TopChiller can design and manufacture all types of MRI chillers for you

- Cooling capacity ranges from 10KW to 150KW

- Temperature control ranges from 9℃ to 20℃

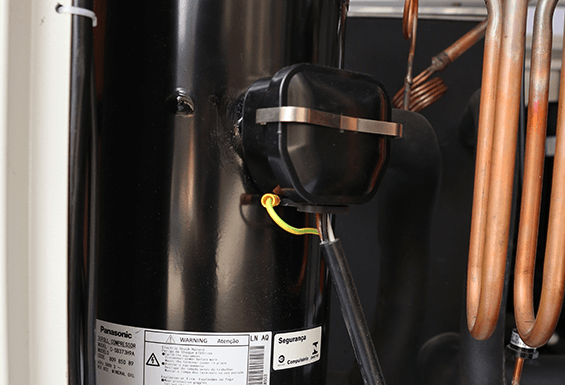

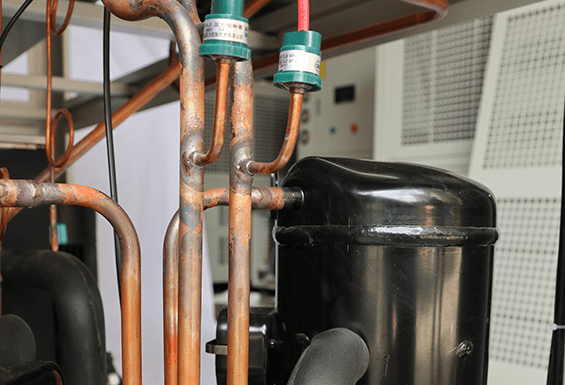

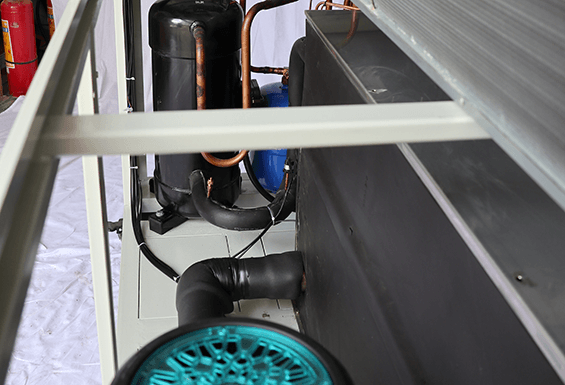

- Famous branded quiet scroll compressor

- Two separate, efficient refrigeration circuits

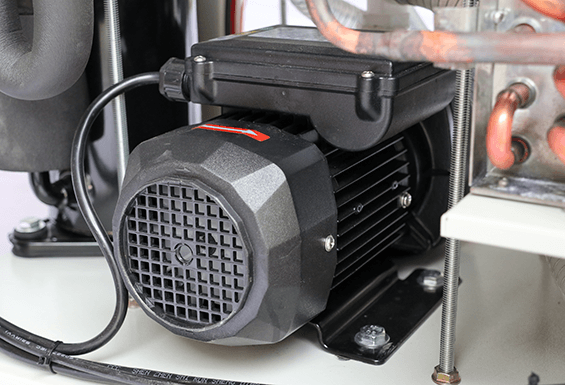

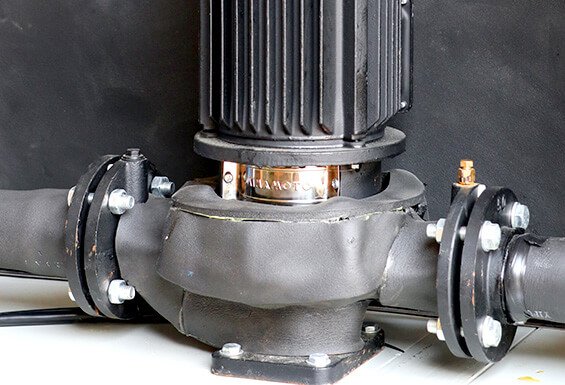

- Filter flow meter & two water pump system

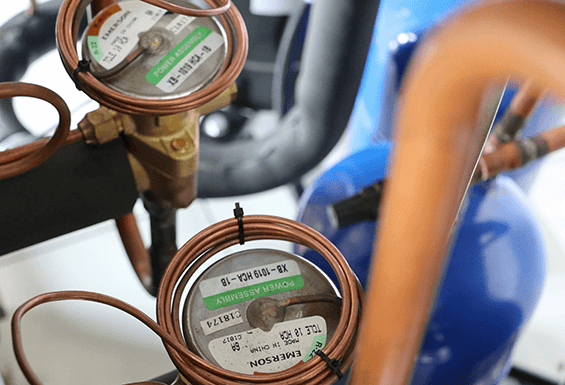

- Thermostatic or capillary type expansion valve

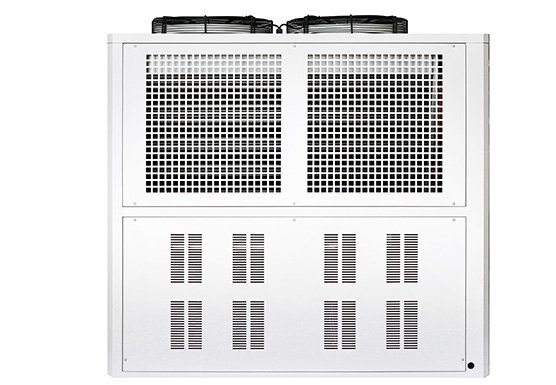

- Compact design, control system, easy installation

- Warranty time up to 24 months after purchase

Your Premier MRI Chiller Manufacturer and Supplier Over 20 Years

MRI Chiller and MRI Cooling System is a built-in self-diagnostic device used for cooling production and adjustment of peculiar temperature tolerance in MRI machines by using chilled air or water circulation around the condenser.

TopChiller is a well-known and most trustworthy company of China manufacturing MRI Chiller over years with a superb experience and supplying it to the world marketplace on high demands.

TopChiller is successfully offering a wide range of varying capacity MRI Chiller Models by focusing on the installation of units with a list of options and modifications to customize the MRI Chiller according to the needs of customers since 1999.

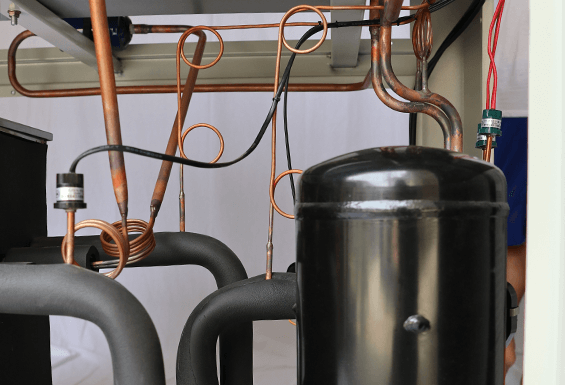

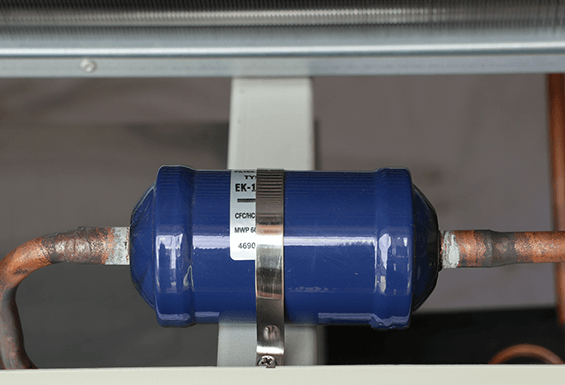

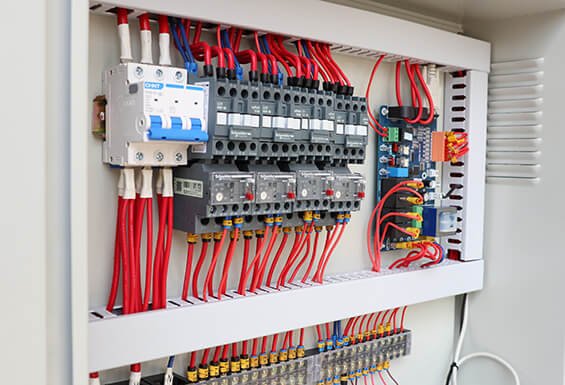

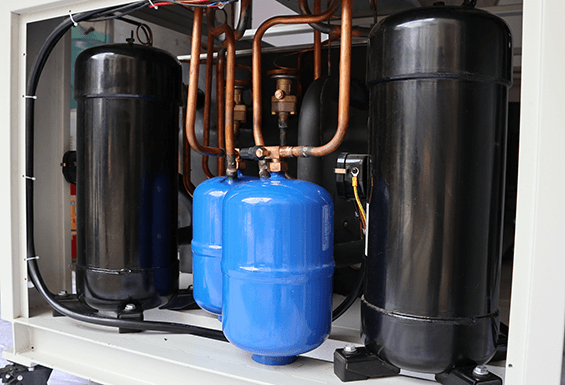

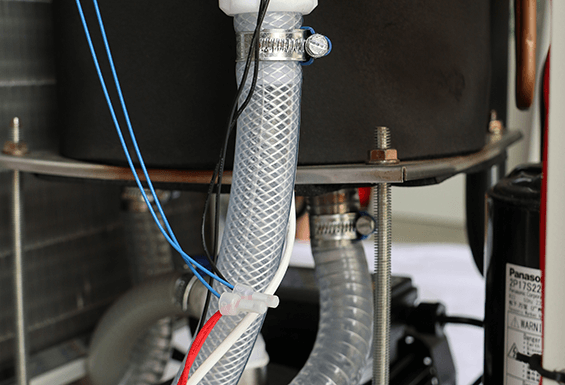

MRI Chiller designed by TopChiller comprises of different primary components as scroll compressor, energy-efficient condenser, evaporator, flow meter, capillary, thermostatic expansion valve, water pump, water tank, dual refrigeration circuit, protecting devices, and power supply.

TopChiller designed MRI Chiller is used for medical instruments due to its large number of benefits as given below:

- MRI Chiller is energy efficient to maintain uptime of MRI machine configured by the use of chilled water circulation and two water pumps that steadily cool cold head and prevent the machine from heating bursts and damages.

- The cold head is a special component of an MRI machine converting gaseous helium into liquid form by releasing a large amount of heat that is absorbed and released from the machine by an efficient insulated heat exchanger, consequently preventing a gas explosion.

- MRI Chiller is equipped with dual independent refrigeration circuits configuring the constant flow of refrigerant for cooling effect working independently. if one circuit is damaged, another one will continue its performance.

- TopChiller designed MRI Chiller is featured with an environment-friendly refrigerant with closed-loop circulation, preventing direct contact of water with ambient temperature and ultimately stopping the entry of dust, clogging, and corrosion.

- MRI Chiller performs quiet operation configured by use of branded quiet operating scroll compressor and sound insulators.

MRI Chiller is the best cooling device for medical equipment and other clinical applications as given below:

Radiation therapy, cyclotron system, CT scanning, MRI medical machines, cancer treatment, blood cooling, laboratory samples preservation, surgical equipment, body fluids protection, and linear accelerators, etc.

Are you looking way around to buy the best working and steadfast MRI Chiller for your application?

Are you investigating for a well-reputed company ensuring the manufacturing of portable, and energy-efficient MRI Chiller to attain suggestions and support to promote your business?

You are getting the right way. TopChiller is highly reputed and the best one to choose. Move to contact with TopChiller sales and engineers for getting a quote, buying guidelines, and technical support for the best MRI Chiller selection.

TopChiller team will assist you to select the best MRI Chiller at reasonable costs regarding your application requirements.

General Description:

MRI Chiller is a built-in self-diagnostic cooling machine used for cooling and modification of irregular temperature in MRI machines by using chilled water or air circulation around the condenser.

MRI Chiller designed by TopChiller contains the following branded parts: scroll compressor, evaporator, expansion valves, and condenser. All of these take part in a refrigeration cycle, which maintains the temperature in a narrow range. An environment-friendly refrigerant and water are used as a coolant.

Radiation therapy machines, cyclotron system, CT scan, MRI machines, blood cooling, laboratory samples preservation, surgical machines, body fluids protection, linear accelerators, etc are the prominent applications of MRI Chiller

If you are looking for a well-reputed brand ensuring the manufacturing of energy-efficient cooling systems to maintain your MRI machine. Your search ends here, TopChiller is a renowned company with over 20 years of rich experience designing and manufacturing the latest technology MRI Chillers.

Contact TopChiller well-trained customer service for obtaining information on the suitable MRI Chiller. Our inventory is full of proficient MRI Chiller models with various unique features, capacity ranges, and models ready to be delivered.

Features and Advantages:

Significant features and advantages of MRI Chiller are explained here:

- MRI Chiller consists of scroll compressors that have outstanding qualities. These compressors are designed to reduce power consumption by installing an automatic motor and hybrid wrap scroll.

- The excellent combination properties of the refrigerator make a perfect match for your MRI machine. One of the indicators of high efficiency is low IKW, which can be achieved with exceptional condensing by a large-sized condenser.

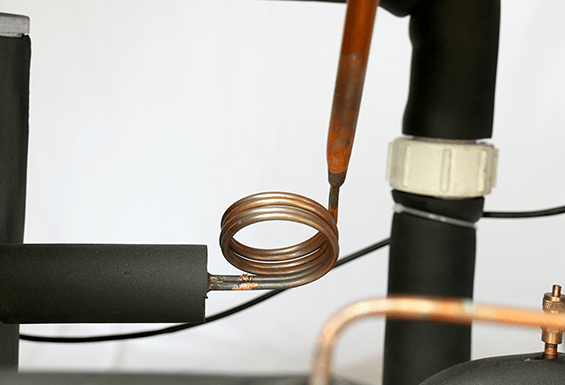

- Copper is used to manufacture the evaporator and shell tubes because tubes made up of copper can bear water of high pH. SS-304 is used as the primary material to make the sheets and shells.

- Blades are coated with hydrophobic materials, which repel the moisture, thus enhancing the efficiency of the condenser.

- An extra pump can be used; such excellent qualities conserve energy and ensure an undisturbed cooling process.

- Data Sheet

- Image Gallery

- Main Parts

- Video

| MRI Chiller Technical Specifications | ||||||||||||||

| Items Model | AC-0.5A | AC-1A | AC-1.5A | AC-2A | AC-2.5A | AC-3A | AC-4A | AC-5A | AC-6A | AC-8AD | AC-10AD | AC-12AD | AC-15AD | |

| Cooling capacity | Kcal/h 50HZ/60HZ | 1419 | 2451 | 3182 | 4833 | 5848 | 7181 | 9288 | 11988 | 14534 | 18576 | 23994 | 29068 | 38270 |

| 1703 | 2941 | 3784 | 5800 | 7018 | 8617 | 11146 | 14386 | 17441 | 22291 | 28793 | 34882 | 45924 | ||

| KW 50HZ/60HZ | 1.65 | 2.85 | 3.7 | 5.62 | 6.8 | 8.35 | 10.8 | 13.94 | 16.9 | 21.6 | 27.9 | 33.8 | 44.5 | |

| 1.98 | 3.42 | 4.4 | 6.74 | 8.2 | 10.02 | 12.96 | 16.73 | 20.28 | 25.92 | 33.48 | 40.56 | 53.4 | ||

| Input power | KW | 0.88 | 1.35 | 2 | 2.25 | 2.66 | 3.27 | 4.07 | 5.75 | 6.45 | 8.25 | 11.5 | 12.9 | 17.45 |

| Max Current | A | 5.4 | 8.2 | 12 | 13.6 | 6.6 | 8.2 | 10.1 | 13.8 | 15.5 | 20 | 27.9 | 31.3 | 42.4 |

| Power source | 1PH~220V/3PH~220V/380V 50HZ/60HZ | 3PH~380V/415V/480V~50HZ/60HZ(3PH~200V/220V 50HZ/60HZ) | ||||||||||||

| Refrigerant | Type | R22/R407C/134a/404A/410A | ||||||||||||

| Control | Capillary / thermostatic expansion valve | |||||||||||||

| Compressor | Type | Hermetic Rotary | Hermetic scroll ( piston ) | |||||||||||

| Power(KW) | 0.45 | 0.89 | 1.3 | 1.73 | 2.1 | 2.7 | 3.5 | 4.55 | 5.25 | 3.5×2 | 4.55×2 | 5.25×2 | 7×2 | |

| Condenser | Type | Efficient finned copper tube with aluminum+low noise external rotor fan | ||||||||||||

| Air flow (m3/h) | 750 | 1000 | 1500 | 2000 | 2500 | 3000 | 4000 | 5000 | 6000 | 8000 | 10000 | 12000 | 15000 | |

| Air blower(KW) | 0.06 | 0.09 | 0.15 | 0.15 | 0.19 | 0.14×2 | 0.14×2 | 0.19×2 | 0.19×2 | 0.25×2 | 0.45×2 | 0.45×2 | 0.6×2 | |

| Evaporator | Type | SS Tank coil / shell and tube type / Plate type heat exchanger | ||||||||||||

| Chilled water (m3/h) | 0.28 | 0.49 | 0.64 | 0.97 | 1.12 | 1.44 | 1.86 | 2.4 | 2.91 | 3.71 | 4.8 | 5.81 | 7.65 | |

| 0.34 | 0.59 | 0.76 | 1.16 | 1.4 | 1.72 | 2.23 | 2.88 | 3.49 | 4.46 | 5.76 | 7 | 9.18 | ||

| Water tank(L) | 10.6 | 18.3 | 27 | 27 | 50 | 50 | 60 | 60 | 110 | 120 | 200 | 200 | 270 | |

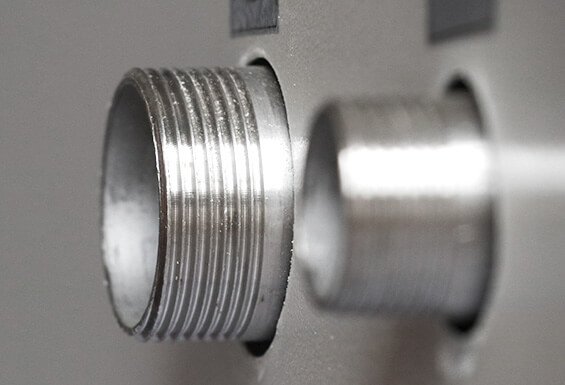

| Inlet/outlet pipe (inch) i | 1/2″ | 1/2″ | 1/2″ | 1/2″ | 1″ | 1″ | 1″ | 1″ | 1″ | 1-1/2″ | 2″ | 2″ | 2″ | |

| Water pump | Power (kw) | 0.37 | 0.37 | 0.37 | 0.37 | 0.37 | 0.37 | 0.37 | 0.75 | 0.75 | 0.75 | 1.5 | 1.5 | 2.2 |

| Max lift(m) | 22 | 22 | 22 | 22 | 22 | 22 | 22 | 30 | 30 | 25 | 25 | 25 | 28 | |

| Max flow (m3) | 5.4 | 5.4 | 5.4 | 5.4 | 5.4 | 5.4 | 5.4 | 8.1 | 8.1 | 8.1 | 13.5 | 13.5 | 25.2 | |

| Safety protection | Compressor inner protection, over current protection, high/low pressure protection, over temperature protection, flow rate protection, phase sequence/phase missing protection, low level coolant protection, anti freezing protection, exhaust overheat protection | |||||||||||||

| Dimension | L(mm) | 550 | 550 | 600 | 600 | 720 | 980 | 980 | 1150 | 1150 | 1350 | 1500 | 1500 | 1860 |

| W(mm) | 350 | 450 | 500 | 500 | 550 | 520 | 520 | 560 | 560 | 680 | 760 | 760 | 850 | |

| H(mm) | 695 | 845 | 985 | 985 | 1350 | 1170 | 1170 | 1215 | 1215 | 1530 | 1660 | 1660 | 1900 | |

| Net weight(KG) | 45 | 62 | 85 | 95 | 125 | 152 | 175 | 185 | 215 | 283 | 345 | 382 | 580 | |

| Note: The above specifications are according to the following design conditions: 1, 12℃/7℃.Chilled water inlet/outlet temperature 12℃/7℃. 2, 33℃/38℃.Cooling air inlet/outlet temperature 33℃/38℃. We reserve the right to modify the specification without further notice. | ||||||||||||||

| MRI Chiller Technical Specifications | |||||||||||||

| Items Model | AC-15AT | AC-20AD | AC-20AF | AC-25AD | AC-25AF | AC-30AD | AC-30AT | AC-40AD | AC-40AF | AC-50AD | AC-50AF | AC-60AD | |

| Cooling capacity | Kcal/h 50HZ/60HZ | 36120 | 49966 | 47988 | 58480 | 58136 | 74734 | 74922 | 98040 | 99760 | 119024 | 116960 | 144996 |

| 43344 | 59959 | 57586 | 70176 | 69763 | 89681 | 89990 | 117648 | 119712 | 142829 | 140352 | 173995 | ||

| KW 50HZ/60HZ | 42 | 58.1 | 55.8 | 68 | 67.6 | 86.9 | 87.2 | 114 | 116 | 138.4 | 136 | 168.6 | |

| 50.4 | 69.72 | 66.96 | 81.6 | 81.12 | 104.28 | 104.64 | 136.8 | 139.2 | 166.08 | 163.2 | 202.3 | ||

| Input power | KW | 17.1 | 21.73 | 22 | 25.4 | 24.8 | 33.39 | 33.1 | 44.91 | 43.3 | 57.3 | 54 | 65 |

| Max Current | A | 43.2 | 52.7 | 53.3 | 63.7 | 61.3 | 81 | 80.2 | 109 | 106 | 135.5 | 128.5 | 135 |

| Power source | 3PH~380V/415V/480V~50HZ/60HZ(3PH~200V/220V 50HZ/60HZ) | ||||||||||||

| Refrigerant | Type | R22/R407C/134a/404A/410A | |||||||||||

| Control | Capillary / Thermostatic expansion valve | ||||||||||||

| Compressor | Type | Hermetic scroll ( piston ) | |||||||||||

| Power(KW) | 4.55×3 | 8.96×2 | 4.55×4 | 10.8×2 | 5.25×4 | 13.62×2 | 8.96×3 | 18.78×2 | 8.96×4 | 23.6×2 | 10.8×4 | 27.4×2 | |

| Condenser | Type | Efficient finned copper tube with aluminum+low noise external rotor fan | |||||||||||

| Air flow (m3/h) | 15000 | 20000 | 20000 | 25000 | 25000 | 30000 | 30000 | 40000 | 40000 | 50000 | 50000 | 60000 | |

| Air blower(KW) | 0.6×2 | 0.78×2 | 0.78×2 | 0.78×2 | 0.78×2 | 0.42×6 | 0.42×6 | 0.6×6 | 0.6×6 | 0.78×6 | 0.78×6 | 0.78×6 | |

| Evaporator | Type | SS Tank coil/ shell and tube type/Plate type heat exchanger | |||||||||||

| Chilled water (m3/h) | 7.22 | 10 | 9.6 | 11.69 | 11.62 | 14.94 | 15 | 19.6 | 19.95 | 23.8 | 23.4 | 29 | |

| 8.67 | 11.99 | 11.51 | 14.03 | 13.95 | 17.93 | 18 | 23.52 | 23.94 | 28.6 | 28.1 | 34.8 | ||

| Water tank(L) | 270 | 350 | 350 | 350 | 350 | 420 | 420 | 580 | 580 | 580 | 580 | 580 | |

| inlet/outlet pipe (inch) | 2″ | 2″ | 2″ | 2-1/2″ | 2-1/2″ | 2-1/2″ | 2-1/2″ | 3″ | 3″ | 3″ | 3″ | 3″ | |

| Water pump | Power(kw) | 2.2 | 2.2 | 2.2 | 2.2 | 2.2 | 4 | 4 | 4 | 4 | 5.5 | 5.5 | 5.5 |

| Max lift(m) | 28 | 28 | 28 | 28 | 28 | 30 | 30 | 30 | 30 | 32 | 32 | 32 | |

| Max flow (m3) | 25.2 | 25.2 | 25.2 | 25.2 | 25.2 | 36 | 36 | 36 | 36 | 40 | 40 | 40 | |

| Safety devices | Compressor inner protection, over current protection, high/low pressure protection, over temperature protection, flow rate protection, phase sequence/phase missing protection, low level coolant protection, anti freezing protection, exhaust overheat protection | ||||||||||||

| Dimension | L(mm) | 1860 | 2020 | 2020 | 2020 | 2020 | 2200 | 2200 | 2350 | 2350 | 2600 | 2600 | 2600 |

| W(mm) | 850 | 950 | 950 | 950 | 950 | 1150 | 1150 | 1350 | 1350 | 1500 | 1500 | 1500 | |

| H(mm) | 1900 | 2000 | 2000 | 2000 | 2000 | 1980 | 1980 | 2000 | 2000 | 2100 | 2100 | 2100 | |

| Net weight(KG) | 580 | 650 | 650 | 810 | 810 | 890 | 890 | 1112 | 1112 | 1320 | 1320 | 1320 | |

| Note: The above specifications are according to the following design conditions: 1, Chilled water inlet/outlet temperature 12℃/7℃. 2, Cooling air inlet/outlet temperature 33℃/38℃. We reserve the right to modify the specification without further notice. | |||||||||||||

Why TopChiller is Your Reliable MRI Chiller Manufacturer and Supplier In China?

MRI Chiller-An Ultimate FAQ Guide by TopChiller.

- What is an MRI Chiller?

- What are the Features of an MRI Chiller?

- What are the Major Components of an MRI Chiller?

- What is the Working Mechanism of an MRI Chiller?

- What are the Sizes of MRI Chiller Available in the Market?

- How to Choose the Best Size of an MRI Chiller for your Applications?

- What is the Purpose of Using an MRI Chiller for your MRI Machine?

- What is the Significance of Redundancy of an MRI Chiller?

- What is the Standard of Energy Efficiency of an MRI Chiller?

- What are the Benefits of an MRI Chiller for your MRI Machine?

- What are the Accessories of an MRI Chiller?

- How to Carry Out the Testing and Certification of an MRI Chiller?

- What is the Comparison Between Water Cooled and Air Cooled MRI Chiller?

- What is the Difference Between a Drop-In and a Closed-Loop MRI Chiller?

- How to Differentiate Between an Open Loop and an In-Line MRI Chiller?

- What are the Process Fluid Recommendations for your MRI Chiller?

- What are the Installation Rules for an MRI Chiller?

- How to Calculate the Efficiency of an MRI Chiller?

- What are the Maintenance Tips and Tricks for your MRI Chiller?

- How to Troubleshoot Problems of your MRI Chiller?

What is an MRI Chiller?

MRI Chiller displaces or removes the heat produced by hi-tech MRI machines, which tend to become overheated when run for a long time. This heat must be removed; otherwise, it can cause permanent damage and safety hazards.

With good temperature regulation and constant heat removal, you can obtain more excellent uptime and higher efficiency from your MRI machine.

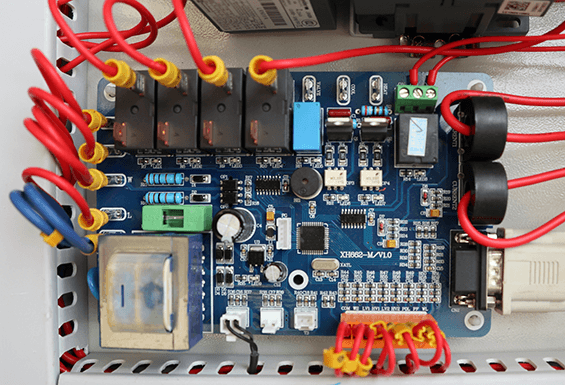

An MRI Chiller comes with an advanced microprocessor unit that controls its function. The refrigeration cycle keeps on running and displacing the heat, thus creating a comfortable and ideal environment.

The installation and maintenance are simple. You can use some high-tech accessories to increase efficiency and reliability.

The heat removed by the chiller is measured in BTU (British Thermal Units every hour) or KWH (Kilowatts per Hour).

MRI Chiller Designed by TopChiller

What are the Features of an MRI Chiller?

Here are some features and qualities of an MRI Chiller:

Excellent Quality Materials

The material used for the manufacturing is of excellent quality, ensuring enhanced fidelity and longevity.

Each unit is checked for the standard of material used and given a warranty of some duration.

Outstanding Authenticity

The unit is outlined in a way to offer increased uptime. It consists of an automated city water switchover that controls the system in case the basic scanner cooling unit stops working.

Environment Friendly

Ecologically sound cooling devices are used in enclosed loop systems that ensure that your unit is certified by the EPA and assure water preservation, minimizing damage.

Purpose-Built Design

There is an offer of a purpose-built outline and customization according to your requirements.

If there is any power failure, there must be an alternate system for the cooling process. For this purpose, an instant compressor with all the compressors’ integrated working ability must be used.

General Features

- Simple assembly and maintenance reduce the need for professional help.

- High-quality components enhance reliability.

- The excellent quality refrigerant does not deplete the ozone layer and does not add to the pollution.

- The cooling capacity falls in the range of 10KW to 150KW.

- The temperature control range is 9℃ to 20℃.

- There are two separate and efficient refrigeration circuits.

- A thermostatic or capillary-type expansion valve is present for smooth refrigeration.

What are the Major Components of an MRI Chiller?

Each component works in coordination to create a smooth refrigeration cycle. The main parts of an MRI Chiller are listed here:

Scroll Compressors

The purpose of using a scroll compressor is to minimize the sound and vibration produced by the chiller. It is to create a comfortable environment for the patients in the hospital.

Emergency By-Pass Valve

The bypass valve helps turn off the chiller to restore its function whenever there is an emergency.

Therefore, the MRI Chiller keeps running smoothly with sufficient water flow even in an emergency.

Evaporators

It works by removing heat from a system by the process of evaporation. The heat energy from the system is taken away by the evaporating molecules.

It comes with a delivery system that deals with heat transfer from the MRI machine to the chiller.

Advanced Temperature Controller

The sensitive microprocessor unit can regulate the operating power loads, which detects any fast loads or shocks quickly. In this way, the temperature is controlled in a definite range.

Condenser

The heat from the refrigerant is transferred to the cooling water by allowing heat transfer through the condenser coils. The in-built tank increases the residence time.

Expansion Valves

The high pressure is reduced to low pressure by the expansion valves that control the refrigerant flow and quantity.

MRI Chiller Scroll Compressor

What is the Working Mechanism of an MRI Chiller?

The working mechanism of an MRI Chiller is as follows:

Compression of Refrigerant

The refrigerant is forced towards the scroll compressor from the main refrigerant storage tank. It uses scrolls to compress the refrigerant, thus increasing its pressure and reducing the volume.

The compressed refrigerant is then forced to the evaporator.

Collection of Heat

Helium gas in the cold head is responsible for the collection of heat. This heat is then transferred to the evaporators. The cold head does this step.

In the evaporator, the refrigerant absorbs the heat and lowers the system’s temperature by transforming it into a gaseous state.

Release of Heat

The flowing cold water surrounding the condenser coils absorbs the heat from the refrigerant as the residence time increases.

As the refrigerant gets cold, it is again converted into a liquid. The heated water then goes to the water tower, and the heat is transferred to the environment.

Final Stage

The refrigerator fluid moving through the tubes made up of copper is agitated by the tubular switches of tubes.

Thermal energy in the form of heat is produced as a result of this agitation which then moves through copper tubes of shells and evaporators.

The expansion valve further reduces the pressure and controls the flow of the refrigerant.

What are the Sizes of MRI Chiller Available in the Market?

There is a vast array of MRI Chiller based on size, capacity, and efficiency. The size of the chiller shall be in accordance with the cooling load and demand of your application.

Another factor is the availability of space and whether it has to be placed indoors or outdoors.

The most commonly available and used sizes are 5 tons and 7.5 tons. For applications with multiple machines running simultaneously, the most frequently found sizes are 12.5 tons and 15 tons.

The latter sizes are for the situations where several MRI machines are working in a series.

How to Choose the Best Size of an MRI Chiller for your Applications?

The famous MRI Chiller sizes are 7.5 tons (90,000 BTU/hr) and 5 tons (60,000 BTU/hr) specifically designed for MRI machines. You must decide the required size according to your application beforehand.

High-pressure pumps are of minimum cost and are used to channel the cold head compressor to the chiller. Therefore, the adjustment of the cold head shall be kept in mind.

To conserve the energy and your investment, you can ideally utilize a smaller unit of 7.5 tons for an MRI machine.

Installation Site

Whether it has to be placed indoors or outdoors, you should have an idea about the available space for the installation. For water-cooled types, you need extra space for the cooling tower.

Reservoir

The refrigerant and water reservoir need a designated storage area which must be considered while deciding the size of the chiller.

Maintenance Requirement

More oversized the chiller, the greater the maintenance requirement. The oil, lubricant and refrigerant will also be required in more significant quantities.

What is the Purpose of Using an MRI Chiller for your MRI Machine?

The MRI Chiller is for your MRI machine’s safety and maximum productivity. It works as an integrated cooling system for removing the heat produced by hi-tech machines.

It prevents any damage to the machine by controlling the temperature in case of overheating, system collapse, or leakage.

The heat from these emergency events can damage the machine and cause ignition of fire and complete collapse of the system.

With proper cooling and optimum temperature, you can obtain more accurate results, which help diagnose and investigate any disease.

An overheated or underworking MRI machine can lead to a misleading diagnosis, thus risking the patient’s life.

It is crucial for patients with a terminal disease that need prompt treatment. Precise scans and quick diagnoses can only be made if your MRI machine is in the best working condition.

An MRI machine works by using a powerful magnetic field to photograph the internal organs. Therefore it consumes a significant amount of energy and releases heat.

A regular HVAC system is not sufficient to deal with the cooling load. The most suitable temperature for your MRI machine is about – 270 °C or – 450 °F, known as the cryogenic temperature.

An MRI Chiller provides excellent temperature accuracy, +/ – 1°F.

What is the Significance of Redundancy of an MRI Chiller?

Using the N+1 design, where the number of cooling circuits required for a specific heat load is denoted by N and +1 is the redundancy, you can find out the value.

It is an essential factor in determining an MRI Chiller’s performance and reliability. It lowers the expenditure of energy and the running cost by maximizing uptime.

In this way, you can operate your chiller at an affordable price.

How to Determine the Reliability of an MRI Chiller?

To determine the reliability of your MRI Chiller, you must follow the following steps:

Factory Testing

It is necessary to conduct all the factory tests to make sure that the chiller works in the given conditions. It helps in the prediction of efficiency as well.

Temperature Control

The temperature control must be accurate and precise. Any rapid change must be detected quickly.

Microprocessor Accuracy

The microprocessor shall be convenient and accurate to have strong control over the system. The thermostat needs close monitoring and control.

Rating and Reviews

It is essential to look at the reviews and ratings of other users of the same model. It enables you to predict the results of your application.

Energy Consumption

The greater the energy consumption, the greater will be the running cost, thus affecting the productivity of your application. Therefore, go for energy-effective ways.

MRI Chiller Factory Testing

What is the Standard of Energy Efficiency of an MRI Chiller?

The standard of energy efficiency of an MRI Chiller is based on environmental responsibility. It is essential only to use energy-efficient compressors and EPA-approved refrigerants.

There shall be a supplemental fluid cooler and a regular cooling agent to reduce energy consumption.

Other energy-saving options are:

- EC condenser fan motors allow stable refrigerant temperatures and save energy in the long run.

- Variable frequency drive employed on pumps helps you reduce energy consumption.

What are the Benefits of an MRI Chiller for your MRI Machine?

Here are some of the significant benefits of an MRI Chiller:

Efficiency

It provides lifetime efficiency if maintained well. This is because of strong composition and standard certification.

Damage Protection

An MRI Chiller protects your expensive and highly sensitive MRI machines and other industrial equipment by reducing overheating and its effects.

Extensive Variety

You can opt for a water-cooled or air-cooled chiller based on your preferences. Open-loop and closed-loop types are also an option.

Simple Operation

It has an easy, user-friendly interface that enables you to control the chiller. There is an advanced, well-integrated central system for maximum efficiency.

What are the Accessories of an MRI Chiller?

The most commonly used accessories of an MRI Chiller that help in increasing the efficiency and productivity of your application are listed below:

- Protective Coatings

- Spare Parts Kits

- Phase Monitors

- Clean Condenser Filter

- Pump Upgrades

- Automatic City Switchovers

- Remote Control

MRI Chiller Phase Alarm

How to Carry Out the Testing and Certification of an MRI Chiller?

The testing of an MRI Chiller must be done before dispatching the order for delivery. It is tested under specific external conditions to ensure proper working and maximum efficiency.

The certification requires the approval of the Air Conditioning, Heating, and Refrigeration Institute, which is abbreviated as AHRI.

The recent AHRI Standard 550/590 must be considered the third party is verifying the MRI Chiller’s efficiency.

The necessary codes and standards are as follows:

- GB/T 18430.1 – water chilling (heat pump) packages using the vapor compression cycle

- ASME Section VIII – boiler and pressure vessel.

- ANSI/ASHRAE 34 – number designation and safety classification of refrigerants.

- AHRI 550/590 – water chilling packages using the vapor compression cycle.

What is the Comparison Between Water Cooled and Air Cooled MRI Chiller?

As a water cooled chiller has a silent operation and produces less vibration, it is preferred in a hospital environment where excessive noise can cause a disturbance. Therefore, an MRI Chiller is primarily a water cooled type.

It uses water as the primary cooling agent, whereas the air cooled type requires ambient air and therefore has to be installed outdoors to allow a good flow of air.

A water cooled type requires a steady supply of water and can be installed indoors, which is convenient. The water can be stored in a storage tank or reservoir.

Air Cooled MRI Chiller

What is the Difference Between a Drop-In and a Closed-Loop MRI Chiller?

Drop-In Type

A Drop-in MRI Chiller is equipped with evaporator coils and cooling agent tanks.

The operator coil is submerged in the tank, and the cooling agent is pumped with the help of an agitation pump.

Closed Loop Type

In this type, the cooling agent from the tank is circulated in the chiller in such a way that it moves through the sealed coolant loops.

It spindles before returning to the tank. Thus it has a closed system that is confined to the premises of the MRI Chiller.

Closed Loop MRI Chiller

How to Differentiate Between an Open Loop and an In-Line MRI Chiller?

In an Open Loop MRI Chiller, a continuous flow of cooling fluid is utilized for accurate temperature regulation. It requires water and not air for its cooling process. Therefore, it is preferred and has an easy maintenance routine.

An in-line type uses high-quality inbuilt evaporators that control the cooling process and absorb heat from the passing fluid. It is done under high pressure by producing the right temperature difference.

A pump is used to force the high-pressure fluid from a tank to the evaporator.

What are the Process Fluid Recommendations for your MRI Chiller?

The process fluid recommendations are necessary for optimum working and are listed as follows:

- The ratio of water to glycol must be considered according to the external conditions while installing the chiller. It must be 50% and 30% outdoors and indoors, respectively.

- A precise amount of liquid is required for 100% glycol solution. Correct dilution can be achieved by using distilled water deionized water. Normal water from the tap is not suitable for glycol.

- The water can be mixed with glycol before adding it to the system or filled individually and mixed later.

- The accuracy of mixture concentration must be checked with a refractometer or hydrometer.

- It is suggested to use propylene glycol in chillers.

- It is necessary to fill the pipes and chiller storage individually because there are valves that prevent the backflow. Due to the blockage in the backflow, it can’t be filled in the pipes.

- When you have to refill the glycol in the future, the brand, kind, and quality of glycol used in the past with the date of filling mentioned on the chiller prove very helpful.

What are the Installation Rules for an MRI Chiller?

An MRI Chiller is manufactured to be installed on a smooth and even surface made up of solid material, preferably outside.

To keep your product safe and sound, it is advised to plan an optimal installation procedure.

A few points should be considered:

- An outside MRI Chiller is not designed to be installed indoors. Must be kept outside.

- Before installation, the outside environment, like air temperature conditions, must be checked.

- The unit must be installed away from surrounding machines to maintain proper ventilation.

- Must look for the suitable area provided around the unit to release heat.

Ground-Level Setting

Select a solid surface according to the size of your unit and ground the product on it.

Consider a minimum 5 feet adjustment from walls and make the unit secure by bolting at 8 feet with ½”.

Plumbing

Pipelines made up of copper are recommended. The length of channels must be according to measurements.

The expense will be significantly reduced if you have a nearby supply of city water. Try to decrease the pressure on the pump by reducing the frequency of turns.

Distance

The standard distance between the unit and the MRI machine must be followed in limits.

It is suitable to keep the MRI machine near the unit for better working conditions.

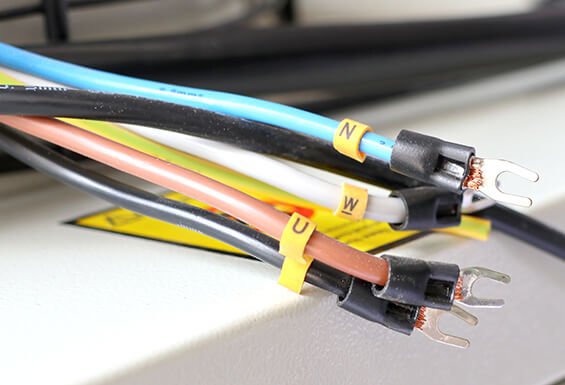

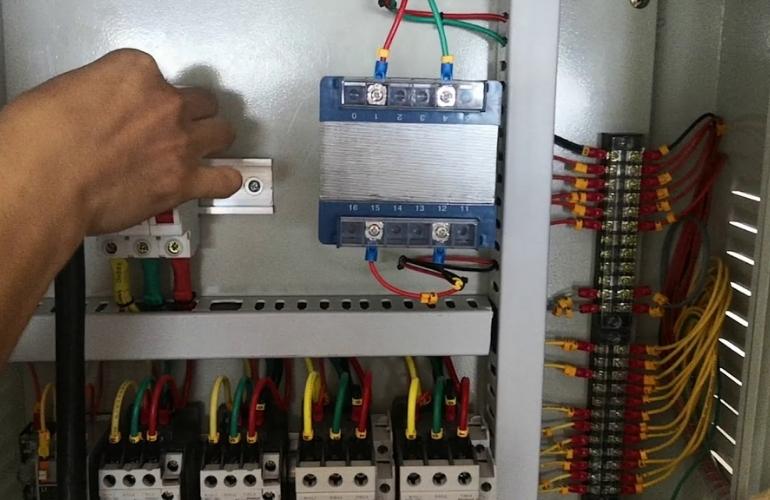

Electrical

The recommended level is 480V for a new MRI Chiller. 240V, used in the past, is more expensive and needs the expertise to operate. But it is available most of the time.

It is suggested to check the voltage before installing a new unit and replacing the one with 240V.

MRI Chiller Installation

How to Calculate the Efficiency of an MRI Chiller?

To calculate the efficiency of an MRI Chiller, you can use the output and input, respectively. It refers to the ability of a chiller to produce cooling and maximize the productivity of an application.

It can be calculated by dividing the output by input when both are measured in BTU. The unit for efficiency is kW/ton.

You can also obtain the percentage efficiency by multiplying the ratio by 100. Efficiency between 80-100 % is valued the most.

What are the Maintenance Tips and Tricks for your MRI Chiller?

Listed below are some maintenance tips and tricks for your MRI Chiller:

- All the water inlets and outlets shall be checked for any leakage.

- Any vibrations and unusual sounds shall be detected at an earlier level.

- All the electricity connections shall be well insulated to maintain a steady electricity supply.

- Old and dirty filter driers shall be cleaned and replaced.

- All the cooling coils shall be checked for erosion and distortion of fins.

- The condenser coils tend to get blocked and obstruct and must be cleaned regularly.

- Lubrication and air dampness shall also be checked.

- There shall be a daily record of the fluid levels, flow rates, and efficiency.

- Maintain the oil and refrigerant level according to the requirement.

- Inspect the tubes closely to see if there is any corrosion or leakage.

- The condenser water must be kept at a lower temperature to allow maximum heat transfer.

- Check the Y strainer of the MRI Chiller regularly for utilizing an inline cartridge filter.

- Maintain the glycol concentration to avoid freezing the water and the refrigerant.

- You can use variable frequency drives to save energy, and therefore you can have a standard function in times of energy breakdown.

MRI Chiller Y Strainer Cleaning

How to Troubleshoot Problems of your MRI Chiller?

These are some of the problems and their solutions related to your MRI Chiller:

Low-Pressure Trips

The reasons can be:

- Low refrigerant level

- Low water flow

- Mud and debris in the tubes

- Power assembly damage

- Water filter clogged

High-Pressure Trip

The reasons can be:

- Poor flow in the water-cooled condenser

- Substandard quality water causes mineral growth in the tubes.

Other problems

- The condenser fan might be out of order.

- The temperature of chilled water might be too high.

- An oil pump leakage low superheats or decreased level of oil.

- The thermostat might be set to a deficient level causing freezing of the water, thus reducing the water flow.

- Over amped wires or shorted motors may lead to complete loss of function.

- The starter might trip, or the circuit might be tripped, thus hindering the normal function of the MRI Chiller.

- Poor heat exchange in the evaporator and inability of the chiller to reach the thermostat point.

Solutions

- All these problems can be solved through a good maintenance routine.

- Early detection of a problem is necessary to reduce the effects of damage.

MRI Chiller Troubleshooting