TopChiller can design and manufacture all types of industrial chillers for you

- Cooling capacity ranges from 1 Ton to 150 Ton

- Temperature control from ranges 5℃ to 30℃

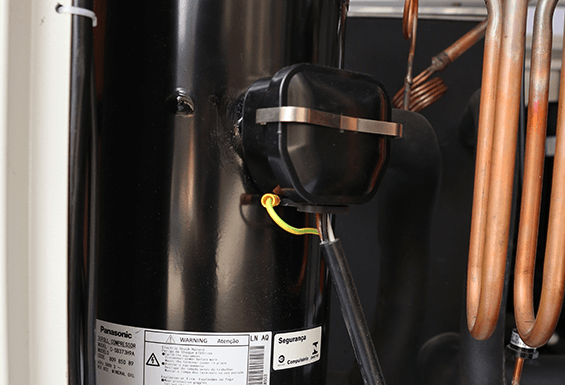

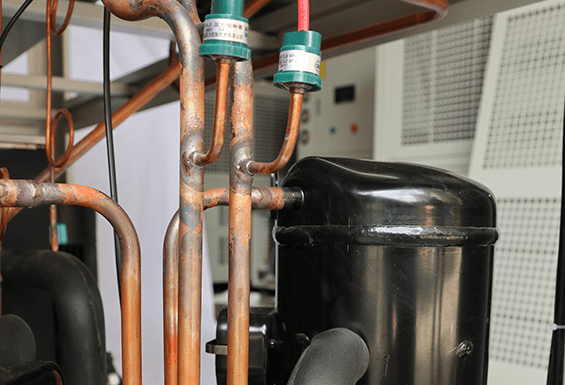

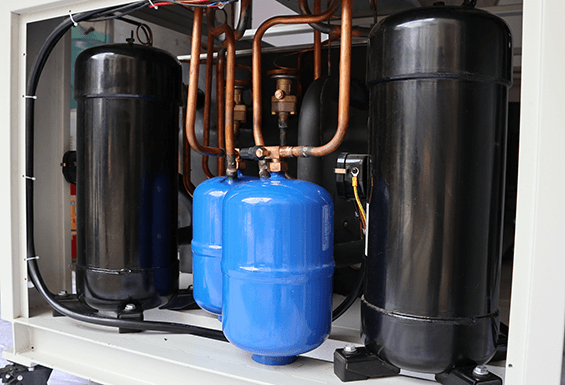

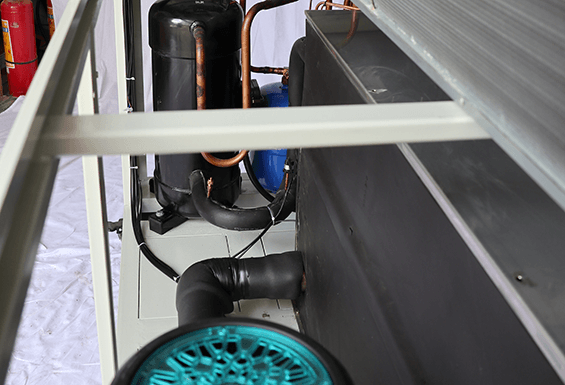

- Hermetic or semi-hermetic branded compressor

- Stainless steel shell & heat reclaim system

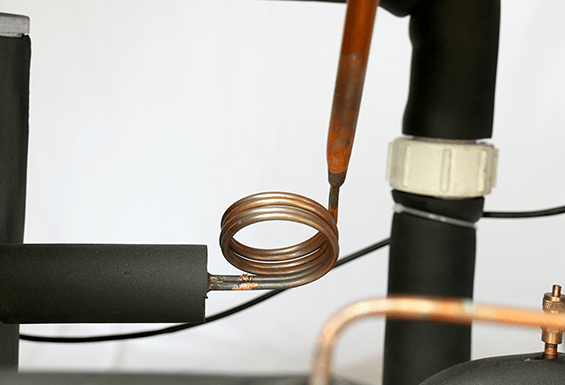

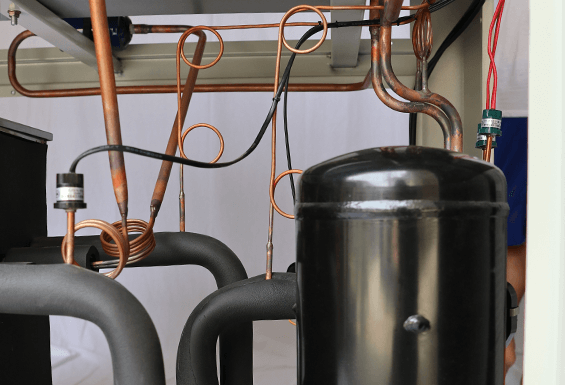

- Copper tube heat exchanger& evaporator

- Carel controller & efficient condenser fans

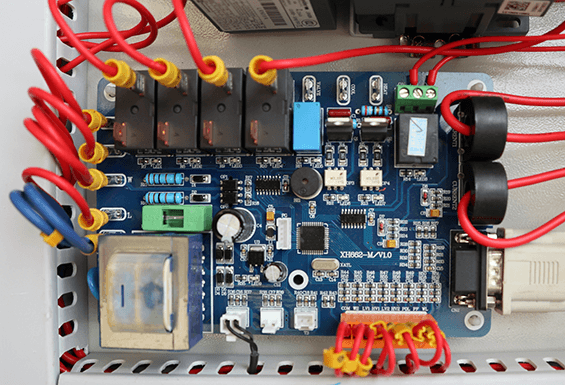

- Intelligent PID based temperature controller

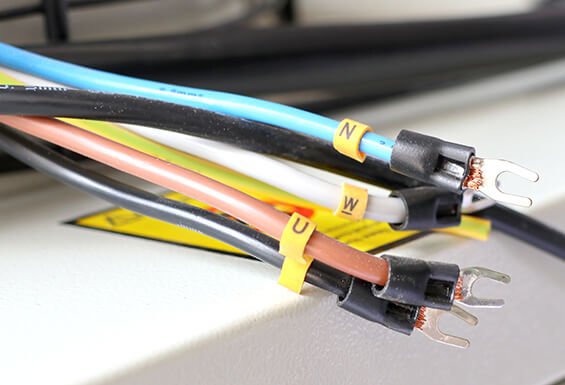

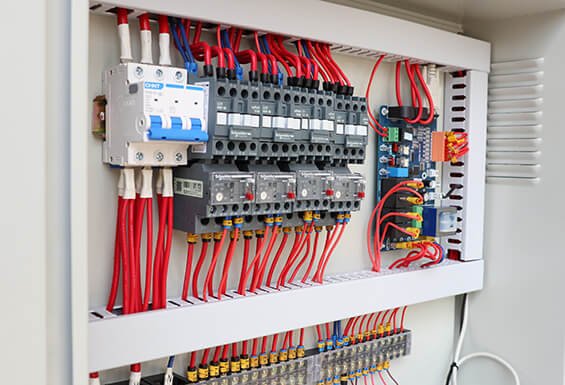

- Control panel & protection multiple alarms

Your Premier Industrial Chiller Manufacturer and Supplier in China

Industrial Chiller is a versatile type of cooling machine that is specific for releasing heat from different industrial processing machines by using air-cooled or water-cooled circulation around the energy-efficient condenser.

TopChiller is the leading company of China that was evolved about twenty years ago on the global map as a manufacturer of energy-efficient Industrial Chiller for different industrial applications with warranty for quality assurance.

TopChiller is famous among clients and companies by accommodating the basic requirements claimed by customers about chiller specifications and spending more time to understand the problems dictated by the client before customizing since 1999 his marvelous work.

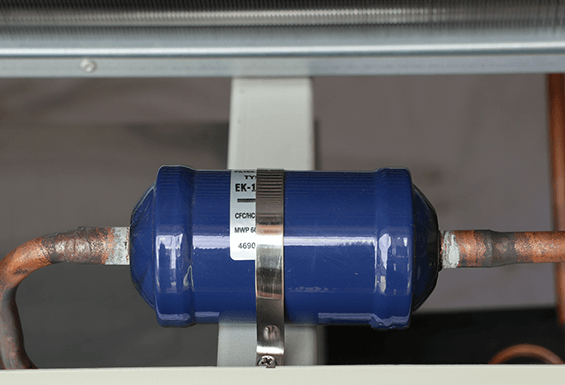

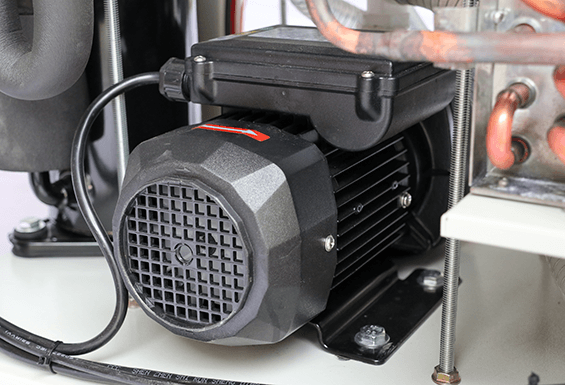

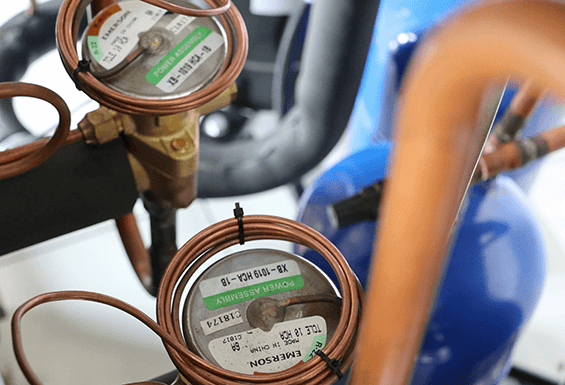

Dual semi-hermetic compressor, hot gas bypass, dry filter, expansion valves, heat reclaim system, multiple alarms, air/water-cooled condenser, rotor fans, distribution units, evaporator, copper tube heat exchanger, temperature controller, and power supply are basic components of Industrial Chiller.

Industrial Chiller is highly durable to deal high heat processing with many other benefits for industrial applications as given below:

- TopChiller designed Industrial Chiller is highly stable and efficient in heat releasing from industrial machines configured by heat load-bearing condenser that consistently accept the coming heat from evaporator without getting any damage supported by rotor fans.

- Industrial Chiller ensures the heat discharge from a processing system by using chilled water or ambient air circulation to produce cooling depending on application type and heating load.

- TopChiller designed industrial Chiller credibly deals with high heating produced during machine processing featured by multiple alarms and control panel that prevents the unit from high /low temperature, pressure, and current fluctuations related damages by automatic pre-diagnosis and regulation.

- TopChiller engineered Industrial Chiller has lower costs of maintenance featured by hot gas bypass valve that maintains the temperature of refrigerant before entering into compressor with conservation of power that used in ‘ON and ‘OFF’ by a circuit breaker.

Industrial Chiller is renowned among different industrial and commercial applications as:

Metals finishing, fermentation industry, medical industry, tires production, laser industry, commercial printing, pool heating, dry cleaning, injection molding, machine tools manufacturing, plating, die-cutting, and explosion industry, etc.

If you are dealing with high-heat evolving applications and looking for an efficient working Industrial Chiller to cool down your application?

If you are in search of the best reliable and trustworthy Industrial Chiller manufacturing company in China to level up your business by getting valued instructions?

Don’t feel any hesitation and make an instant decision about TopChiller selection as TopChiller is a trustworthy company for all our customers.

Contact us today for getting details about Industrial Chiller installation, a full buying guide, or a quote to size the best Industrial Chiller for your application at affordable charges.

TopChiller has hired technocrats and professional experts that are directed to deal with the queries of clients with optimal solutions.

General Description:

An Industrial Chiller is a heavy-duty cooling device used to displace the heat produced by the running machinery in various industries. It can deal with greater cooling loads and serves the purpose with little maintenance and high output.

Except for the water-cooled configuration Industrial Chiller manufactured by TopChiler also comes with an air-cooled configuration. The standard components include a branded compressor, an evaporator, a condenser, integral pumps, water tanks, and premium quality expansion valves.

Industrial Chiller designed by TopChiller is famous among different industrial and commercial applications such as beverage, welding, plastic, chemical processing, food, medical, textile, semiconductor, laboratories, pharmaceutical, and laser. It keeps suitable quality heat exchange mechanisms for maximum application productivity.

If you are dealing with high-heat developing industrial applications and searching for a professional manufacturer of Industrial Chiller, your search ends here.

Based on the initiative to maximize efficiency and premium manufacturing standards 20 years ago, TopChiller has succeeded in making its name all around the globe.

Contact TopChiller today to get details about Industrial Chiller, a complete buying guide, or a quote to size the best one for your application at your doorstep.

Features and Advantages:

The most outstanding features of an Industrial Chiller are stated below:

- The screw, scroll, and hermetic compressors are used according to the configuration, and each one has the properties like long service time, high quality, low sound, and warranty.

- Industrial Chiller has an electric automatic control system connected to the demulsifier to supply power to the pump and compressor. It deals with the temperature controller, delay controller, pressure protection, relay overload protection, etc.

- The evaporator coil is made up of two materials, which is stainless steel and copper. The former has more suitable for avoiding any contamination, and the latter has better heat transfer.

- It comes in a weatherproof design and weather-resistant body that can fight against harsh weather like snow, rain, and even hot and humid weather.

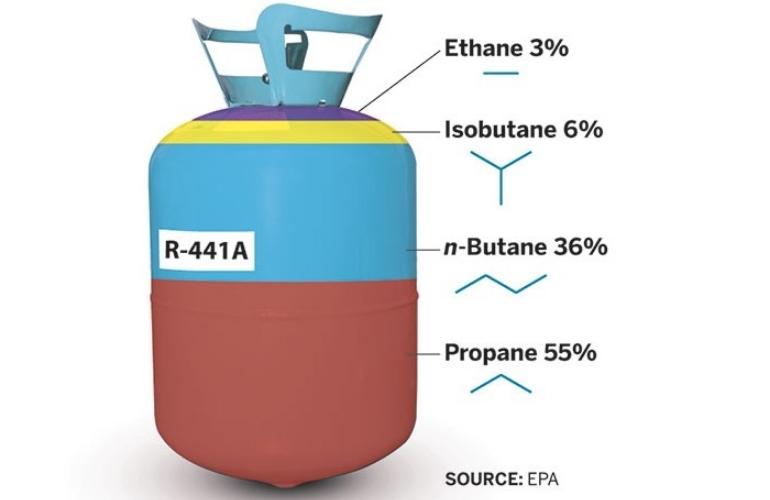

- To provide the highest efficiency with minimum input, it is fully charged with human-friendly refrigerants, mainly R134a, R407c, and R41oa.

- Data Sheet

- Image Gallery

- Main Parts

- Video

| Industrial Chiller Technical Specifications | ||||||||||||||

| Items Model | AC-0.5A | AC-1A | AC-1.5A | AC-2A | AC-2.5A | AC-3A | AC-4A | AC-5A | AC-6A | AC-8AD | AC-10AD | AC-12AD | AC-15AD | |

| Cooling capacity | Kcal/h 50HZ/60HZ | 1419 | 2451 | 3182 | 4833 | 5848 | 7181 | 9288 | 11988 | 14534 | 18576 | 23994 | 29068 | 38270 |

| 1703 | 2941 | 3784 | 5800 | 7018 | 8617 | 11146 | 14386 | 17441 | 22291 | 28793 | 34882 | 45924 | ||

| KW 50HZ/60HZ | 1.65 | 2.85 | 3.7 | 5.62 | 6.8 | 8.35 | 10.8 | 13.94 | 16.9 | 21.6 | 27.9 | 33.8 | 44.5 | |

| 1.98 | 3.42 | 4.4 | 6.74 | 8.2 | 10.02 | 12.96 | 16.73 | 20.28 | 25.92 | 33.48 | 40.56 | 53.4 | ||

| Input power | KW | 0.88 | 1.35 | 2 | 2.25 | 2.66 | 3.27 | 4.07 | 5.75 | 6.45 | 8.25 | 11.5 | 12.9 | 17.45 |

| Max Current | A | 5.4 | 8.2 | 12 | 13.6 | 6.6 | 8.2 | 10.1 | 13.8 | 15.5 | 20 | 27.9 | 31.3 | 42.4 |

| Power source | 1PH~220V/3PH~220V/380V 50HZ/60HZ | 3PH~380V/415V/480V~50HZ/60HZ(3PH~200V/220V 50HZ/60HZ) | ||||||||||||

| Refrigerant | Type | R22/R407C/134a/404A/410A | ||||||||||||

| Control | Capillary / thermostatic expansion valve | |||||||||||||

| Compressor | Type | Hermetic Rotary | Hermetic scroll ( piston ) | |||||||||||

| Power(KW) | 0.45 | 0.89 | 1.3 | 1.73 | 2.1 | 2.7 | 3.5 | 4.55 | 5.25 | 3.5×2 | 4.55×2 | 5.25×2 | 7×2 | |

| Condenser | Type | Efficient finned copper tube with aluminum+low noise external rotor fan | ||||||||||||

| Air flow (m3/h) | 750 | 1000 | 1500 | 2000 | 2500 | 3000 | 4000 | 5000 | 6000 | 8000 | 10000 | 12000 | 15000 | |

| Air blower(KW) | 0.06 | 0.09 | 0.15 | 0.15 | 0.19 | 0.14×2 | 0.14×2 | 0.19×2 | 0.19×2 | 0.25×2 | 0.45×2 | 0.45×2 | 0.6×2 | |

| Evaporator | Type | SS Tank coil / shell and tube type / Plate type heat exchanger | ||||||||||||

| Chilled water (m3/h) | 0.28 | 0.49 | 0.64 | 0.97 | 1.12 | 1.44 | 1.86 | 2.4 | 2.91 | 3.71 | 4.8 | 5.81 | 7.65 | |

| 0.34 | 0.59 | 0.76 | 1.16 | 1.4 | 1.72 | 2.23 | 2.88 | 3.49 | 4.46 | 5.76 | 7 | 9.18 | ||

| Water tank(L) | 10.6 | 18.3 | 27 | 27 | 50 | 50 | 60 | 60 | 110 | 120 | 200 | 200 | 270 | |

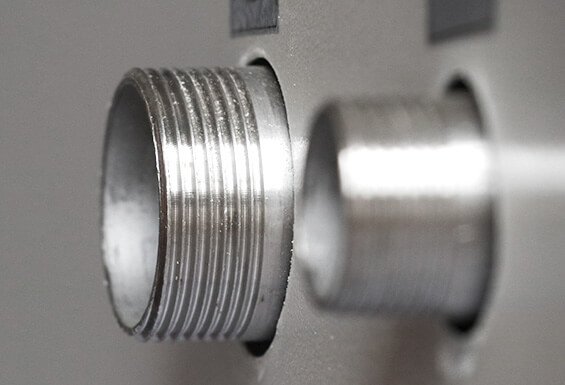

| Inlet/outlet pipe (inch) i | 1/2″ | 1/2″ | 1/2″ | 1/2″ | 1″ | 1″ | 1″ | 1″ | 1″ | 1-1/2″ | 2″ | 2″ | 2″ | |

| Water pump | Power (kw) | 0.37 | 0.37 | 0.37 | 0.37 | 0.37 | 0.37 | 0.37 | 0.75 | 0.75 | 0.75 | 1.5 | 1.5 | 2.2 |

| Max lift(m) | 22 | 22 | 22 | 22 | 22 | 22 | 22 | 30 | 30 | 25 | 25 | 25 | 28 | |

| Max flow (m3) | 5.4 | 5.4 | 5.4 | 5.4 | 5.4 | 5.4 | 5.4 | 8.1 | 8.1 | 8.1 | 13.5 | 13.5 | 25.2 | |

| Safety protection | Compressor inner protection, over current protection, high/low pressure protection, over temperature protection, flow rate protection, phase sequence/phase missing protection, low level coolant protection, anti freezing protection, exhaust overheat protection | |||||||||||||

| Dimension | L(mm) | 550 | 550 | 600 | 600 | 720 | 980 | 980 | 1150 | 1150 | 1350 | 1500 | 1500 | 1860 |

| W(mm) | 350 | 450 | 500 | 500 | 550 | 520 | 520 | 560 | 560 | 680 | 760 | 760 | 850 | |

| H(mm) | 695 | 845 | 985 | 985 | 1350 | 1170 | 1170 | 1215 | 1215 | 1530 | 1660 | 1660 | 1900 | |

| Net weight(KG) | 45 | 62 | 85 | 95 | 125 | 152 | 175 | 185 | 215 | 283 | 345 | 382 | 580 | |

| Note: The above specifications are according to the following design conditions: 1, 12℃/7℃.Chilled water inlet/outlet temperature 12℃/7℃. 2, 33℃/38℃.Cooling air inlet/outlet temperature 33℃/38℃. We reserve the right to modify the specification without further notice. | ||||||||||||||

| Industrial Chiller Technical Specifications | |||||||||||||

| Items Model | AC-15AT | AC-20AD | AC-20AF | AC-25AD | AC-25AF | AC-30AD | AC-30AT | AC-40AD | AC-40AF | AC-50AD | AC-50AF | AC-60AD | |

| Cooling capacity | Kcal/h 50HZ/60HZ | 36120 | 49966 | 47988 | 58480 | 58136 | 74734 | 74922 | 98040 | 99760 | 119024 | 116960 | 144996 |

| 43344 | 59959 | 57586 | 70176 | 69763 | 89681 | 89990 | 117648 | 119712 | 142829 | 140352 | 173995 | ||

| KW 50HZ/60HZ | 42 | 58.1 | 55.8 | 68 | 67.6 | 86.9 | 87.2 | 114 | 116 | 138.4 | 136 | 168.6 | |

| 50.4 | 69.72 | 66.96 | 81.6 | 81.12 | 104.28 | 104.64 | 136.8 | 139.2 | 166.08 | 163.2 | 202.3 | ||

| Input power | KW | 17.1 | 21.73 | 22 | 25.4 | 24.8 | 33.39 | 33.1 | 44.91 | 43.3 | 57.3 | 54 | 65 |

| Max Current | A | 43.2 | 52.7 | 53.3 | 63.7 | 61.3 | 81 | 80.2 | 109 | 106 | 135.5 | 128.5 | 135 |

| Power source | 3PH~380V/415V/480V~50HZ/60HZ(3PH~200V/220V 50HZ/60HZ) | ||||||||||||

| Refrigerant | Type | R22/R407C/134a/404A/410A | |||||||||||

| Control | Capillary / Thermostatic expansion valve | ||||||||||||

| Compressor | Type | Hermetic scroll ( piston ) | |||||||||||

| Power(KW) | 4.55×3 | 8.96×2 | 4.55×4 | 10.8×2 | 5.25×4 | 13.62×2 | 8.96×3 | 18.78×2 | 8.96×4 | 23.6×2 | 10.8×4 | 27.4×2 | |

| Condenser | Type | Efficient finned copper tube with aluminum+low noise external rotor fan | |||||||||||

| Air flow (m³/h) | 15000 | 20000 | 20000 | 25000 | 25000 | 30000 | 30000 | 40000 | 40000 | 50000 | 50000 | 60000 | |

| Air blower(KW) | 0.6×2 | 0.78×2 | 0.78×2 | 0.78×2 | 0.78×2 | 0.42×6 | 0.42×6 | 0.6×6 | 0.6×6 | 0.78×6 | 0.78×6 | 0.78×6 | |

| Evaporator | Type | SS Tank coil/ shell and tube type/Plate type heat exchanger | |||||||||||

| Chilled water (m³/h) | 7.22 | 10 | 9.6 | 11.69 | 11.62 | 14.94 | 15 | 19.6 | 19.95 | 23.8 | 23.4 | 29 | |

| 8.67 | 11.99 | 11.51 | 14.03 | 13.95 | 17.93 | 18 | 23.52 | 23.94 | 28.6 | 28.1 | 34.8 | ||

| Water tank(L) | 270 | 350 | 350 | 350 | 350 | 420 | 420 | 580 | 580 | 580 | 580 | 580 | |

| inlet/outlet pipe (inch) | 2″ | 2″ | 2″ | 2-1/2″ | 2-1/2″ | 2-1/2″ | 2-1/2″ | 3″ | 3″ | 3″ | 3″ | 3″ | |

| Water pump | Power(kw) | 2.2 | 2.2 | 2.2 | 2.2 | 2.2 | 4 | 4 | 4 | 4 | 5.5 | 5.5 | 5.5 |

| Max lift(m) | 28 | 28 | 28 | 28 | 28 | 30 | 30 | 30 | 30 | 32 | 32 | 32 | |

| Max flow (m³) | 25.2 | 25.2 | 25.2 | 25.2 | 25.2 | 36 | 36 | 36 | 36 | 40 | 40 | 40 | |

| Safety devices | Compressor inner protection, over current protection, high/low pressure protection, over temperature protection, flow rate protection, phase sequence/phase missing protection, low level coolant protection, anti freezing protection, exhaust overheat protection | ||||||||||||

| Dimension | L(mm) | 1860 | 2020 | 2020 | 2020 | 2020 | 2200 | 2200 | 2350 | 2350 | 2600 | 2600 | 2600 |

| W(mm) | 850 | 950 | 950 | 950 | 950 | 1150 | 1150 | 1350 | 1350 | 1500 | 1500 | 1500 | |

| H(mm) | 1900 | 2000 | 2000 | 2000 | 2000 | 1980 | 1980 | 2000 | 2000 | 2100 | 2100 | 2100 | |

| Net weight(KG) | 580 | 650 | 650 | 810 | 810 | 890 | 890 | 1112 | 1112 | 1320 | 1320 | 1320 | |

| Note: The above specifications are according to the following design conditions: 1, Chilled water inlet/outlet temperature 12℃/7℃. 2, Cooling air inlet/outlet temperature 33℃/38℃. We reserve the right to modify the specification without further notice. | |||||||||||||

| Industrial Chiller Technical Specifications | |||||||||||

| Model Items | AW-3W | AW-4W | AW-5W | AW-6W | AW-8WD | AW-10WD | AW-12WD | AW-15WD | AW-15WT | AW-20WD | |

| Cooling Capacity | kcal/h 50HZ/60HZ | 8170 | 11266 | 14018 | 16340 | 22532 | 28036 | 32680 | 43172 | 42140 | 56760 |

| 9804 | 13519 | 16822 | 19608 | 27038 | 33643 | 39216 | 51806 | 50568 | 68112 | ||

| KW 50HZ/60HZ | 9.5 | 13.1 | 16.3 | 19 | 26.2 | 32.6 | 38 | 50.2 | 49 | 66 | |

| 11.4 | 15.72 | 19.56 | 22.8 | 31.44 | 39.12 | 45.6 | 60.24 | 58.8 | 79.2 | ||

| Input Power | KW | 3.07 | 3.87 | 5.3 | 5.95 | 7.75 | 10.6 | 11.9 | 16.25 | 15.85 | 19.71 |

| Max Current | A | 7.5 | 9.4 | 12.9 | 14.4 | 18,8 | 25.7 | 28.9 | 39.4 | 38.2 | 47.8 |

| power source | 3PH~380V/415V/480V~50HZ/60HZ(3PH~200V/220V 50HZ/60HZ) | ||||||||||

| Refrigerant | Type | R22/R407C/134a/404A/410A | |||||||||

| Control | Capillary / Thermostatic expansion valve | ||||||||||

| Compressor | Type | Hermetic scroll ( piston ) | |||||||||

| Power(KW) | 2.7 | 3.5 | 4.55 | 5.2 | 3.5×2 | 4.55×2 | 5.2×2 | 7×2 | 4.55×3 | 8.96×2 | |

| Condenser | Type | Shell and tube/ SS plate type heat exchanger | |||||||||

| Cooling water (m³/h) | 2.1 | 2.9 | 3.6 | 4.2 | 5.7 | 7.1 | 8.3 | 11 | 10.8 | 14.4 | |

| 2.4 | 3.3 | 4.1 | 4.8 | 6.6 | 8.3 | 9.6 | 12.8 | 12.5 | 16.7 | ||

| Inlet/outlet pipe (inch) | 1 1/2″ | 1 1/2″ | 1 1/2″ | 1 1/2″ | 1 1/2″ | 1 1/2″ | 1 1/2″ | 2″ | 2″ | 2″ | |

| Evaporator | Type | SS Tank with cooper coil / Shell and tube/Plate heat exchanger | |||||||||

| Chilled water | 1.63 | 2.25 | 2.8 | 3.27 | 4.5 | 5.6 | 6.53 | 8.63 | 8.43 | 11.35 | |

| 1.96 | 2.7 | 3.36 | 3.92 | 5.4 | 6.73 | 7.84 | 10.36 | 10.1 | 13.62 | ||

| Water tank(L) | 60 | 60 | 60 | 90 | 150 | 200 | 200 | 330 | 330 | 330 | |

| inlet/outlet pipe (inch) | 1″ | 1″ | 1″ | 1″ | 1-1/2″ | 2″ | 2″ | 2″ | 2″ | 2″ | |

| Water pump | Power(kw) | 0.37 | 0.37 | 0.75 | 0.75 | 0.75 | 1.5 | 1.5 | 2.2 | 2.2 | 2.2 |

| Max lift(m) | 22 | 22 | 30 | 30 | 25 | 25 | 25 | 28 | 28 | 28 | |

| Max flow (m³) | 5.4 | 5.4 | 8.1 | 8.1 | 8.1 | 13.5 | 13.5 | 25.2 | 25.2 | 25.2 | |

| Safety protection | Compressor inner protection, over current protection, high/low pressure protection, over temperature protection, flow rate protection, phase sequence/phase missing protection, low level coolant protection, anti freezing protection, exhaust overheat protection | ||||||||||

| Dimension | L(mm) | 910 | 910 | 910 | 910 | 1250 | 1250 | 1250 | 1600 | 1600 | 1600 |

| W(mm)) | 480 | 480 | 480 | 480 | 680 | 680 | 680 | 750 | 750 | 750 | |

| H(mm)) | 1000 | 1000 | 1000 | 1000 | 1380 | 1380 | 1380 | 1600 | 1600 | 1600 | |

| Net weight(KG) | 125 | 135 | 160 | 180 | 230 | 260 | 330 | 420 | 420 | 460 | |

| Note: The above specifications are according to the following design conditions: 1, Chilled water inlet/outlet temperature 12℃/7℃. 2, Chiller temperature control range 5℃/35℃. We reserve the right to modify the specification without further notice. | |||||||||||

| Industrial Chiller Technical Specifications | |||||||||||

| Model Items | AW-20WF | AW-25WD | AW-25WF | AW-30WD | AW-30WT | AW-40WD | AW-40WF | AW-50WD | AW-50WF | AW-60WD | |

| Cooling capacity | kcal/h 50HZ/60HZ | 56072 | 66048 | 65360 | 83420 | 85140 | 114036 | 113520 | 134504 | 132096 | 169764 |

| 67286 | 79258 | 78432 | 100104 | 102168 | 136843 | 136224 | 161405 | 158515 | 203717 | ||

| KW 50HZ/60HZ | 65.2 | 76.8 | 76 | 97 | 99 | 132.6 | 132 | 156.4 | 153.6 | 197.4 | |

| 76.56 | 92.16 | 91.2 | 116.4 | 118.8 | 159.12 | 158.4 | 187.68 | 184.32 | 236.88 | ||

| Input power | KW | 20.4 | 23.8 | 23 | 30.99 | 30.63 | 41.31 | 39.59 | 52.7 | 48.7 | 59.3 |

| Max Current | A | 48.5 | 61.7 | 60 | 75.2 | 74.8 | 100.3 | 96.6 | 127.9 | 119.7 | 143.9 |

| Power Source | 3PH~380V/415V/480V~50HZ/60HZ(3PH~200V/220V 50HZ/60HZ) | ||||||||||

| Refrigerant | Type | R22/R407C/134a/404A/410A | |||||||||

| Control | Thermostatic expansion valve | ||||||||||

| Compressor | Type | Hermetic scroll ( piston ) | |||||||||

| Power(KW) | 4.55×4 | 10.8×2 | 5.2×4 | 13.62×2 | 8.96×3 | 18.78×2 | 8.96×4 | 23.6×2 | 10.8×4 | 26.9×2 | |

| Condenser | Type | Shell and tube/ SS plate type heat exchanger | |||||||||

| Cooling Water (m³/h) | 14.4 | 17 | 16.7 | 21.4 | 21.7 | 29.3 | 28.9 | 35 | 33.9 | 43.2 | |

| 16.6 | 19.6 | 19.3 | 24.7 | 25.1 | 33.8 | 34.4 | 40.4 | 39.1 | 50 | ||

| inlet/outlet pipe (inch) | 2″ | 2″ | 2 1/2″ | 2 1/2″ | 2 1/2″ | 3″ | 3″ | 3″ | 3″ | 4″ | |

| Evaporator | Type | SS Tank with cooper coil / Shell and tube/Plate heat exchanger | |||||||||

| Chilled Water (m³/h) | 11.21 | 13.21 | 13.1 | 16.68 | 17.02 | 22.8 | 22.7 | 26.9 | 26.41 | 33.95 | |

| 13.45 | 15.85 | 15.68 | 20.02 | 20.43 | 27.36 | 27.24 | 32.27 | 31.7 | 40.73 | ||

| Water Tank (L) | 330 | 350 | 350 | 450 | 450 | 580 | 580 | 620 | 620 | 620 | |

| inlet/outlet pipe (inch) | 2″ | 2″ | 2″ | 2-1/2″ | 2-1/2″ | 3″ | 3″ | 3″ | 3″ | 4″ | |

| Water pump | Power(kw) | 2.2 | 2.2 | 2.2 | 4 | 4 | 4 | 4 | 5.5 | 5.5 | 5.5 |

| Max lift(m) | 28 | 28 | 28 | 30 | 30 | 30 | 30 | 32 | 32 | 32 | |

| Max flow (m³) | 25.2 | 25.2 | 25.2 | 36 | 36 | 36 | 36 | 40 | 40 | 40 | |

| Safety protection | Compressor inner protection, over current protection, high/low pressure protection, over temperature protection, flow rate protection, phase sequence/phase missing protection, low level coolant protection, anti freezing protection, exhaust overheat protection | ||||||||||

| Dimension | L(mm) | 1600 | 1950 | 1950 | 1950 | 1950 | 2000 | 2000 | 2000 | 2000 | 2200 |

| W(mm) | 750 | 850 | 850 | 850 | 850 | 980 | 980 | 980 | 980 | 1100 | |

| H(mm) | 1600 | 1700 | 1700 | 1700 | 1700 | 1700 | 1700 | 1700 | 1700 | 1850 | |

| Net weight(KG) | 460 | 680 | 680 | 720 | 720 | 870 | 870 | 980 | 980 | 1120 | |

| Note: The above specifications are according to the following design conditions: 1, Chilled water inlet/outlet temperature 12℃/7℃. 2, Chiller temperature control range 5℃/35℃. We reserve the right to modify the specification without further notice. | |||||||||||

Why TopChiller is Your Reliable Industrial Chiller Manufacturer and Supplier In China?

Industrial Chiller-An Ultimate FAQ Guide by TopChiller.

- What is an Industrial Chiller?

- What are the Features of an Industrial Chiller?

- What are the Types of an Industrial Chiller?

- What is the Working Principle of an Industrial Chiller?

- What are the Significant Applications of an Industrial Chiller?

- What are the Major Components of an Industrial Chiller?

- What are the Compressor Types Used in an Industrial Chiller?

- What is the Function of an Evaporator in an Industrial Chiller?

- What are the Advantages of Using an Industrial Chiller for your Business?

- What is the Difference Between a Vapour Compression and a Vapour Absorption Industrial Chiller?

- How to Avoid Overheating of your Industrial Chiller?

- How to Select the Best Size of an Industrial Chiller for your Application?

- How to Calculate the Cooling Capacity of your Industrial Chiller?

- How to Choose the Most Suitable Industrial Chiller for your Applications?

- How to Make your Industrial Chiller Long Lasting?

- What is the Heat Load of an Industrial Chiller?

- What is the Calibration of an Industrial Chiller?

- What Types of Maintenance are Required for your Industrial Chiller?

- How to Increase the Efficiency of your Industrial Chiller?

- How to Troubleshoot the Problems of your Industrial Chiller?

What is an Industrial Chiller?

An Industrial Chiller is a dedicated device for controlling and monitoring the temperature of industries by producing cooling. It helps obtain the maximum output since the application receives the optimum temperature.

Another function is to displace the heat to be no harm to the running machinery in the area. The heating up of machines can lead to poor performance and long-term damage, which must be avoided by reducing the heat.

Sometimes, the industrial process itself produces heat which makes the environment uncomfortable and must be removed.

An Industrial Chiller uses either water or air as a cooling agent and works in harmony with the industry. You can install it inside the industry or outside since it is well adapted to all kinds of weather changes.

It needs little maintenance, and the refrigeration cycle serves the purpose without any additional requirement.

Industrial Chiller Designed by TopChiller

What are the Features of an Industrial Chiller?

An Industrial Chiller comes with the following excellent features:

- A logging facility is available.

- The microprocessor unit is extremely powerful and reliable, equipped with advanced technology.

- Industrial Chiller is energy-saving and cost-effective.

- The maintenance requirement is small and is very user-friendly.

- You can easily avail of it at a very affordable price with energy-efficient technology.

- Compressor choices can be made, and other customization offers are also available.

- Quick and easy installation procedure.

- It does not produce much noise and vibration; thus very convenient to use even in unpopulated areas.

- There is an automatic tube cleaning facility which helps to increase the lifespan significantly.

What are the Types of an Industrial Chiller?

In terms of application, the types are as follows:

- Laser Chiller

- Glycol Chiller

- Plastic Chiller

- Brewery Chiller

- Waterjet Chiller

- Styrene Chiller

- Anodizing and Plating Chiller

- Medical Chiller

Industrial Chiller can also be categorized based on the compressor being used:

- Semi-Hermetic Scroll

- Semi-Hermetic Screw

- Reciprocating

Another classification is done on the basis of temperature control range:

High-Temperature Industrial Chiller

The conventional refrigerant must have a range of 5 to 30 degrees. It is the most extensively used type since most of the applications fall in this category.

Medium Temperature Industrial Chiller

It works at 0 to -15 degrees and therefore requires a cryogenic chilling liquid. Ethylene glycol is the best choice here.

Low-Temperature Industrial Chiller

The temperature range is -15 to -35. It is usually for the pharmaceutical and chemical industries.

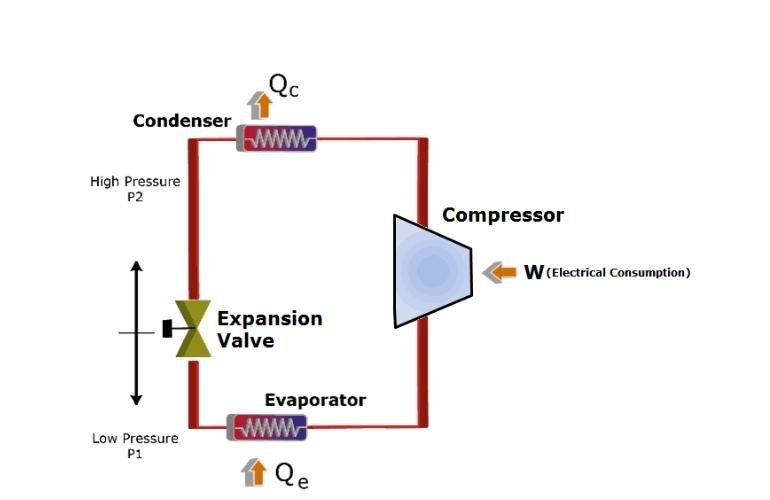

What is the Working Principle of an Industrial Chiller?

The working principle of an Industrial Chiller is based on either an open or a closed loop. The cooling process begins from the evaporator. The refrigerant, which is flowing through the tubes, is evaporated in the evaporator.

The refrigerant absorbs the heat produced in this process, and the water is cooled, which is sent back to the process.

Now the refrigerant in the form of vapors is sent to the compressor, which compresses it and turns it back into the liquid form, increasing the pressure and temperature.

The high-pressure refrigerant then goes to the condenser, where the heat is removed by using air or water. In this way, the refrigerant is turned back into its original form.

The cooling continues until the refrigerant reaches the expansion valve, where the pressure is dropped, and the remaining refrigerant is boiled off.

These three fundamental principles are used throughout the cycle:

- Compressor-Adiabatic Compression

- Condenser- Exothermic Process

- Evaporator- Endothermic Process

What are the Significant Applications of an Industrial Chiller?

The significant applications of an Industrial Chiller include:

Plastic Industry

The hot plastic which needs to be blown, stamped, and injected must be cooled down, and therefore an Industrial Chiller is required.

The gearbox, barrel of the extruder, and the hydraulics of the molding machine also require cooling down and working in a narrow temperature range.

Injection Molding

The most important part of molding is cooling the melted plastic poured into the mold. It cools and solidifies later.

If it is not cooled properly, the outcome would be a poor quality product as 90% of the cycle depends upon cooling.

Thermoforming

This process is for the production of disposable lids, containers, trays, cups, etc. This process requires molten plastic to pass through a thermoforming machine. It is then solidified with the help of mating mold and a pressure box.

A vacuum is also used to suck all the extra air to get the product in the desired shape.

Food Industry and Baking

Food needs to be stored at an optimum temperature, and the different food processing techniques also require a narrow range temperature maintained by Industrial Chiller.

Brewing

The brewing and beverage industry uses regulated temperatures to produce and store various beverages. A definite temperature is necessary to obtain the best results for any brewing process.

Pharmaceutical

Such industries have huge plants to manufacture drugs formed through sensitive chemical reactions.

Medical

In hospitals and medical laboratories, aside from MRI machines, there are C T scan machines, medical lasers, bolograph systems, blood analyzers, and linear accelerators, which need a controlled temperature, which is only possible by an Industrial Chiller.

What are the Major Components of an Industrial Chiller?

The major components of an Industrial Chiller are as follows:

Evaporator

As evaporation is a cooling process, the refrigerant is evaporated, and the heat is liberated to control the temperature.

Compressor

It increases the pressure on the refrigerant and reduces the distance between the particles lowering the volume.

Condenser

The condenser converts the refrigerant back into its original form by turning it into a liquid from a gaseous state.

Expansion valves

As the refrigerant is allowed to expand, cooling is produced, and it is utilized to cool down the water and air, which is being used as a cooling agent.

Cooling Tower

These are only used in Water Cooled Industrial Chiller as it needs a good water reservoir. It is not necessary to keep it inside the industry, and it is mainly planted outside or on the roof.

You might need to use antifreeze to prevent the water from freezing in the tank and the pipes for extremely cold places.

Refrigerant

It is also an essential component because it plays a central role in the refrigeration cycle. The quality and level of the refrigerant must be kept under strict check.

What are the Compressor Types Used in an Industrial Chiller?

The most commonly used compressor in an Industrial Chiller are listed below:

Rotary/Screw Compressor

These compressors are of low capacity and cannot be used for more significant applications; however, they are suitable for small industries.

Centrifugal Compressor

It uses centrifugal force to compress the fluid and move very fast. High-volume refrigerants can be used, and their compression rates are low.

Reciprocating Compressor

It has cylindrical pistons that are further divided into hermetic compressors and open compressors.

It uses electric motors and combustion engines to deal with high-pressure gases.

Scroll Compressor

There are two scrolls, a fixed and a moving one. The fixed is attached to the compressor’s body, and the moving one follows the directions of the stationary scroll.

Industrial Chiller Scroll Compressor

What is the Function of an Evaporator in an Industrial Chiller?

The evaporator works as the essential cooling point because it evaporates the refrigerant. As the refrigerant evaporates, each one of its molecules takes the energy from the system and breaks free, leaving low energy behind.

Low energy refers to low temperature and thus cooling. On the other hand, the refrigerant which has just broken off from the system possesses higher energy and thus tends to be at a higher temperature.

What are the Advantages of Using an Industrial Chiller for your Business?

The outstanding advantages of using an Industrial Chiller have been listed below:

- Maintains and regulates the temperature within a narrow range.

- It keeps the environment comfortable for the staff to work in.

- Keep working machinery running by lowering the heat production and displacing the heat produced.

- Decreases the chance of damage to the machinery caused by overheating.

- Lowers the chance of fire ignition in the working environment.

- Provides maximum efficiency for your applications, and you can obtain the best quality product at a specific temperature.

- Keeps the temperature optimum for any application. For example, if you require freezing temperature for storage of food, but can be obtained in no time.

Biodegradable Refrigerant for Industrial Chiller

What is the Difference Between a Vapour Compression and a Vapour Absorption Industrial Chiller?

The difference between vapor compression and vapor absorption Industrial Chiller is as follows:

Coefficient of Performance

The vapor compression type has a higher coefficient of performance, and the vapor absorption-type has a lower.

Charging of Refrigerant

The former has a simple refrigerant charging, whereas the latter needs a complex procedure.

Leakage Possibility

There is a greater leakage possibility in vapor compression type and vice versa in vapor absorption type.

Effect of Part Load

There is a decrease in the performance at part load in the case of vapor compression.

Location

The vapor compression type is more suitable for indoor installation as it is less bulky and requires shelter, while the other is suitable for outdoor installation.

Wear and Tear

The former has a lot more wear and tear, and it uses high-grade work energy compared to the latter.

Industrial Chiller Vapor Compression System

How to Avoid Overheating of your Industrial Chiller?

To avoid overheating of your Industrial Chiller, opt for the following points:

- Always use good quality refrigerant which is biodegradable.

- Please keep checking the refrigerant level and never let it go below the indicated limit.

- Maintain a stable water connection to provide ample amounts of water.

- Keep a check on the writing and its insulation. Make sure all the wires are insulated.

- There shall be no obstruction in the refrigeration cycle. Carry out an inspection to rule out any such obstruction in the duct system.

- Your Industrial Chiller must be placed in a well-ventilated area to allow maximum airflow and prevent the usage of the same hot air again and again.

- It is better to place it outside in the open air as it receives good ventilation in this way.

How to Select the Best Size of an Industrial Chiller for your Application?

To select the best size of an Industrial Chiller, you must keep the following things in mind:

- Site of Installation

- Size of your Industry

- Water-Cooled or Air-Cooled Type

- Temperature Requirements

- The Capacity of the Industrial Chiller

The temperature difference between the inlet temperature of the medium of cooling and the required temperature of the medium of cooling must be calculated to find out the ΔT°F.

This is to calculate the cooling capacity in units of BTU/hr.

The formula used is:

BTU/hr = Gallons per hour x 8.33 x ΔT°F

The BTU per hour needs to be converted into tons. This can be done by dividing it by 12000.

You can calculate the best size of your Industrial Chiller in tons by oversizing it by 20% as;

The best size according to your requirements = Tons x 1.2.

How to Calculate the Cooling Capacity of your Industrial Chiller?

The cooling capacity refers to the ability of the Industrial Chiller to produce cooling.

The given formula can calculate it;

Q = ṁ x Cp x ΔT

The temperature must be converted into Kelvin by adding 273.15K to celsius.

The specific heat capacity denoted by Cp is measured in units of kJ per kg per kelvin.

How to Choose the Most Suitable Industrial Chiller for your Applications?

To choose the most suitable Industrial Chiller, go for the following steps:

Consider your Application Demands

According to your application, look for an Industrial Chiller in size and efficiency.

Site

If you have to place it indoors, consider a one. However, if you place it outside, a bigger one won’t do any harm.

Availability of Water

A water-cooled type Industrial Chiller is only suitable if you have plenty of water available on the site.

If your industry is in an area with a scanty supply of water, you might need to spend more on water purchases, which turns out to be very inconvenient.

Low Maintenance

Make sure that your chiller needs minimum maintenance. An air-cooled type does not require much maintenance because it does not require water storage and extra piping.

Reviews

Always look up reviews online or talk to others using these devices before. Do your research about each model, and then go for the one which suits you the most.

Biodegradability

It is essential to see that the refrigerant being used is environmentally friendly. Otherwise, it can be a significant health hazard.

How to Make your Industrial Chiller Long Lasting?

To make your Industrial Chiller long-lasting, consider the given points:

Cleanliness and Maintenance

Any built-up debris or dust in the pipelines due to insufficient cleaning can lead to obstruction in the flow, leading to decreased performance and long-term damage.

There must be a thorough maintenance routine after a month. An inspection must be carried out to check any damages that should be fixed before they impact the overall performance.

Site of Installation

The site shall be chosen wisely. It must be high above the ground. There shall not be any other machinery very close to your Industrial Chiller.

Water Source

Good water supply leads to better performance and higher efficiency. Make sure you set up a stable water supply to receive the desired cooling effect.

Refrigerant

Only an environment-friendly refrigerant shall be used so that there is no harm to the environment and no addition to pollution.

Also, these refrigerants are of good quality and require one-time investment only.

Ventilation

Suppose you install it in a well-ventilated area. In that case, there are significant chances of increased life span because it keeps on receiving good quality air, and there is no disturbance in the refrigeration process.

Maintain the Daily Register

Keep monitoring your chiller to see if it is working correctly. Maintain a historical record of its operational performance.

It will help analyze operational conditions such as pressures, fluid rates, temperatures, and fluid levels.

Condenser Water Treatment

Prevention of corrosion and algae in the condenser water is essential. It can be avoided by treating the water with suitable chemicals.

Flow Rate Adjustment

The flow rate must be adjusted and maintained very precisely.

Fix the Damages

If you see that something is out of the required parameters or not working correctly, get it fixed or changed as soon as possible.

Maintain the Daily Register for your Industrial Chiller

What is the Heat Load of an Industrial Chiller?

It refers to the cooling demand of the application before the Industrial Chiller is being used. If your chiller is operating at its maximum cooling capacity, the heat load is said to be a full load.

Although it provides high efficiency, it leads to early exhaustion and cannot be run for extended periods.

On the other hand, the part load means that your Industrial Chiller operates at a capacity lower than its maximum capacity. It is for maximum applications.

Also, there are fewer chances of exhaustion and burnout, leading to overheating. It provides greater efficiency for more extended periods.

What is the Calibration of an Industrial Chiller?

It refers to the grading and numbering to check the level or measure it on a specific scale.

It can be done on any measuring instrument, sensors, and sensitive equipment by comparing it to a standard measuring instrument.

Accurate measurements must evaluate the performance of your Industrial Chiller. It will help detect any deceleration in the performance, and early detection can help save the system from more significant losses.

You can obtain more precise results about careful calibration.

What Types of Maintenance are Required for your Industrial Chiller?

Two types of maintenances are required for maximum productivity of your Industrial Chiller:

Preventive Maintenance

This is the maintenance routine you should opt to prevent any damage or loss or the emergence of any defect.

It includes all the practices that you must do daily and comprises the following points

- Check the level of oil and the refrigerant.

- Keep a record of the performance.

- Provide best conditions in terms of temperature, airflow, and ventilation.

- Maintain a suitable and sufficient water supply.

- Use chemical water treatment.

- Only use high-quality refrigerants.

- Keep a check on the microprocessor unit.

- Only allow a trained person to operate it.

- Keep a check on the wiring and insulation.

- Clean all the pipes and dust thoroughly so that there is no accumulation of debris.

- Install a filter for air and water so that no dirt can enter the system in the first place.

Corrective Maintenance

This is required when your Industrial Chiller faces a problem and must be corrected immediately.

If there is a defect in any part of the system, immediately fix it or change it to restore maximum performance. This type of maintenance is unscheduled and requires immediate attention.

Industrial Chiller Maintenances

How to Increase the Efficiency of your Industrial Chiller?

There should be a proper maintenance routine for your Industrial Chiller, which must be repeated weekly, monthly, and annually according to the requirement.

- Check the level of the refrigerant.

- Inspect the quality of the refrigerant.

- A thorough inspection of all the ducts shows any dirt and debris accumulation.

- Check all the insulation.

- Fix the damages as soon as they appear.

- Compare the performance in different weather conditions and refrigerants to choose the most appropriate one.

- Keep the system clean all the time.

- Make sure you install it on a higher level from the ground.

Install your Industrial Chiller on a Higher Level From the Ground

How to Troubleshoot the Problems of your Industrial Chiller?

Problems of Power

It might be due to:

- Loose connection or low voltage from the electricity supply

- If your Industrial Chiller is a phase 3 system, and you have an incorrect phase sequence, it might fail to power

- There might be some blown fuse or circuit tipping

- The switch button might be defective

How to Fix it

- Check all the connections

- See if you have switched on the power button

- Maintain a stable electricity supply

- Change the fuse in case of any tipping

Low Fluid Flow

It might be due to:

- The fluctuating voltage or improper voltage

- The reservoir might be out of the fluid

- High ambient temperature

- The evaporator is iced up

- There might be some obstruction in the pipelines

- Any closed valves or defective valves can lead to this

- The cooling fluid is not matching the temperature conditions

- The fuel filter might be choked or blocked

- They clogged air filters or condensers

How to fix it

- Make sure the pipeline is patent

- Check all the valves

- Check the electricity connection

- Maintain the fluid level

- Use antifreeze and maintain the conditions for maximum flow

Water Leakage

The causes of leakage can be:

- High ambient temperature

- Iced up evaporator

- Leaky pump

- Damaged ball valve or shunt

How to Fix

- Adjust the temperature for the best working

- Replace the leaky pipes

- Change the damaged valves

High-Pressure Alarm Sound

Causes include

- The air in the system

- Excessive refrigerant level

- The expansion valve opening is too small or damaged

- The cooling water valve is open

- Narrow cooling water flows pipe

- The cooling water temperature is very high

- Excessive refrigerant

How to Fix

Check the system thoroughly and fix the arising problem