TopChiller can design and manufacture all types of industrial air chillers for you

- Cooling capacity ranges 5 Ton up to 120 Ton

- Temperature control ranges -15℃ to 25℃

- Energy-efficient top branded compressor

- Stainless steel heat exchanger &evaporator

- Air-cooled energy-efficient insulated condenser

- An automated control system, filter, and dryer

- Emergency alarm & hot gas bypass installation

- Warranty up to 24 months after purchase

Your Premier Industrial Air Chiller Manufacturer and Supplier in China

Industrial Air Chiller is a compact refrigeration machine having peculiar features to release heat from industrial machinery working under refrigeration principle by using chilled air circulation.

TopChiller is a renowned company of China that was established in 1999, working constantly as manufacturer and supplier of Industrial Air Chiller and supplying it to global markets with credibility and standardization.

With 20 years of excellent experience, TopChiller is servicing the whole world with a high-performance full stock of Industrial Air Chiller models with different capacities confirming worldwide reputation.

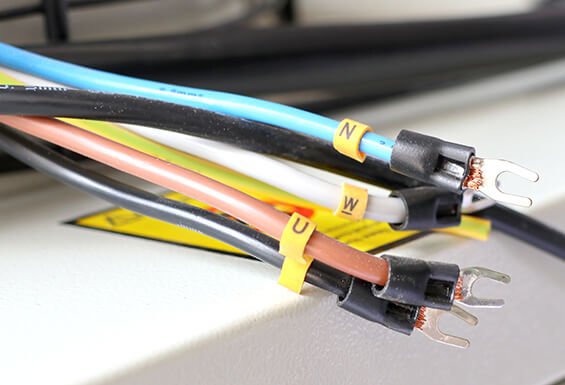

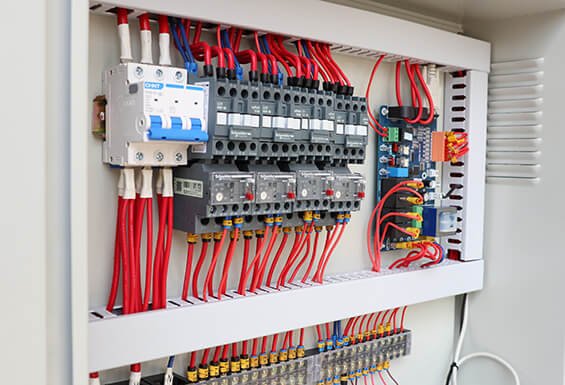

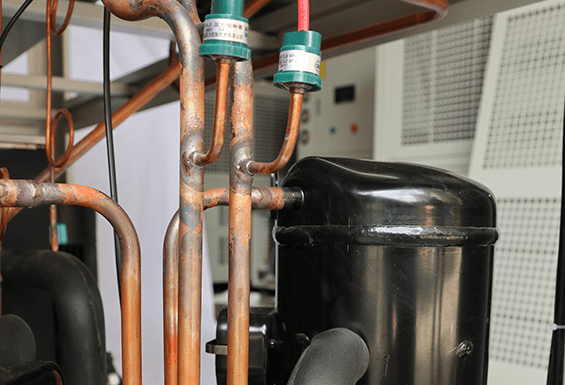

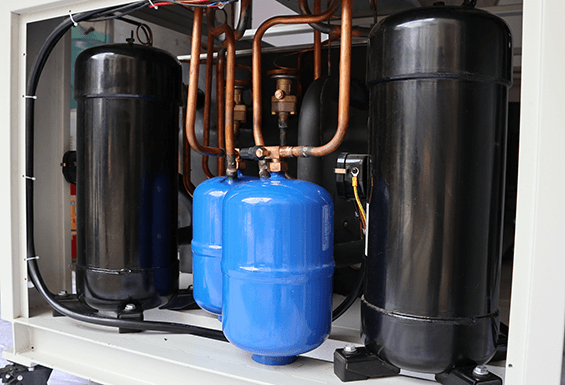

TopChiller engineered Industrial Air Chiller is featured with different branded components as hot gas bypass, branded compressor, dry filter, expansion valves, condenser fans, power supply, distribution units, evaporator, heat exchanger, solenoid valves, temperature controlling device, and power supply.

Industrial Air Chiller has a wide variety of benefits for industrial applications as given below:

- TopChiller designed Industrial Air Chiller makes a highly precise and regulated performance configured by the installation of an automated control panel that is instructed to control the heat flow, temperature, pressure, and power supply at set point automatically if there any fluctuation may happen.

- Industrial Air Chiller provides a cooling effect to industrial machinery by releasing heat produced during processing by working on three principles as phase change, heat flow, and boiling point by using condenser, evaporator, and heat exchanger.

- TopChiller brand Industrial Air Chiller is featured with hot gas bypass configuring the stabilized and continuous working of the unit by preventing the compressor from high pressure and condensate freezing.

- Industrial Air Chiller ensures the steadfast cooling and noise-free operation to industrial machinery by using rotor fans and filter that ensures the purity of circulating air inside the unit by filtering the dust particles obstructing in performance.

- PLC-based microprocessor controller plays a vital role to deal with high heating absorbed from industrial machines by maintaining it to set point or cut off the power supply in emergency preventing unit from heating damage.

Industrial Air Chiller has an assorted number of applications as:

Metal industry, medical industry, tires manufacturing, plastic and laser industry, commercial printing, transportation, composite manufacturing, machine tools production, plating, die-cutting, and semi-conductors, etc.

If you are looking for a highly specific and energy-conserving Industrial Air Chiller for your application?

If you are desiring to make contact with a reliable Industrial Air Chiller manufacturing company in China for the establishment of your business?

It is the best platform you hit. TopChiller is best to choose for its significant manufacturing and technical facilities. So without wasting time make contact with TopChiller personnel and expertise for getting assistance about the Industrial Air Chiller liability and durability regarding your application requirements.

TopChiller sales are directed to discuss the specific features of the client’s application and help you to select the best Industrial Air Chiller suitable for your application.

General Description:

An Industrial Air Chiller is an outstanding piece of machinery that is featured to cool down the atmosphere of industrial facilities by removing heat using air as a condensing medium.

It has a compact design that works under the principle of refrigeration. The unit absorbs excess heat from the industrial space and releases it into the outer atmosphere, employing air circulating throughout the system.

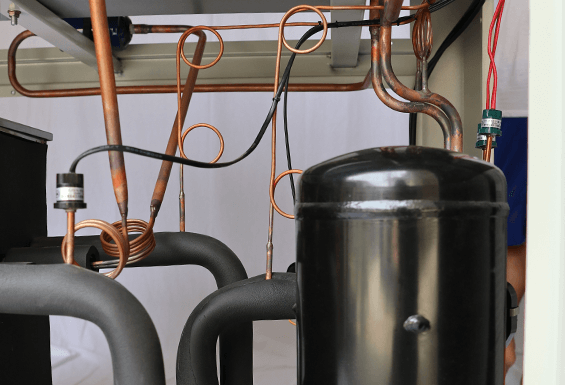

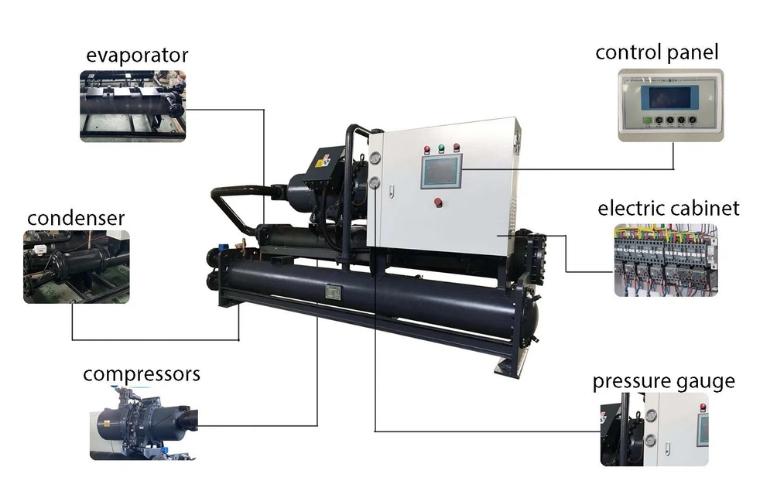

An Industrial Air Chiller designed by TopChiller possesses various essential components, out of which an imported quality evaporator, heavy-duty compressor, stable condenser, and an expansion valve are the major ones.

Industrial Air Chiller manufactured by TopChiller is specifically used for commercial and industrial applications. Primarily, it is used in industries where sufficient amounts of heat are produced that is efficiently exhausted by an. Such principal applications are the plastic industry, injection molding, food and beverage, thermal forming, blow molding, extrusion, plasma, laser, and medical industries.

TopChiller, a well-known manufacturer and supplier established 20 years sago, has introduced premium quality Industrial Air Chiller models and offers incredible features with efficient performance and long life.

If you have a lookout for a precise Industrial Air Chiller by a reliable manufacturer, here will be an end to your quest.

TopChiller is a brand recognized worldwide due to its quality and affordable prices. Reach out to our sales engineer without delay to have your Industrial Air Chiller at the best rates.

Features and Advantages:

An Industrial Air Chiller by TopChiller has been highlighted among others owing to its following remarkable features:

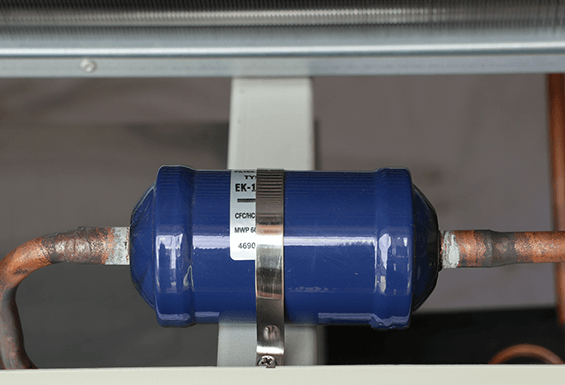

- An Industrial Air Chiller is featured by various safety devices to ensure the long life span of the unit. These primarily include compressor protectors, flow rate protection, anti-freezing protection, over-temperature protection, high and low-pressure protection, exhaust overheat protection, and over current protection.

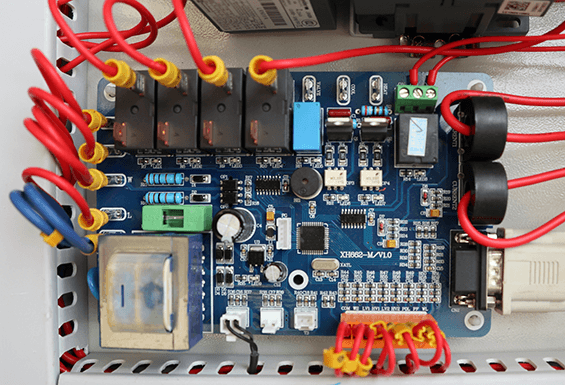

- PLC-based microprocessor controller maintains the cooling of industrial equipment by optimizing it to a set point. Moreover, it shuts down the system by cutting off the power supply in an emergency, preventing the unit from any damage.

- The filters ensure consistent operation by removing the contaminants that hinder the unit’s overall performance.

- The unit possesses an automatic tube cleaning facility that maintains the cleanliness of the unit and ensures its long-term operation.

- Our high-performance Industrial Air Chiller is configured by an automated control panel that controls the pressure, temperature, power supply, and heat flow at optimized levels if any fluctuation occurs.

- Data Sheet

- Image Gallery

- Main Parts

- Video

| Industrial Air Chiller Technical Specifications | ||||||||||||||

| Items Model | AC-0.5A | AC-1A | AC-1.5A | AC-2A | AC-2.5A | AC-3A | AC-4A | AC-5A | AC-6A | AC-8AD | AC-10AD | AC-12AD | AC-15AD | |

| Cooling capacity | Kcal/h 50HZ/60HZ | 1419 | 2451 | 3182 | 4833 | 5848 | 7181 | 9288 | 11988 | 14534 | 18576 | 23994 | 29068 | 38270 |

| 1703 | 2941 | 3784 | 5800 | 7018 | 8617 | 11146 | 14386 | 17441 | 22291 | 28793 | 34882 | 45924 | ||

| KW 50HZ/60HZ | 1.65 | 2.85 | 3.7 | 5.62 | 6.8 | 8.35 | 10.8 | 13.94 | 16.9 | 21.6 | 27.9 | 33.8 | 44.5 | |

| 1.98 | 3.42 | 4.4 | 6.74 | 8.2 | 10.02 | 12.96 | 16.73 | 20.28 | 25.92 | 33.48 | 40.56 | 53.4 | ||

| Input power | KW | 0.88 | 1.35 | 2 | 2.25 | 2.66 | 3.27 | 4.07 | 5.75 | 6.45 | 8.25 | 11.5 | 12.9 | 17.45 |

| Max Current | A | 5.4 | 8.2 | 12 | 13.6 | 6.6 | 8.2 | 10.1 | 13.8 | 15.5 | 20 | 27.9 | 31.3 | 42.4 |

| Power source | 1PH~220V/3PH~220V/380V 50HZ/60HZ | 3PH~380V/415V/480V~50HZ/60HZ(3PH~200V/220V 50HZ/60HZ) | ||||||||||||

| Refrigerant | Type | R22/R407C/134a/404A/410A | ||||||||||||

| Control | Capillary / thermostatic expansion valve | |||||||||||||

| Compressor | Type | Hermetic Rotary | Hermetic scroll ( piston ) | |||||||||||

| Power(KW) | 0.45 | 0.89 | 1.3 | 1.73 | 2.1 | 2.7 | 3.5 | 4.55 | 5.25 | 3.5×2 | 4.55×2 | 5.25×2 | 7×2 | |

| Condenser | Type | Efficient finned copper tube with aluminum+low noise external rotor fan | ||||||||||||

| Air flow (m3/h) | 750 | 1000 | 1500 | 2000 | 2500 | 3000 | 4000 | 5000 | 6000 | 8000 | 10000 | 12000 | 15000 | |

| Air blower(KW) | 0.06 | 0.09 | 0.15 | 0.15 | 0.19 | 0.14×2 | 0.14×2 | 0.19×2 | 0.19×2 | 0.25×2 | 0.45×2 | 0.45×2 | 0.6×2 | |

| Evaporator | Type | SS Tank coil / shell and tube type / Plate type heat exchanger | ||||||||||||

| Chilled water (m3/h) | 0.28 | 0.49 | 0.64 | 0.97 | 1.12 | 1.44 | 1.86 | 2.4 | 2.91 | 3.71 | 4.8 | 5.81 | 7.65 | |

| 0.34 | 0.59 | 0.76 | 1.16 | 1.4 | 1.72 | 2.23 | 2.88 | 3.49 | 4.46 | 5.76 | 7 | 9.18 | ||

| Water tank(L) | 10.6 | 18.3 | 27 | 27 | 50 | 50 | 60 | 60 | 110 | 120 | 200 | 200 | 270 | |

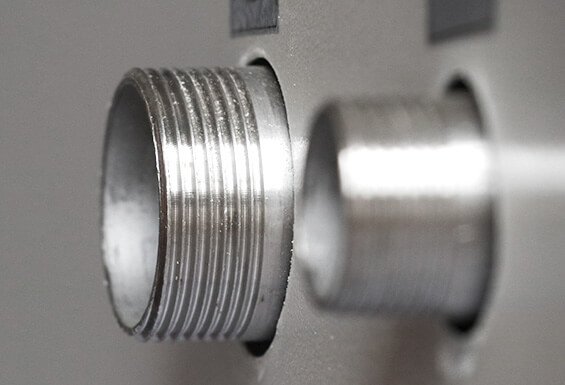

| Inlet/outlet pipe (inch) i | 1/2″ | 1/2″ | 1/2″ | 1/2″ | 1″ | 1″ | 1″ | 1″ | 1″ | 1-1/2″ | 2″ | 2″ | 2″ | |

| Water pump | Power (kw) | 0.37 | 0.37 | 0.37 | 0.37 | 0.37 | 0.37 | 0.37 | 0.75 | 0.75 | 0.75 | 1.5 | 1.5 | 2.2 |

| Max lift(m) | 22 | 22 | 22 | 22 | 22 | 22 | 22 | 30 | 30 | 25 | 25 | 25 | 28 | |

| Max flow (m3) | 5.4 | 5.4 | 5.4 | 5.4 | 5.4 | 5.4 | 5.4 | 8.1 | 8.1 | 8.1 | 13.5 | 13.5 | 25.2 | |

| Safety protection | Compressor inner protection, over current protection, high/low pressure protection, over temperature protection, flow rate protection, phase sequence/phase missing protection, low level coolant protection, anti freezing protection, exhaust overheat protection | |||||||||||||

| Dimension | L(mm) | 550 | 550 | 600 | 600 | 720 | 980 | 980 | 1150 | 1150 | 1350 | 1500 | 1500 | 1860 |

| W(mm) | 350 | 450 | 500 | 500 | 550 | 520 | 520 | 560 | 560 | 680 | 760 | 760 | 850 | |

| H(mm) | 695 | 845 | 985 | 985 | 1350 | 1170 | 1170 | 1215 | 1215 | 1530 | 1660 | 1660 | 1900 | |

| Net weight(KG) | 45 | 62 | 85 | 95 | 125 | 152 | 175 | 185 | 215 | 283 | 345 | 382 | 580 | |

| Note: The above specifications are according to the following design conditions: 1, 12℃/7℃.Chilled water inlet/outlet temperature 12℃/7℃. 2, 33℃/38℃.Cooling air inlet/outlet temperature 33℃/38℃. We reserve the right to modify the specification without further notice. | ||||||||||||||

| Industrial Air Chiller Technical Specifications | |||||||||||||

| Items Model | AC-15AT | AC-20AD | AC-20AF | AC-25AD | AC-25AF | AC-30AD | AC-30AT | AC-40AD | AC-40AF | AC-50AD | AC-50AF | AC-60AD | |

| Cooling capacity | Kcal/h 50HZ/60HZ | 36120 | 49966 | 47988 | 58480 | 58136 | 74734 | 74922 | 98040 | 99760 | 119024 | 116960 | 144996 |

| 43344 | 59959 | 57586 | 70176 | 69763 | 89681 | 89990 | 117648 | 119712 | 142829 | 140352 | 173995 | ||

| KW 50HZ/60HZ | 42 | 58.1 | 55.8 | 68 | 67.6 | 86.9 | 87.2 | 114 | 116 | 138.4 | 136 | 168.6 | |

| 50.4 | 69.72 | 66.96 | 81.6 | 81.12 | 104.28 | 104.64 | 136.8 | 139.2 | 166.08 | 163.2 | 202.3 | ||

| Input power | KW | 17.1 | 21.73 | 22 | 25.4 | 24.8 | 33.39 | 33.1 | 44.91 | 43.3 | 57.3 | 54 | 65 |

| Max Current | A | 43.2 | 52.7 | 53.3 | 63.7 | 61.3 | 81 | 80.2 | 109 | 106 | 135.5 | 128.5 | 135 |

| Power source | 3PH~380V/415V/480V~50HZ/60HZ(3PH~200V/220V 50HZ/60HZ) | ||||||||||||

| Refrigerant | Type | R22/R407C/134a/404A/410A | |||||||||||

| Control | Capillary / Thermostatic expansion valve | ||||||||||||

| Compressor | Type | Hermetic scroll ( piston ) | |||||||||||

| Power(KW) | 4.55×3 | 8.96×2 | 4.55×4 | 10.8×2 | 5.25×4 | 13.62×2 | 8.96×3 | 18.78×2 | 8.96×4 | 23.6×2 | 10.8×4 | 27.4×2 | |

| Condenser | Type | Efficient finned copper tube with aluminum+low noise external rotor fan | |||||||||||

| Air flow (m³/h) | 15000 | 20000 | 20000 | 25000 | 25000 | 30000 | 30000 | 40000 | 40000 | 50000 | 50000 | 60000 | |

| Air blower(KW) | 0.6×2 | 0.78×2 | 0.78×2 | 0.78×2 | 0.78×2 | 0.42×6 | 0.42×6 | 0.6×6 | 0.6×6 | 0.78×6 | 0.78×6 | 0.78×6 | |

| Evaporator | Type | SS Tank coil/ shell and tube type/Plate type heat exchanger | |||||||||||

| Chilled water (m³/h) | 7.22 | 10 | 9.6 | 11.69 | 11.62 | 14.94 | 15 | 19.6 | 19.95 | 23.8 | 23.4 | 29 | |

| 8.67 | 11.99 | 11.51 | 14.03 | 13.95 | 17.93 | 18 | 23.52 | 23.94 | 28.6 | 28.1 | 34.8 | ||

| Water tank(L) | 270 | 350 | 350 | 350 | 350 | 420 | 420 | 580 | 580 | 580 | 580 | 580 | |

| inlet/outlet pipe (inch) | 2″ | 2″ | 2″ | 2-1/2″ | 2-1/2″ | 2-1/2″ | 2-1/2″ | 3″ | 3″ | 3″ | 3″ | 3″ | |

| Water pump | Power(kw) | 2.2 | 2.2 | 2.2 | 2.2 | 2.2 | 4 | 4 | 4 | 4 | 5.5 | 5.5 | 5.5 |

| Max lift(m) | 28 | 28 | 28 | 28 | 28 | 30 | 30 | 30 | 30 | 32 | 32 | 32 | |

| Max flow (m³) | 25.2 | 25.2 | 25.2 | 25.2 | 25.2 | 36 | 36 | 36 | 36 | 40 | 40 | 40 | |

| Safety devices | Compressor inner protection, over current protection, high/low pressure protection, over temperature protection, flow rate protection, phase sequence/phase missing protection, low level coolant protection, anti freezing protection, exhaust overheat protection | ||||||||||||

| Dimension | L(mm) | 1860 | 2020 | 2020 | 2020 | 2020 | 2200 | 2200 | 2350 | 2350 | 2600 | 2600 | 2600 |

| W(mm) | 850 | 950 | 950 | 950 | 950 | 1150 | 1150 | 1350 | 1350 | 1500 | 1500 | 1500 | |

| H(mm) | 1900 | 2000 | 2000 | 2000 | 2000 | 1980 | 1980 | 2000 | 2000 | 2100 | 2100 | 2100 | |

| Net weight(KG) | 580 | 650 | 650 | 810 | 810 | 890 | 890 | 1112 | 1112 | 1320 | 1320 | 1320 | |

| Note: The above specifications are according to the following design conditions: 1, Chilled water inlet/outlet temperature 12℃/7℃. 2, Cooling air inlet/outlet temperature 33℃/38℃. We reserve the right to modify the specification without further notice. | |||||||||||||

| Industrial Air Chiller Technical Specifications | ||||||||||||||

| Model Items | TPAS-80ASH | TPAS-110ASH | TPAS-140ASH | TPAS-160ASH | TPAS-190ASH | TPAS-210ASH | TPAS-250ASH | TPAS-290ASH | TPAS-310ASH | TPAS-340ASH | TPAS-400ASH | TPAS-430ASH | ||

| Cooling capacity | kcal/h | 68800 | 94600 | 122980 | 135020 | 164260 | 180600 | 212420 | 245100 | 266600 | 292400 | 348300 | 369800 | |

| KW | 80 | 110 | 143 | 157 | 191 | 210 | 247 | 285 | 310 | 340 | 405 | 430 | ||

| Input power | KW | 32.5 | 43.6 | 54.7 | 59.7 | 73.6 | 79.6 | 88.2 | 101.2 | 112.8 | 123.8 | 145 | 155 | |

| Max Current | A | 57 | 75 | 95 | 103 | 125 | 135 | 151 | 173 | 191 | 211 | 246 | 263 | |

| Power source | 3PH~380V/415V/480V~50HZ/60HZ(3PH~200V/220V 50HZ/60HZ) | |||||||||||||

| Refrigerant | Type | R22(R134a/R407c/R404A) | ||||||||||||

| Charge | kg | 21 | 28 | 35 | 42 | 49 | 56 | 63 | 70 | 77 | 84 | 98 | 112 | |

| Control | Thermostatic expansion valve | |||||||||||||

| Compressor | Type | Semi-hermetic screw | ||||||||||||

| Power | KW | 30 | 40 | 50 | 55 | 67 | 73 | 82 | 95 | 104 | 115 | 134 | 142 | |

| Start mode | Y-△ | |||||||||||||

| Capacity control | % | 0-33-66-100 | 0-25-50-75-100 | |||||||||||

| Evaporator | Type | Shell and tube (SS plate heat exchanger) | ||||||||||||

| Chilled water | m³/h | 13.8 | 18.9 | 24.6 | 27.0 | 32.8 | 36.1 | 42.5 | 49.0 | 53.3 | 58.4 | 70.0 | 74.0 | |

| Water pressure | KPa | 32 | 32 | 35 | 38 | 42 | 42 | 45 | 43 | 43 | 43 | 41 | 43 | |

| Pipe connection | Inch | 3″ | 3″ | 3″ | 4″ | 4″ | 4″ | 4″ | 4″ | 5″ | 5″ | 6″ | 6″ | |

| Condenser | Type | Air cooled type high efficiency finned cooper tube | ||||||||||||

| Fan | Type | m³/h | Big volume & low noise axil fan | |||||||||||

| Power | KW | 0.42×6 | 0.6×6 | 0.78×6 | 0.78×6 | 1.1×6 | 1.1×6 | 0.78×8 | 0.78×8 | 1.1×8 | 1.1×8 | 1.1×10 | 1.1×12 | |

| Air volume | m³/h | 30000 | 40000 | 50000 | 60000 | 70000 | 80000 | 90000 | 100000 | 110000 | 116000 | 145000 | 165000 | |

| Safety protection devices | Inner thermostat for compressor motor, unit overload relay,high and low pressure switch, freeze protection thermostat, reverse phase protection relay, discharge gas thermostat, flow switch | |||||||||||||

| Dimension | Length | mm | 2200 | 2350 | 2600 | 2600 | 2650 | 2650 | 3400 | 3400 | 3800 | 3800 | 4800 | 5800 |

| Width | mm | 1150 | 1350 | 1500 | 1500 | 1900 | 1900 | 1700 | 1700 | 1900 | 1900 | 1900 | 1900 | |

| Height | mm | 1980 | 2000 | 2100 | 2100 | 2200 | 2200 | 2200 | 2200 | 2200 | 2200 | 2200 | 2200 | |

| Net weight | kg | 1100 | 1300 | 1600 | 1900 | 2200 | 2350 | 2550 | 2800 | 2850 | 2950 | 3200 | 3550 | |

| Running weight | kg | 1300 | 1500 | 1840 | 2200 | 2530 | 2700 | 2950 | 3250 | 3350 | 3560 | 3650 | 3950 | |

| The above specifications are according to the following design conditions: 1, Chilled water inlet/outlet temperature 12℃/7℃. 2, Cooling air inlet/outlet temperature 30℃/38℃. We reserve the right to modify the specifications without further notice. | ||||||||||||||

| Industrial Air Chiller Technical Specifications | ||||||||||||||

| Model Items | TPAS-160ADH | TPAS-220ADH | TPAS-285ADH | TPAS-315ADH | TPAS-380ADH | TPAS-420ADH | TPAS-495ADH | TPAS-570ADH | TPAS-620ADH | TPAS-680ADH | TPAS-810ADH | TPAS-860ADH | ||

| Cooling capacity | kcal/h | 137600 | 189200 | 245960 | 270040 | 328520 | 361200 | 424840 | 490200 | 533200 | 584800 | 696600 | 739600 | |

| KW | 160 | 220 | 286 | 314 | 382 | 420 | 494 | 570 | 620 | 680 | 810 | 860 | ||

| Input power | KW | 64.7 | 86.6 | 106.2 | 118.8 | 145 | 159.2 | 177.2 | 207.6 | 225.6 | 247.6 | 290 | 310.4 | |

| Max Current | A | 114 | 149 | 185 | 205 | 250 | 274 | 308 | 358 | 388 | 428 | 500 | 533 | |

| Power Source | 3PH~380V/415V/480V~50HZ/60HZ(3PH~200V/220V 50HZ/60HZ) | |||||||||||||

| Refrigerant | Type | R22(R134a/R407c/R404A) | ||||||||||||

| Charge | kg | 21×2 | 28×2 | 35×2 | 42×2 | 49×2 | 56×2 | 63×2 | 70×2 | 77×2 | 84×2 | 98×2 | 112×2 | |

| Control | Thermostatic expansion valve | |||||||||||||

| Compressor | Type | Semi-hermetic screw | ||||||||||||

| Power | KW | 30×2 | 40×2 | 50×2 | 55×2 | 67×2 | 73×2 | 82×2 | 95×2 | 104×2 | 115×2 | 134×2 | 142×2 | |

| Start mode | Y-△ | |||||||||||||

| Capacity control | % | 0-33-66-100 | 0-25-50-75-100 | |||||||||||

| Evaporator | Type | Shell and tube (SS plate heat exchanger) | ||||||||||||

| Chilled water | m³/h | 27.5 | 37.8 | 49.1 | 54 | 65.7 | 72.2 | 85 | 98 | 106.6 | 117 | 139.3 | 147.9 | |

| Water pressure | KPa | 32 | 32 | 35 | 38 | 42 | 42 | 45 | 43 | 43 | 43 | 41 | 43 | |

| Pipe connection | Inch | 4″ | 4″ | 4″ | 5″ | 6″ | 6″ | 6″ | 6″ | 8″ | 8″ | 8″ | 10″ | |

| Condenser | Type | Air cooled type high efficiency finned cooper tube | ||||||||||||

| Fan | Type | m³/h | Big volume & low noise axil fan | |||||||||||

| Power | KW | 0.78×6 | 1.1×6 | 0.78×8 | 1.1×8 | 1.1×10 | 1.1×12 | 1.1×12 | 1.1×16 | 1.1×16 | 1.1×16 | 1.1×20 | 1.1×24 | |

| Air volume | m³/h | 60000 | 80000 | 100000 | 116000 | 145000 | 165000 | 180000 | 205000 | 225000 | 242000 | 285000 | 325000 | |

| Safety protection devices | Inner thermostat for compressor motor, unit overload relay, high and low pressure switch, freeze protection thermostat, reverse phase protection relay, discharge gas thermostat, flow switch | |||||||||||||

| Dimension | Length | mm | 2600 | 2650 | 3400 | 3800 | 4800 | 5800 | 5800 | 7800 | 7800 | 8000 | 9800 | 11600 |

| Width | mm | 1500 | 1900 | 1700 | 1900 | 1900 | 1900 | 2200 | 2000 | 2200 | 2200 | 2200 | 2200 | |

| Height | mm | 2100 | 2200 | 2200 | 2200 | 2200 | 2200 | 2300 | 2250 | 2250 | 2300 | 2350 | 2350 | |

| Net weight | kg | 2050 | 2520 | 2980 | 3180 | 3420 | 3730 | 3950 | 4330 | 4650 | 4930 | 5450 | 5850 | |

| Running weight | kg | 2360 | 2870 | 3420 | 3690 | 3780 | 4180 | 4380 | 4650 | 4920 | 5360 | 5830 | 6530 | |

| The above specifications are according to the following design conditions: 1, Chilled water inlet/outlet temperature 12℃/7℃. 2, Cooling air inlet/outlet temperature 30℃/38℃. We reserve the right to modify the specifications without further notice. | ||||||||||||||

Why TopChiller is Your Reliable Industrial Air Chiller Manufacturer and Supplier In China?

Industrial Air Chiller-An Ultimate FAQ Guide by TopChiller.

- What is an Industrial Air Chiller?

- What are the Prominent Features of an Industrial Air Chiller?

- What are the Main Components of an Industrial Air Chiller?

- What is the Protection Features of an Industrial Air Chiller?

- How Does an Industrial Air Chiller Work?

- What are the Advantages you will Get from an Industrial Air Chiller?

- In Which Industries Do an Industrial Air Chiller Applicable?

- How Does an Industrial Air Chiller Different from an Industrial Water Chiller?

- What is the Difference Between a Portable Air Chiller and Stationary Industrial Air Chiller?

- How to Size an Appropriate Industrial Air Chiller for your Industry?

- How to Calculate the Cooling Capacity of an Industrial Air Chiller?

- How is an Industrial Air Chiller Better than an Industrial Water Chiller?

- What are the Control Features of an Industrial Air Chiller?

- Is an Industrial Air Chiller Energy-Efficient?

- How to Customize your Industrial Air Chiller?

- What Types of Compressors can be Installed in an Industrial Air Chiller?

- How to Adjust Different Parameters in your Industrial Air Chiller?

- What are the Common Problems of an Industrial Air Chiller?

- How to Troubleshoot the Common Problems of your Industrial Air Chiller?

What is an Industrial Air Chiller?

An Industrial Air Chiller is a prime quality cooling system based on a closed-loop that circulates fluid throughout the system to remove the heat from an industrial unit through the air.

The working principle of the unit is based on the compression, condensation, and evaporation of the refrigerant. It enables to control of the temperature of the industrial area by circulating chilled water through the unit and withdrawing excessive heat with the help of air.

In industries, heat produces adequate quantities that need to be removed. An Industrial Air Chiller gives a way to get rid of this excess heat and increases the production rate of industrial machinery by cooling.

The unit contains the significant components of an evaporator, compressor, condenser, and expansion valve. The unit has made the installation easy as it does not carry the complications of the cooling tower.

It is used in numerous industrial processes, including plastic injection, laser, water jet cutting, plastic extruding, craft brewery, plasma, welding, and chemicals.

It offers significant savings on water expenses as it can circulate the coolant again and again through the closed-loop.

TopChiller Industrial Air Chiller

What are the Prominent Features of an Industrial Air Chiller?

The following remarkable features of an Industrial Air Chiller are listed below:

Advanced Control System

The unit possesses a microprocessor control system that maintains the cooling ranges and optimizes the unit at set points.

Even if the unit endures the power failure, it automatically restores the operation status.

Energy Efficiency

It contains multiple compressors that boost its performance and reduce energy consumption.

Furthermore, the unit has a small compact structure. It has a uniform air distribution throughout the system, increasing its efficiency by 30%.

It reduces the loss of power by the compressor.

Easy Installation

It neither requires a separate space room for its installation nor needs cooling towers. The installation process is merely about the pipeline connection between units using two standard flexible pipe joints.

Thus, the installation has been made easy in an Industrial Air Chiller.

Protection Devices

An Industrial Air Chiller protects itself with various protection devices to ensure its long life.

These protection devices are compressor protectors, flow rate protection, anti-freezing protection, over-temperature protection, high and low-pressure protection, exhaust overheat protection, over-current protection, and many more.

Reliability

The unit operates quietly and has higher durability, remarkable efficiency, and reduced power consumption. It has a reliable structure and stable configuration.

What are the Main Components of an Industrial Air Chiller?

Typically, an Industrial Air Chiller is composed of the following essential components:

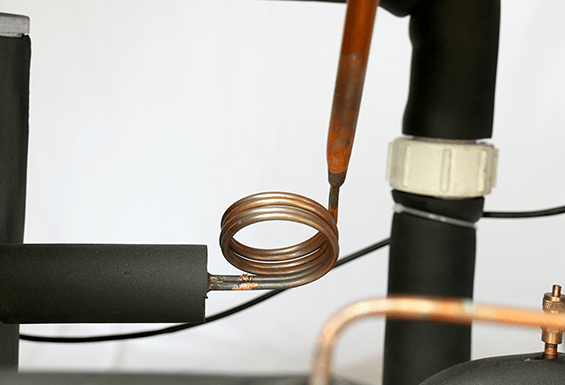

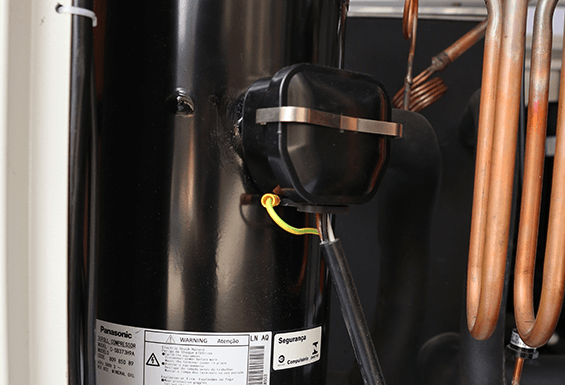

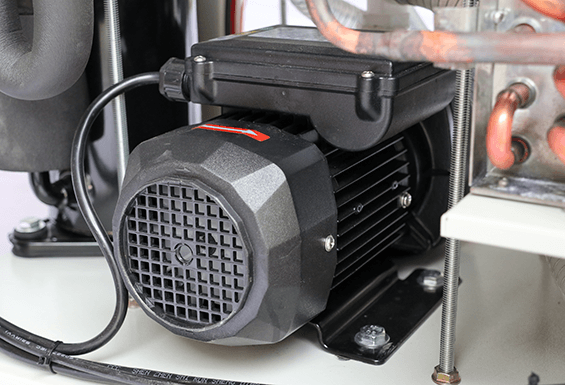

Compressor

Scroll compressor, screw, and reciprocating compressors are usually used in an Industrial Air Chiller. It plays a role in raising the pressure and temperature of the refrigerant.

Condenser

A condenser is a bundle of horizontal pipes surrounded by thin metal sheets. It proceeds the condensation process through the refrigerant and removes heat from it.

Condenser Fans

Across the condenser coils, the condenser fans suck air and force it out into the ambient temperature.

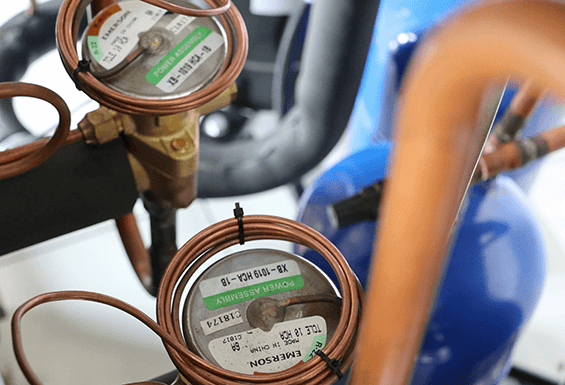

Expansion Valve

The expansion valve expands the refrigerant before entering the evaporator. It reduces the pressure of the refrigerant.

Evaporator

In the evaporator, the refrigerant gets boiled by absorbing heat from the process water. It then converts into low-pressure gas from low-pressure liquid.

Filter Dryer

If the traces of moisture get stuck in the refrigeration cycle, a filter dryer serves to remove this moisture.

Industrial Air Chiller Major Components

What is the Protection Features of an Industrial Air Chiller?

An Industrial Air Chiller is provided with various protection features. These features allow the unit to respond smartly to any emergency.

Among many, a few of the prominent protection features are named below:

- Overcurrent Protection For Compressor

- Antifreeze Protection

- Flow Switch

- Tank Level Sensor

- Overheating Protection

- Outlet Temperature Indication

- High-Pressure Safety Switch

- Low-Pressure Safety Switch

- Condensing Pressure Switch

- Water Pressure Gauge

- Overloading Protection

- Compressor Overheating Protection

- Phase Sequence Protection

- Over-Temperature Protection

Industrial Air Chiller Water Pressure Gauge

How Does an Industrial Air Chiller Work?

The working of an Industrial Air Chiller forms a closed loop that cyclically involves compression and absorption.

A compressor is said to be the driving force of the refrigeration cycle. It converts the refrigerant liquid into vapors. The refrigerant is a highly pressurized and superheated vapor when it exits the compressor and enters the condenser.

The refrigerant runs along the pipes lying horizontally in the condenser. Here, it will withdraw its thermal energy and transfer it into the ambient air forced by the condenser fan.

At this point, the refrigerant starts to condense and gets converted back into a liquid. Later, when it leaves the condenser, it is a high-pressure, saturated liquid having a moderate temperature.

The refrigerant, before entering the evaporator, passes by an expansion valve. It monitors the flow of refrigerants. It adjusts its flow rate within optimized ranges.

A small cavity only allows a little refrigerant to flow by an expansion valve. It lowers the pressure and expands it in a semi-liquid state.

Ultimately, the refrigerant flows through the evaporator, passing by a series of horizontal tubes. It becomes a low-pressure saturated vapor with a low temperature when it leaves the evaporator.

This vaporization is accomplished by the chilled process water that will have delivered its heat energy to the refrigerant.

The refrigerant vapors will again go through the compressor, repeating the cycle.

What are the Advantages you will Get from an Industrial Air Chiller?

An Industrial Air Chiller is a preferred choice to meet the cooling requirements of an industrial unit.

Besides, you will get many advantages of using an Industrial Air Chiller as a cooling solution for your warmer industrial environment.

Continuous Operation

It uses multiple refrigeration circuits with various protection features that ensure your chiller’s long-term service and continuous operation.

It keeps on cooling the industrial environment with the same efficiency according to your cooling needs.

Low Maintenance

An Industrial Air Chiller has an advantage by which it has been made easy to maintain.

Easy Installation

Unlike an industrial water chiller, an Industrial Air Chiller does not need the installation of cooling towers. It carries a simple engineering installation process that operates quietly.

Lower Space Requirements

It does not require a separate room for its installation. Instead, it requires a little space to install; thus, it is perfect for industries with restricted space.

Minimal Water Cost

The unit has reduced water consumption by using air to dissipate heat from the system. Therefore, it is an ideal choice for industrial plants enduring water drought.

Low Power Consumption

The Industrial Air Chiller has an advantage in having a lower power consumption.

In Which Industries Do an Industrial Air Chiller Applicable?

An Industrial Air Chiller has a vast area of industrial applications. It is used in all commercial plants where the rate of heat production is higher, and it essentially needs to be removed.

Besides, it is used in many industries to keep the temperature under control. These mainly include:

- Injection Molding

- Blow Molding

- Extrusion

- Chemical and Pharmaceutical Industries

- Laser Cutting

- Machine Tools

- Thermoforming Equipment

- Semiconductor

- Optics

- Linear Accelerator Cooling

- Welding

- Research Laboratories

- CNC Machine

- Plasma Cutting

- Analytical Instrument

How Does an Industrial Air Chiller Different from an Industrial Water Chiller?

An Industrial Air Chiller uses ambient air that utilizes fans to eliminate excessive heat produced in the system. Therefore, it does not contain a cooling tower and requires less maintenance.

It demands less space for installation and is easy to install. The Industrial Air Chiller does not need an adequate water supply thus has fewer operation costs.

It typically has a small size and is suitable for small or medium-scale applications.

On the other hand, an industrial water chiller circulates water throughout the system and removes heat employing the cooling tower. It is more efficient in cooling, having a more precise heat transfer.

It is more durable, having a longer life appropriate for larger applications. It is more energy-efficient.

But the industrial water chiller is big; thus, it needs a larger surface area for installation. It essentially requires a continuous and sufficient water supply, having a more complicated installation process.

What is the Difference Between a Portable Air Chiller and Stationary Industrial Air Chiller?

An Industrial Air Chiller can be of two types based on its structure and mobility. It can be a Portable Industrial Air Chiller or a Stationary Industrial Air Chiller.

As represented by the name, a Portable Industrial Air Chiller can be moved easily from one application unit to another. It has a small size and requires less surface area. One can bring it to other application areas and make it of use.

All of its components are assembled within a movable size of it thus, do not possess any installation efforts. Moreover, it is less pricey than a Stationary Industrial Air Chiller and more energy efficient.

Yet, it is less powerful than the other one. Therefore, suitable for temporary use or smaller-scale industrial areas.

On the contrary, the Stationary Industrial Air Chiller is immobile, stays fixed where installed. The unit is bigger in size that extends over a larger area. It is not easy to install as it involves installing the major components on a particular site.

It is more powerful and efficiently used for larger industrial applications to produce enormous cooling effects.

However, it is more costly than the stationary ones. It demands more maintenance efforts and operational costs.

Portable Air Chiller

How to Size an Appropriate Industrial Air Chiller for your Industry?

Heat is produced as a by-product of the refrigeration cycle. This heat essentially needs to be removed.

If you select the correct size of your Industrial Air Chiller, you will have an ideal cooling effect for your application unit with minimal energy consumption.

However, if you fail to pick the proper size for the unit, it can directly impact the production rate and the working of your application area.

If you select an Industrial Air Chiller larger than the requirements of your application area, the energy will get wasted, and the operational costs will increase.

On the contrary, the heat will not dissipate efficiently on time if you select a smaller unit than your application needs. It would impact the regular operation of the system and the production efficiency of the product.

Therefore, the appropriate sizing of a chiller is an essential factor to consider to meet the ideal cooling requirements.

You can select the appropriate size for your Industrial Air Chiller by considering the following:

- Calculate the Temperature Differential.

ΔT°F = The inlet temperature of the cooling medium – the required temperature of the cooling medium.

- Calculate the cooling capacity by the following formula in BTU/hr.

Cooling Capacity in BTU/hr. = Gallons per hour x ΔT°F x 8.33

- Convert the cooling capacity from BTU per hour into tons by dividing it by 12000.

- You can determine the ideal size or tonnage of your Industrial Air Chiller by oversizing it by 20%.

The ideal size of an Industrial Air Chiller will be the product of tons and 1.2.

How to Calculate the Cooling Capacity of an Industrial Air Chiller?

The cooling capacity of an Industrial Air Chiller can be defined as the unit’s capability to withdraw heat from your industrial plant. Its S.I unit is watt but is usually measured in BTU per unit hour.

To measure the cooling capacity of an Industrial Air Chiller, you need to determine the following parameters.

- The temperature difference between the temperatures of inlet water (°C) and the required temperature of chilled water (ΔT°F)

- Calculate the flow rate of water per hour(m³/hour)

Finally, you can figure out the tons of cooling capacity by putting the value in the given formula.

Tons of cooling capacity = rate of water flow x Differential Temperature ÷ 0.86 ÷ 3.517

How is an Industrial Air Chiller Better than an Industrial Water Chiller?

An Industrial Air Chiller uses ambient air to dissipate heat produced in the system. However, an industrial water chiller uses water in the place of air.

An Industrial Air Chiller is better than an industrial water chiller if you consider the following factors.

No Cooling Tower

An Industrial Air Chiller does not use a cooling tower to get rid of heat. Contrarily, it uses fans to exhaust heat to the outer atmosphere.

Easy Installation

Another advantage of An Industrial Air Chiller is that it does not involve complex engineering installation. Due to the lack of a cooling tower, it is easy to install.

Easy Maintenance

It is easier to maintain than an industrial water chiller with lower maintenance expenses.

Small Size

It is small; thus, it does not need a separate room or a larger area for its installation. However, the reverse is the case of an industrial water chiller that requires a larger surface area.

Limited Water Costs

As an Industrial Air Chiller uses air to remove heat, it does not cost as much as the industrial water chiller.

It does not need an adequate quantity of water. Thus, it is a perfect choice for industrial plants in water-deficient areas.

Industrial Water Chiller

What are the Control Features of an Industrial Air Chiller?

An Industrial Air Chiller possesses various control features. Some of which are the following:

- Cooling capacity control is available at four steps (100%, 75%, 50%, 25%), three steps (100%, 66%, 33%).

- Remote Control Panel

- Microprocessor Control System

- Central Control

- Programmable Logic Controller

- Touchscreen Options

- Pressure Indicators

- Temperature Indicators

- Programmable Logic Controller

- High and Low-Pressure Refrigeration Safety Control

- Flow Switch

- Touchscreen Options

- Fan Staging Controls

- Safety Controls

Industrial Air Chiller Touch Screen

Is an Industrial Air Chiller Energy-Efficient?

An Industrial Air Chiller is highly energy efficient. It has adopted the following features to reduce its energy costs.

- It is possessed by an insulated condenser and high-quality compressors that efficiently reduce energy consumption.

- Condenser fan motors are modified to consume minimal energy and have more stable refrigerant temperatures.

- An Industrial Air Chiller contains multiple compressors that boost its performance and reduce energy consumption.

- Variable frequency drive is introduced on pumps to reduce energy consumption.

- Furthermore, the unit has a small compact structure. It has a uniform air distribution throughout the system. It reduces the loss of power by the compressor.

How to Customize your Industrial Air Chiller?

Conveniently, you can customize your industrial Air Chiller according to your requirements.

Following are a few customization features that would be helpful to modify under your needs and preferences.

Heat Exchanger

- Custom Tank Fittings

- Fluid Level Sight Glass

- VFD (Variable Frequency Drive) Available for Pumps

- Tank Low-Level Indicator With Alarm

- On-Board or Remote Tank and Pump Packages

Redundancy

You would have an opportunity to have flexible redundancy customization by which you can customize various components of your unit. These may include:

- Dual Circuit or Multi-Circuit Units

- Full Capacity Redundancy

- Auto-Changeover Redundant Pumps

- Full Electrical Isolation

Controls

Besides, a few of the control options can be customized that including:

- Central Control for Multiple Units

- Custom Programming for Application Control

- On-Board or Remote Touchscreen Options

What Types of Compressors can be Installed in an Industrial Air Chiller?

The Industrial Air Chiller varies based on the type of compressors used. There are four significant types of compressor used in it.

Centrifugal Compressor

The centrifugal compressor uses centrifugal force to compress the refrigerant. It moves at a very high speed.

It propels the refrigerant through a rotating impeller to compress it to a highly pressurized state. The kinetic energy is produced when the impeller spins the refrigerant very quickly.

Rotary or Screw Compressor

Rotary or screw compressor converts the refrigerant vapors from low to high pressure using two screws and the male and female rotors.

These rotors rotate in the opposite direction, and the air is drawn in between them. These rotors entrap and compress the refrigerant in a compressor casing.

Scroll Compressor

The scroll compressor contains two scrolls; a fixed and a moving scroll. The fixed scroll usually stays attached to the compressor. At the same time, the moving scroll tracks the path of the fixed scroll.

Between these two scrolls, the refrigerant is slowly pushed to the center and consequently reduces the volume of the refrigerant.

Industrial Air Chiller Scroll Compressor

Reciprocating Compressor

The reciprocating compressor is further classified into hermetic compressors and open compressors.

It contains pistons and a cylinder. Electric motors and combustion engines drive this compressor to provide gases at high pressure.

When the piston moves downward, the refrigerants draw into the cylinder. And as the piston reverses its direction, moving upwards, compresses the refrigerant and directs it towards the condenser.

How to Adjust Different Parameters in your Industrial Air Chiller?

When the Industrial Air Chiller starts up, it is set to default. You can customize different parameters from factory settings.

The modern Industrial Air Chiller has a temperature controller that automatically adjusts its temperature according to the temperature of the industrial area to meet its cooling requirements.

The selected constant temperature control mode is set at a water temperature of 25°.

It possesses thermostat indicators (D1 and D2). D1 operates in intelligent control mode when it is turned ON. It switches to temperature control mode when it turns OFF.

D2, when turned ON, works in refrigerating state while shifts to the insulation working state when switched OFF. The unit operates in the energy-saving state when D2 flashes.

Various alarms occur in case of any error or malfunctioning. The error code and the temperature will be displayed when an alarm occurs.

The alarm display stays until the alarm condition is eliminated.

The water temperature will be automatically adjusted according to temperature changes under the Intelligent control mode.

What are the Common Problems of an Industrial Air Chiller?

An Industrial Air Chiller may endure some problems due to various possible reasons. A few of the most common issues are discussed below:

Start-Up Failure

In case if your Industrial Air Chiller fails to run normally, it may happen due to low refrigerant charge, incorrect unit configuration, or most possibly the unit is not getting power.

Insufficient Cooling

Sometimes, the unit does not produce enough cooling. There are multiple probable causes behind this, like leak refrigerant, high ambient temperature, or improper voltage.

It may also occur when the cooling fluid does not match the temperature conditions.

High-Pressure Alarm

Excessive refrigerant, the air in the system, or the expansion valve is extraordinarily narrow or damaged may cause a high-pressure alarm to buzz.

Water Leakage

Another most commonly faced problem is the water leakage somewhere in the system.

The leakage happens mostly in pumps when the seal there is not correctly connected or damaged due to some cause. The water leakage can also occur from the ball valve and shunt.

Industrial Air Chiller Water Leakage Inspection

Insufficient Fluid Flow

Reduced pumping or insufficient flow of fluid happens primarily due to several reasons.

Some of these are inadequate fluid in the reservoir, failure of the pump, blocked fuel filter, improper voltage, partially or even fully closed valves, or sometimes when the fluid restricts in the pipelines.

Condensed Water

The serious problem of condensate water may happen when the water’s temperature is much lower than the ambient temperature with a high rate of moisture.

How to Troubleshoot the Common Problems of your Industrial Air Chiller?

Once if you have analyzed the cause of the problem, you can troubleshoot the common problems of your Industrial Air Chiller.

Some of the feasible ways of fixing the problems are as given:

High-Temperature Alarm

In case if the alarm is buzzing for high temperature, firstly ensure the proper ventilation for the air inlet and outlet.

Inspect the power supply circuit and look if found any fault. Restore factory settings to ensure sufficient time for refrigeration. Reduce the heat load and keep the dust gauze clean.

Malfunctioning of Compressor

In case if the refrigeration compressor is not working correctly or not running at all, check the electric cabling and analyze the display for any relevant information.

You will have to replace the compressor if it does not start working at last.

Nonfunctional Compressor Fan

If the compressor fan is not working, check the electric cabling. If the power contactor of the fan is defective, you will need to replace it. The loss of refrigerant gas may also cause the problem.

Low Condensation Pressure

There are several reasons behind the falling of condensation pressure. You need to analyze the cause and respond accordingly.

There might be an improper function of condenser fans; ensure their proper operation.

Establish the normal conditions if the ambient temperature or cooling water temperature goes too low. Fix the issue of the refrigerant leak if found any.