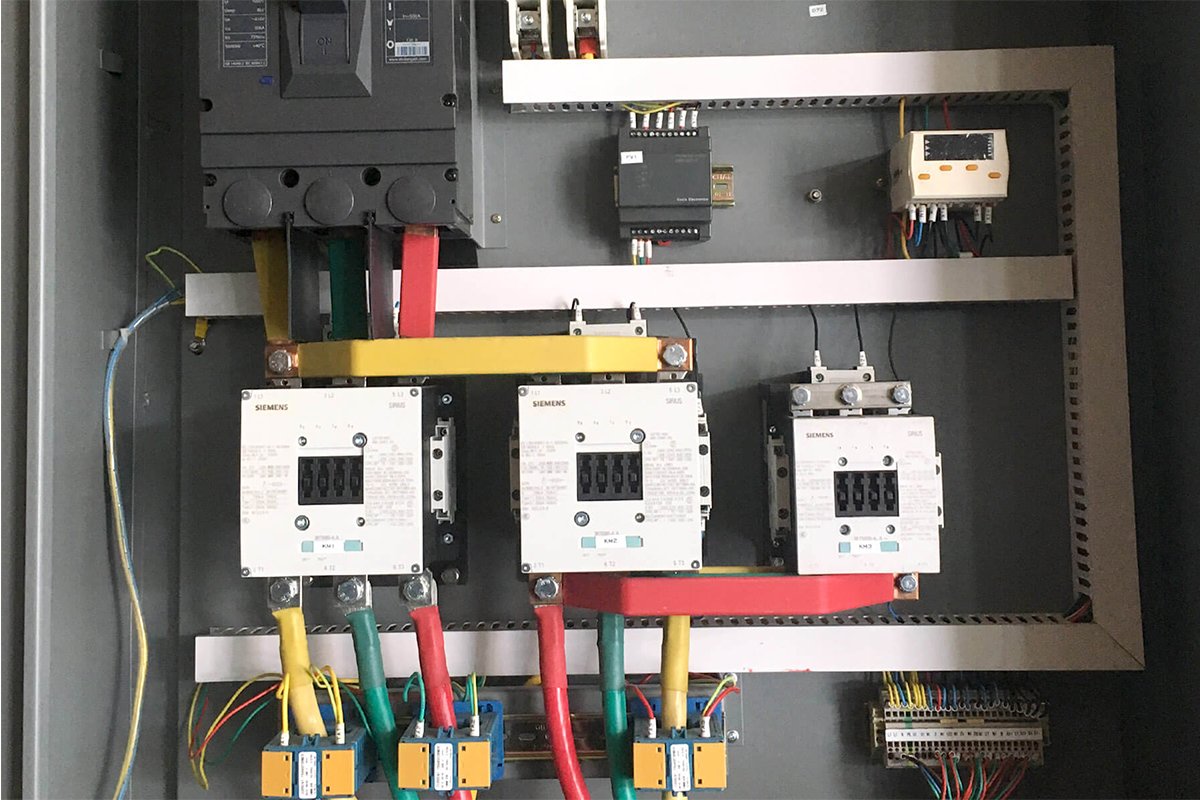

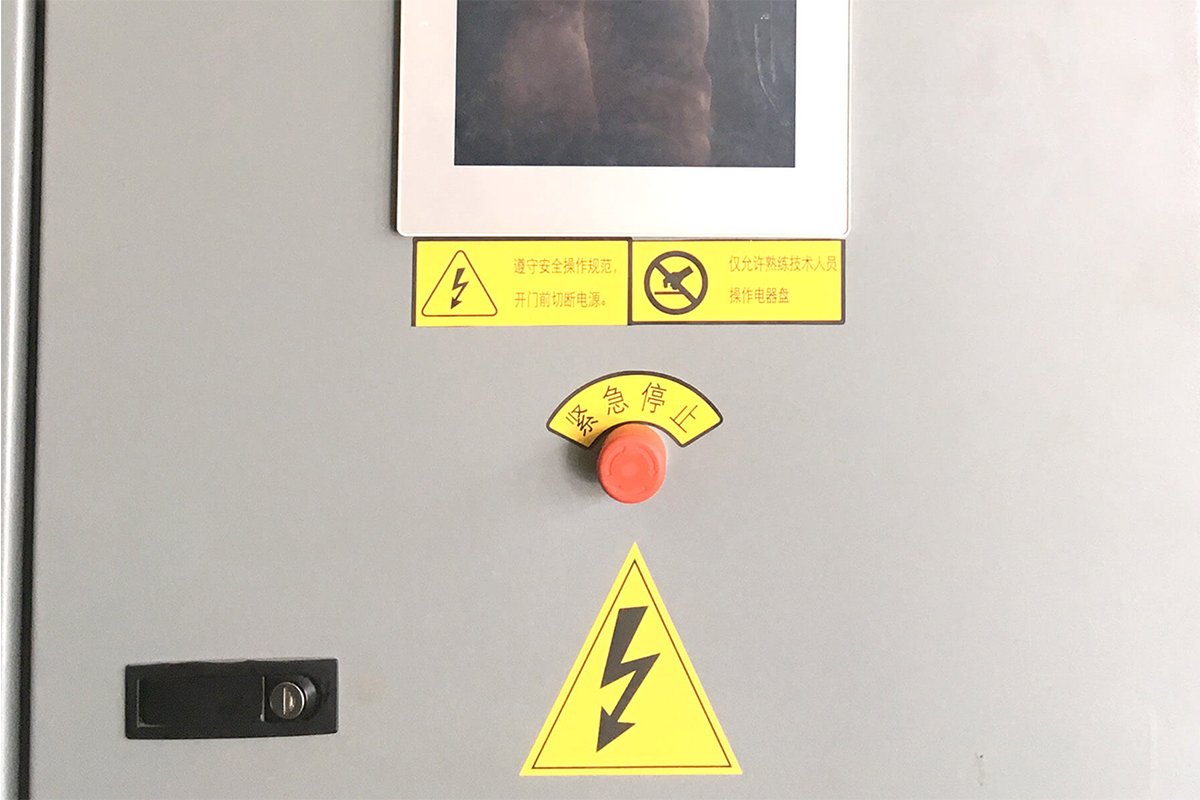

- PLC-based temperature controlling unit & screen display

- Low operating costs, easy installation & compact design

- Branded stainless steel heat exchangers for deionized water

- 24 months warranty for reliability after first purchasing

Your Premier Water Cooled Water Chiller Manufacturer and Supplier in China

Water Cooled Water Chiller is a cooling unit that executes the cooling effect for different industrial applications by using chilled water circulation inside coils and releases out heat from the system by using water around condensing coils.

TopChiller is a foremost and professional manufacturing company of China that is servicing energy-efficient and reliable Water Cooled Water Chiller all over the world internationally for over the last twenty years with credibility and standard certifications.

Since its 1999 inception, TopChiller is given its best to gratify customer expectations by manufacturing a full stock of Water Cooled Water Chiller models with different ranges and successfully supplying to all global markets with superb appreciation.

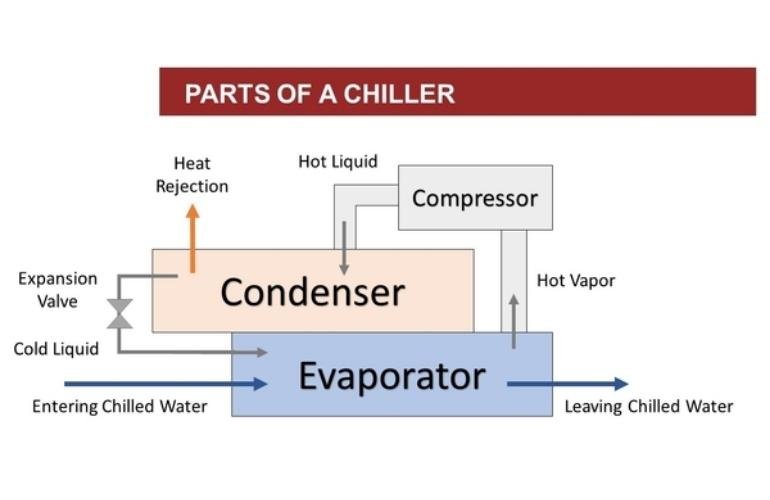

Water Cooled Water Chiller is made of some basic components as scroll/screw/centrifugal compressors, water-cooled condenser, shell and tube type evaporator, heat exchanger, water pump, multiple alarms, water tank, fan motor, refrigerant tank, power supply, water level indicator, and protection devices.

TopChiller brand Water Cooled Water Chiller has different advantages for different industrial and commercial applications as given below:

- Water Cooled Water Chiller is featured with water tank, water pumps, and pipelines that configures the fluent cooling effect by absorbing a high amount of heat from processed heating water of machines by providing chilled water from tank to target area by pipelines.

- TopChiller manufactured Water Cooled Water Chiller has protection devices as flow switches, temperature and pressure-flow regulating units, and over current protection units enabling durable and energy-efficient performance with instant heat discharge.

- Water Cooled Water Chiller is featured with filters at water tanks that protect the unit from the entry of extra salts, ions, dust, and debris ultimately protecting from clogging.

- TopChiller engineered Water Cooled Water Chiller configures optimized cooling to processing application and prevents water tank from overloading by using water level indicator system that ensures the maintenance of water level at a set point inside the tank.

Water Cooled Water Chiller performs streamline operation and implemented for different applications as:

Medical industries, biotechnology, nuclear industry, laboratories, hospitals, pharmaceutical industry, drugs designing, plastic industry, supermarkets, metalworking, hypermarkets, offices, and chemical processing, etc.

Are you wandering around in search of a steadfast and high heat-absorbing capacity Water Cooled Water Chiller for your application?

Are you looking way around for hitting the best company manufacturing Water Cooled Water Chiller for getting the best assisting guidelines to establish your business?

Just make an eye view at industrial world and world best enterprises, you will find the fame and name of TopChiller all over the World.

Contact us today for getting updates and customization services about Water Cooled Water Chiller according to your application requirements at the best rates. Our team is intended to avail you of all services you may claim.

General Description:

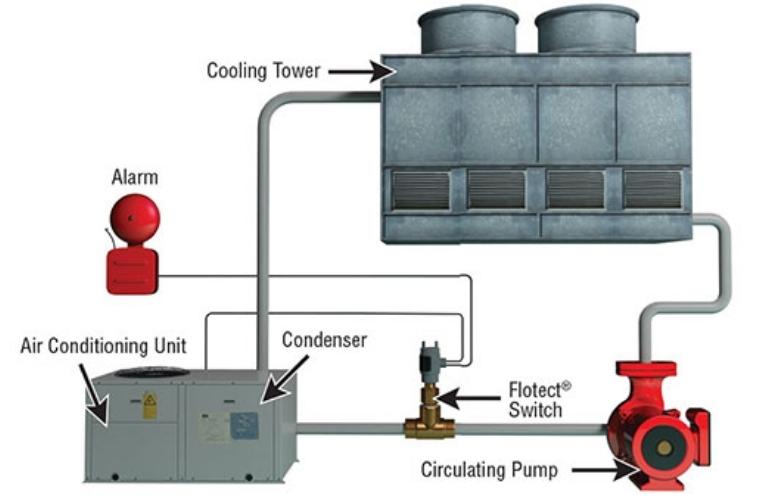

Water Cooled Water Chiller is a reliable cooling unit that is efficient in performance featured by a cooling tower. It executes the cooling effect in a specified application by water coolant and rejects heat out of the system by the water-cooled condenser.

Water Cooled Water Chiller manufactured by TopChiller works on the refrigeration principle and comes with core components as:

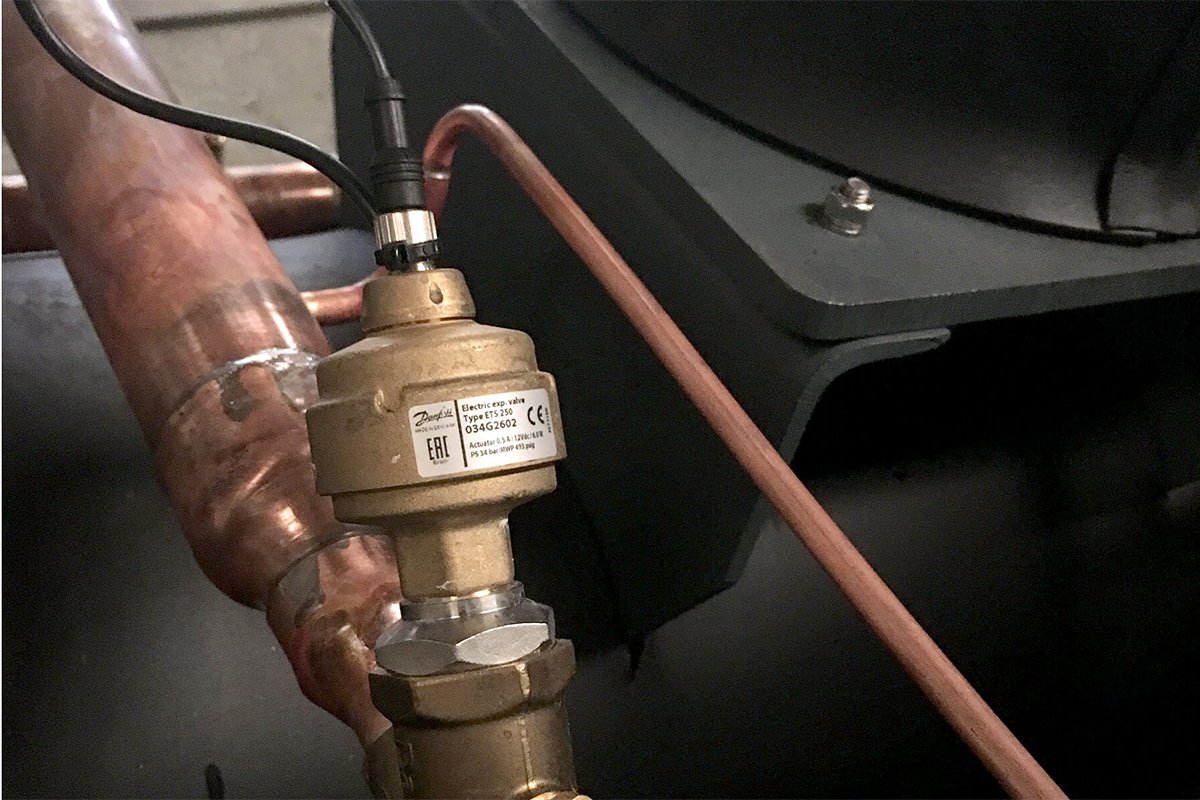

Scroll/screw compressor, water-cooled condenser, economizer, expansion valves, and shell and tube heat exchanger. Its service life is powered by flow switches, oil sensors, pressure switches, emergency alarms, and a control system.

The Water Cooled Water Chiller, designed by TopChiller, is famous for its easy installation for indoor applications. It is widely used for industrial applications such as pharmaceuticals, hospitals, shopping malls, laboratories, chemical processing, plastic, medical, nuclear, biotechnology, etc.

TopChiller has got a lead in the global market as the best manufacturer and supplier for introducing simple designs and a modular system of Water Cooled Water Chillers.

Most users demand a small-sized, energy-efficient water cooling unit suitable for indoor applications. So TopChiller offers Water Cooled Water Chiller assuring customer trust under its reliable working as an innovator manufacturer for years.

So please place your order by contacting us today without any doubt at the best suitable price.

Features and Advantages:

Water Cooled Water Chiller is fabricated with an assorted number of features to offer diverse benefits as given below:

- Efficiently heat is discharged from the system through a chilled water supply provided by the cooling tower and water pipes in the condenser.

- The PLC-based microprocessor is integrated with an assorted number of digital alarms indicating the malfunctioning of any unit component.

- Heat is efficiently exchanged between the refrigerant and hot water from the system configured by a shell and tube-type heat exchanger.

- The whole unit’s durable and energy-efficient working under the integration of protection devices as flow switches, oil level sensor, thermostat, etc.

- The sound free operation of the scroll/screw compressor is configured by installing vibration isolators as spring isolators.

TopChiller can design energy-saving Water Cooled Water Chiller according to your applications.

- Image Gallery

- Main Parts

- Data Sheet

- Video

| Water Cooled Water Chiller Technical Specifications | Water Cooled Water Chiller Technical Specifications | |||||||||||||||||||||||

| Model Items | TPW-100WSH | TPW-135WSH | TPW-175WSH | TPW-190WSH | TPW-230WSH | TPW-255WSH | TPW-300WSH | TPW-350WSH | TPW-375WSH | TPW-415WSH | Model Items | TPW-470WSH | TPW-500WSH | TPW-560WSH | TPW-590WSH | TPW-610WSH | TPW-720WSH | TPW-790WSH | TPW-840WSH | TPW-940WSH | ||||

| Cooling Capacity | kcal/h | 86000 | 116100 | 150500 | 163400 | 197800 | 219300 | 258000 | 301000 | 322500 | 356900 | Cooling Capacity | kcal/h | 425700 | 447200 | 490200 | 533200 | 550400 | 645000 | 705200 | 756800 | 851400 | ||

| KW | 100 | 135 | 175 | 190 | 230 | 255 | 300 | 350 | 375 | 415 | KW | 495 | 520 | 570 | 620 | 640 | 750 | 820 | 880 | 990 | ||||

| Input Power | KW | 22 | 30 | 37 | 42 | 51 | 56 | 65 | 75 | 80 | 90 | Input Power | KW | 103 | 109 | 118 | 127 | 131 | 151 | 167 | 177 | 199 | ||

| Max Current | A | 40 | 53 | 67 | 73 | 89 | 97 | 109 | 126 | 137 | 153 | Max Current | A | 177 | 187 | 203 | 218 | 225 | 260 | 288 | 306 | 345 | ||

| Power Source | 3PH~380V/415V/480V~50HZ/60HZ(3PH~200V/220V 50HZ/60HZ) | Power Source | 3PH~380V/415V/480V~50HZ/60HZ(3PH~200V/220V 50HZ/60HZ) | |||||||||||||||||||||

| Refrigerant | Type | R22(R134a/R407c/R404A) | Refrigerant | Type | R22(R134a/R407c/R404A) | |||||||||||||||||||

| Charge | kg | 17 | 22 | 27 | 33 | 38 | 43 | 50 | 55 | 60 | 66 | Charge | kg | 82 | 88 | 94 | 100 | 110 | 121 | 132 | 143 | 165 | ||

| Control | Thermostatic expansion valve | Control | Thermostatic Expansion Valve | |||||||||||||||||||||

| Compressor | Type | Semi-hermetic screw | Compressor | Type | Semi-hermetic Screw | |||||||||||||||||||

| Power | KW | 22 | 30 | 37 | 42 | 51 | 56 | 65 | 75 | 80 | 90 | Power | KW | 103 | 109 | 118 | 127 | 131 | 151 | 167 | 177 | 199 | ||

| Start mode | Y-△ | Start Mode | Y-△ | |||||||||||||||||||||

| Capacity control | % | 0-33-66-100 | 0-25-50-75-100 | Capacity Control | % | 0-25-50-75-100 | ||||||||||||||||||

| Evaporator | Type | Shell and tube (SS plate heat exchanger) | Evaporator | Type | Shell and tube (SS plate heat exchanger) | |||||||||||||||||||

| Chilled water | m³/h | 17.2 | 23.2 | 30 | 32.7 | 40 | 43.9 | 51.6 | 60.2 | 64.5 | 71.4 | Chilled Water | m3/h | 85.1 | 89.4 | 98 | 106.6 | 110 | 129 | 141 | 151.3 | 170.4 | ||

| Water pressure | KPa | 35 | 35 | 35 | 38 | 40 | 42 | 42 | 45 | 45 | 43 | Water Pressure | KPa | 40 | 41 | 43 | 45 | 45 | 45 | 45 | 43 | 45 | ||

| Pipe connection | Inch | 3″ | 3″ | 3″ | 3″ | 4″ | 4″ | 4″ | 4″ | 4″ | 4″ | Pipe Connection | Inch | 5″ | 5″ | 5″ | 6″ | 6″ | 8″ | 8″ | 10″ | 10″ | ||

| Condenser | Type | Water cooled type shell and tube | Condenser | Type | water cooled type Shell and tube | |||||||||||||||||||

| Cooling water | m³/h | 21 | 28.4 | 36.6 | 40 | 48.3 | 53.5 | 62.8 | 73 | 78.2 | 86.8 | Cooling Water | m3/h | 102.8 | 108.2 | 118.3 | 128.5 | 132.6 | 155 | 169.7 | 181.8 | 204.5 | ||

| Water pressure | KPa | 42 | 42 | 42 | 43 | 42 | 43 | 43 | 45 | 45 | 45 | Water Pressure | KPa | 48 | 45 | 46 | 48 | 46 | 48 | 48 | 45 | 47 | ||

| Pipe connection | Inch | 3″ | 3″ | 3″ | 4″ | 4″ | 4″ | 4″ | 4″ | 5″ | 5″ | Pipe Connection | Inch | 5″ | 5″ | 6″ | 6″ | 6″ | 8″ | 8″ | 10″ | 10″ | ||

| Safety protection devices | Inner thermostat for compressor motor, unit overload relay, high and low pressure switch, freeze protection thermostat, reverse phase protection relay, discharge gas thermostat, flow switch | Safety protection devices | Inner thermostat for compressor motor, unit overload relay,high and low pressure switch, freeze protection thermostat, reverse phase protection relay, discharge gas thermostat, flow switch | |||||||||||||||||||||

| Dimension | Length | mm | 2150 | 2350 | 2450 | 2600 | 2750 | 2800 | 2800 | 2900 | 2900 | 3000 | Dimension | Length | mm | 3000 | 3100 | 3300 | 3500 | 3800 | 3900 | 4100 | 4300 | 4500 |

| Width | mm | 560 | 620 | 650 | 680 | 780 | 950 | 950 | 950 | 950 | 1200 | Width | mm | 1200 | 1250 | 1380 | 1380 | 1380 | 1380 | 1450 | 1480 | 1480 | ||

| Height | mm | 1550 | 1650 | 1650 | 1650 | 1650 | 1800 | 1950 | 1950 | 1950 | 1580 | Height | mm | 1580 | 1630 | 1630 | 1750 | 1750 | 1750 | 1780 | 1780 | 1780 | ||

| Net weight | kg | 650 | 900 | 1050 | 1200 | 1550 | 1800 | 1900 | 2050 | 2050 | 2350 | Net weight | kg | 2500 | 2500 | 2650 | 2850 | 3150 | 3350 | 3620 | 3850 | 4160 | ||

| Running weight | kg | 820 | 1050 | 1200 | 1400 | 1800 | 2100 | 2200 | 2350 | 2380 | 2530 | Running weight | kg | 2700 | 3000 | 3100 | 3350 | 3750 | 4000 | 4300 | 4600 | 5000 | ||

| The above specifications are according to the following design conditions: 1, Chilled water inlet/outlet temperature 12℃/7℃. 2, Cooling water inlet/outlet temperature 25℃/30℃. We reserve the right to modify the specifications without further notice. | The above specifications are according to the following design conditions: 1, Chilled water inlet/outlet temperature 12℃/7℃. 2, Cooling water inlet/outlet temperature 25℃/30℃. We reserve the right to modify the specifications without further notice. | |||||||||||||||||||||||

| Water Cooled Water Chiller Technical Specifications | Water Cooled Water Chiller Technical Specifications | |||||||||||||||||||||||

| Model Items | TPW-200WDH | TPW-270WDH | TPW-350WDH | TPW-380WDH | TPW-460WDH | TPW-510WDH | TPW-600WDH | TPW-700WDH | TPW-750WDH | TPW-830WDH | Model Items | TPW-990WDH | TPW-1040WDH | TPW-1140WDH | TPW-1240WDH | TPW-1280WDH | TPW-1500WDH | TPW-1640WDH | TPW-1760WDH | TPW-1980WDH | ||||

| Cooling Capacity | kcal/h | 172000 | 232200 | 301000 | 326800 | 395600 | 438600 | 516000 | 602000 | 645000 | 713800 | Cooling Capacity | kcal/h | 851400 | 894400 | 980400 | 1066400 | 1100800 | 1290000 | 1410400 | 1513600 | 1702800 | ||

| KW | 200 | 270 | 350 | 380 | 460 | 510 | 600 | 700 | 750 | 830 | KW | 990 | 1040 | 1140 | 1240 | 1280 | 1500 | 1640 | 1760 | 1980 | ||||

| Input Power | KW | 44 | 60 | 74 | 84 | 102 | 112 | 130 | 150 | 160 | 180 | Input Power | KW | 206 | 218 | 236 | 254 | 262 | 302 | 334 | 354 | 398 | ||

| Max Current | A | 40 | 53 | 67 | 73 | 89 | 97 | 109 | 126 | 137 | 153 | Max Current | A | 354 | 374 | 406 | 436 | 450 | 520 | 576 | 612 | 490 | ||

| Power Source | 3PH~380V/415V/480V~50HZ/60HZ(3PH~200V/220V 50HZ/60HZ) | Power Source | 3PH~380V/415V/480V~50HZ/60HZ(3PH~200V/220V 50HZ/60HZ) | |||||||||||||||||||||

| Refrigerant | Type | R22 (R134a / R407c / R404A) | Refrigerant | Type | R22 (R134a / R407c / R404A) | |||||||||||||||||||

| Charge | kg | 17×2 | 22×2 | 27×2 | 33×2 | 38×2 | 43×2 | 50×2 | 55×2 | 60×2 | 66×2 | Charge | kg | 82×2 | 88×2 | 94×2 | 100×2 | 110×2 | 121×2 | 132×2 | 143×2 | 165×2 | ||

| Control | Thermostatic expansion valve | Control | Thermostatic expansion valve | |||||||||||||||||||||

| Compressor | Type | Semi-hermetic screw | Compressor | Type | Semi-hermetic screw | |||||||||||||||||||

| Power | KW | 22×2 | 30×2 | 37×2 | 42×2 | 51×2 | 56×2 | 65×2 | 75×2 | 80×2 | 90×2 | Power | KW | 103×2 | 109×2 | 118×2 | 127×2 | 131×2 | 151×2 | 167×2 | 177×2 | 199×2 | ||

| Start mode | Y-△ | Start mode | Y-△ | |||||||||||||||||||||

| Capacity Control | % | 0-33-66-100 | 0-25-50-75-100 | Capacity control | % | 0-25-50-75-100 | ||||||||||||||||||

| Evaporator | Type | Shell and tube (SS plate heat exchanger) | Evaporator | Type | Shell and tube (SS plate heat exchanger) | |||||||||||||||||||

| Chilled Water | m3/h | 34 | 46 | 60 | 65 | 79 | 88 | 103 | 120 | 120 | 143 | Chilled water | m³/h | 170 | 179 | 196 | 213 | 220 | 258 | 282 | 303 | 340 | ||

| Water Pressure | KPa | 35 | 35 | 35 | 38 | 40 | 42 | 42 | 45 | 45 | 43 | Water pressure | KPa | 40 | 41 | 43 | 45 | 45 | 45 | 45 | 43 | 45 | ||

| Pipe Connection | Inch | 4″ | 4″ | 4″ | 5″ | 5″ | 6″ | 6″ | 6″ | 8″ | 8″ | Pipe connection | Inch | 8″ | 8″ | 8″ | 8″ | 10″ | 10″ | 10″ | 12″ | 12″ | ||

| Condenser | Type | Water cooled type shell and tube | Condenser | Type | Water cooled type shell and tube | |||||||||||||||||||

| Cooling Water | m3/h | 42 | 57 | 73 | 80 | 97 | 107 | 126 | 146 | 156 | 174 | Cooling water | m³/h | 206 | 216 | 237 | 257 | 265 | 310 | 339 | 364 | 409 | ||

| Water Pressure | KPa | 42 | 42 | 42 | 43 | 42 | 43 | 43 | 45 | 45 | 45 | Water pressure | KPa | 48 | 45 | 46 | 48 | 46 | 48 | 48 | 45 | 47 | ||

| Pipe Connection | Inch | 4″ | 4″ | 4″ | 5″ | 6″ | 4″×2 | 4″×2 | 4″×2 | 5″×2 | 5″×2 | Pipe connection | Inch | 5″×2 | 5″×2 | 6″×2 | 6″×2 | 6″×2 | 8″×2 | 8″×2 | 10″×2 | 10″×2 | ||

| Safety protection devices | Inner thermostat for compressor motor, unit overload relay,high and low pressure switch, freeze protection thermostat, reverse phase protection relay, discharge gas thermostat, flow switch | Safety Protection Devices | Inner thermostat for compressor motor, unit overload relay,high and low pressure switch, freeze protection thermostat, reverse phase protection relay, discharge gas thermostat, flow switch | |||||||||||||||||||||

| Dimension | Length | mm | 2750 | 2800 | 2800 | 2950 | 2950 | 3150 | 3480 | 3480 | 3480 | 3650 | Dimension | Length | mm | 3650 | 3650 | 3750 | 3750 | 4230 | 4230 | 4350 | 4350 | 4420 |

| Width | mm | 750 | 780 | 780 | 810 | 810 | 850 | 875 | 875 | 895 | 1120 | Width | mm | 1120 | 1220 | 1300 | 1450 | 1380 | 1480 | 1450 | 1560 | 1650 | ||

| Height | mm | 1650 | 1650 | 1650 | 1650 | 1750 | 1750 | 1850 | 1850 | 1850 | 1950 | Height | mm | 1950 | 1950 | 2100 | 2150 | 2150 | 2250 | 2250 | 2300 | 2450 | ||

| Net weight | kg | 1650 | 1800 | 1850 | 2200 | 2450 | 2650 | 2800 | 2800 | 3450 | 3750 | Net weight | kg | 3950 | 4100 | 4450 | 4700 | 5000 | 5250 | 5500 | 5750 | 6000 | ||

| Running weight | kg | 1950 | 2180 | 2240 | 2660 | 2960 | 3200 | 3380 | 3580 | 4160 | 4360 | Running weight | kg | 4760 | 4770 | 5270 | 5460 | 5800 | 6100 | 6400 | 6680 | 6970 | ||

| The above specifications are according to the following design conditions: 1, Chilled water inlet/outlet temperature 12℃/7℃. 2, Cooling water inlet/outlet temperature 25℃/30℃. We reserve the right to modify the specifications without further notice. | The above specifications are according to the following design conditions: 1, Chilled water inlet/outlet temperature 12℃/7℃. 2, Cooling water inlet/outlet temperature 25℃/30℃. We reserve the right to modify the specifications without further notice. | |||||||||||||||||||||||

Why TopChiller is Your Reliable Water Cooled Water Chiller Manufacturer and Supplier In China?

Water Cooled Water Chiller-An Ultimate FAQ Guide by TopChiller.

- What is Water Cooled Water Chiller?

- What are the Core Components of Water Cooled Water Chiller?

- What are the Leading Features of Water Cooled Water Chiller?

- What are Typical Operations of Water Cooled Water Chiller?

- What are the Applications of Water Cooled Water Chiller?

- What are the Benefits to Use a Water Cooled Water Chiller for your Industry?

- How is Air Cooled Water Chiller Different from Water Cooled Water Chiller?

- Which Type of Condenser in Installed in Water Cooled Water Chiller?

- What is the Working Mechanism of Screw Compressor in Water Cooled Water Chiller?

- What is a Modular System of Water Cooled Water Chiller?

- What is Seasonal Shut Down Procedure of Water Cooled Water Chiller?

- What are the Different Operational Modes of Water Cooled Water Chiller?

- What is the Vibration Isolation Process of Water Cooled Water Chiller?

- Why is Condensing Water Treatment Important for your Water Cooled Water Chiller?

- How to Prevent Water Freezing in your Water Cooled Water Chiller?

- What is the Capacity Control Process of Water Cooled Water Chiller?

- How Does Control System of Water Cooled Water Chiller Work?

- What are Safety Controls of Water Cooled Water Chiller?

- How to Size a Water Cooled Water Chiller for your Industry?

- How to Increase Working Efficiency of your Water Cooled Water Chiller?

What is Water Cooled Water Chiller?

Water Cooled Water Chiller is a highly reliable and durable cooling device that mediates its cooling effect using chilled water circulation.

It is available with different cooling capacities and types based on the compressor integrated. A scroll or screw compressor can be used for compression.

Water Cooled Water Chiller is famous for its integrated simple design and modulating system to meet the needs for different cooling capacities. It is highly reliable and efficient in the cooling and heat removing process.

It is configured with different operating modes for easy installation and maintenance.

Water Cooled Water Chiller Designed by TopChiller

What are the Core Components of Water Cooled Water Chiller?

The core components of Water Cooled Water Chiller are given below:

Scroll/Screw Compressor

Energy-efficient scroll or screw compressors can be installed to provide the hot gas refrigerant. Screw or scroll rotors put compression force over refrigerants when entering compression space.

Condenser

A water-cooled condenser is used that is integrated with the cooling tank. Chilled water from cooling tanks comes and circulates in the condenser to absorb the heat from the incoming refrigerant.

Heat Exchanger

Shell and tube type heat exchanger is used for Water Cooled Water Chiller, mediated to evaporate the refrigerant by processed water.

Expansion Valves/Economizer

Through the economizer fed line or expansion valve, the pressure of the refrigerant is released before entering the evaporator.

Control System

The microprocessor control unit is interconnected with different alarms and controls for regulating the overall operation.

Water Cooled Water Chiller Major Parts

What are the Leading Features of Water Cooled Water Chiller?

Water Cooled Water Chiller cools down a system by discharging heat of the system through chilled water circulation. It consists of some top features increasing its stability and reliability as:

- Energy-efficient, branded scroll/screw compressor for refrigeration compression

- Water pumps made of stainless steel material assures a high flow rate and water protection

- Corrosion resistive reservoir designed with stainless material.

- Water-cooled condensers for heat discharging are collected from the system.

- R-407c refrigerant with eco-friendly behaviour performs its function under ambient temperature.

- Shell and tube type heat exchanger designed with rust protection and heat exchanging mechanism.

- Safety devices and emergency alarms for unit protection.

- Microprocessor controller for regulating the operation of Water Cooled Water Chiller

- Easy Installation, repairing, and maintenance of the unit.

What are Typical Operations of Water Cooled Water Chiller?

Water Cooled Water Chiller is a suitable cooling unit for use even at a high temperature. Its typical cooling operation is explained below:

Step 1

Each screw/scroll compressor receives the incoming refrigerant under low pressure.

Compressors put compression force over refrigerants and discharge hot gas with high pressure. The discharge valve leaves the compressor and enters into the condenser.

Step 2

A water-cooled condenser is integrated with a cooling tower. Chilled water circulates inside condenser coils.

The refrigerant condensed here by rejecting its heat to chilled water of cooling tower. Liquid refrigerant drains from the condenser and enters into the economizer fed line.

Step 3

Economizer valves assist liquid refrigerant in dropping its pressure and then flashes it in the economizer tank. It has an intermediate temperature fluctuating between the temperature of the condenser and evaporator.

Refrigerant leaves the economizer and enters the heat exchanger through the economizer fed line.

Step 4

After entering a flooded evaporator, it starts boiling by ensuring the cooling of water circulating in the evaporator.

Step 5

Chilled water discharges the evaporator and enters your required application’s duct system.

It continuously supplies the cooling effect by collecting system heat when water gets hot moves back to the evaporator for cooling.

Step 6

While the evaporated refrigerant passes through the suction pipe and filters, it gets entered into the compressor. It compresses back here to restart the cycle.

What are the Applications of Water Cooled Water Chiller?

Water Cooled Water Chiller is renowned for its durable working and efficiency. Now today, it is preferably used for a large scale of applications as given below:

- Metalworking

- Pharmaceutical Industry

- Plastic Industry

- Biotechnology

- Nuclear Industry

- Hospitals

- Chemicals Processing

- Laboratories

- Offices

- Supermarkets

What are the Benefits to Use a Water Cooled Water Chiller for your Industry?

A Water Cooled Water Chiller provides an assorted number of benefits for its users as given below:

Modulation System

Modular designing of the unit consists of more than one refrigeration circuit connected either in series or parallel manner. If any compressors may get damaged, the overall working is not disturbed.

Durability

Stainless steel material is used to construct the whole unit, increasing service life by showing corrosion resistance.

Environment-Friendly Behavior

A water-cooled condenser is used for heat dissipation to work efficiently even in a high ambient temperature with an environment-friendly refrigerant.

Heating and Cooling Mode

Integrating an electric heater with Water Cooled Water Chiller can be used in heating and cooling mode as per application requisites.

Energy Saving Efficient Performance

Economizer and branded compressors ensure efficient and reliable working with energy-saving features.

How is Air Cooled Water Chiller Different from Water Cooled Water Chiller?

It consists of an air-cooled condenser for heat discharge coming from the system. Ambient air circulates over condenser coils and takes the heat from the refrigerant to condense it into a liquid state.

Water is used as a coolant for collecting heat from the system, and it circulates in an evaporator for heat exchange.

It does not have a cooling tower. It is environmentally friendly, has a small size with its easy installation.

Water Cooled Water Chiller

It is more efficient as compared to the air-cooled chiller. Water-cooled condensers are used for the final heat discharge of the system as compared to air-cooled condensers.

Water Cooled Water Chiller also consists of water coolant for heat collection from the system. Cooling tower, water piping is connected to it. It can deal efficiently with high ambient temperature compared to the air-cooled chiller.

Air Cooled Water Chiller

Which Type of Condenser is Installed in Water Cooled Water Chiller?

Water Cooled Condenser

A water-cooled condenser consisting of copper tubes is placed in Water Cooled Water Chiller. The cooling tower is integrated with the condenser. Cool water gets enter from the cooling tower to condenser tubes through water pipes.

Chilled water circulates over compressed refrigerant from the compressor and converts it into a liquid state by dissipating its heat.

As a result, water heats up and leaves the condenser to enter the cooling tower to receive its cooling. The working of the cooling tower is controlled by:

A three-way valve modulates and helps it mix the condenser warm water with its cool water.

What is the Working Mechanism of Screw Compressor in Water Cooled Water Chiller?

The screw compressor is an energy-efficient, and a vibration-free component that’s working mechanism for Water Cooled Chiller is given below:

1 Suction

The upper and lower pressure is set so that screws can bear the load easily. First, the compressor sucks the refrigerant inside through a suction pipe.

Screw rotors rotate, the refrigerant enters the suction groove, and the suction gas inlet is shut down.

2 Compression

Rotor grooves and rotor tooth make the compression space where the refrigerant is compressed.

When screws rotors of compressor rotate, compression space decreases and the compression force is applied over the refrigerant. As a result, the temperature and pressure are increased to discharge level.

3 Discharge

The pressure of the refrigerant reaches discharge level, and finally, compressed refrigerant discharges out from the compressor from the discharged port.

Water Cooled Water Chiller Explosion Proof Screw Compressor

What is a Modular System of Water Cooled Water Chiller?

Water Cooled Water Chiller is also fabricated with a modular design that makes it durable and increases its cooling capacity.

Modular System

The modular system consists of more than one refrigeration circuit. Each modulating unit comes with its complete packing to be installed easily. Modules are available with different cooling capacities.

Modules are integrated in a parallel manner. Each module has its refrigeration circuit. If one module is damaged, there will be no effect on the overall working of the unit. Each module will work independently as a backup.

What is Seasonal Shut Down Procedure of Water Cooled Water Chiller?

When you have not used Water Cooled Water Chiller for a long duration, then shut it down by the following procedure as given below:

- Make sure to de-energize/cut off the power supply so that energy may remain conserved in that specific duration, either a month or more.

- It drained the cooling tower so that it may be prevented from freezing damages.

- Note down the ambient temperature. If it goes above the freezing point, there is no need to drain the condenser.

- No need to remove water filled in the heat exchanger and condenser. Both will stay outside better during that duration.

- If the ambient temperature is lower from the freezing point, the chances of water freezing inside evaporator tubes will be greater. In this situation, drain the water from the condenser and evaporator to avoid clogging.

- Remove the drains and vent plug from each vessel. Make sure to blow out evaporator tubes through compressed air as stagnant water can cause rusting.

- After that, take oil as a sample from each compressor of the Water Cooled Water Chiller for laboratory testing and analysis. Make sure to perform oil testing at the end and start seasonal operating.

- If you find a change in oil quality, replace it with a new oil supply for a startup operation.

What are the Different Operational Modes of Water Cooled Water Chiller?

Water Cooled Water Chiller can be used with different operating modes as given below:

Cooling Mode

This is the primary and foremost operating mode of Water Cooled Water Chiller. The essential purpose of this cooling mode is to produce chilled water to cool down a system. The chiller with cooling mode works the same manner as the standardized chiller.

Heating Mode

The Water Cooled Water Chiller only produces heating effects by producing hot water to keep warm a required application.

Heating and Cooling Mode (Cooling Priority)

Sometimes the chiller is integrated with an electric heater to work on heating and cooling mode. But the cooling mode is preferably used, and the heating mode is integrated with the system optionally.

Heating and Cooling Mode (Heating Priority)

Sometimes the chiller is installed with both heating and cooling mode. But its heating mode is preferably used to maintain temperature when there is low ambient temperature.

What is the Vibration Isolation Process of Water Cooled Water Chiller?

Water Cooled Water Chiller is integrated with a scroll/screw compressor for energy-efficient working. But if the compressor is producing sounds while operating, it can be removed through the vibration isolation process as given below:

Vibration Isolation Process

Vibration isolators can be used to separate the vibration produced during operation to ensure sound-free working. Shear isolators or spring isolators are accessories options integrated with the compressor.

There would be a need to isolate water pipes and water circulating in the condenser using flexible connectors for installing spring isolators.

A flexible channel is used for most desiring isolation between water pipes and electrical conduits, which assist in protecting noise spread or transmission during operation.

Why is Condensing Water Treatment Important for your Water Cooled Water Chiller?

The water should be cleaned, free from mineral deposition and algae growth as its deposition decrease the working efficiency and gradually damage the whole condenser unit.

So there is a need for water treatment to increase the unit working efficiency and durability. It can be done in Water Cooled Water Chiller by following the steps as given below:

Inspection of Working Efficiency of Condenser

Record the full load performance and heat-dissipating from the condenser on the log sheet.

The best way to check the performance is to find the difference between the water temperature and saturated refrigerant in the condenser.

Condenser approach= Temperature of the saturated condenser- Temperature of leaving cooled water

If the condenser approach goes with a 2⁰F increment than the temperature recorded at cleaning conditions, it will indicate a need for condenser cleaning.

Inspection of Working Efficiency of Condenser

Vessels Cleaning

Waterside surfaces are instructed to be cleaned annually or often if used foul water. Through physical and chemical methods, the cleaning process can be done.

The water in the heat exchanger can be cleaned using the acidic solution. It is passed inside the heat exchanger and condenser water coils.

It flushed out all the deposited minerals and algae from water and cleaned them for efficient processing.

Ensure to wash the coils after using any chemical water treatment specialists recommend. In this way, coils will remain protected from rust.

Water should be drained first for physical vessel cleaning in Water Cooled Water Chiller. Then remove the heads and make sure cleaning of each tube with a cleaning brush.

After completion of cleaning, refill the water to resume operation.

How to Prevent Water Freezing in your Water Cooled Water Chiller?

If water may freeze inside evaporator or condenser coils, it may cause damage as tubes leak, crack, and split.

These damages are costly to repair. So there is a need to prevent water freezing in Water Cooled Water by following some steps:

Standby Unit at Lower Temperature

If the ambient temperature is less than 32⁰F, make sure to drain the chiller by opening the heads of each tube. Use compressed air for the complete dryness of condenser coils.

Glycol mixture can also be used as an anti-freezing agent and ensure that the freezing temperature should be less than ambient temperature.

Protection in Operation

The water can also be frozen inside the evaporator if water flow is stopped, and a cutout of low suction pressure.

Proper working of flow switches that control chilled water flow rate and pump interlocking system prevents water from freezing.

There are four types of protective devices that protect the evaporator from freezing. So before starting the operation, first confirm that all devices are functioning correctly.

Protection in Maintenance

Sometimes during installation or removal of refrigerant from Water Cooled Water Chiller, the chances of water freezing inside the evaporator are possible.

It is possible only if the water is not flowing in evaporator coils. Reduction in pressure to 58 psig also assists water freezing. So make sure to inspect the water flow rate in the evaporator before starting maintenance.

Start maintenance process and refrigerant installation when water will flow in evaporator coils.

Frozen Evaporator of Water Cooled Water Chiller

What is the Capacity Control Process of Water Cooled Water Chiller?

The capacity-controlled process depends on the application heat load. By changing the water outlet temperature, the capacity can be controlled. Continues capacity controlling process is given below:

By regulating outlet temperature using electronic system capacity, Water Cooled Water Chiller can be controlled.

Process

The position of the side valve is adjusted that can be done freely to almost 15% to 100%. The control system mediates the comparison in temperature value measured by thermistor and temperature set points.

Based on the measured value, the control system transfers the signals to side valves and adjusts them as per application needs.

When the thermistors calculated temperature is far from the setpoint, and quick response is required. The control system can be programmed for fast control.

The precise value of capacity controlling can also be adjusted when the measured value of temperature is close to the set point.

It is possible by Water Cooled Water Chiller because of the installation of energy-efficient screw compressors with adjustable side valves.

How Does Control System of Water Cooled Water Chiller Work?

The PLC-based microprocessor control system of the Water Cooled Water Chiller is featured with the display screen. All of the emergencies and ringing alarms are shown on the microprocessor screen.

The touch screen is easy to adjust and control. Different required features and set points can easily be adjusted over it. It can operate efficiently in different languages.

Many digital alarms and protection devices are connected to it that detects any change in temperature, voltage, or pressure.

The microprocessor controller generates alarms to inform about emergencies and gives a button on the screen to reset the system.

Water Cooled Water Chiller PLC Controller

What are Safety Controls of Water Cooled Water Chiller?

The Water Cooled Water Chiller is durable and efficient in its operation due to the integration of different safety controls with it as:

Oil Level Sensor

The oil sensors are present in each compressor to inspect the changes in oil level. If the oil level goes down for 60 seconds in operation, the sensors will detect it.

A message is generated and sent to the microcomputer for action.

The microcomputer turns off the compressor. The fault appears on the display screen that is amended, and values are set on a standard set point.

Evaporator Freeze Switch Off

If the water coolant temperature drops from the set point in the evaporator, the microcomputer detects the fault and generates an alarm. The problem is troubleshot to prevent the water from freezing.

Cut off for Low Pressure

When the pressure of the refrigerant goes down from adjusted low pressure, the microprocessor will turn on the alarm light.

It stops the operation of the compressor by recording the alarm. The pressure is adjusted back to resume working by pressing the reset button.

Overload Protector

It configures compressor protection from the high current by monitoring three-phase current. Unit tripping is factory mounted function that can be reset as per your application needs.

Sensor Alarms

These alarms are mediated to find any change in temperature, pressure, and voltage of the Water Cooled Water Chiller. Alarms ensure to alert the operator about the problem.

Low Differential Pressure Alarm

To lubricate the compressor, a differential pressure runs between evaporator and condenser as 30 psi. If pressure drops and retains continuously for 3 minutes, alarms turn on, and the compressor turns off.

Water Cooled Water Chiller Safety Alarm Indication

How to Size a Water Cooled Water Chiller for your Industry?

Water Cooled Water Chiller is available with different sizes and cooling capacities. It is also available with a modulation system. So you can size it by following way:

Heat Load of Application

Measure the heat load of the application by just finding out the difference of temperature between inlet and outlet water.

The difference will represent how much heat is added by the system in water. This heating load is represented by ‘delta T’.

Water Flow Rate

Measure the water outlet flow rate in GPM by using a flow meter. If it is not available, calculate the time taken by water to fill five gallons and then divide it by one gallon.

Heat Load in BTU

Using flow rate and temperature difference, find out the total heat your application can input into the chiller.

BTU per Hour = 500 X GPM X TEMPERATURE DIFFERENCE

Required Cooling Capacity in Tons

For calculating cooling that your application is required in tons from Water Cooled Water Chiller, put BTU/hour in the following formula.

TONS = (BTU/HR) / (12,000)

How to Increase Working Efficiency of your Water Cooled Water Chiller?

The working efficiency of Water Cooled Water Chiller can be increased by considering some key points as given below:

Periodic Inspection of Whole Unit

Check out the temperature and pressure of the unit as the pressure in the condenser should not be much changed. Note it on the log sheet. If you find any change, sort it out for efficient working.

Vessels Cleaning

For durability and efficiency, clean out the evaporator and condenser vessel. In this way, all algae and minerals deposition will eliminate, and the water flow rate will increase.

Oil Charging

Oil is charged from the factory. After a specific duration, check out the oil level; if it may go downturn, turn off the compressor before extensive damage and refill the oil levelling.

Refrigerant Charging

Refrigerant is also charged from the factory. But in some cases, if you see bubbles forming in the sight glass, it will be about undercharging. Charge the refrigerant for efficient working in Water Cooled Water Chiller.

Water Cooled Water Chiller Maintenances