TopChiller can design and manufacture all types of oil chillers for you

- Cooling capacity ranges from 1 ton to 50 ton

- Temperature control ranges from 10°C to 25°C

- Oil flow rate ranges from 8LPM to 100LPM

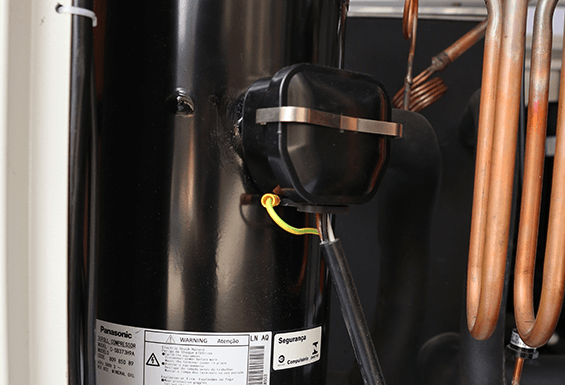

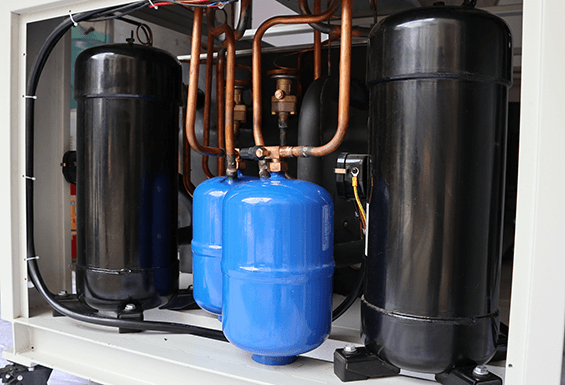

- Energy-efficient Hermetic type compressor

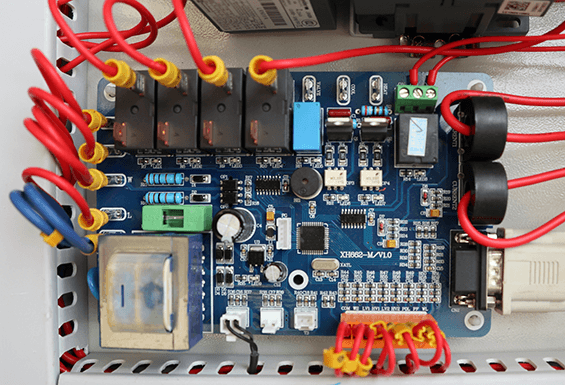

- ‘H-smart’ microprocessor-based controller

- Anti-corrosive and anti-freezing refrigerant

- Galvanized steel body with powder coating

- Equipment extended warranty for 24 months

Premier Oil Chiller/Cooler Manufacturer and Supplier Over 20 Years

Oil Chiller is a cooling machine that works on the evaporation principle to cool the CNC machine oil, and lubricating oil is used for different machines processing by using chilled water/air circulation around the machine.

TopChiller is an emerging and significant company of China among the world’s top enterprises for its manufacturing and supplying capability standardized and quality assured Oil Chiller to all global markets since 1999.

With twenty years of utmost experience, TopChiller Company is now enabled to provide an end-to-end solution to our customers regarding their all ambiguities by providing a full line of Oil Chiller models with varying capacities.

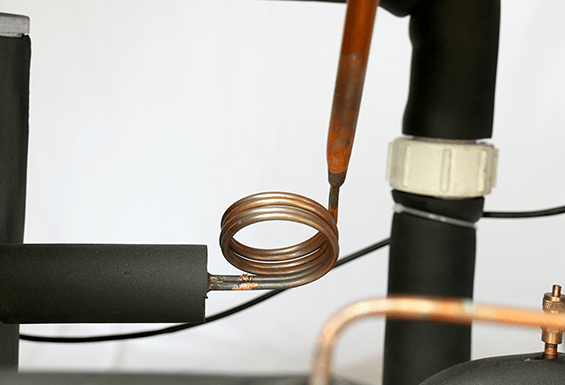

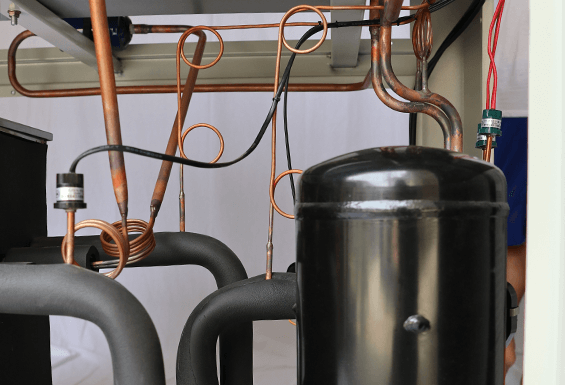

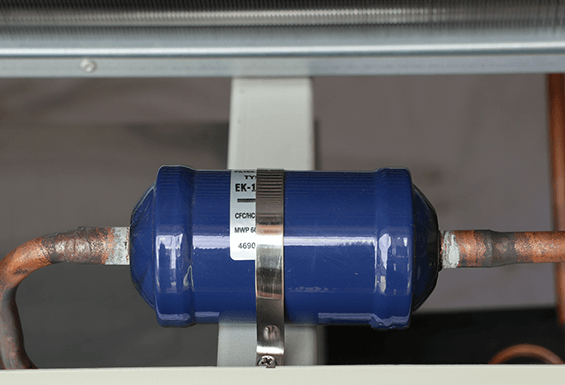

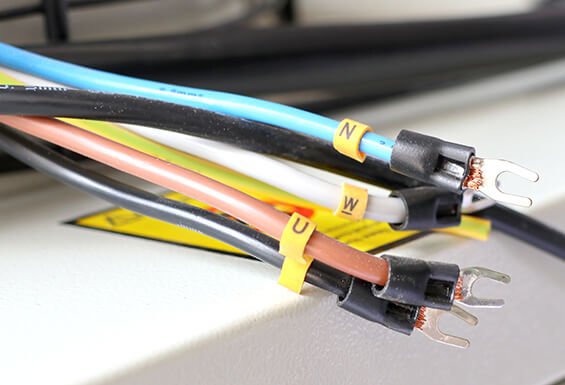

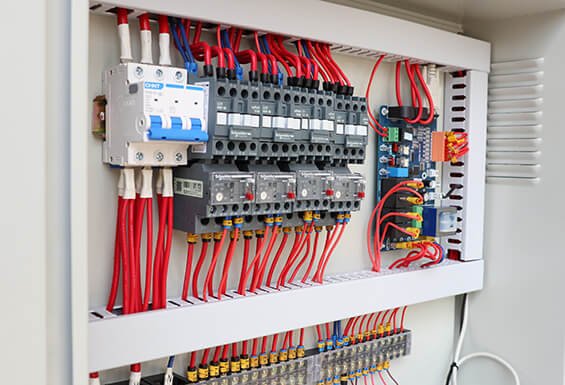

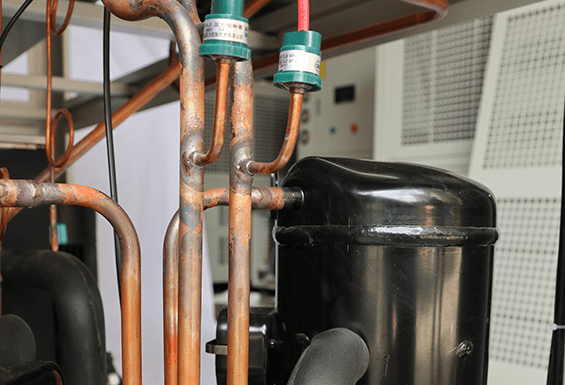

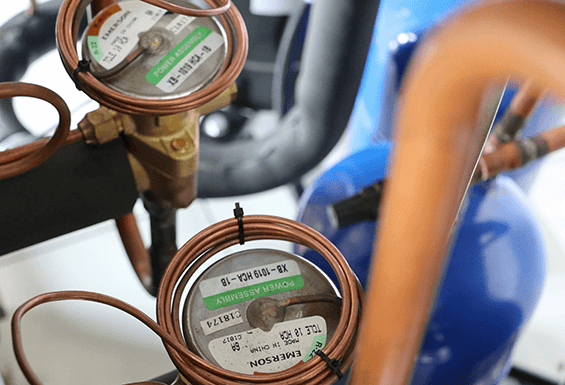

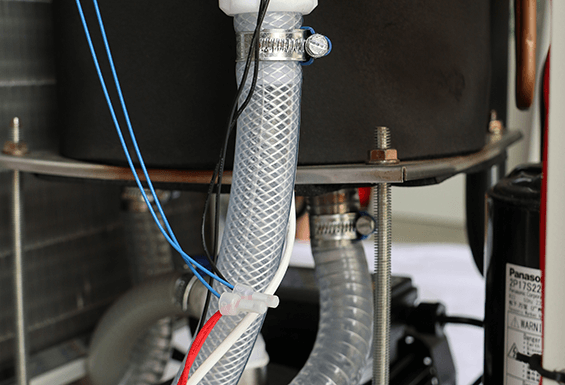

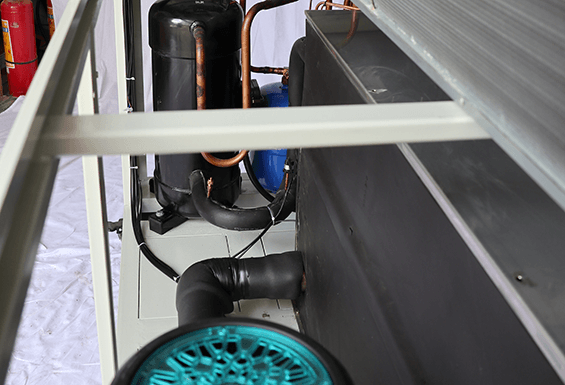

Scroll compressor, protection devices, H-smart microprocessor, energy-efficient condenser, evaporator, expansion valves, brazed plate heat exchanger, piping and tubing, power supply are the primary components of Oil Chiller.

TopChiller brand Oil Chiller has a great range of benefits for industrial machinery as given below:

- The Oil Chiller is responsible for providing a consistent and steady cooling effect to the spindle and other hydraulic machines to prevent the damage of machine components due to a high amount of heat accumulation.

- TopChiller designed Oil Chiller ensures reliable performance with the protection of industrial machining featured by the installation of an efficient condenser with high heating capacity triggering to cool the oil that gets heated by using chilled water or air circulation constantly around the condenser.

- Oil Chiller is enabled for trouble-free operation even at harsh industrial conditions configured by the recirculation mechanism of refrigerant inside the unit that releases out heat continuously by getting cooling effect from the condenser.

- TopChiller designed Oil Chiller reduces the costs of maintenance for owner by factory mounting maintenance and simple design unit as scroll compressor is simple with rotating units requiring no maintenance.

- Smart ‘H’ microprocessor installation in Oil Chiller ensures the recognition and maintenance of temperature automatically by using a twisted pair of wires.

Oil Chiller is the durable and sturdy designed unit used for a wide variety of applications as:

Plastics industry, electroplating industry, hydraulic machines, CNC machines, furnaces in factories, plasma spray machines, induction hardening machine, laser work, welding, aeronautical testing, defense laboratory and, blow molding and injection molding machines.

If you need to buy an energy-efficient and superb quality Oil Chiller for the upscaling of your application and production increment?

If you are wandering in search of a reliable Oil Chiller manufacturing company for making a contract or getting help regarding your business build-up?

Yes, it’s the right way you choose. TopChiller accomplishes the needs of any corporate, or domestic client. So make a visit or do contact with TopChiller professional engineers and discuss your queries or get a quote for purchasing an Oil Chiller at reasonable costs.

TopChiller team is fulfilling the cooling requirement and other requisites for an Oil Chiller required by the client instantly.

- Data Sheet

- Image Gallery

- Main Parts

- Video

| Oil Chiller Technical Specifications | |||||||||||||||||

| Item Model | AC-0.5A | AC-1A | AC-1.5A | AC-2A | AC-2.5A | AC-3A | AC-4A | AC-5A | AC-6A | AC-8AD | AC-10AD | AC-12AD | AC-15AD | AC-20AD | AC-25AD | AC-30AT | |

| Cooling capacity | Kcal/h 50HZ/60HZ | 1419 | 2451 | 3182 | 4833 | 5848 | 7181 | 9288 | 11988 | 14534 | 18576 | 23994 | 29068 | 38270 | 49966 | 58480 | 74922 |

| 1703 | 2941 | 3784 | 5800 | 7018 | 8617 | 11146 | 14386 | 17441 | 22291 | 28793 | 34882 | 45924 | 59959 | 70176 | 89990 | ||

| KW 50HZ/60HZ | 1.65 | 2.85 | 3.7 | 5.62 | 6.8 | 8.35 | 10.8 | 13.94 | 16.9 | 21.6 | 27.9 | 33.8 | 44.5 | 58.1 | 68 | 87.2 | |

| 1.98 | 3.42 | 4.4 | 6.74 | 8.2 | 10.02 | 12.96 | 16.73 | 20.28 | 25.92 | 33.48 | 40.56 | 53.4 | 69.72 | 81.6 | 104.64 | ||

| Input power | KW | 0.88 | 1.35 | 2 | 2.25 | 2.66 | 3.27 | 4.07 | 5.75 | 6.45 | 8.25 | 11.5 | 12.9 | 17.45 | 21.73 | 25.4 | 33.1 |

| Max Current | A | 5.4 | 8.2 | 12 | 13.6 | 6.6 | 8.2 | 10.1 | 13.8 | 15.5 | 20 | 27.9 | 31.3 | 42.4 | 52.7 | 63.7 | 80.2 |

| Power source | 1PH~220V/3PH~220V/380V 50HZ/60HZ | 3PH~380V/415V/480V~50HZ/60HZ(3PH~200V/220V 50HZ/60HZ) | |||||||||||||||

| Refrigerant | Type | R22/R407C/134a/404A/410A | |||||||||||||||

| Control | Capillary / thermostatic expansion valve | ||||||||||||||||

| Compressor | Type | Hermetic Rotary | Hermetic scroll ( piston ) | ||||||||||||||

| Power(KW) | 0.45 | 0.89 | 1.3 | 1.73 | 2.1 | 2.7 | 3.5 | 4.55 | 5.25 | 3.5×2 | 4.55×2 | 5.25×2 | 7×2 | 8.96×2 | 10.8×2 | 8.96×3 | |

| Condenser | Type | Efficient finned copper tube with aluminum+low noise external rotor fan | |||||||||||||||

| Air flow (m³/h) | 750 | 1000 | 1500 | 2000 | 2500 | 3000 | 4000 | 5000 | 6000 | 8000 | 10000 | 12000 | 15000 | 20000 | 25000 | 30000 | |

| Air blower(KW) | 0.06 | 0.09 | 0.15 | 0.15 | 0.19 | 0.14×2 | 0.14×2 | 0.19×2 | 0.19×2 | 0.25×2 | 0.45×2 | 0.45×2 | 0.6×2 | 0.78×2 | 0.78×2 | 0.42×6 | |

| Evaporator | Type | SS Tank coil / shell and tube type / Plate type heat exchanger | |||||||||||||||

| Chilled water (m³/h) | 0.28 | 0.49 | 0.64 | 0.97 | 1.12 | 1.44 | 1.86 | 2.4 | 2.91 | 3.71 | 4.8 | 5.81 | 7.65 | 10 | 11.69 | 15 | |

| 0.34 | 0.59 | 0.76 | 1.16 | 1.4 | 1.72 | 2.23 | 2.88 | 3.49 | 4.46 | 5.76 | 7 | 9.18 | 11.99 | 14.03 | 18 | ||

| Water tank(L) | 10.6 | 18.3 | 27 | 27 | 50 | 50 | 60 | 60 | 110 | 120 | 200 | 200 | 270 | 350 | 350 | 420 | |

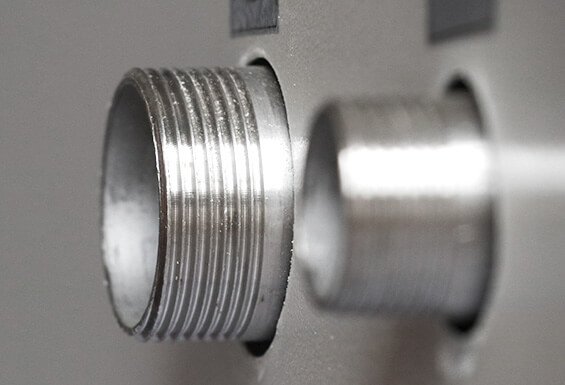

| Inlet/outlet pipe (inch) | 1/2″ | 1/2″ | 1/2″ | 1/2″ | 1″ | 1″ | 1″ | 1″ | 1″ | 1-1/2″ | 2″ | 2″ | 2″ | 2″ | 2-1/2″ | 2-1/2″ | |

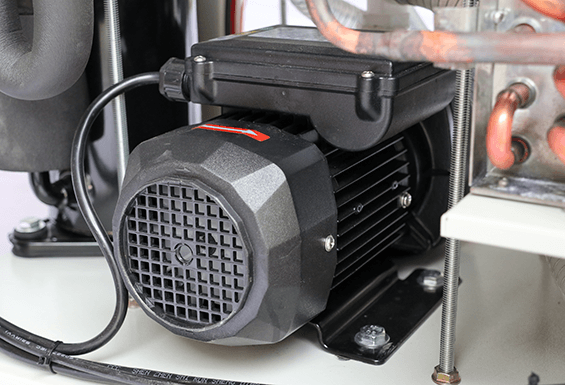

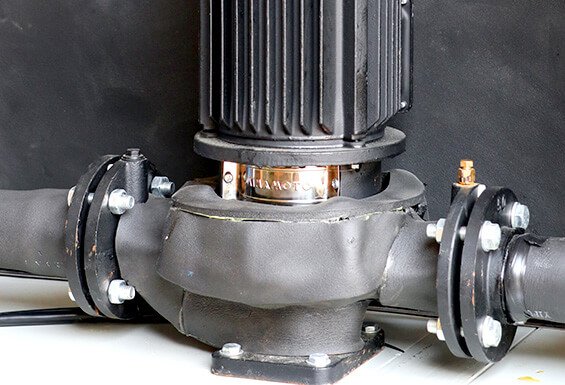

| Oil pump | Power (kw) | 0.37 | 0.37 | 0.37 | 0.37 | 0.37 | 0.37 | 0.37 | 0.75 | 0.75 | 0.75 | 1.5 | 1.5 | 2.2 | 2.2 | 2.2 | 4 |

| Max lift(m) | 22 | 22 | 22 | 22 | 22 | 22 | 22 | 30 | 30 | 25 | 25 | 25 | 28 | 28 | 28 | 30 | |

| Max flow (m3) | 5.4 | 5.4 | 5.4 | 5.4 | 5.4 | 5.4 | 5.4 | 8.1 | 8.1 | 8.1 | 13.5 | 13.5 | 25.2 | 25.2 | 25.2 | 36 | |

| Safety protection | Compressor inner protection, over current protection, high/low pressure protection, over temperature protection, flow rate protection, phase sequence/phase missing protection, low level coolant protection, anti freezing protection, exhaust overheat protection | ||||||||||||||||

| Dimension | L(mm) | 500 | 560 | 600 | 600 | 720 | 850 | 980 | 1100 | 1180 | 1450 | 1530 | 1530 | 1650 | 1850 | 1900 | 2250 |

| W(mm) | 350 | 420 | 420 | 480 | 550 | 580 | 520 | 580 | 620 | 750 | 750 | 750 | 910 | 1000 | 1050 | 1400 | |

| H(mm) | 600 | 720 | 770 | 910 | 1350 | 1030 | 1170 | 1350 | 1350 | 1500 | 1630 | 1630 | 1740 | 1850 | 1970 | 1950 | |

| Net weight(KG) | 45 | 70 | 85 | 95 | 125 | 150 | 175 | 195 | 220 | 285 | 350 | 370 | 510 | 630 | 820 | 950 | |

| Note: The above specifications are according to the following design conditions: 1, 12℃/7℃.Chilled water inlet/outlet temperature 12℃/7℃. 2, 33℃/38℃.Cooling air inlet/outlet temperature 33℃/38℃. We reserve the right to modify the specification without further notice. | |||||||||||||||||