TopChiller can design and manufacture all types of air cooled chillers for you

- Cooling capacity ranges from 5 Ton to 200 Ton

- Temperature control ranges from 5°C to 35°C

- World-class scroll or screw-type compressor

- Corrosion-free wetted surfaces and valves

- Polyethylene coated tank & smart controller

- Hot gas bypass and variable speed fans

- Environment-friendly CFC free refrigerant

- Protecting devices across the cooling load

Your Premier Air Cooled Chiller Manufacturer and Supplier in China

Air Cooled Chiller is a cooling device that works on evaporation and refrigeration principle to escape the heat from industrial applications by using air-cooled circulation around the condenser unit.

TopChiller is the best company in China that earned global fame by manufacturing energy-efficient and certified Air Cooled Chiller for the whole world since 1999.

TopChiller is constantly in action for manufacturing a full stock of Air Cooled Chiller on increasing demands by our customers and world-famous companies for over last twenty years of magnificent experience.

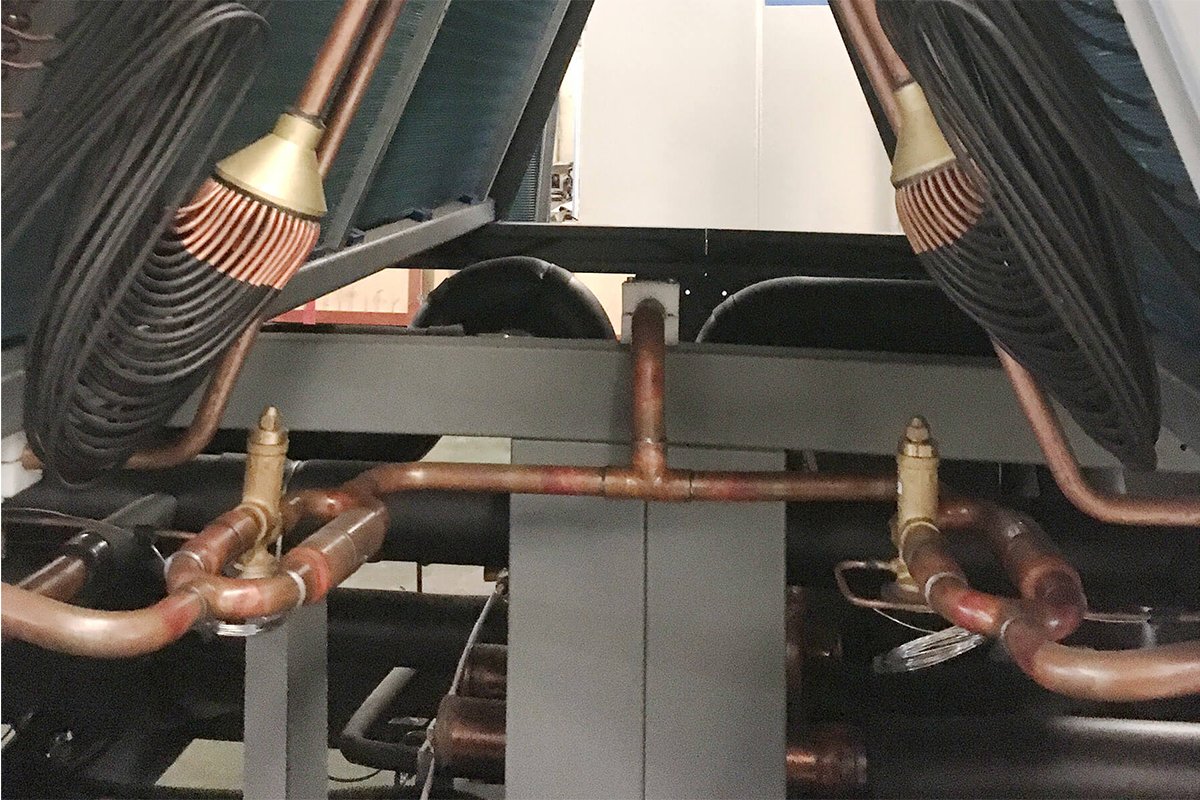

Air Cooled Chiller is primarily made of different branded components as scroll/screw compressor, energy-efficient condenser, CFC free refrigerant, hot gas bypass, protection devices, stainless steel heat exchanger, electric supply, PID controller, and storage tank.

TopChiller brand Air Cooled Chiller is used for different industries having outstanding benefits as given below:

- Air Cooled Chiller has a lower cost of maintenance configured by the installation of hot gas bypass that prevents the compressor and coils of the unit from high pressure and heat load damages by stabilizing the refrigerant flow by its valve.

- TopChiller designed Air Cooled Chiller ensures the efficient and instant heat release from machine configured by use of chilled air circulation around the condenser that quickly absorbs the heat from the condenser producing cooling effect.

- Air Cooled Chiller is featured with cooling fans attached to the condenser and evaporating tube that directly leads heat to gather at condenser for final discharge as by absorbing heat process water gets evaporated and releases out heat by expansion fans.

- TopChiller engineered Air Cooled Chiller has a compact design, occupying a lower place configured by the absence of water tank and water pumps inside the unit.

- Air Cooled Chiller is environment friendly with the installation of CFC-free refrigerant preventing ozone layer from depletion.

Air Cooled Chiller is efficient in heating discharge, utilized for a wide number of applications as given below:

HVAC system, commercial industries, hotels, hospitals, food processing, clinical labs, medical industry, plastic industry, pharmaceutical industry, and drugs designing, etc.

If you are planning to buy a compact design, low space requiring Air Cooled Chiller for your application?

If you are facing water scarcity and desiring an associative relationship with a company manufacturing Air Cooled Chiller for the development and flourishment of your business?

TopChiller is a worldwide company that supports greatly to customers. You can rely on it to meet your needs. TopChiller team is servicing our customers for 24 hours. Make contact with TopChiller experts if you want to purchase an Air-Cooled Chiller or other technical help.

TopChiller team will approach you within no time and guide you properly to size Air Cooled Chiller at reasonable rates for your application.

General Description:

Air Cooled Chiller refers to a useful cooling device used to remove excess heat, provide HVAC function and maintain the optimum temperature in industrial applications. The primary cooling source is chilled water, and the heat is removed by using ambient air currents.

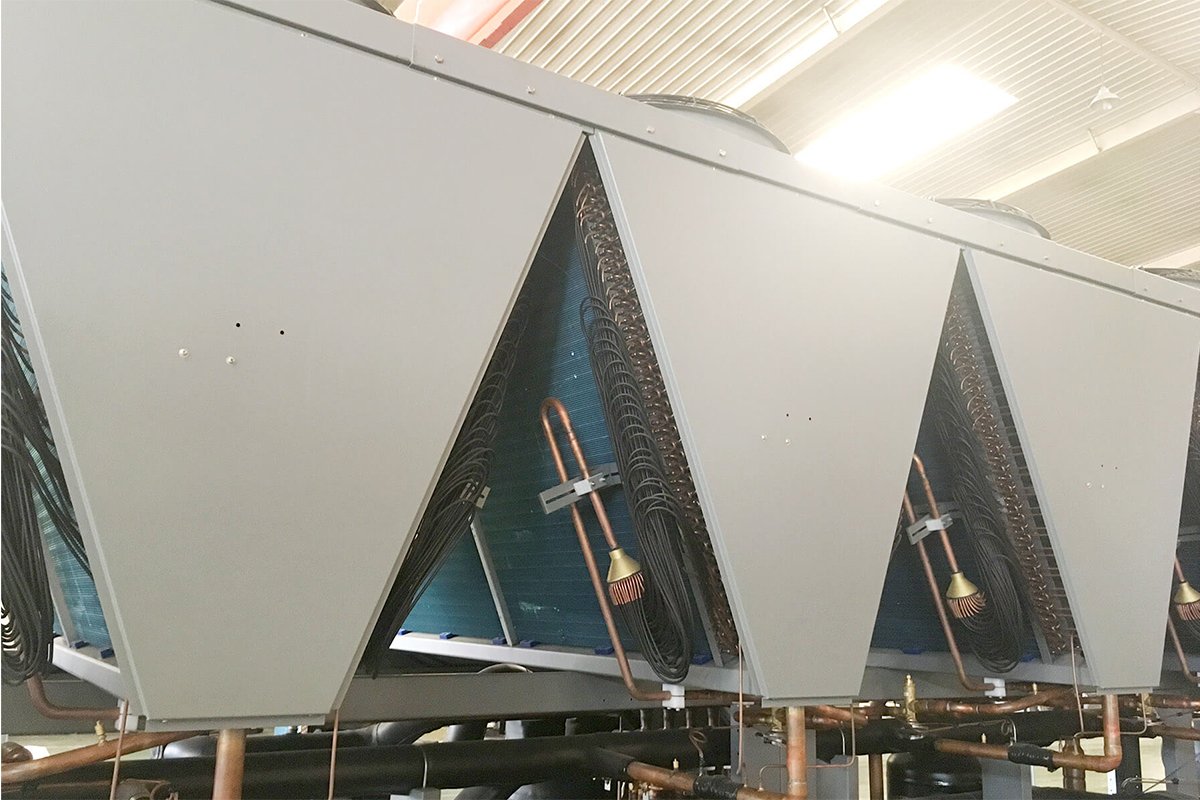

Air Cooled Chiller manufactured by TopChiller contains significant components, including a compressor, evaporator, condenser, fans, and expansion valve. It comes in different configurations, and you can add up the compressors in a series or parallel manner to obtain higher efficiency.

Due to the wide range of features and advantages, Air Cooled Chiller designed by TopChiller is being used in the laser industry, food factories, electroplating plants, plastic manufacturing, medical, industrial and commercial buildings.

TopChiller is the top brand of China that earned global fame by manufacturing energy-efficient and certified air cooling systems since 1999. With over 20 years of rich experience, we have succeeded in making our name in the market worldwide. The variety of Air Cooled Chiller is extensive, and our inventory is continuously updated with the latest technology models.

You can contact our sales team for getting access to our highly rated Air Cooled Chiller models. Our customer service is open 24/7 to provide professional guidelines, maintenance and installation services.

Features and Advantages:

Air Cooled Chiller manufactured by TopChiller contains the following features and advantages:

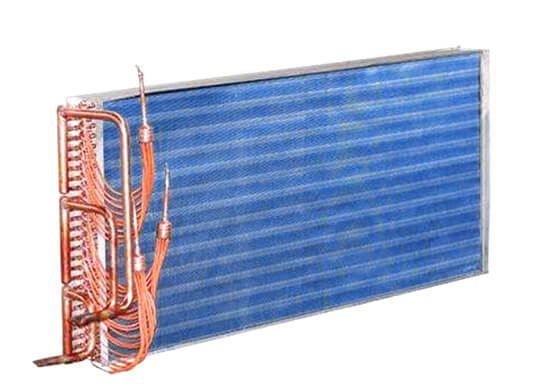

- The aluminium fin condenser is huge and coated with a resin coating which helps to decrease corrosion. A SUS304 immersion coil evaporator also provides excellent stability and convenience, thus making maintenance and cleaning easier.

- Motors are entirely encompassed air over (TEAO) six shafts with class ‘F’ protection and IP55 safety, which promises enhanced life and are distinctive to cooling.

- The covering of the Air Cooled Chiller is manufactured with zinc-coated jolt steel, which is treated with phosphoric acid and then heated after layering of electrostatic powder of about 60 microns.

- A built-in hydronic buffer tank that has a large pump. Valves are installed at the inlet and outlet to adjust the water pressure. It enables you to have an obstruction-free, low maintenance function.

- Partially airtight compressors utilize oil vision glass valves to provide release and suction and a crankshaft heater. All coils of standard levels consist of 3 or 4 columns /12FPI, ⅜ “O. D tubes.

- Data Sheet

- Image Gallery

- Main Parts

- Video

| Air Cooled Chiller Technical Specifications | ||||||||||||||

| Model Items | TPAS-80ASH | TPAS-110ASH | TPAS-140ASH | TPAS-160ASH | TPAS-190ASH | TPAS-210ASH | TPAS-250ASH | TPAS-290ASH | TPAS-310ASH | TPAS-340ASH | TPAS-400ASH | TPAS-430ASH | ||

| Cooling capacity | kcal/h | 68800 | 94600 | 122980 | 135020 | 164260 | 180600 | 212420 | 245100 | 266600 | 292400 | 348300 | 369800 | |

| KW | 80 | 110 | 143 | 157 | 191 | 210 | 247 | 285 | 310 | 340 | 405 | 430 | ||

| Input power | KW | 32.5 | 43.6 | 54.7 | 59.7 | 73.6 | 79.6 | 88.2 | 101.2 | 112.8 | 123.8 | 145 | 155 | |

| Max Current | A | 57 | 75 | 95 | 103 | 125 | 135 | 151 | 173 | 191 | 211 | 246 | 263 | |

| Power source | 3PH~380V/415V/480V~50HZ/60HZ(3PH~200V/220V 50HZ/60HZ) | |||||||||||||

| Refrigerant | Type | R22(R134a/R407c/R404A) | ||||||||||||

| Charge | kg | 21 | 28 | 35 | 42 | 49 | 56 | 63 | 70 | 77 | 84 | 98 | 112 | |

| Control | Thermostatic expansion valve | |||||||||||||

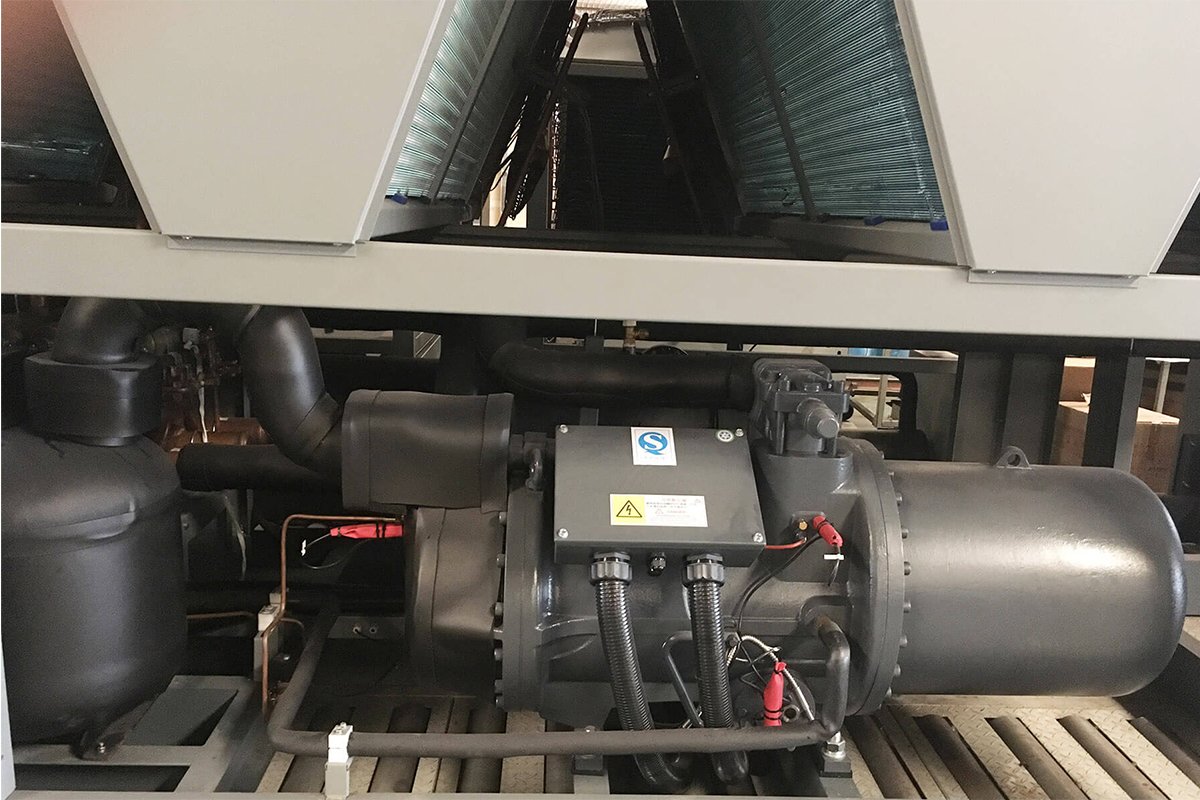

| Compressor | Type | Semi-hermetic screw | ||||||||||||

| Power | KW | 30 | 40 | 50 | 55 | 67 | 73 | 82 | 95 | 104 | 115 | 134 | 142 | |

| Start mode | Y-△ | |||||||||||||

| Capacity control | % | 0-33-66-100 | 0-25-50-75-100 | |||||||||||

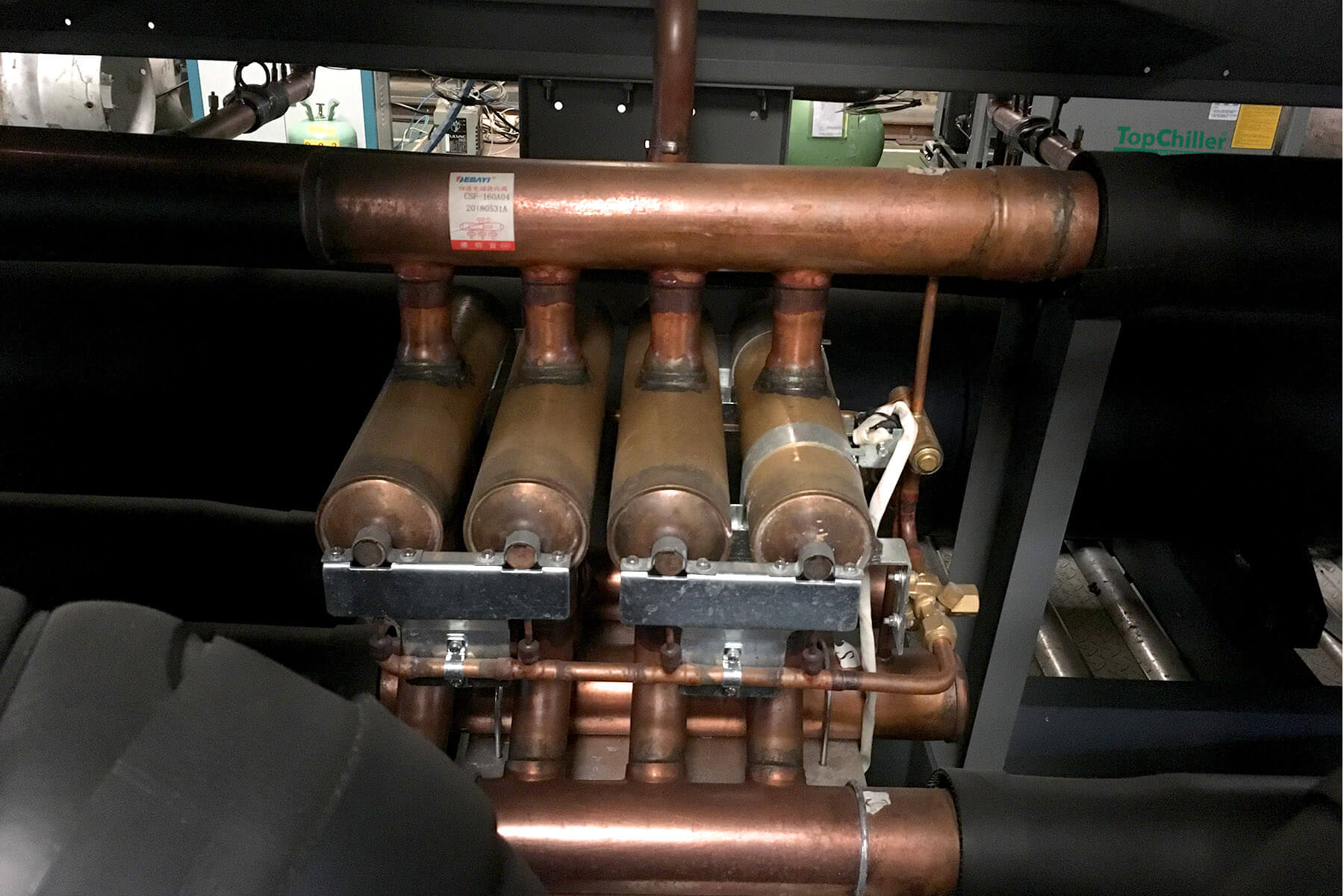

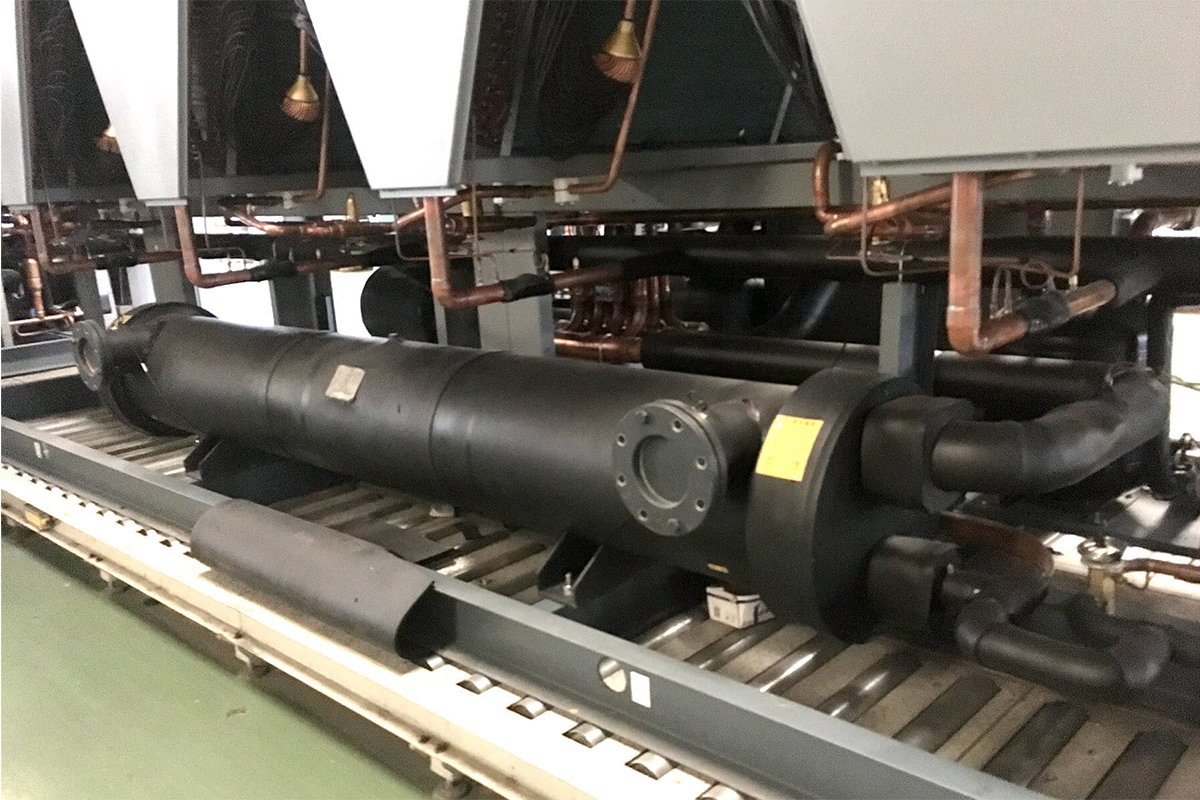

| Evaporator | Type | Shell and tube (SS plate heat exchanger) | ||||||||||||

| Chilled water | m³/h | 13.8 | 18.9 | 24.6 | 27.0 | 32.8 | 36.1 | 42.5 | 49.0 | 53.3 | 58.4 | 70.0 | 74.0 | |

| Water pressure | KPa | 32 | 32 | 35 | 38 | 42 | 42 | 45 | 43 | 43 | 43 | 41 | 43 | |

| Pipe connection | Inch | 3″ | 3″ | 3″ | 4″ | 4″ | 4″ | 4″ | 4″ | 5″ | 5″ | 6″ | 6″ | |

| Condenser | Type | Air cooled type high efficiency finned cooper tube | ||||||||||||

| Fan | Type | m³/h | Big volume & low noise axil fan | |||||||||||

| Power | KW | 0.42×6 | 0.6×6 | 0.78×6 | 0.78×6 | 1.1×6 | 1.1×6 | 0.78×8 | 0.78×8 | 1.1×8 | 1.1×8 | 1.1×10 | 1.1×12 | |

| Air volume | m³/h | 30000 | 40000 | 50000 | 60000 | 70000 | 80000 | 90000 | 100000 | 110000 | 116000 | 145000 | 165000 | |

| Safety protection devices | Inner thermostat for compressor motor, unit overload relay,high and low pressure switch, freeze protection thermostat, reverse phase protection relay, discharge gas thermostat, flow switch | |||||||||||||

| Dimension | Length | mm | 2200 | 2350 | 2600 | 2600 | 2650 | 2650 | 3400 | 3400 | 3800 | 3800 | 4800 | 5800 |

| Width | mm | 1150 | 1350 | 1500 | 1500 | 1900 | 1900 | 1700 | 1700 | 1900 | 1900 | 1900 | 1900 | |

| Height | mm | 1980 | 2000 | 2100 | 2100 | 2200 | 2200 | 2200 | 2200 | 2200 | 2200 | 2200 | 2200 | |

| Net weight | kg | 1100 | 1300 | 1600 | 1900 | 2200 | 2350 | 2550 | 2800 | 2850 | 2950 | 3200 | 3550 | |

| Running weight | kg | 1300 | 1500 | 1840 | 2200 | 2530 | 2700 | 2950 | 3250 | 3350 | 3560 | 3650 | 3950 | |

| The above specifications are according to the following design conditions: 1, Chilled water inlet/outlet temperature 12℃/7℃. 2, Cooling air inlet/outlet temperature 30℃/38℃. We reserve the right to modify the specifications without further notice. | ||||||||||||||

| Air Cooled Chiller Technical Specifications | ||||||||||||||

| Model Items | TPAS-160ADH | TPAS-220ADH | TPAS-285ADH | TPAS-315ADH | TPAS-380ADH | TPAS-420ADH | TPAS-495ADH | TPAS-570ADH | TPAS-620ADH | TPAS-680ADH | TPAS-810ADH | TPAS-860ADH | ||

| Cooling capacity | kcal/h | 137600 | 189200 | 245960 | 270040 | 328520 | 361200 | 424840 | 490200 | 533200 | 584800 | 696600 | 739600 | |

| KW | 160 | 220 | 286 | 314 | 382 | 420 | 494 | 570 | 620 | 680 | 810 | 860 | ||

| Input power | KW | 64.7 | 86.6 | 106.2 | 118.8 | 145 | 159.2 | 177.2 | 207.6 | 225.6 | 247.6 | 290 | 310.4 | |

| Max Current | A | 114 | 149 | 185 | 205 | 250 | 274 | 308 | 358 | 388 | 428 | 500 | 533 | |

| Power Source | 3PH~380V/415V/480V~50HZ/60HZ(3PH~200V/220V 50HZ/60HZ) | |||||||||||||

| Refrigerant | Type | R22(R134a/R407c/R404A) | ||||||||||||

| Charge | kg | 21×2 | 28×2 | 35×2 | 42×2 | 49×2 | 56×2 | 63×2 | 70×2 | 77×2 | 84×2 | 98×2 | 112×2 | |

| Control | Thermostatic expansion valve | |||||||||||||

| Compressor | Type | Semi-hermetic screw | ||||||||||||

| Power | KW | 30×2 | 40×2 | 50×2 | 55×2 | 67×2 | 73×2 | 82×2 | 95×2 | 104×2 | 115×2 | 134×2 | 142×2 | |

| Start mode | Y-△ | |||||||||||||

| Capacity control | % | 0-33-66-100 | 0-25-50-75-100 | |||||||||||

| Evaporator | Type | Shell and tube (SS plate heat exchanger) | ||||||||||||

| Chilled water | m³/h | 27.5 | 37.8 | 49.1 | 54 | 65.7 | 72.2 | 85 | 98 | 106.6 | 117 | 139.3 | 147.9 | |

| Water pressure | KPa | 32 | 32 | 35 | 38 | 42 | 42 | 45 | 43 | 43 | 43 | 41 | 43 | |

| Pipe connection | Inch | 4″ | 4″ | 4″ | 5″ | 6″ | 6″ | 6″ | 6″ | 8″ | 8″ | 8″ | 10″ | |

| Condenser | Type | Air cooled type high efficiency finned cooper tube | ||||||||||||

| Fan | Type | m³/h | Big volume & low noise axil fan | |||||||||||

| Power | KW | 0.78×6 | 1.1×6 | 0.78×8 | 1.1×8 | 1.1×10 | 1.1×12 | 1.1×12 | 1.1×16 | 1.1×16 | 1.1×16 | 1.1×20 | 1.1×24 | |

| Air volume | m³/h | 60000 | 80000 | 100000 | 116000 | 145000 | 165000 | 180000 | 205000 | 225000 | 242000 | 285000 | 325000 | |

| Safety protection devices | Inner thermostat for compressor motor, unit overload relay, high and low pressure switch, freeze protection thermostat, reverse phase protection relay, discharge gas thermostat, flow switch | |||||||||||||

| Dimension | Length | mm | 2600 | 2650 | 3400 | 3800 | 4800 | 5800 | 5800 | 7800 | 7800 | 8000 | 9800 | 11600 |

| Width | mm | 1500 | 1900 | 1700 | 1900 | 1900 | 1900 | 2200 | 2000 | 2200 | 2200 | 2200 | 2200 | |

| Height | mm | 2100 | 2200 | 2200 | 2200 | 2200 | 2200 | 2300 | 2250 | 2250 | 2300 | 2350 | 2350 | |

| Net weight | kg | 2050 | 2520 | 2980 | 3180 | 3420 | 3730 | 3950 | 4330 | 4650 | 4930 | 5450 | 5850 | |

| Running weight | kg | 2360 | 2870 | 3420 | 3690 | 3780 | 4180 | 4380 | 4650 | 4920 | 5360 | 5830 | 6530 | |

| The above specifications are according to the following design conditions: 1, Chilled water inlet/outlet temperature 12℃/7℃. 2, Cooling air inlet/outlet temperature 30℃/38℃. We reserve the right to modify the specifications without further notice. | ||||||||||||||

| Air Cooled Chiller Technical Specifications | ||||||||||||||

| Items Model | AC-0.5A | AC-1A | AC-1.5A | AC-2A | AC-2.5A | AC-3A | AC-4A | AC-5A | AC-6A | AC-8AD | AC-10AD | AC-12AD | AC-15AD | |

| Cooling capacity | Kcal/h 50HZ/60HZ | 1419 | 2451 | 3182 | 4833 | 5848 | 7181 | 9288 | 11988 | 14534 | 18576 | 23994 | 29068 | 38270 |

| 1703 | 2941 | 3784 | 5800 | 7018 | 8617 | 11146 | 14386 | 17441 | 22291 | 28793 | 34882 | 45924 | ||

| KW 50HZ/60HZ | 1.65 | 2.85 | 3.7 | 5.62 | 6.8 | 8.35 | 10.8 | 13.94 | 16.9 | 21.6 | 27.9 | 33.8 | 44.5 | |

| 1.98 | 3.42 | 4.4 | 6.74 | 8.2 | 10.02 | 12.96 | 16.73 | 20.28 | 25.92 | 33.48 | 40.56 | 53.4 | ||

| Input power | KW | 0.88 | 1.35 | 2 | 2.25 | 2.66 | 3.27 | 4.07 | 5.75 | 6.45 | 8.25 | 11.5 | 12.9 | 17.45 |

| Max Current | A | 5.4 | 8.2 | 12 | 13.6 | 6.6 | 8.2 | 10.1 | 13.8 | 15.5 | 20 | 27.9 | 31.3 | 42.4 |

| Power source | 1PH~220V/3PH~220V/380V 50HZ/60HZ | 3PH~380V/415V/480V~50HZ/60HZ(3PH~200V/220V 50HZ/60HZ) | ||||||||||||

| Refrigerant | Type | R22/R407C/134a/404A/410A | ||||||||||||

| Control | Capillary / thermostatic expansion valve | |||||||||||||

| Compressor | Type | Hermetic Rotary | Hermetic scroll ( piston ) | |||||||||||

| Power(KW) | 0.45 | 0.89 | 1.3 | 1.73 | 2.1 | 2.7 | 3.5 | 4.55 | 5.25 | 3.5×2 | 4.55×2 | 5.25×2 | 7×2 | |

| Condenser | Type | Efficient finned copper tube with aluminum+low noise external rotor fan | ||||||||||||

| Air flow (m3/h) | 750 | 1000 | 1500 | 2000 | 2500 | 3000 | 4000 | 5000 | 6000 | 8000 | 10000 | 12000 | 15000 | |

| Air blower(KW) | 0.06 | 0.09 | 0.15 | 0.15 | 0.19 | 0.14×2 | 0.14×2 | 0.19×2 | 0.19×2 | 0.25×2 | 0.45×2 | 0.45×2 | 0.6×2 | |

| Evaporator | Type | SS Tank coil / shell and tube type / Plate type heat exchanger | ||||||||||||

| Chilled water (m3/h) | 0.28 | 0.49 | 0.64 | 0.97 | 1.12 | 1.44 | 1.86 | 2.4 | 2.91 | 3.71 | 4.8 | 5.81 | 7.65 | |

| 0.34 | 0.59 | 0.76 | 1.16 | 1.4 | 1.72 | 2.23 | 2.88 | 3.49 | 4.46 | 5.76 | 7 | 9.18 | ||

| Water tank(L) | 10.6 | 18.3 | 27 | 27 | 50 | 50 | 60 | 60 | 110 | 120 | 200 | 200 | 270 | |

| Inlet/outlet pipe (inch) i | 1/2″ | 1/2″ | 1/2″ | 1/2″ | 1″ | 1″ | 1″ | 1″ | 1″ | 1-1/2″ | 2″ | 2″ | 2″ | |

| Water pump | Power (kw) | 0.37 | 0.37 | 0.37 | 0.37 | 0.37 | 0.37 | 0.37 | 0.75 | 0.75 | 0.75 | 1.5 | 1.5 | 2.2 |

| Max lift(m) | 22 | 22 | 22 | 22 | 22 | 22 | 22 | 30 | 30 | 25 | 25 | 25 | 28 | |

| Max flow (m3) | 5.4 | 5.4 | 5.4 | 5.4 | 5.4 | 5.4 | 5.4 | 8.1 | 8.1 | 8.1 | 13.5 | 13.5 | 25.2 | |

| Safety protection | Compressor inner protection, over current protection, high/low pressure protection, over temperature protection, flow rate protection, phase sequence/phase missing protection, low level coolant protection, anti freezing protection, exhaust overheat protection | |||||||||||||

| Dimension | L(mm) | 550 | 550 | 600 | 600 | 720 | 980 | 980 | 1150 | 1150 | 1350 | 1500 | 1500 | 1860 |

| W(mm) | 350 | 450 | 500 | 500 | 550 | 520 | 520 | 560 | 560 | 680 | 760 | 760 | 850 | |

| H(mm) | 695 | 845 | 985 | 985 | 1350 | 1170 | 1170 | 1215 | 1215 | 1530 | 1660 | 1660 | 1900 | |

| Net weight(KG) | 45 | 62 | 85 | 95 | 125 | 152 | 175 | 185 | 215 | 283 | 345 | 382 | 580 | |

| Note: The above specifications are according to the following design conditions: 1, 12℃/7℃.Chilled water inlet/outlet temperature 12℃/7℃. 2, 33℃/38℃.Cooling air inlet/outlet temperature 33℃/38℃. We reserve the right to modify the specification without further notice. | ||||||||||||||

| Air Cooled Chiller Technical Specifications | |||||||||||||

| Items Model | AC-15AT | AC-20AD | AC-20AF | AC-25AD | AC-25AF | AC-30AD | AC-30AT | AC-40AD | AC-40AF | AC-50AD | AC-50AF | AC-60AD | |

| Cooling capacity | Kcal/h 50HZ/60HZ | 36120 | 49966 | 47988 | 58480 | 58136 | 74734 | 74922 | 98040 | 99760 | 119024 | 116960 | 144996 |

| 43344 | 59959 | 57586 | 70176 | 69763 | 89681 | 89990 | 117648 | 119712 | 142829 | 140352 | 173995 | ||

| KW 50HZ/60HZ | 42 | 58.1 | 55.8 | 68 | 67.6 | 86.9 | 87.2 | 114 | 116 | 138.4 | 136 | 168.6 | |

| 50.4 | 69.72 | 66.96 | 81.6 | 81.12 | 104.28 | 104.64 | 136.8 | 139.2 | 166.08 | 163.2 | 202.3 | ||

| Input power | KW | 17.1 | 21.73 | 22 | 25.4 | 24.8 | 33.39 | 33.1 | 44.91 | 43.3 | 57.3 | 54 | 65 |

| Max Current | A | 43.2 | 52.7 | 53.3 | 63.7 | 61.3 | 81 | 80.2 | 109 | 106 | 135.5 | 128.5 | 135 |

| Power source | 3PH~380V/415V/480V~50HZ/60HZ(3PH~200V/220V 50HZ/60HZ) | ||||||||||||

| Refrigerant | Type | R22/R407C/134a/404A/410A | |||||||||||

| Control | Capillary / Thermostatic expansion valve | ||||||||||||

| Compressor | Type | Hermetic scroll ( piston ) | |||||||||||

| Power(KW) | 4.55×3 | 8.96×2 | 4.55×4 | 10.8×2 | 5.25×4 | 13.62×2 | 8.96×3 | 18.78×2 | 8.96×4 | 23.6×2 | 10.8×4 | 27.4×2 | |

| Condenser | Type | Efficient finned copper tube with aluminum+low noise external rotor fan | |||||||||||

| Air flow (m3/h) | 15000 | 20000 | 20000 | 25000 | 25000 | 30000 | 30000 | 40000 | 40000 | 50000 | 50000 | 60000 | |

| Air blower(KW) | 0.6×2 | 0.78×2 | 0.78×2 | 0.78×2 | 0.78×2 | 0.42×6 | 0.42×6 | 0.6×6 | 0.6×6 | 0.78×6 | 0.78×6 | 0.78×6 | |

| Evaporator | Type | SS Tank coil/ shell and tube type/Plate type heat exchanger | |||||||||||

| Chilled water (m3/h) | 7.22 | 10 | 9.6 | 11.69 | 11.62 | 14.94 | 15 | 19.6 | 19.95 | 23.8 | 23.4 | 29 | |

| 8.67 | 11.99 | 11.51 | 14.03 | 13.95 | 17.93 | 18 | 23.52 | 23.94 | 28.6 | 28.1 | 34.8 | ||

| Water tank(L) | 270 | 350 | 350 | 350 | 350 | 420 | 420 | 580 | 580 | 580 | 580 | 580 | |

| inlet/outlet pipe (inch) | 2″ | 2″ | 2″ | 2-1/2″ | 2-1/2″ | 2-1/2″ | 2-1/2″ | 3″ | 3″ | 3″ | 3″ | 3″ | |

| Water pump | Power(kw) | 2.2 | 2.2 | 2.2 | 2.2 | 2.2 | 4 | 4 | 4 | 4 | 5.5 | 5.5 | 5.5 |

| Max lift(m) | 28 | 28 | 28 | 28 | 28 | 30 | 30 | 30 | 30 | 32 | 32 | 32 | |

| Max flow (m3) | 25.2 | 25.2 | 25.2 | 25.2 | 25.2 | 36 | 36 | 36 | 36 | 40 | 40 | 40 | |

| Safety devices | Compressor inner protection, over current protection, high/low pressure protection, over temperature protection, flow rate protection, phase sequence/phase missing protection, low level coolant protection, anti freezing protection, exhaust overheat protection | ||||||||||||

| Dimension | L(mm) | 1860 | 2020 | 2020 | 2020 | 2020 | 2200 | 2200 | 2350 | 2350 | 2600 | 2600 | 2600 |

| W(mm) | 850 | 950 | 950 | 950 | 950 | 1150 | 1150 | 1350 | 1350 | 1500 | 1500 | 1500 | |

| H(mm) | 1900 | 2000 | 2000 | 2000 | 2000 | 1980 | 1980 | 2000 | 2000 | 2100 | 2100 | 2100 | |

| Net weight(KG) | 580 | 650 | 650 | 810 | 810 | 890 | 890 | 1112 | 1112 | 1320 | 1320 | 1320 | |

| Note: The above specifications are according to the following design conditions: 1, Chilled water inlet/outlet temperature 12℃/7℃. 2, Cooling air inlet/outlet temperature 33℃/38℃. We reserve the right to modify the specification without further notice. | |||||||||||||

Why TopChiller is Your Reliable Air Cooled Chiller Manufacturer and Supplier In China?

Air Cooled Chiller-An Ultimate FAQ Guide by TopChiller.

- What is an Air Cooled Chiller?

- What are the Excellent Features of an Air Cooled Chiller?

- What are the Necessary Components of an Air Cooled Chiller?

- What are the Types of Compressors Used in an Air Cooled Chiller?

- What is the Difference Between a Water Cooled Chiller and an Air Cooled Chiller?

- What are the Components of the Control Unit of an Air Cooled Chiller?

- What are the General and Industrial Applications of an Air Cooled Chiller?

- What is the Working Mechanism of an Air Cooled Chiller?

- What is the Capacity Control of your Air Cooled Chiller?

- What are the Types of an Air Cooled Chiller?

- What are the Optional Accessories of an Air Cooled Chiller?

- How to Purchase an Appropriate Air Cooled Chiller for your Industry?

- What are the Installation Guidelines for your Air Cooled Chiller?

- What are the Necessary Standards and Certification of an Air Cooled Chiller?

- What is the Significance of Factory Testing of an Air Cooled Chiller?

- What are the Maintenance Guidelines for your Air Cooled Chiller?

- How to Troubleshoot Problems Arising in your Air Cooled Chiller?

- How to Enhance the Working Efficiency of your Air Cooled Chiller?

What is an Air Cooled Chiller?

An Air Cooled Chiller is an advanced cooling system extensively used in commercial and industrial applications to remove extra heat and offer HVAC purposes.

It dehumidifies air and helps maintain an optimum temperature in restaurants, manufacturing plants, corporate sectors, large buildings, etc.

Air Cooled Chiller comprises a simple infrastructure with a compact assembly. Therefore, it is easy to install and remove. Also, the cooling is long-lasting and efficient for many years after installation.

It uses a high-quality, non-biodegradable refrigerant and processed water as a coolant to preserve heat which is later transferred to the environment, thus producing cooling.

The maintenance requirements are simple, and it has an energy-saving function since it works at the expense of ambient air only.

Top Quality Air Cooled Chiller Designed by TopChiller

What are the Excellent Features of an Air Cooled Chiller?

The most prominent features of Air Cooled Chiller are listed below:

- The cooling capacity range is 2KW to 184.8KW, temperature range, 5℃ to 30℃, and temperature controlling vibration is 1 degrees Celsius.

- It has a simple and compact design with minimum maintenance requirements.

- Various compressors are joined equally during the unit’s manufacturing to achieve an outstanding working ability.

- Compressors used in manufacturing may be partially sealed or sealed with airtight technology.

- The condenser fans are paddle-type aluminium metal blades directly set by electric motors.

- It has a user-friendly microprocessor unit which enables you to obtain easy operation.

- There are different configurations available, like Stationary and Portable Air Cooled Chiller.

What are the Necessary Components of an Air Cooled Chiller?

The necessary components of an Air Cooled Chiller include:

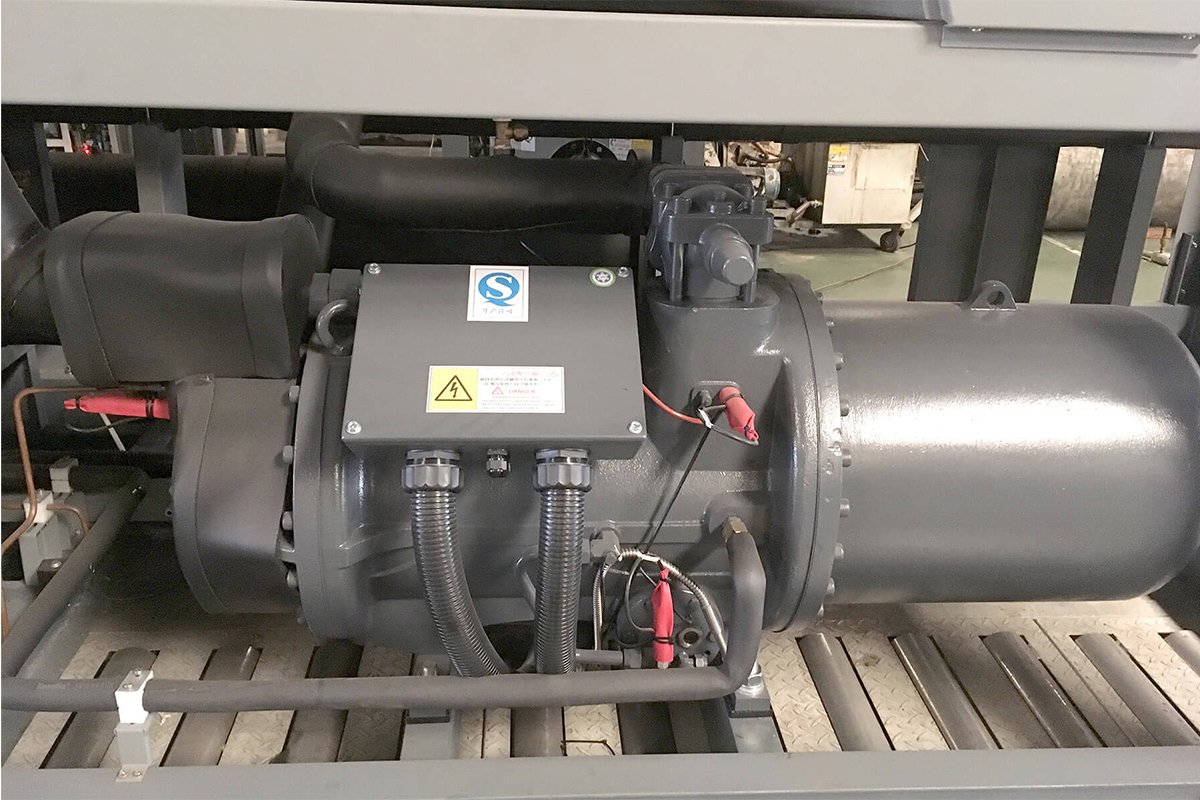

Compressor

The compressor provides the main push required by the refrigerant to move. It increases the pressure and converts the refrigerant into a high-pressure fluid.

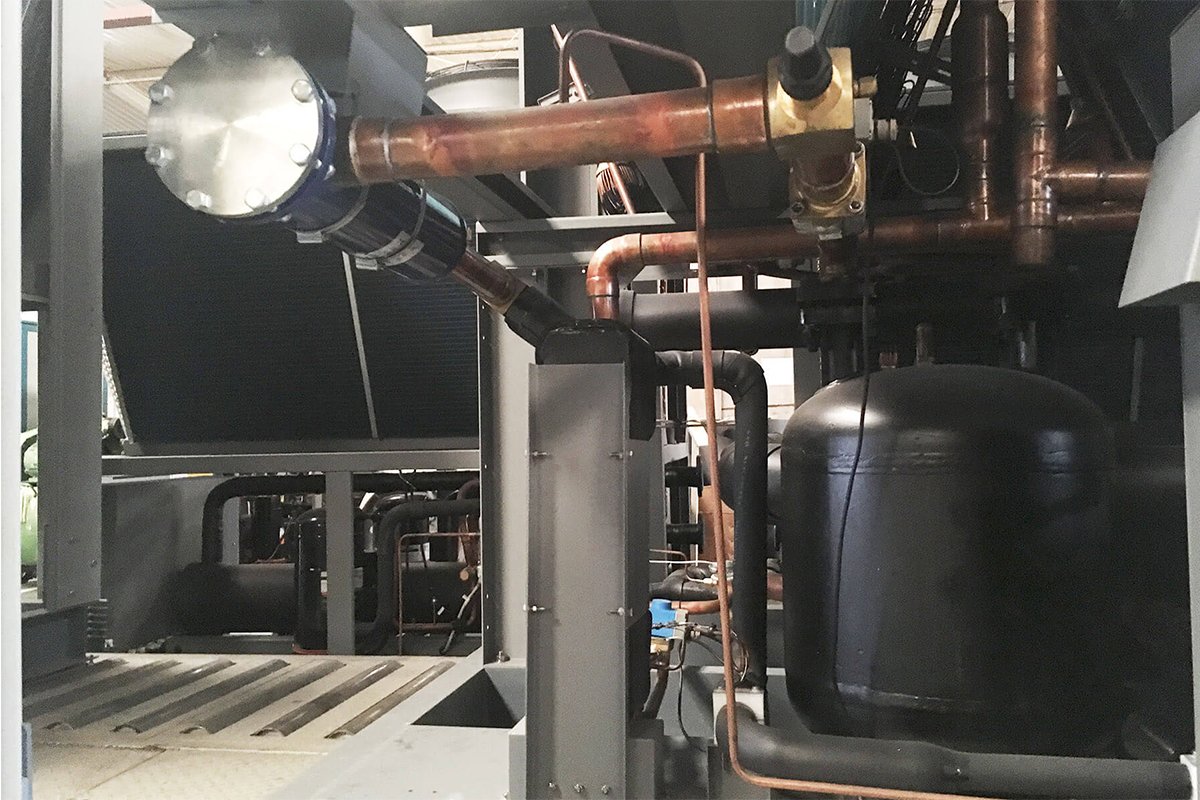

Condenser

It comprises an assembly of horizontal pipes in which the refrigerant is allowed to flow. The ambient air around the pipes absorbs all the heat dissipated from the refrigerant.

The refrigerant undergoes another transition in the physical state as pressure is applied to it to convert it from a high-pressure gas to a high-pressure liquid.

This process liberates a lot of energy which is later absorbed by the ambient air.

Condenser Fans

It is one of the differentiating factors between a Water Cooled Chiller and an Air Cooled Chiller. These fans are utilized to transfer the air across the condenser.

This air carries away all the unwanted heat from the condenser coils.

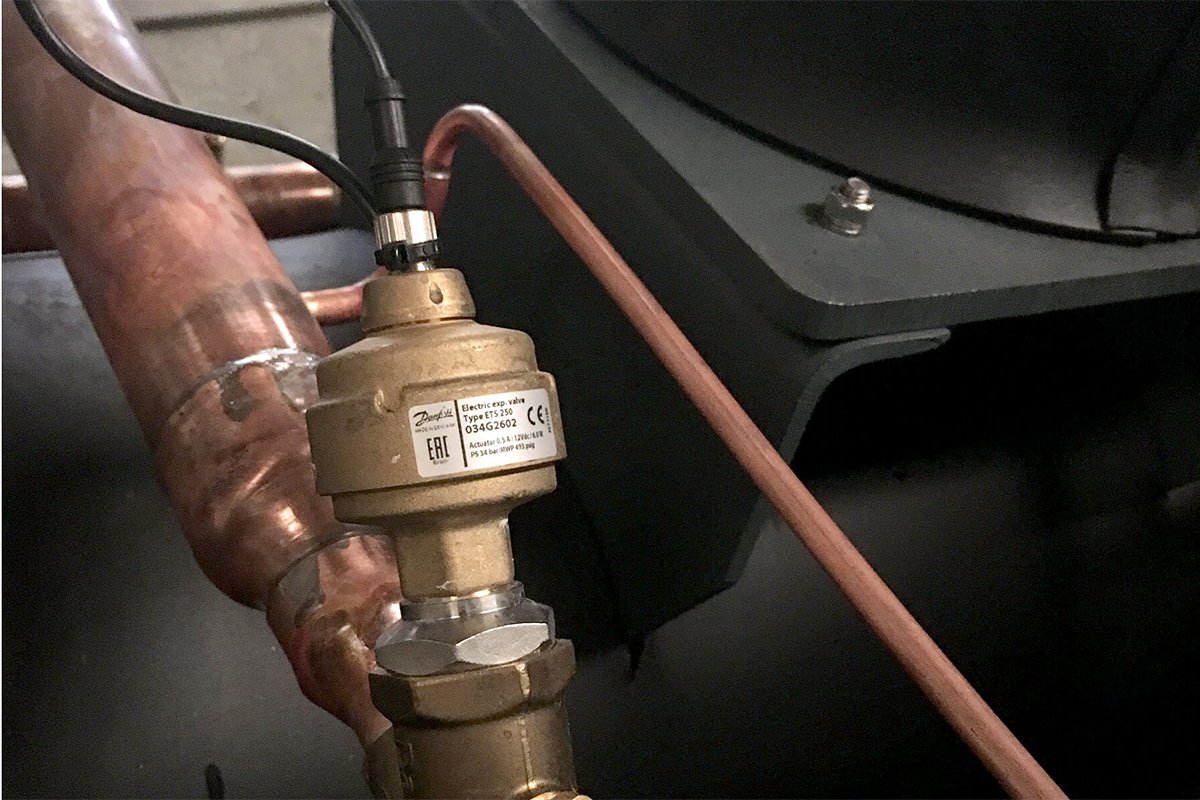

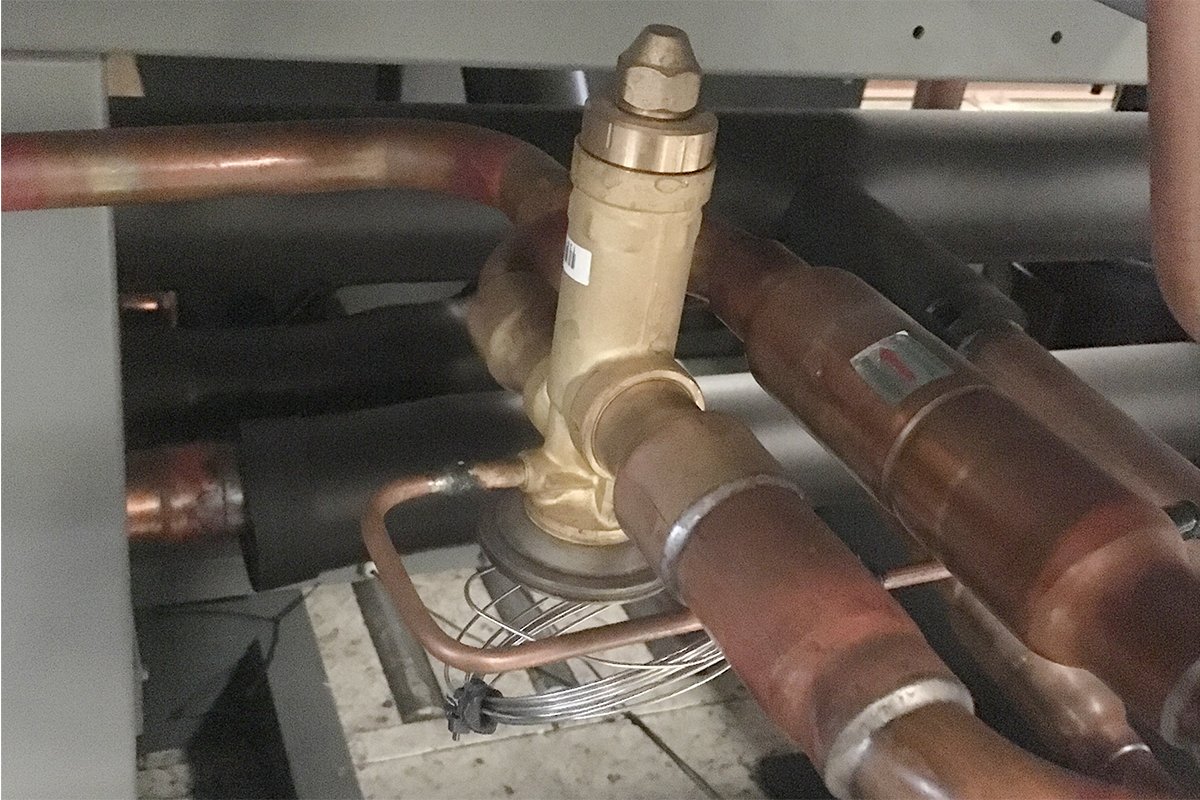

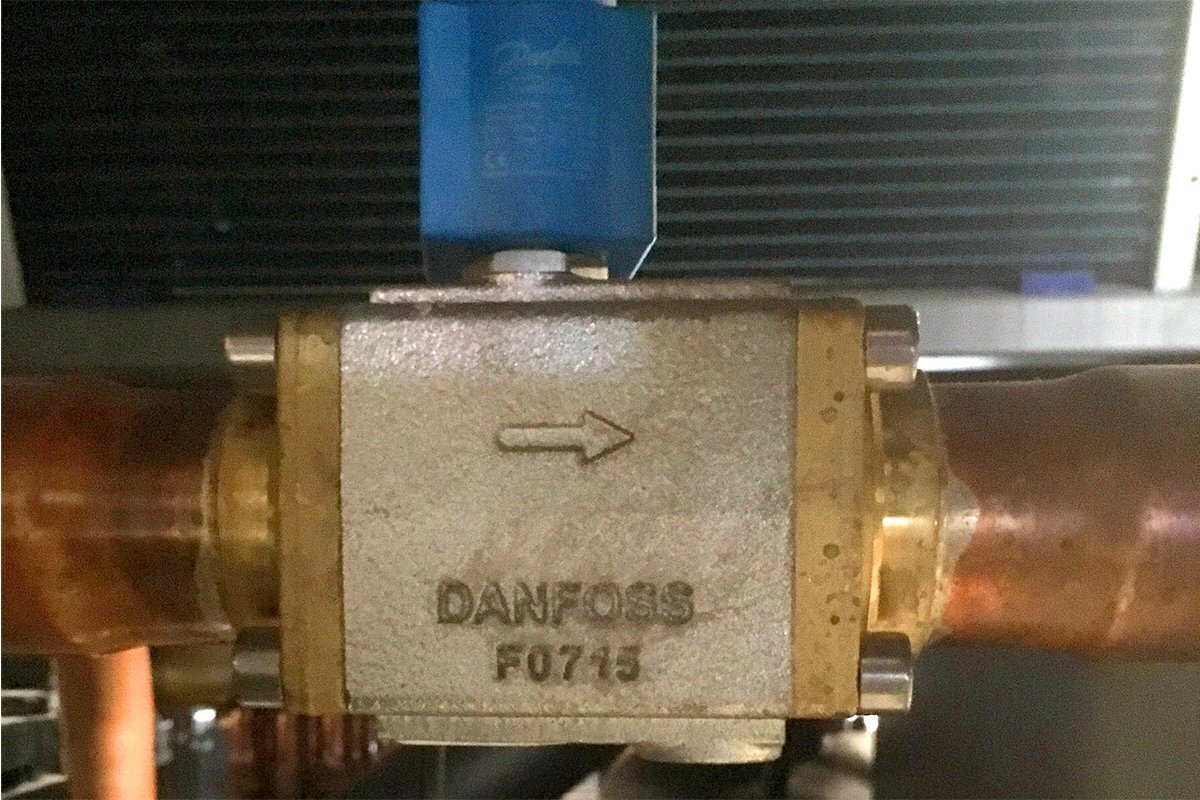

Expansion Valve

The expansion valves are responsible for converting the fluid refrigerant into a gaseous form by allowing it to expand under a low-pressure environment.

This gaseous state is required to enter the evaporator.

Evaporator/Heat Exchanger

The chilled water is produced when the refrigerant undergoes evaporation. The surface molecules of the refrigerant break free from the rest of the molecules and take away energy with them in the form of heat.

This evaporation is a cooling process, and it is required to produce the cooling effect.

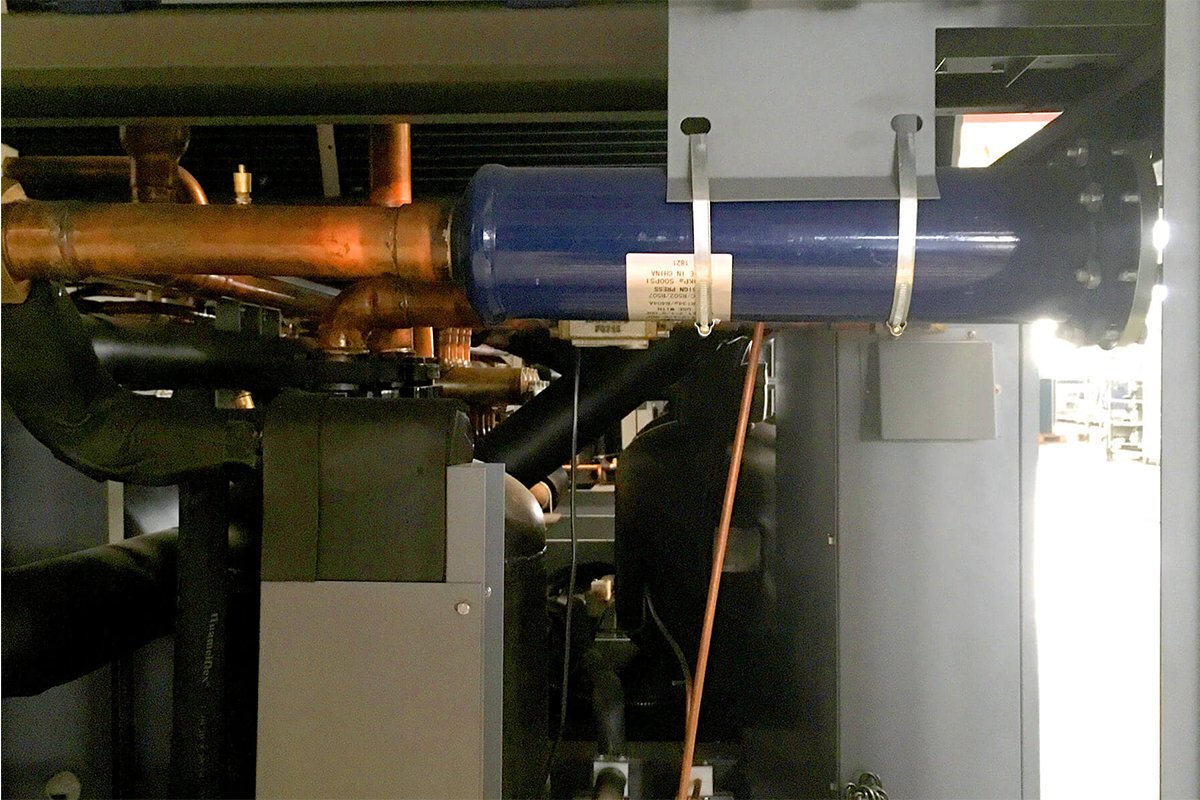

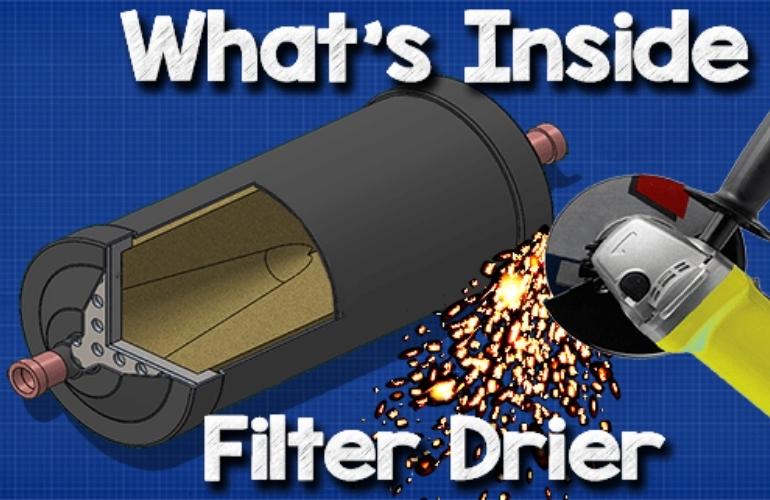

Filter Drier

The unwanted dust, impurities, and humidity can cause damage to the refrigeration system and affect the function of the chiller. Therefore, a filter drier is used to remove all contaminants.

It is important to clean and replace them regularly because they tend to clog and obstruct easily.

Air Cooled Chiller Filter Drier Inside View

What are the Types of Compressors Used in an Air Cooled Chiller?

Four primary kinds of compressors can be used in an Air Cooled Chiller.

- Screw Compressor

- Scroll Compressor

- Reciprocating Compressor

These three types utilize the mechanism of positive replacement to build up the pressure.

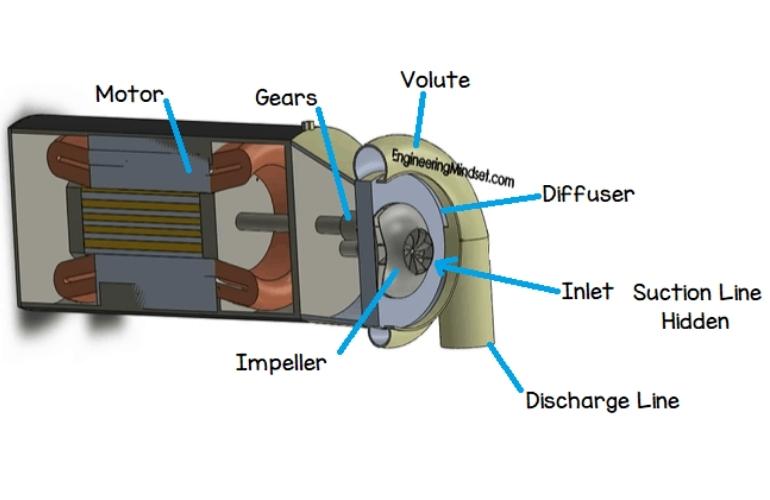

- Centrifugal Compressor

This type uses centrifugal force to build up the pressure.

Air Cooled Chiller Centrifugal Compressor

What is the Difference Between a Water Cooled Chiller and an Air Cooled Chiller?

The significant difference between air and water cooled chillers is mainly based on water, size, installation, portability design, etc.

Although both types use an electronic compressor to push the refrigerant around the system and obtain heat through evaporation, the Air Cooled Chiller has a simpler assembly.

Water Usage

Air Cooled Chiller does not require a cooling tower, water reservoir, or a constant water supply. It uses ambient air rather than moist air for the transfer of heat.

Compressor

Most commonly, an air-cooled type uses a screw or scroll compressor, whereas, for a water-cooled type, a centrifugal or screw compressor is preferred.

Pump

The unwanted heat in the air-cooled system is ejected by using fans which drive the chilled air across the condenser.

A water cooled chiller uses water flow from the cooling tower through a sealed condenser to transfer heat.

Power Consumption

As a wet surface is more helpful for heat transfer, water cooled chillers use less power. An air-cooled type uses 10% more power but produces better heat transfer due to long-lasting results.

Space

An Air Cooled Chiller has an innovative and compact design and does not use much space. There is no cooling tower, extensive pipelines, and pumps that occupy much more space.

Its assembly is also simple, and you don’t have to spend an extra amount on the extensive pipe network.

Maintenance

It has a more solid impression, and since there are no cooling towers, the maintenance is less expensive and relatively simple.

Pricing and Affordability

The air cooled type is less expensive and quite affordable. The installation and maintenance also do not need any extra investment.

What are the Components of the Control Unit of an Air Cooled Chiller?

The control unit of an Air Cooled Chiller consists of the following components:

Liquid Crystal Display

It shows all the operation information in the text. You can choose the language according to your convenience. It also shows the status of the system.

Indicators

The manual indicator lamp shows the state when the manual operation is possible. You can press the manual button for 1.5 seconds to turn it on.

Switch

The primary key to run or stop the chiller is the main switch. It needs to be pressed for 1.5 seconds or longer.

Alarm Lamp

It turns on whenever there is a caution warning or a system’s normal functioning problem.

The message about the alarm is displayed on the LCD, which helps you locate the problem and take action accordingly.

Compressor Run/Stop Key

This key is functional only when more than one compressor is integrated into a system. There are two types of integrated systems: series and parallel.

Therefore, you can switch from one compressor to the other with the help of this key.

Others include:

- BMS Support Function

- Menu Operation Key

- Control Valve Manual Operation Key

- Unit Control Manual Operation Key

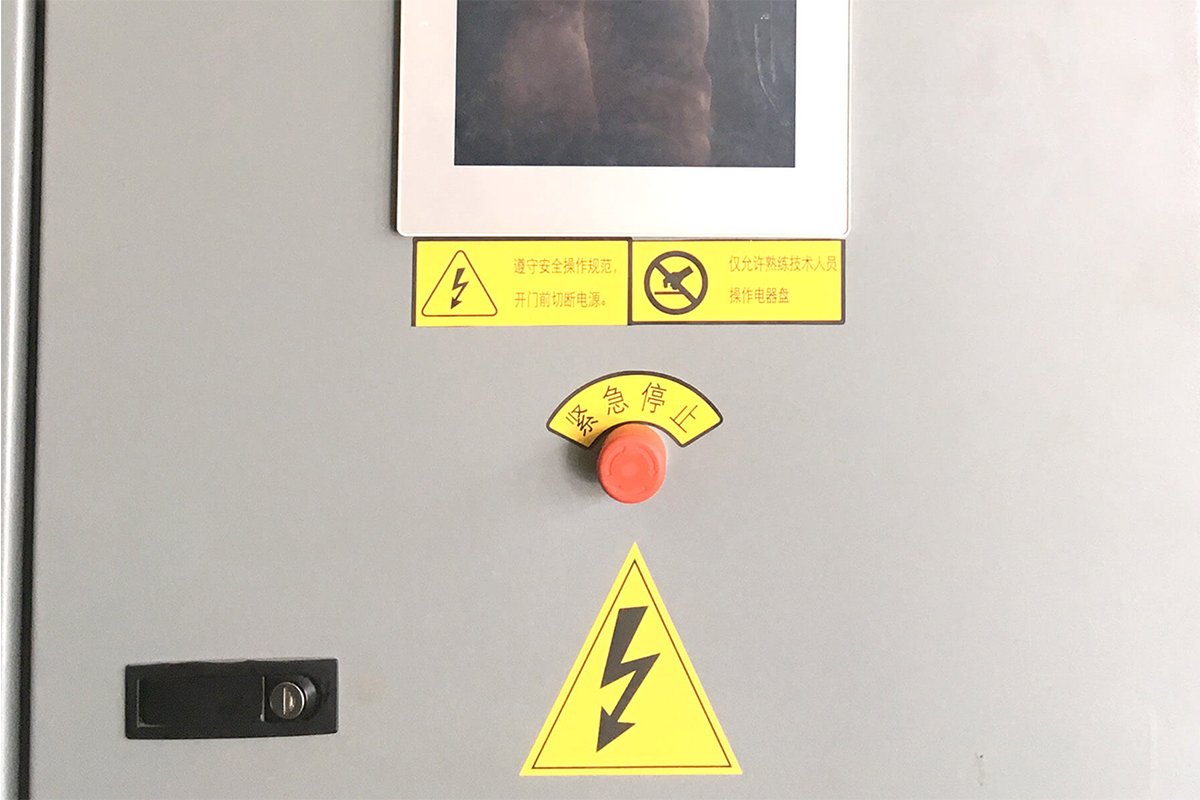

Air Cooled Chiller Control Unit

What are the General and Industrial Applications of an Air Cooled Chiller?

The general and Industrial applications of an Air Cooled Chiller are given below:

- Lasers

- Anodizing

- Blow Moulding

- Plastic

- HVAC

- Injection Moulding

- Office Building

- Chemical Process

- Welding

- Printing

- Cement Cooling

- Food Industry

- Vacuum Forming

- Brewing Industry

- Electronic Industry

The purpose of using an Air Cooled Chiller in these industries is to get rid of the heat produced by the machines and the chemical/ mechanical processes going on in these applications.

It also maintains an optimum temperature which is required for the synthesis of certain products.

Another application is to create a comfortable environment through an HVAC system which allows better ventilation, heating, and cooling.

Due to its efficiency and reliability, it is preferred for large buildings and domestic uses.

What is the Working Mechanism of an Air Cooled Chiller?

The working mechanism for an Air Cooled Chiller is as follows:

- It works by pumping chilled water through fan coil and air handling units that reduce the heat produced by the building.

- When the chilled water enters the system, its temperature is about 6 degrees Celsius, and it is raised to almost double the degrees as it leaves the system.

- Thus there is a rise of 6 degrees Celsius, which occurs due to the absorption of heat from the system.

- This heat is then dumped into the environment as the environment is at a much lower temperature than the water leaving the system. The cycle is then repeated.

- After dissipating all the heat to the environment, the water enters the evaporator through the recirculation pump.

- The evaporator allows the refrigerant to transition from one state to another, thus taking energy from the system while it flows through the evaporator coils.

- The heat produced from these processes can be used for heating purposes as well. For example, it can be a great, inexpensive and convenient source of heating in cold weather.

- The compressor is responsible for pulling the refrigerant, which is in vapor form, from the evaporator coils. This refrigerant is then pumped into the condenser.

- The condenser expands the refrigerant by increasing the temperature and the pressure. This helps the refrigerant to get back into its liquid state.

- As the refrigerant flows through the coils, the air currents around the coils absorb the heat.

- Then this high-pressure liquid is allowed to move through the expansion valve and back to the evaporator.

- The temperature is maintained by the control unit, cooling limit, and partializing of the compressor. It directly depends upon the cooling load.

What is the Capacity Control of your Air Cooled Chiller?

When the cooling load is not constant, capacity control is highly demanded. It refers to the ability of the Air Cooled Chiller to adjust its capacity according to the load so that maximum efficiency can be obtained.

The primary dependence of efficiency is upon the discharge pressure and compressor suction. Superheat and subcooling may also help in the evaluation of efficiency.

When you remove the screw compressor, the suction pressure also lowers, thus decreasing the efficiency.

The capacity control mechanisms adjust the refrigerant flow through the compressor and allow the maintenance of desired suction pressure.

What are the Types of an Air Cooled Chiller?

The main types of Air Cooled Chiller are described here:

Stationary Air Cooled Chiller

It has an extensive network that is easy to install and remove but not ideal for transportation. It needs some level of ducting and therefore is not helpful for every application.

Higher cooling loads can be dealt with by using a stationary type as it has a higher effect and provides higher productivity.

A portable type is ideal for small applications and cannot deal with larger Industrial setups independently. It has a compact and simple design that is relatively easy to assemble and remove.

You don’t need any professional help with this setup, and it can be easily transported or carried to desirable sites.

The efficiency is sufficient to meet the needs of small applications.

What are the Optional Accessories of an Air Cooled Chiller?

The optional accessories of an Air Cooled Chiller are as follows:

Compressor Acoustic Enclosure

It is an accessory device to reduce the sound levels of the compressor. It is composed of painted panels with sound-absorbing insulation and provides maximum sound attenuation.

The sound foam and the paint create the sound damping effect. It is a factory-installed option, and therefore you must inform your manufacturer beforehand.

Condenser Accessories

For higher reliability and resistance against acids, salts, and other damaging agents, the condenser must have the following features:

Pre Coating

A pre-treated polyurethane coating is ideal for the aluminium fins of the condenser.

Copper Fin

It is a more reliable and stable metal for the condenser coils. There are additional copper fins that add to the protective function.

Safety Grills

The exposed condenser can be protected by dirt, debris, and foreign material, which can cause a defect in normal functioning.

How to Purchase an Appropriate Air Cooled Chiller for your Industry?

To purchase the most suitable Air Cooled Chiller, follow the given instructions:

- Choose the type according to the size and cooling demand of your application.

- Look for online reviews, and then order the model that most likely suits your cooling load.

- Decide the sure of installation and ensure that you have a proper electricity connection available.

- You must have an appropriate site for installation outdoors with maximum air currents.

- Check the type of refrigerant because it is highly risky if it is ozone-depleting and biodegradable.

- Ensure that it is certified and according to the country’s standards you live in.

What are the Installation Guidelines for your Air Cooled Chiller?

It is recommended to load or unload your Air Cooled Chiller with the help of a crane to reduce any chances of damage during the transfer of units.

Requirements and Foundations

- You must know about the design of the base when installing your Air Cooled Chiller.

- Before installing your chiller, it is recommended to consult with the architect of your building.

- To minimize the transfer of vibrations during the working time, anti-vibration pads are utilized in a base casing which also reduces noise.

Required Installation Space

It requires a standard place to work, maintain and circulate air. If on cold days, snow gathers in an area, the following guidelines should be kept in mind:

- Heighten the base more than possible snow level.

- The base must be 1 meter greater than the maximum snow height.

- The areas hyped with snow on cold days must not be used for the installation.

- In monsoon regions, if the wind blows at a more incredible speed than the fan-blowing speed, it will damage the heat transfer system because air starts to move rapidly.

- Install your chiller opposite to monsoon wind to prevent this damage from happening.

Water System Installation

- Water systems must be installed on routine installation rules to achieve outstanding results.

- Cool water pipes must be washed bypassed and have a standard area for maintenance.

- Pipelines are manufactured in parallel to prevent minimizing pump capabilities.

- Electrolytic damage of pipelines can occur if your chiller connects with any electric apparatus.

- Underground pipelines should be prevented from corrosion. To check any air gathering, seek water flowing speed, tank, and exhaust location.

- The outer pipe of your chiller covered with a flexible tube and pump is necessary to reduce vibrations transmission.

For maintenance purposes, it’s recommended to install a manual stoppage valve.

It is suggested to use a valve on cold pipelines to suck any air, deflation, and drain.

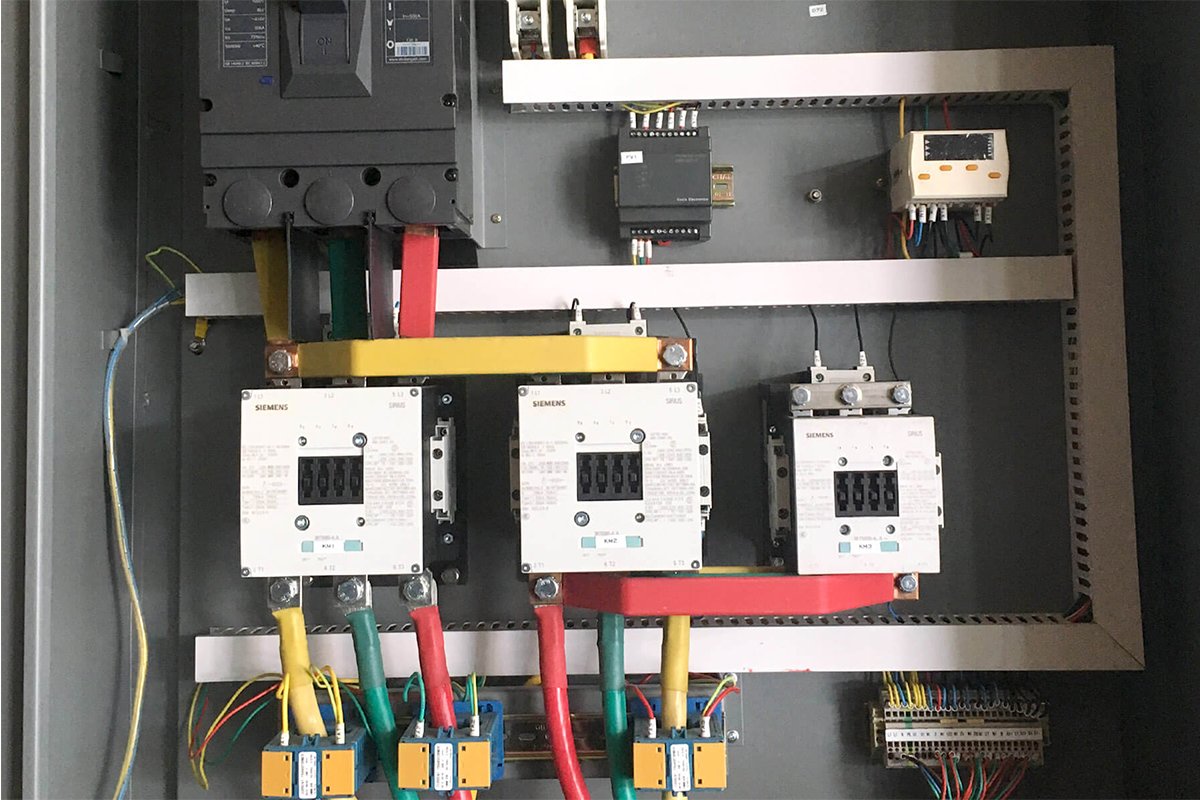

Wiring Requirements

A guard is suggested using the main power supply cable to keep dust away. Circuit breaker devices must be installed on each power supply cable to prevent electric damage.

The power breakers must have the following features:

- Must possess an external operating processor.

- Have a system to get locked when it’s in off mode.

- Can stop conductors to its power supply circuit.

What are the Necessary Standards and Certification of an Air Cooled Chiller?

The Air Conditioning, Heating, and Refrigeration Institute sets the necessary certification standards, abbreviated as AHRI.

The latest standard program is AHRI Standard 550/590. It provides third-party, independent verification after it tests the chiller thoroughly to ensure that it’s efficient enough.

Each Air Cooled Chiller must have the following codes and standards:

- ASME Section VIII – boiler and pressure vessel.

- AHRI 550/590 – water chilling packages using the vapor compression cycle.

- GB/T 18430.1 – water chilling (heat pump) packages using the vapor compression cycle.

- ANSI/ASHRAE 34 – number designation and safety classification of refrigerants.

What is the Significance of Factory Testing of an Air Cooled Chiller?

There are computer-based testing programs that check the compliance of the wiring, electronics sensors, and microprocessor control functions of an Air Cooled Chiller.

The significance of factory testing is as follows:

- It allows the verification of performance and protected function of the whole system.

- Any operational problems are predicted and avoided to assure smooth function for many years.

- The components are separately tested and verified to check the efficiency and capacity.

Structural Strength Analysis

It is to determine the strength of the system and the load it can bear.

Aerodynamics Analysis

This part allows you to evaluate the effect of the air currents and other physical conditions on the efficiency and working of the chiller.

This helps to assess the function by providing the most suitable conditions.

What are the Maintenance Guidelines for your Air Cooled Chiller?

The maintenance tips and tricks for your Air Cooled Chiller are as follows:

- All the inlets and outlets of water shall be checked for any leakage.

- See if any part of the system is being corroded due to the corrosive effects of water-containing salts and other chemicals.

- All the cooling coils shall be cleaned regularly to prevent any accumulation of dirt and debris, which creates a blockage.

- See if there are any twisted fins or leakages in the coils.

- Check the level of the refrigerant and charge it sufficiently whenever required.

- See if any additional vibration or sound is coming from the functioning chiller.

- Regularly check the oil level to ensure sufficient lubrication.

- Use techniques to check the leakage of the refrigerant or the oil.

- The condenser coils tend to grease up and therefore must be checked for any damage or blockage.

- All the electrical connections must be checked to ensure no wiring defect.

- Examine the filter drier regularly to see if it is not clogged up or obstructed. Change it if necessary to allow maximum flow.

- If any component is not working correctly, you must change it not to affect the overall efficiency.

How to Troubleshoot Problems Arising in your Air Cooled Chiller?

High-Pressure Discharge

- Make sure all fins and tubes are clean.

- The level of refrigerant must be sufficient.

Obstruction

- A good cleaning routine can prevent the obstruction caused by dirt and debris.

- A filter drier prevents the entry of any unwanted particles into the system.

Reduction of Air Flow

- The site of installation must be considered to allow maximum airflow.

- It can also be caused by the damage to a fan and reduction in the force of the air.

Low-Pressure Discharge

- Incompletely shut suction or undercharged refrigerant can cause this condition.

- It can be overcome by continuously charging the refrigerant.

Electrical Faults

- Irregular voltage supply can directly damage your Air Cooled Chiller.

- The voltage and phases must be checked in each cycle to ensure proper adjustment.

- There could be any damage to the wiring or insulation.

Controls

- The paddle type sensor is most commonly broken, leading to the chiller’s essential function loss.

- The control system must adjust the correct refrigerant flow towards the evaporator and the condenser.

Noise and Vibration

- Your chiller may produce vibration and noise if any component is damaged or out of place.

- Lack of lubrication at low oil and refrigerant levels can also produce noise.

How to Enhance the Working Efficiency of your Air Cooled Chiller?

To enhance the working efficiency of your Air Cooled Chiller, follow the given steps:

- Always check the insurance and certification of the chiller before purchasing it.

- Factory testing and approval is the most crucial step.

- The chiller capacity must be by the cooling load of the application.

- The maintenance routine shall be followed appropriately, and the functional shall be assessed after regular intervals. It can be done if you keep a record of the maintenance.

- Pay attention to the quality of the refrigerant.

- Check the refrigerant and oil levels at regular intervals.

- The maintenance of a stable electricity connection is essential. Otherwise, any chiller won’t be able to produce the best results.