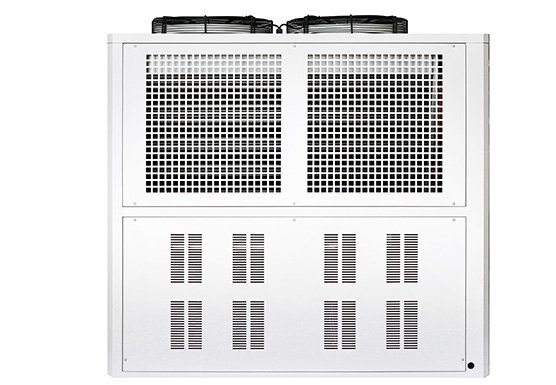

TopChiller can design and manufacture all types of air cooled scroll chillers for you

- Cooling capacity ranges from 5 Ton to 150 Ton

- Temperature control ranges from 7°C to 35°C

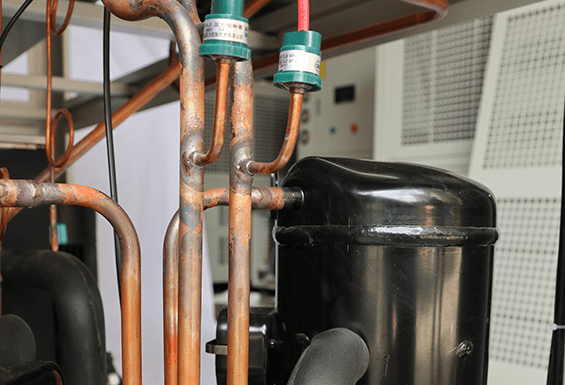

- Energy-efficient top branded scroll compressor

- Separate refrigeration circuits with compressors

- Tube type reliable stainless steel evaporator

- Environment-friendly refrigerant installation

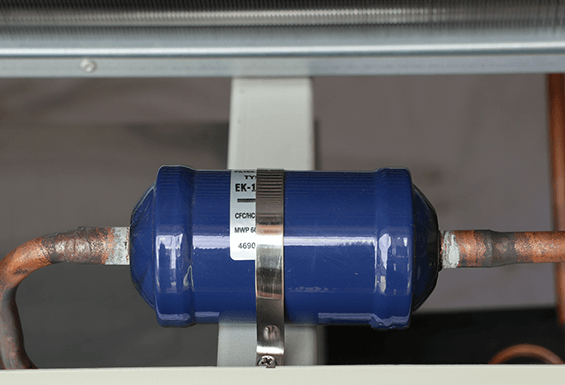

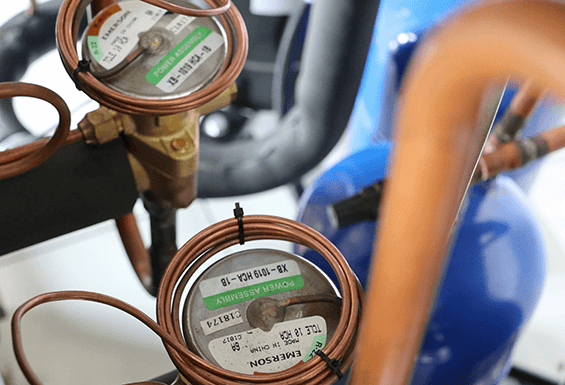

- Expansion valves to control coolant pressure

- Skid mounted unit & tube-in-tube evaporator

Your Premier Air Cooled Scroll Chiller Manufacturer and Supplier

Air Cooled Scroll Chiller is a highly reliable and tropically favorable cooling machine that is used to provide a chilling effect for a processing instrument by using cooled air circulation to discharge heat from the system.

TopChiller is a trustworthy company of China having twenty years of superb experience in the industrial world, and working as a manufacturer and supplier of Air Cooled Scroll Chiller with standardized certifications.

TopChiller is servicing our customers by considering their requirements and queries with deep intentions and manufacturing highly reliable Air Cooled Scroll Chiller accordingly. TopChiller also avails different companies with standardized Air Cooled Scroll Chiller with standard specifications.

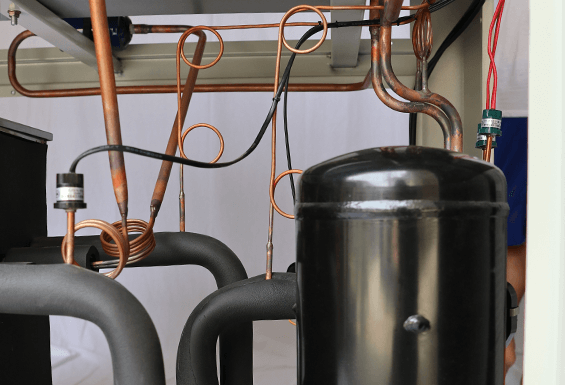

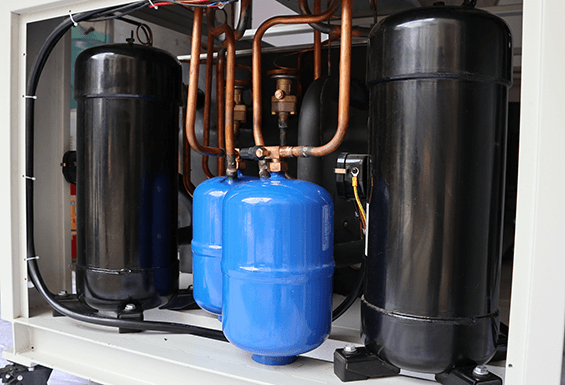

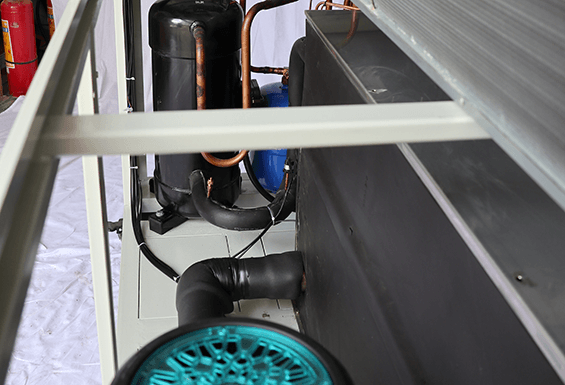

Air Cooled Scroll Chiller made by TopChiller constitutes of efficient scroll compressor, air-cooled copper-coated condenser, control panel, protecting devices, multiple refrigeration circuits, power circuit, tube type evaporator, expansion valves, heat exchanger, and refrigerant tank.

TopChiller designed Air Cooled Scroll Chiller executes a wide variety of benefits for different industrial machines cooling as given below:

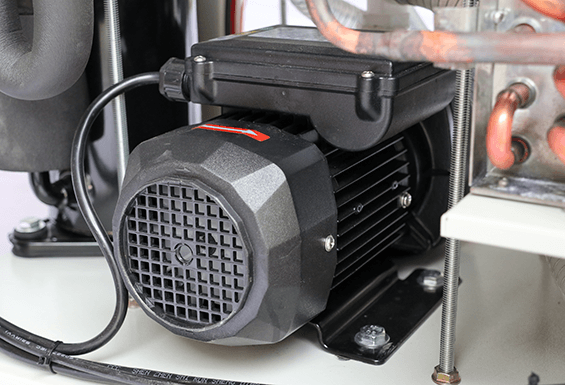

- Air Cooled Scroll Chiller made by TopChiller configures a smooth and noise-free quiet operation by using motors and blade-designed rotor fans with high torque, maintains smooth airflow by absorbing sounds produced during rotation ensuring quiet operation.

- TopChiller designed Air Cooled Scroll Chiller is featured with a modular design having multiple scroll compressors and multiple refrigeration circuits ensuring a steadfast performance in continuous heat dissipation from machines that are sensitive to heat.

- Air Cooled Scroll Chiller provides persistent chilled airflow circulation around the condensing coils, producing a chilling effect and releasing out heat on the environment side.

- Energy-efficient expansion valves are equipped inside Air Cooled Scroll Chiller configuring a relief to refrigerant by releasing pressure from the condensed refrigerant by using its valve expansion.

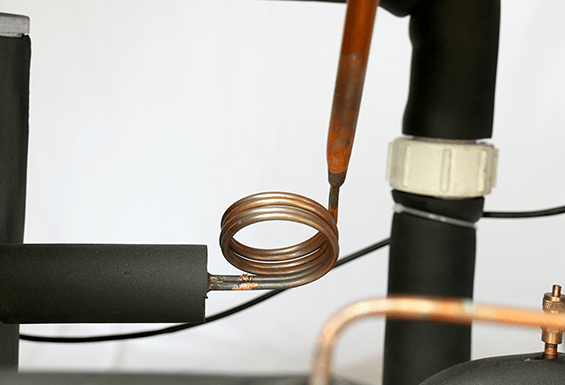

- A newly designed spiral shape heat exchanger improves the heat-absorbing capacity up to 10% as compared to the brazed plate heat exchanger supported by compressions on the fluid by spiral rotating scroll compressors.

Air Cooled Scroll Chiller is renowned among a diverse number of applications as given below:

Injection molding, buildings, hospitals, factories, plastic industry, laser cutting, extrusion, water jet, medical industry, welding, and tools manufacturing, etc.

If you are considering buying the most desired and energy-efficient Air Cooled Scroll Chiller for your application?

If you are wandering around to find a collaborative company as Air Cooled Scroll Chiller manufacturer in China to get the best technical aspects and remedies about establishing your own business?

Don’t waste your time wandering around. Just take a look around your vicinity you will find the vast circle of TopChiller Company. TopChiller is the most preferred company among different enterprises. Contact us to get a quote or buying guide about Air Cooled Scroll Chiller at reasonable prices.

TopChiller team will provide you with all information you may want and repair services within 24 months of warranty time.

General Description:

An Air Cooled Scroll Chiller is a heavy duty cooling unit that efficiently removes heat using dry air currents and a multiple compressor configuration.

TopChiller ensures to maintain maximum quality of components during the manufacturing of Air Cooled Scroll Chiller. The branded components like a condenser, expansion valve, scroll compressors, and evaporator work with accessories like VFDs for maximum output.

The capacity size depends upon the number of compressors joined in series, calculated according to the cooling load.

Air Cooled Scroll Chiller, designed by TopChiller, is used in the tropical region with high-temperature applications like electroplating industries, anodizing plants, blow molding machines, plasma spray machines, food industry, laser plants, etc.

TopChiller is a reliable brand of China, having twenty years of rich experience in the industrial world, working as a manufacturer and supplier of Air Cooled Scroll Chiller.

If you require heavy duty cooling equipment in an affordable range, TopChiller is the flag bearer of creating a unique and innovative Air Cooled Scroll Chiller with reasonable pricing and a long-lasting body.

Contact us, our 24/7 online professional customer care service, for sizing the best Air Cooled Scroll Chiller for your application at an affordable price.

Features and Advantages:

The essential features of an Air Cooled Scroll Chiller are stated below:

- It can work as a multiple compressor configuration where the attributes of each compressor add up to amplify the performance of the refrigeration cycle. A stepped capacity control facility allows you to control various compressors’ operations automatically.

- It is most suitable for tropical areas, and it uses dry air currents to carry out the gaseous exchange in the condenser pills. There is no expense on the steady water supply, and therefore its use is very affordable.

- Air Cooled Scroll Chiller equipped with electronic expansion valves can increase efficiency as the capacity increases.

- The surface area for condensation is high, and the FPI count is low. The axial fans help in low vibration and higher efficiency even in the most challenging conditions.

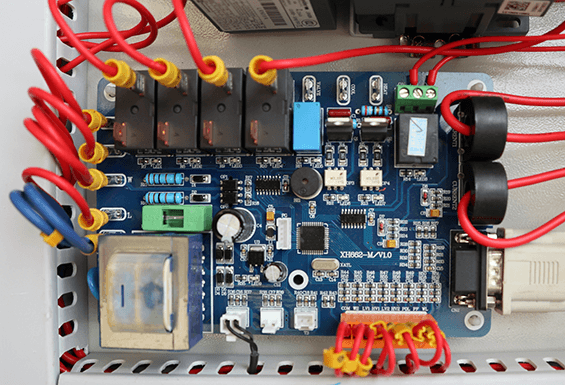

- The microprocessor unit is PLC-based and allows remote operation along with the data logging facility, which helps you keep track of your chiller’s performance.

- Data Sheet

- Image Gallery

- Main Parts

- Video

| Air Cooled Scroll Chiller Technical Specifications | ||||||||||||||

| Items Model | AC-0.5A | AC-1A | AC-1.5A | AC-2A | AC-2.5A | AC-3A | AC-4A | AC-5A | AC-6A | AC-8AD | AC-10AD | AC-12AD | AC-15AD | |

| Cooling capacity | Kcal/h 50HZ/60HZ | 1419 | 2451 | 3182 | 4833 | 5848 | 7181 | 9288 | 11988 | 14534 | 18576 | 23994 | 29068 | 38270 |

| 1703 | 2941 | 3784 | 5800 | 7018 | 8617 | 11146 | 14386 | 17441 | 22291 | 28793 | 34882 | 45924 | ||

| KW 50HZ/60HZ | 1.65 | 2.85 | 3.7 | 5.62 | 6.8 | 8.35 | 10.8 | 13.94 | 16.9 | 21.6 | 27.9 | 33.8 | 44.5 | |

| 1.98 | 3.42 | 4.4 | 6.74 | 8.2 | 10.02 | 12.96 | 16.73 | 20.28 | 25.92 | 33.48 | 40.56 | 53.4 | ||

| Input power | KW | 0.88 | 1.35 | 2 | 2.25 | 2.66 | 3.27 | 4.07 | 5.75 | 6.45 | 8.25 | 11.5 | 12.9 | 17.45 |

| Max Current | A | 5.4 | 8.2 | 12 | 13.6 | 6.6 | 8.2 | 10.1 | 13.8 | 15.5 | 20 | 27.9 | 31.3 | 42.4 |

| Power source | 1PH~220V/3PH~220V/380V 50HZ/60HZ | 3PH~380V/415V/480V~50HZ/60HZ(3PH~200V/220V 50HZ/60HZ) | ||||||||||||

| Refrigerant | Type | R22/R407C/134a/404A/410A | ||||||||||||

| Control | Capillary / thermostatic expansion valve | |||||||||||||

| Compressor | Type | Hermetic Rotary | Hermetic scroll ( piston ) | |||||||||||

| Power(KW) | 0.45 | 0.89 | 1.3 | 1.73 | 2.1 | 2.7 | 3.5 | 4.55 | 5.25 | 3.5×2 | 4.55×2 | 5.25×2 | 7×2 | |

| Condenser | Type | Efficient finned copper tube with aluminum+low noise external rotor fan | ||||||||||||

| Air flow (m3/h) | 750 | 1000 | 1500 | 2000 | 2500 | 3000 | 4000 | 5000 | 6000 | 8000 | 10000 | 12000 | 15000 | |

| Air blower(KW) | 0.06 | 0.09 | 0.15 | 0.15 | 0.19 | 0.14×2 | 0.14×2 | 0.19×2 | 0.19×2 | 0.25×2 | 0.45×2 | 0.45×2 | 0.6×2 | |

| Evaporator | Type | SS Tank coil / shell and tube type / Plate type heat exchanger | ||||||||||||

| Chilled water (m3/h) | 0.28 | 0.49 | 0.64 | 0.97 | 1.12 | 1.44 | 1.86 | 2.4 | 2.91 | 3.71 | 4.8 | 5.81 | 7.65 | |

| 0.34 | 0.59 | 0.76 | 1.16 | 1.4 | 1.72 | 2.23 | 2.88 | 3.49 | 4.46 | 5.76 | 7 | 9.18 | ||

| Water tank(L) | 10.6 | 18.3 | 27 | 27 | 50 | 50 | 60 | 60 | 110 | 120 | 200 | 200 | 270 | |

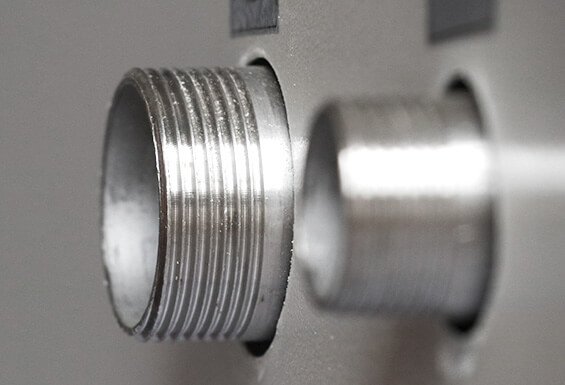

| Inlet/outlet pipe (inch) i | 1/2″ | 1/2″ | 1/2″ | 1/2″ | 1″ | 1″ | 1″ | 1″ | 1″ | 1-1/2″ | 2″ | 2″ | 2″ | |

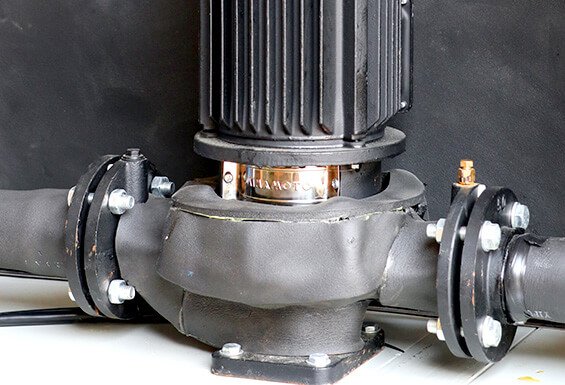

| Water pump | Power (kw) | 0.37 | 0.37 | 0.37 | 0.37 | 0.37 | 0.37 | 0.37 | 0.75 | 0.75 | 0.75 | 1.5 | 1.5 | 2.2 |

| Max lift(m) | 22 | 22 | 22 | 22 | 22 | 22 | 22 | 30 | 30 | 25 | 25 | 25 | 28 | |

| Max flow (m3) | 5.4 | 5.4 | 5.4 | 5.4 | 5.4 | 5.4 | 5.4 | 8.1 | 8.1 | 8.1 | 13.5 | 13.5 | 25.2 | |

| Safety protection | Compressor inner protection, over current protection, high/low pressure protection, over temperature protection, flow rate protection, phase sequence/phase missing protection, low level coolant protection, anti freezing protection, exhaust overheat protection | |||||||||||||

| Dimension | L(mm) | 550 | 550 | 600 | 600 | 720 | 980 | 980 | 1150 | 1150 | 1350 | 1500 | 1500 | 1860 |

| W(mm) | 350 | 450 | 500 | 500 | 550 | 520 | 520 | 560 | 560 | 680 | 760 | 760 | 850 | |

| H(mm) | 695 | 845 | 985 | 985 | 1350 | 1170 | 1170 | 1215 | 1215 | 1530 | 1660 | 1660 | 1900 | |

| Net weight(KG) | 45 | 62 | 85 | 95 | 125 | 152 | 175 | 185 | 215 | 283 | 345 | 382 | 580 | |

| Note: The above specifications are according to the following design conditions: 1, 12℃/7℃.Chilled water inlet/outlet temperature 12℃/7℃. 2, 33℃/38℃.Cooling air inlet/outlet temperature 33℃/38℃. We reserve the right to modify the specification without further notice. | ||||||||||||||

| Air Cooled Scroll Chiller Technical Specifications | |||||||||||||

| Items Model | AC-15AT | AC-20AD | AC-20AF | AC-25AD | AC-25AF | AC-30AD | AC-30AT | AC-40AD | AC-40AF | AC-50AD | AC-50AF | AC-60AD | |

| Cooling capacity | Kcal/h 50HZ/60HZ | 36120 | 49966 | 47988 | 58480 | 58136 | 74734 | 74922 | 98040 | 99760 | 119024 | 116960 | 144996 |

| 43344 | 59959 | 57586 | 70176 | 69763 | 89681 | 89990 | 117648 | 119712 | 142829 | 140352 | 173995 | ||

| KW 50HZ/60HZ | 42 | 58.1 | 55.8 | 68 | 67.6 | 86.9 | 87.2 | 114 | 116 | 138.4 | 136 | 168.6 | |

| 50.4 | 69.72 | 66.96 | 81.6 | 81.12 | 104.28 | 104.64 | 136.8 | 139.2 | 166.08 | 163.2 | 202.3 | ||

| Input power | KW | 17.1 | 21.73 | 22 | 25.4 | 24.8 | 33.39 | 33.1 | 44.91 | 43.3 | 57.3 | 54 | 65 |

| Max Current | A | 43.2 | 52.7 | 53.3 | 63.7 | 61.3 | 81 | 80.2 | 109 | 106 | 135.5 | 128.5 | 135 |

| Power source | 3PH~380V/415V/480V~50HZ/60HZ(3PH~200V/220V 50HZ/60HZ) | ||||||||||||

| Refrigerant | Type | R22/R407C/134a/404A/410A | |||||||||||

| Control | Capillary / Thermostatic expansion valve | ||||||||||||

| Compressor | Type | Hermetic scroll ( piston ) | |||||||||||

| Power(KW) | 4.55×3 | 8.96×2 | 4.55×4 | 10.8×2 | 5.25×4 | 13.62×2 | 8.96×3 | 18.78×2 | 8.96×4 | 23.6×2 | 10.8×4 | 27.4×2 | |

| Condenser | Type | Efficient finned copper tube with aluminum+low noise external rotor fan | |||||||||||

| Air flow (m³/h) | 15000 | 20000 | 20000 | 25000 | 25000 | 30000 | 30000 | 40000 | 40000 | 50000 | 50000 | 60000 | |

| Air blower(KW) | 0.6×2 | 0.78×2 | 0.78×2 | 0.78×2 | 0.78×2 | 0.42×6 | 0.42×6 | 0.6×6 | 0.6×6 | 0.78×6 | 0.78×6 | 0.78×6 | |

| Evaporator | Type | SS Tank coil/ shell and tube type/Plate type heat exchanger | |||||||||||

| Chilled water (m³/h) | 7.22 | 10 | 9.6 | 11.69 | 11.62 | 14.94 | 15 | 19.6 | 19.95 | 23.8 | 23.4 | 29 | |

| 8.67 | 11.99 | 11.51 | 14.03 | 13.95 | 17.93 | 18 | 23.52 | 23.94 | 28.6 | 28.1 | 34.8 | ||

| Water tank(L) | 270 | 350 | 350 | 350 | 350 | 420 | 420 | 580 | 580 | 580 | 580 | 580 | |

| inlet/outlet pipe (inch) | 2″ | 2″ | 2″ | 2-1/2″ | 2-1/2″ | 2-1/2″ | 2-1/2″ | 3″ | 3″ | 3″ | 3″ | 3″ | |

| Water pump | Power(kw) | 2.2 | 2.2 | 2.2 | 2.2 | 2.2 | 4 | 4 | 4 | 4 | 5.5 | 5.5 | 5.5 |

| Max lift(m) | 28 | 28 | 28 | 28 | 28 | 30 | 30 | 30 | 30 | 32 | 32 | 32 | |

| Max flow (m³) | 25.2 | 25.2 | 25.2 | 25.2 | 25.2 | 36 | 36 | 36 | 36 | 40 | 40 | 40 | |

| Safety devices | Compressor inner protection, over current protection, high/low pressure protection, over temperature protection, flow rate protection, phase sequence/phase missing protection, low level coolant protection, anti freezing protection, exhaust overheat protection | ||||||||||||

| Dimension | L(mm) | 1860 | 2020 | 2020 | 2020 | 2020 | 2200 | 2200 | 2350 | 2350 | 2600 | 2600 | 2600 |

| W(mm) | 850 | 950 | 950 | 950 | 950 | 1150 | 1150 | 1350 | 1350 | 1500 | 1500 | 1500 | |

| H(mm) | 1900 | 2000 | 2000 | 2000 | 2000 | 1980 | 1980 | 2000 | 2000 | 2100 | 2100 | 2100 | |

| Net weight(KG) | 580 | 650 | 650 | 810 | 810 | 890 | 890 | 1112 | 1112 | 1320 | 1320 | 1320 | |

| Note: The above specifications are according to the following design conditions: 1, Chilled water inlet/outlet temperature 12℃/7℃. 2, Cooling air inlet/outlet temperature 33℃/38℃. We reserve the right to modify the specification without further notice. | |||||||||||||

Why TopChiller is Your Reliable Air Cooled Scroll Chiller Manufacturer and Supplier In China

Air Cooled Scroll Chiller-An Ultimate FAQ Guide by TopChiller.

- What is an Air Cooled Scroll Chiller?

- What are the Key Components of an Air Cooled Scroll Chiller?

- What are the Prominent Features of an Air Cooled Scroll Chiller?

- What are the Benefits of Using an Air Cooled Scroll Chiller for your Industry?

- How to Ensure Evaporator Freeze Protection for your Air Cooled Scroll Chiller?

- How Does an Air Cooled Scroll Chiller Achieve Partial Heat Recovery?

- What are the Sound Pressure and Power Levels of an Air Cooled Scroll Chiller?

- What Does the Electrical Control Centre of your Air Cooled Scroll Chiller Include?

- What are the Control Options and Accessories for your Air Cooled Scroll Chiller?

- What are the Unit Capacity Controls of your Air Cooled Scroll Chiller?

- What are the Features of Air Cooled Scroll Chiller Compressor and Condenser?

- What are the Inspection and Handling Instructions for your Air Cooled Scroll Chiller?

- How to Build Water Pipe Connection for your Air Cooled Scroll Chiller?

- How to Customize your Air Cooled Scroll Chiller for your Application?

- What are the Safety Devices Available for an Air Cooled Scroll Chiller?

- What is the Startup Process for an Air Cooled Scroll Chiller?

- What Types of Alarms are Present in an Air Cooled Scroll Chiller?

- What are the Troubleshooting Tips for your Air Cooled Scroll Chiller?

What is an Air Cooled Scroll Chiller?

An Air Cooled Scroll Chiller is cooling equipment that offers tight temperature control and has multiple compressor configurations, in which a separate refrigeration circuit supports each compressor.

It is best to withstand harsh tropical weather conditions. Distinct refrigeration circuits help in easy servicing and maintenance of your unit.

There is also a storage tank and a fluid pump on its skid. It comes with multiple refrigerant options and a wide capacity range of 10 to 400 tons, making it useful for various applications.

The design simplicity of an Air Cooled Scroll Chiller makes it reliable and benefit you with lower life cycle cost. Low-speed and direct drive compressor technology is used for higher efficiency.

Energy Efficient Air Cooled Scroll Chiller by TopChiller

What are the Key Components of an Air Cooled Scroll Chiller?

Different high-quality components join together to make your Air Cooled Scroll Chiller fully functional. A short detail to each of these components is given below:

Casing

- An easy to assemble and disassemble structure for trouble-free service and maintenance

- Aesthetically appealing and insulated exterior for avoiding condensation

- A structure for preventing abnormal noise and vibration

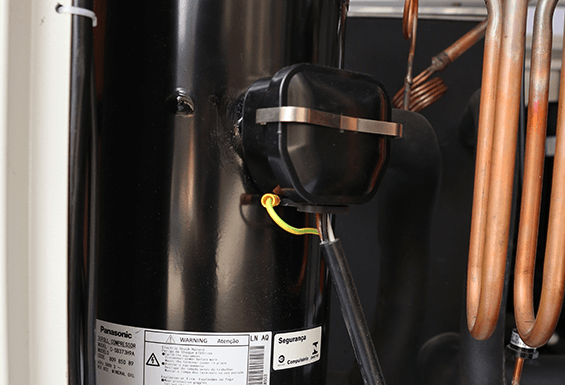

Scroll Compressor

- With completely sealed hermetic type casing

- R410A refrigerant use and noise prevention rubber installation

- 30Hz to 127Hz frequency variable boundary range

Condenser

- 9% pure heat exchanger, vacuumed condenser coil, and BLDC type motor

- No deformation or leakage on high-pressure testing

- Propellant type fans for adequate cooling airflow

Electronic Expansion Valve

- Forms low-temperature and low-pressure refrigerant from high-temperature and high-pressure refrigerant

- Active linear electronic expansion valve to balance evaporator load and refrigerant amount

Evaporator

- Carbon steel DX type shell and tube type heat exchanger having a robust structure

- No water leakage for ensuring maximum durability

- NBR insulated evaporator shell

Explosion Proof Air Cooled Scroll Chiller

What are the Prominent Features of an Air Cooled Scroll Chiller?

An Air Cooled Scroll Chiller has various excellent features to help its smooth operation and efficient performance. These features are:

- Multiple refrigerant options are available.

- Fully charged, pre-wired and run-tested for easy and quick installation.

- Time-tested, reliable, and highly efficient scroll compressors.

- Power saving compressor operation.

- Low initial capital cost and starting current due to multiple compressor configurations.

- Quiet operation condenser fans and condenser for efficient noise control.

- Optional tandem circuits for ensuring maximum efficiency.

- Intelligent microprocessor controls for easy operation, low maintenance, and a wide range of operating features.

Air Cooled Scroll Chiller Intelligent Microprocessor Controller

What are the Benefits of Using an Air Cooled Scroll Chiller for your Industry?

You can enjoy multiple benefits by using an Air Cooled Scroll Chiller. Some of these great benefits are discussed below:

Digital Control

Due to efficient digital controls, this ensures maximum power saving and optimal cooling by accurate setting adjustments. Temperature can be easily adjusted to 0.1°C levels.

Built-In Time Delays

In case of any power failure or turning on or off the compressor, it needs some time to complete the action.

Longer compressor life is ensured due to built-in time delay controller features by automatically adhering to these time delays.

Auto Load Distribution

If the total capacity of your Air Cooled Scroll Chiller is more than the air conditioning load, then only the required compressors are kept On by the microprocessor, whereas the rest are switched off.

The controller also controls the compressors’ even turning on and off at regular intervals. As a result, the equal load is maintained, leading to efficient performance.

BMS Compatibility

BMS also referred to as Building Management System, helps remote operation flexibility.

Non-Volatile Memory

Non-volatile memory stores the controller settings staying through power failures which do not require you to reset the settings after each failure.

How to Ensure Evaporator Freeze Protection for your Air Cooled Scroll Chiller?

Where temperatures fall below zero, evaporator freeze-up can become a problem when using an Air Cooled Scroll Chiller.

The evaporator features an electric heating plate and insulation protection to prevent freeze-ups from preventing this problem. This protects the evaporator from ambient temperatures as low as -29°C (20°F).

The loss of protection of the evaporator itself and the water piping outside the unit is mainly due to heater burnouts and power failures, even if having the freeze protection feature.

Read the following information to enhance the protection feature.

- Drain the chilled water piping and the evaporator and wash with glycol if the unit is not used in winter.

- For draining glycol, vent connections and drain are given on the evaporator.

- Using a year-round glycol solution to preserve the chilled water system from freezing. The freezing point must be about 5.6°C (or 10°F) lower than the lowest surrounding temperature. Or it should be 10°F lower than the minimum design exit water temperature, considering the lowest option.

- Using glycol anti-freeze usually helps best with preventing freeze-up along with maintaining safety.

- But influenced by the concentration of glycol used, the process conduction might be compromised.

- You should determine a minimum fluid concentration for glycol applications depending on the Burst Protection limitations.

- Adding insulation and thermostatically regulated heat tracing to uncovered piping. After adding the tracing, you should remove and replace the factory insulation.

- A factory-built connection is already built between a 115V circuit and the evaporator heater in the control box.

- The control circuit and another separate source might fulfill this power demand.

- The heater cable operates automatically through the fluid sensing thermostat, which improves its anti-freeze protection.

- You should permanently close the disconnect evaporator heater switch unless you drain out the evaporator during the winter.

- When drained, protect the evaporator from heat.

- Thermal contraction and expansion cause water volume changes, which are accommodated by installing an expansion water tank.

Air Cooled Scroll Chiller Expansion Water Tank

How Does an Air Cooled Scroll Chiller Achieve Partial Heat Recovery?

Between the condenser coils and the compressor, an additional auxiliary heat exchanger is added to every Air Cooled Scroll Chiller refrigerant circuit, helping in gaining partial heat recovery.

The heat is moved from the compressor discharge gas to a separate water loop by the heat exchangers for use in various heating tasks. When the Air Cooled Scroll Chiller is functioning, the heating recovery cycle can only be availed at that time.

An auxiliary heat exchanger for partial heat recovery allows water to return up to 155°F, but the drawback is that you cannot set this value.

Depending on the water flow rate, operation temperatures, and the required cooling load, the heat production can reach a maximum of half of the nominal cooling capacity.

What are the Sound Pressure and Power Levels of an Air Cooled Scroll Chiller?

Sound Pressure Level

The level of sound from the source that you can measure at a certain distance and is dependent on the surroundings is referred to as sound pressure. Distance is another factor that causes variation in this sound pressure.

Take an example of a brick wall, one distanced 10 feet apart from the unit, and the other distanced 20 feet apart; both will have different effects on the sound. Decibels (dB) are used to express sound pressure.

The sound pressure observations are always made in the free field where no reflective surfaces are present under the Air Cooled Scroll Chiller other than the floor with the help of a handheld sound meter.

Following the standard AHRI protocols of leaving evaporator water temperature at 7°C (44°F) and average air temperature at 35°C (95°F), you can record the value of sound pressure.

For this, maintain a distance of 10 meters (30 feet) from the side of your Air Cooled Scroll Chiller.

Controlling Air Cooled Scroll Chiller Noise

Sound Power Levels

Sound power is a statistical number that can’t be physically measured, unlike sound pressure.

Opposite to sound pressure, sound power is not affected by the nearby environment or distance from the source.

It may be considered as the unit’s fundamental sound level, regardless of the obstructions or the distance.

A specific area is specified for taking the measurements, and with the help of mathematics, the sound power is recorded in dB.

Acoustical consultants frequently conduct extensive acoustic analysis using sound power octave band data.

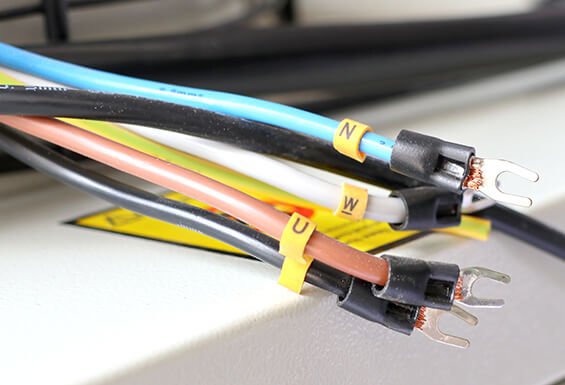

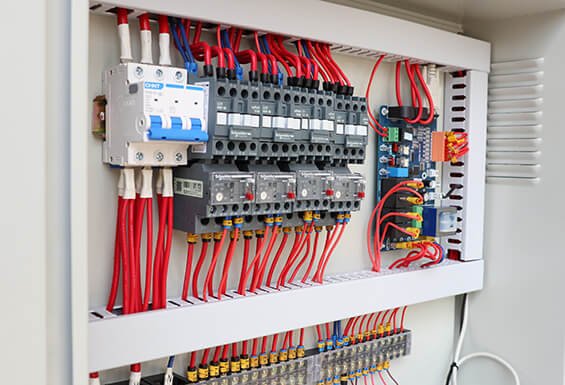

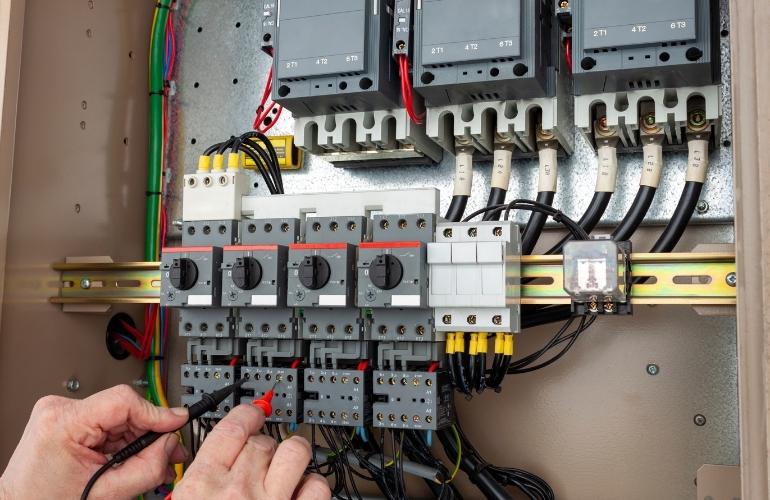

What Does the Electrical Control Centre of your Air Cooled Scroll Chiller Include?

The motor starting parts and the equipment protection and operating controls are enclosed in a weather-resistant control panel, centrally located, and have tool-locked and hinged doors.

Temperature and overload protection for the compressor motor is included as part of the standard equipment.

The electric control panel of your Air Cooled Scroll Chiller has the following details:

- Additional phase voltage monitor with low or high voltage for offering maximum phase reversal safety

- A block of the power terminal

- Control transformer

- Output, input, and control terminal block

- Additional ground-fault protection

- Additional disconnecting switch

- A head pressure control system with fan staging

- Fan contactors featuring short circuit protection

- Single-point standard power connection

What are the Control Options and Accessories for your Air Cooled Scroll Chiller?

To increase the functional performance of your Air Cooled Scroll Chiller, you can add the following optional accessories:

- Variable Speed Fans With High Efficiency

- Factory-Installed Low Ambient Control

- Fast Loading Standby Equipment

- Field-Installed Alarm Bell

- Factory Supplied Water Flow Switch

- High Ambient Control Panel

Air Cooled Scroll Chiller Water Flow Switch

What are the Unit Capacity Controls of your Air Cooled Scroll Chiller?

Air Cooled Scroll Chiller features various unit capacity controls, which are separately mentioned below under different sections.

Staging the Compressor in Cooling Mode

Only turn on the first compressor if all the following conditions are being satisfied:

- The startup temperature is lower than the Evaporator Long-Wavelength Temperature (LWT).

- In case of an inactive motor protection delay.

Adding Another Compressor

If all of the following conditions are being satisfied, you can add an additional compressor:

- There is an inactive Stage Up Delay.

- When the stage up temperature is lower than the Evaporator Long-Wavelength Temperature (LWT).

- There is an inactive unit capacity hold.

- There is an inactive max pull-down rate.

Remove a Compressor

If all of the following conditions are being satisfied, you can remove a compressor:

- When the stage is down, the temperature is higher than the Evaporator Long-Wavelength Temperature (LWT).

- Multiple compressors are running.

- There is an inactive Stage Down Delay.

Stopping the Last Compressor

If all of the following conditions are being satisfied, you should stop the last compressor:

- Only a single compressor is working.

- The shutdown temperature is higher than the Evaporator Long-Wavelength Temperature (LWT).

Stage Up Delay

According to the definition of the Stage Up Delay set point is the smallest duration that passes between the capacity stage increases.

This delay is only applicable if there is one running compressor at least.

When more than one compressor is attached, and the first one quickly starts and shuts down for any reason, the second compressor will turn on without passing this minimum duration.

Stage Down Delay

According to the definition of the Stage Down Delay set point is the smallest duration that passes between the capacity stage decreases.

What are the Features of the Air Cooled Scroll Chiller Compressor and Condenser?

The compressor and condenser are among the essential components in an Air Cooled Scroll Chiller.

This is why these components possess certain essential control features that are mentioned below:

Control Features of the Scroll Compressor

- R410A refrigerant use

- Sealed hermetic type casing

- Vibration prevention rubber

- 30Hz to 127Hz frequency variable boundary

Air Cooled Scroll Chiller R410A Refrigerant

Control Features of the Condenser

- 9% pure heat exchanger

- 48 levels of 14FPI and 3 rows for heat exchanger arrangement

- 18 MPa or above pressure tested

- BLDC type motor

What are the Inspection and Handling Instructions for your Air Cooled Scroll Chiller?

For the inspection and handling of your Air Cooled Scroll Chiller, there are some vital protocols that you must follow; these include:

Inspection Protocol

- Check all of the products with the bill of lading to ensure they are in order.

- On arrival, keenly examine all units to figure out any damages.

- Notify the carrier of any shipment damage and register a claim with them.

- Before unloading, double-check the nameplate to ensure it corresponds to the available power supply.

- After the equipment has been sent from the factory, the company is not liable for any physical damage.

Handling Protocol

- Take care not to damage the equipment by handling it roughly.

- It is not permissible to push or pull the unit from any part except for its base.

- Keep the pushing vehicle as far away from the unit to avoid damage to the end frame and the sheet metal cabinet. Cables and spreader bars should be strategically placed to prevent damage to the cabinet or condenser coils.

- All lifting places must be utilized to avoid causing harm to the unit.

- Improperly moving, rigging, or lifting the unit may result in personal injury, damage to the property, and even death sometimes.

- Pay close attention to the movement and rigging directions.

- It is not safe to stand underneath the unit during installation or lifting.

- Coil surfaces and sharp edges come with a high risk of injury.

- Do not make contact with coil surfaces and sharp edges.

Air Cooled Scroll Chiller Inspection

How to Build Water Pipe Connection for your Air Cooled Scroll Chiller?

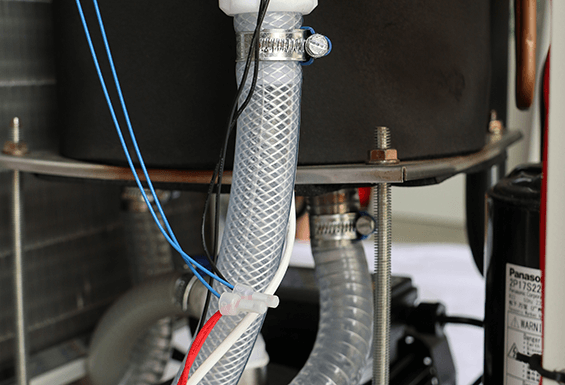

A supply strainer that links to the evaporator is necessary for the inlet water piping to eliminate evaporator damage and possible system failure.

This filter should be fitted before the chilled liquid pumps may be used. The following features must be included in any field-installed water piping connections of your Air Cooled Scroll Chiller:

- A removable filter is installed to avoid clogging of the evaporator at the water inlet. Within 1500mm or 5 feet of the pipe length from the downstream of the welded parts and evaporator inlet connection, attach a cleanable filter.

- A perforation size of no more than 1.6 mm or 0.063″ is required in the filter.

- In case of no flow or low flow conditions, for the prevention of evaporator freeze-up, a water flow switch should be connected in the horizontal piping of the evaporator outlet.

- An option for a factory-installed flow switch must be present.

- Assuring sufficient water pressure requires an expansion tank and a regulating valve.

- The lower connection pipe (the bottom part) and the higher connection pipe (the top part) are the sites for the vent and drain connections of the piping.

- Before unit startup, to ensure enough evaporator circulation, you must get rid of the air from the water system.

- To reduce stress on the connections and fittings, it is necessary to provide independent and sufficient pipe support.

Water Pipe Connection for Air Cooled Scroll Chiller

How to Customize your Air Cooled Scroll Chiller for your Application?

To customize your Air Cooled Scroll Chiller for your application, you are facilitated with the following options:

Wind Load Rated

As per the tests, it can manage a wind load of up to 186 mph. You also get an additional engineer-stamped certificate which indicates that the building and designing of your equipment are tested to fulfill the required wind load requirements.

Hot Gas Bypass

Enables the unit to run at 10% of its maximum capacity. There is a factory-installed solenoid valve, hot gas bypass valve, and manual shutdown valve for every circuit.

The field piping instructions always vary with the manufacturer’s guidelines.

Low Ambient Control

Fan VFD allows low-temperature unit operation. But you will need a high ambient control box for operation in the surrounding temperature range of 52°C (125°F) to 40°C (105°F).

Ground Fault Protection

A circuit breaker works by protecting the equipment against the harm caused by line-to-ground fault conditions.

This is helpful when the requirement for conductor protection is higher than the current. This circuit breaker is pre-installed in the factory in your Air Cooled Scroll Chiller.

Phase Loss Protection

LED lights and phase loss featuring high and low voltage protection help identify the problem for safeguarding the compressor motor from burning out.

Some Other Options Available

There are also some additional options available for the customization of your Air Cooled Scroll Chiller, which include:

- A pre-installed thermal dispersion flow switch

- Factory mounted BAS interface module

- Connected to the control panel, there is a paddle-style, field-installed chilled water flow switch

- Field installed rubber-in-shear vibration isolators

- Field wired remote operator interface panel

- In the case of brazed plate evaporators, the lower value of 0.063″ perforations on the evaporator input strainer with grooved couplings and extension pipe.

- Field Installed spring vibration isolators

- 115V GFI convenience outlet

- Field installed seismic-rated spring isolators

- Compressor sound reduction package

What are the Safety Devices Available for an Air Cooled Scroll Chiller?

Various safety devices are installed in Air Cooled Scroll Chiller to ensure safe operation without causing any harm to the operators or the environment.

Some of the primary safety devices used for specific parameters are listed below:

Normal Refrigerant Pressure

- High voltage protection sensor

- High-pressure switch

Temperature

- Power module application sensor

- IPM temperature detection sensor

- Compressor discharge temperature superheating detection sensor

- Chiller and burst protection sensor

Current and Voltage Control Logic

- Fan motor overcurrent protection

- Compressor overcurrent protection

Chilled Water Flow

- A chilled water flow switch

Air Cooled Scroll Chiller Temperature Detection Sensor

What is the Startup Process for an Air Cooled Scroll Chiller?

You have to follow proper protocols to start up your Air Cooled Scroll Chiller properly. For this, you need to follow the given tips:

Startup Steps

- Check the flow of chilled water.

- Check that your Air Cooled Scroll Chiller has been instructed to start by a remote start/stop or time clock (if equipped).

- Three things must have a lower temperature than the system water temperature. These include the total leaving water temperature, the addition of one-half the control band, and the startup cooling controller

- The unit nominal flow percentage should be the base for adjusting the evaporation temperature, and the starting temperature is fixed as the starting point.

- Verify that the controller’s setpoints are sufficiently complying with the factory settings.

- Turn on the PS1 (pump-down switch).

- Turn on the S1 (system switch).

When the Air Cooled Scroll Chiller is already functioning for some time and has gained stability, do the following checks:

- If the oil level in the compressor is adequate. (Note that there are no oil sight glasses in some scroll compressors).

- If there is flashing in the refrigerant sight glass.

- If the condenser fan rotation is regular and maintained.

What Types of Alarms are Present in an Air Cooled Scroll Chiller?

Different types of alarms are already installed in your Air Cooled Scroll Chiller for your safety and conduction of smooth operation. The most critical alarms include:

- The Inadequate Demand Limit Input Alarm

- Input LWT Reset Button Fault Alarm

- Evaporator EWT Sensor Fault Alarm

Air Cooled Scroll Chiller High Pressure Alarm

What are the Troubleshooting Tips for your Air Cooled Scroll Chiller?

Some of the most helpful troubleshooting tips for your Air Cooled Scroll Chiller are mentioned below:

- Bad Demand Limit Input

On the activation of out-of-range demand limit input, wrong demand limit input is triggered. For this problem, the out-of-range signal value is more than 21mA and more petite than 3mA. This limits you from using the demand limit function.

Solution

Auto-clear the settings when the demand limit stays in the normal range for 5 seconds or is disabled.

- Input LWT Reset Button Fault

This problem arises when the LWT reset input exceeds the normal range. For this problem, the out-of-range signal value is more than 21mA and less than 3mA. This limits you from resetting the LWT.

Solution

Auto-clear the settings when the LWT stays in the normal range for 5 seconds or is disabled.

Air Cooled Scroll Chiller Troubleshooting