TopChiller can design and manufacture all types of fermentation chillers for you

- Cooling capacity ranges from 3KW to 150KW

- Temperature control from ranges -15°C to 20°C

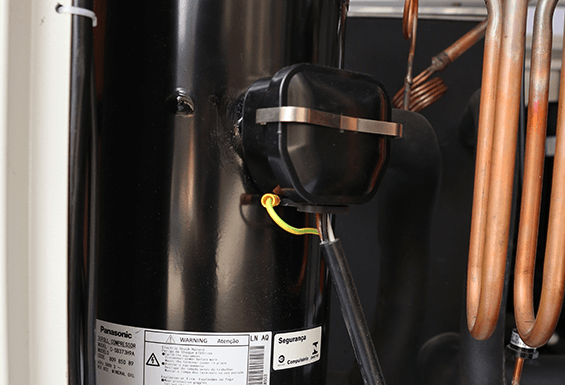

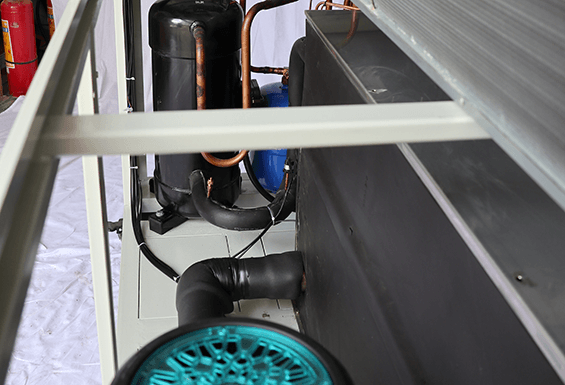

- Famous brand scroll/screw compressor

- Double jacketed & glycol cooling plate

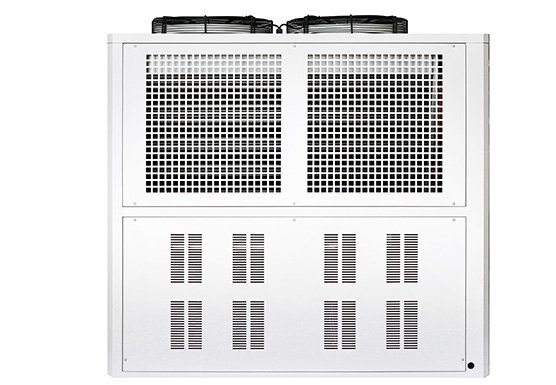

- Finned type hydrophilic efficient condenser

- Micro-computer controller & screen display

- Anti-frozen and high/low-pressure protection

- Lower noise, easy operation & super cooling

Premier Fermentation Chiller Manufacturer and Supplier Over 20 Years

Fermentation Chiller is an optimal designed cooling machine that configures the regulation of fermentation environment according to ambient temperature inside fermentation chamber by using chilled glycol solution.

TopChiller is a renowned manufacturing company of China that was founded in 1999 to avail the world marketplace with a wide series of Fermentation Chiller with warranty authenticity and reliability.

TopChiller Company is persistently engaged in manufacturing a collection of Fermentation Chiller as per global standards for over the last twenty years of marvelous experience and supplying to our customers all over the world.

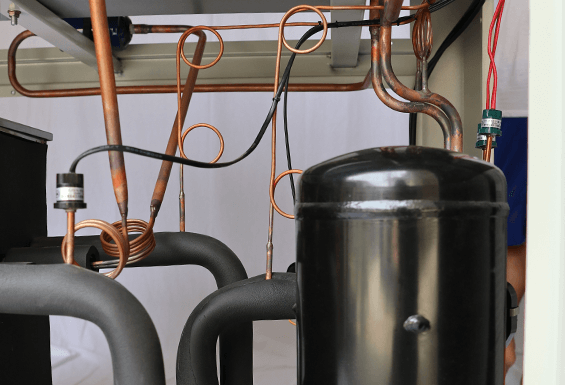

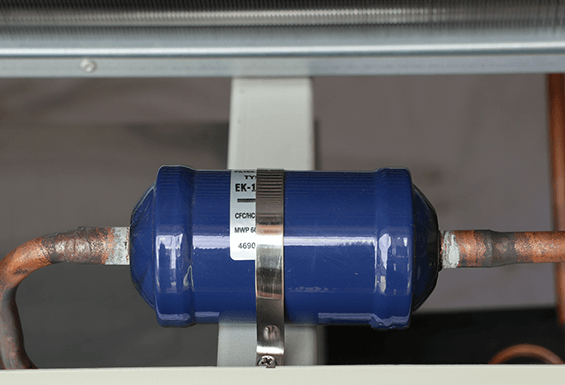

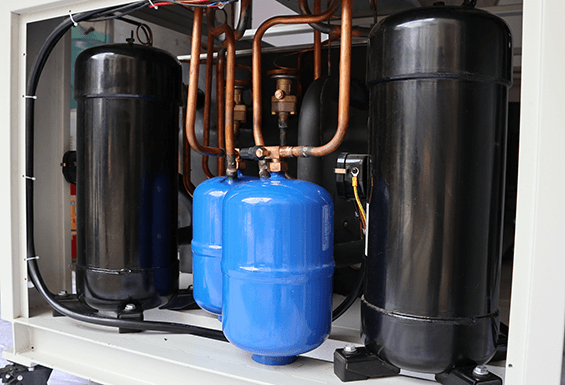

Fermentation Chiller is designed by different quality based components as scroll/screw compressor, temperature controlling unit, power supply lines, distribution units as pipes and tank, evaporator, hydrophilic condenser, heat exchanger, refrigeration tank, and control panel.

TopChiller engineered Fermentation Chiller is widely used in food & beverage industries due to its large number of benefits as given below:

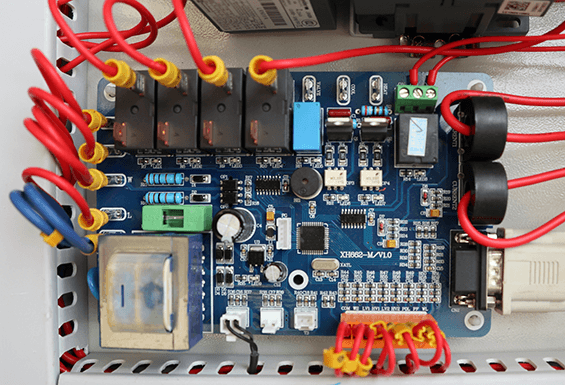

- Fermentation Chiller is highly reliable and precise in optimal temperature regulation of fermentation machine configured by the installation of automatic temperature regulating control panel and micro-computer providing screen display alarms about emergencies.

- TopChiller brand Fermentation Chiller is steadfast in its performance featured by insulated and hydrophilic nature condenser that is enabled to release collected heat from the system even in presence of an excess amount of humidity.

- Fermentation Chamber performs its working in cooling temperature that is provided by cooling jacket as well chilled glycol distribution unit connected to fermentation machine ensuring the consistent release of energy and heat-producing in the chamber.

- TopChiller engineered Fermentation Chiller maintains a lower cooling temperature of wort and solution inside the chamber preventing yeast or other fermenting microbes from denaturation by using a closed-loop heat exchanger that quickly absorbs heat and provides cooling to the machine.

- Fermentation Chiller ensures an efficient, flawless, and noise-sensitive chilling process featured by a top-class compressor and frozen protecting devices.

- TopChiller designed Fermentation Chiller is easy to install with caster wheels and conserves energy by regulating temperature from malting to pouring preventing any fouling.

Fermentation Chiller is used for a various number of applications due to its temperature maintaining features as:

Citric acid production, beer and beverage manufacturing, bakery products, alcoholic fermentation as ethanol fermentation, temperature-sensitive drugs formulation and wine production, etc.

If you are discerning for a valued and efficient product enhancing Fermentation Chiller for your application?

If you are in a quest to find the best associative company in China supplying peculiar, optimal temperature regulating Fermentation Chiller to get technical assistance for your business flourishing?

Don’t be hesitate. Just move ahead and do visit or make contact with TopChiller professional staff to get clear all of your ambiguities regarding Fermentation Chiller processing and buying assistance.

Our team will avail you to size the best suitable Fermentation Chiller for your application at a lower price.

General Description:

Fermentation Chiller is a dedicated device for maintaining optimum temperature during fermentation which is an exothermic process. Glycol is used as a coolant, and therefore it is also called a glycol chiller.

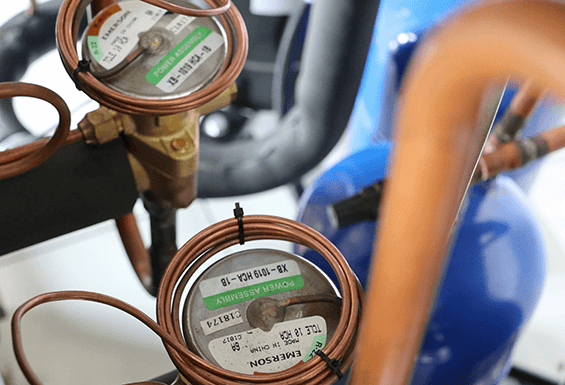

The premium quality components like the refrigerant, compressor, evaporator, expansion valve and condenser work closely to run the refrigeration cycle.

Fermentation Chiller, manufactured by TopChiller, comes with an innovative and advanced microprocessor unit with remote function and thermostat. The most common applications include wineries, brewing factories, food processing units, and alcohol industries.

Whether you are looking for an affordable Fermentation Chiller, TopChiller has your back with an extensive range of fermentation cooling systems. Each one is equipped with high-tech features and a simple, sturdy assembly.

With over 20 years of experience in the market, TopChiller has succeeded in creating an impact all around the globe. Our strength lies in supreme quality and a highly competent Fermentation Chiller with unique features.

Hit us up on our all-time active professional customer service to obtain Fermentation Chiller price, guidance, installation, and maintenance services.

TopChiller can help you to customize Fermentation Chiller according to your applications.

Features and Advantages:

Mentioned below are the unique features and advantages of a Fermentation Chiller:

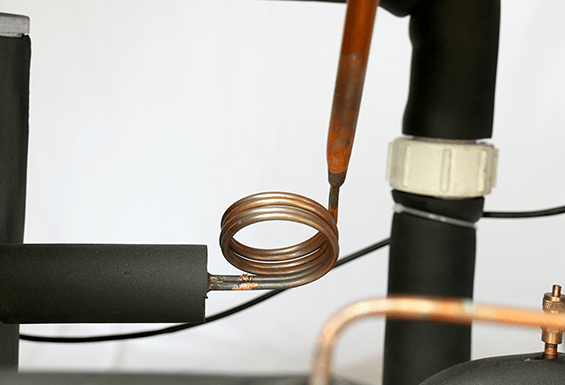

- It is equipped with a rod-shaped or circular coil made up of solid metal like aluminum or copper. The most common use of the coil is to dip it in the tank directly. The normal-sized coil is sufficient for 50 gallons of the size of the chiller, and it helps in increasing efficiency.

- The usual temperature regulation range is from 7 to 15 degrees Celsius. It can go as low as -3 degrees as well. However, it offers a very narrow range in most applications resulting in accurate and precise control.

- Modern, digital, and sensitive temperature sensors detect the slightest temperature change. This sensitivity allows accuracy and precision.

- The use of an immersion rod or ice pack is made in applications where accurate results are not required. The two mentioned accessories bring drastic effects on the temperature.

- A highly advanced microprocessor control unit enables you to control the chiller from a remote site. The sophisticated design makes the installation and maintenance easier.

- Data Sheet

- Image Gallery

- Main Parts

- Video

Fermentation Chiller Technical Specification

| Items/Model | Temp. | TPL-3AL | TPL-5AL | TPL-6AL | TPL-8AL | TPL-10AL | TPL-12AL | TPL-15AL | TPL-20AL | TPL-25AL | TPL-30AL | TPL-40AL | ||

| Cooling Capacity | KW 50HZ/60HZ | -10℃ | 3.80 4.60 | 6.30 7.60 | 7.50 9.00 | 9.10 10.90 | 13.20 15.80 | 16.10 19.30 | 19.50 23.40 | 26.40 31.70 | 32.20 38.60 | 39.00 46.80 | 52.00 62.40 | |

| -20℃ | 1.90 2.30 | 3.00 3.60 | 4.00 4.80 | 6.00 7.20 | 7.10 8.50 | 8.00 9.60 | 13.90 16.70 | 16.90 20.30 | 20.80 25.00 | 24.40 29.30 | 30.80 37.00 | |||

| -30℃ | 1.00 1.20 | 1.60 1.90 | 1.90 2.30 | 2.70 3.20 | 3.20 3.80 | 3.80 4.60 | 6.10 7.30 | 9.50 11.4 | 12.10 14.50 | 14.30 17.10 | 19.00 22.80 | |||

| -35℃ | 0.67 0.80 | 1.04 1.25 | 1.50 1.80 | 2.30 2.80 | 2.80 3.40 | 3.00 3.60 | 4.30 5.20 | 6.35 7.62 | 8.30 10.00 | 10.10 12.10 | 13.35 16.00 | |||

| Evaporator | Chilled Water (m³/h) | -10℃ | 0.65 0.79 | 1.10 1.30 | 1.30 1.50 | 1.60 1.90 | 2.30 2.70 | 2.80 3.30 | 3.40 4.10 | 4.50 5.40 | 5.60 6.70 | 6.70 8.10 | 9.00 10.80 | |

| -20℃ | 0.33 0.40 | 0.52 0.62 | 0.69 0.83 | 1.10 1.30 | 1.23 1.47 | 1.38 1.65 | 2.39 2.87 | 2.85 3.45 | 3.57 4.30 | 4.20 5.04 | 5.30 6.36 | |||

| -30℃ | 0.17 0.21 | 0.28 0.33 | 0.33 0.40 | 0.47 0.55 | 0.55 0.65 | 0.65 0.80 | 1.10 1.30 | 1.60 2.00 | 2.10 2.50 | 2.46 2.90 | 3.30 3.90 | |||

| -35℃ | 0.12 0.14 | 0.18 0.22 | 0.26 0.31 | 0.40 0.48 | 0.48 0.58 | 0.52 0.62 | 0.72 0.89 | 1.10 1.31 | 1.43 1.72 | 1.74 2.09 | 2.30 2.76 | |||

| Type | Shell and tube type/Plate type heat exchanger | |||||||||||||

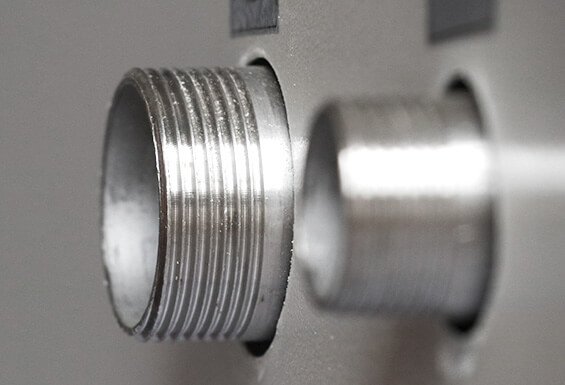

| Inlet/outlet pipe | lnch | 1″ | 1″ | 1″ | 1″ | 1-1/2″ | 1-1/2″ | 2″ | 2″ | 2″ | 2-1/2″ | 2-1/2″ | ||

| Input power | KW | 3.18 | 4.86 | 5.61 | 7.25 | 9.4 | 10.9 | 13.5 | 18.8 | 22.55 | 28.5 | 37.5 | ||

| Max Current | A | 7.8 | 12 | 13.7 | 18 | 23 | 26.5 | 33 | 46 | 55 | 69 | 91 | ||

| Power Source | 3PH~380V/415V/480V~50HZ/60HZ(3PH~200V/220V 50HZ/60HZ) | |||||||||||||

| Refrigerant | Type | R22(R404A/R507) | ||||||||||||

| Control | z | |||||||||||||

| Compressor | Type | Hermetic scroll ( piston ) | ||||||||||||

| Power | KW | 2.25 | 3.75 | 4.5 | 6 | 7.5 | 9 | 11.3 | 7.5*2 | 9.37*2 | 11.3*2 | 30 | ||

| Condenser | Type | Efficient finned copper tube with aluminum + low noise external rotor fan | ||||||||||||

| Water pump | Power | KW | 0.75 | 0.75 | 0.75 | 0.75 | 1.1 | 1.1 | 1.5 | 2.2 | 2.2 | 4 | 5.5 | |

| Max lift | m | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 25 | 20 | ||

| Safety protection | Compressor inner protection, over current protection, high / low pressure protection, over temperature protection, flow rate protection, phase sequence/phase missing protection, low level coolant protection, anti freezing protection | |||||||||||||

| Dimension | Length | mm | 980 | 1150 | 1150 | 1350 | 1500 | 1500 | 1860 | 2020 | 2020 | 2200 | 2350 | |

| Width | mm | 520 | 560 | 560 | 680 | 760 | 760 | 850 | 950 | 950 | 1150 | 1350 | ||

| Height | mm | 1170 | 1215 | 1215 | 1530 | 1660 | 1660 | 1900 | 2000 | 2000 | 1980 | 2000 | ||

| Net weight(KG) | Kg | 135 | 165 | 210 | 310 | 450 | 530 | 750 | 835 | 920 | 1080 | 1125 | ||

| Note: The above specifications are according to the following design conditions: 1, Chilled water inlet/outlet temperature difference 3℃/8℃. 2, Cooling air inlet/outlet temperature 30℃/38℃ | ||||||||||||||

Why TopChiller is Your Reliable Fermentation Chiller Manufacturer and Supplier In China?

Fermentation Chiller-An Ultimate FAQ Guide by TopChiller.

- What is a Fermentation Chiller?

- What are the Proficient Features of a Fermentation Chiller?

- What are the Significant Components of a Fermentation Chiller?

- How Does a Fermentation Chiller Work?

- What are the Benefits of a Fermentation Chiller for your Business?

- What is the Basic Agent Used in a Fermentation Chiller?

- What are the Uses of a Fermentation Chiller?

- How to Check the Quality of your Fermentation Chiller?

- What are the Tips and Tricks for Accurate Temperature Regulation for your Fermentation Chiller?

- How to Obtain Maximum Efficiency of your Fermentation Chiller?

- How to Differentiate Between an Air Cooled and a Water Cooled Fermentation Chiller?

- What are the Most Suitable Compressor Types for a Fermentation Chiller?

- What is the Capacity of a Fermentation Chiller?

- What is the Sizing Strategy for your Fermentation Chiller?

- What is the Significance of Using Water in your Fermentation Chiller?

- What is the Right Proportion of Water and Glycol for your Fermentation Chiller?

- What are the Installation Instructions for your Fermentation Chiller?

- What are the Common Problems and Solutions of a Fermentation Chiller?

What is a Fermentation Chiller?

Fermentation Chiller is a specialized cooling device used to maintain the optimum temperature for fermentation. It uses an electrochemical mechanism and glycol for producing cooling and removing extra heat.

It aids in regulating temperature in a narrow range with less electricity and power consumption. Thus, it is an economical and convenient cooling device for several industrial applications.

As fermentation is a process by the anaerobic respiration of anaerobic bacteria, it needs a specific temperature to keep going.

Anaerobic bacteria undergo gaseous exchange and produce ethanol which is the product of fermentation. The final products include alcohol, beer, wine, etc.

Any change in the optimum temperature affects the fermentation product’s flavor and quality; therefore, temperature regulation is a crucial step in this process.

Fermentation Chiller’s major applications include wineries, breweries, food industries, and distilled spirit production factories. The fermentation process is exothermic, and the resultant heat must be removed for better results.

Fermentation Chiller Manufactured by TopChiller

What are the Proficient Features of a Fermentation Chiller?

The main features of a Fermentation Chiller are stated below:

- It comes in a vast variety of cooling capacities.

- There is an advanced and human-friendly microprocessor unit which makes its use convenient.

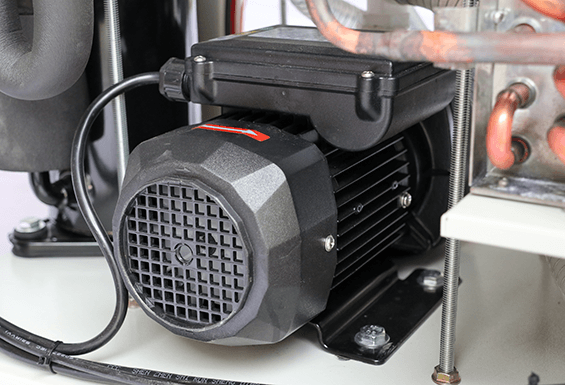

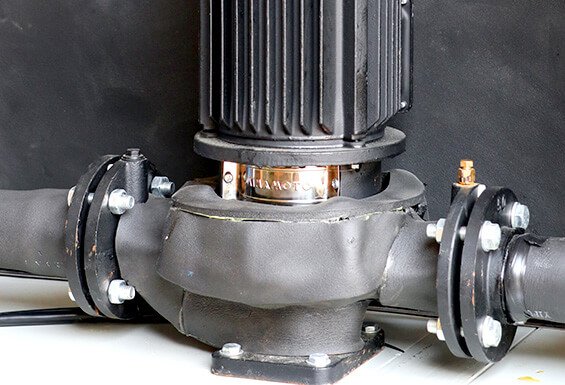

- It is equipped with strong water pumps for a stable water supply.

- The condenser tubes are made up of high-quality copper.

- The installation process and maintenance routine are simple and easy.

- The body is made up of strong stainless steel material, which is resistant to chemical corrosion.

- Fermentation Chiller can resist any mechanical damage and external oxidation.

What are the Significant Components of a Fermentation Chiller?

The significant components of a Fermentation Chiller work in harmony to regulate the system’s temperature. The main components are mentioned below:

Refrigerant Reservoir

Depending upon the size of the chiller, the refrigerant reservoir comes in various capacities, generally proportional to the size and usage.

The body and lining of the reservoir are constructed of high corrosion and damage-resistant material so that there is no contamination in the refrigerant.

It comes with calibration and an alarm indicator that helps monitor the refrigerant level.

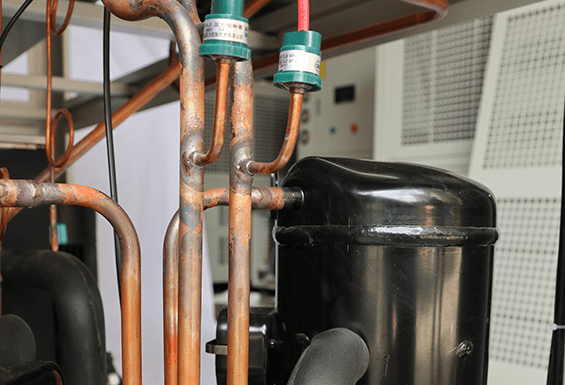

Compressor

It is a heavy duty device that increases the pressure of the refrigerant, thus forcing it through the entire system of the Fermentation Chiller. There are several types, and each one has its specifications.

Distribution Unit

It comprises all the tanks, reservoirs, and pipes of different sizes that supply the fluids to the system.

Whether it be the water or the refrigerant, the destruction unit must be patent and leakage-free to maintain a steady supply.

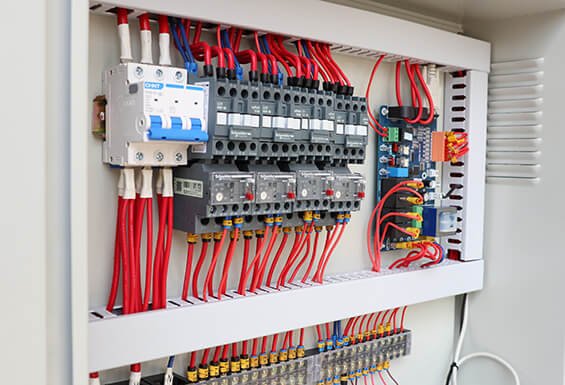

Control Panel

It works as a brain and central monitoring system for the programming and operation of your Fermentation Chiller.

It comes with a remote-controlled system, an LCD screen, a set of alarm indicators, and a proper calibration system.

You can also set the required temperature on the thermostat unit, directly controlled by the control panel.

Evaporator

It deals with the cooling process obtained through evaporation. The refrigerant is allowed to evaporate so that the transition in the physical state from liquid to gas can take away some energy from the system in the form of heat.

The evaporated refrigerant is passed on to the distribution system and the condenser for further processing.

Condenser

It uses air and water to remove heat from the refrigerant, which flows through its coil. The coils are made up of high-quality metal which has good conductivity.

Expansion Valves

For controlling the flow of refrigerant throughout the system, you need the expansion valves that permit and prevent its flow.

The valves permit the refrigerant to flow back to the compressor within a controlled range by lowering its pressure.

Fermentation Chiller Control Panel

How Does a Fermentation Chiller Work?

The principle of operation of a Fermentation Chiller is based on heat flow, the transition of the physical state of the coolant, and the boiling point.

The Transition of Coolant Phase

The coolant undergoes change from its liquid state to a gaseous state. This gas is then cooled beyond the supercooling limit to convert it back into the liquid state.

Energy in the form of heat is released and absorbed in this process, which helps maintain temperature.

When heating is required, the heat is absorbed, and when cooling is required, the heat is dissipated to the environment.

Flow of Energy

As heat flows from a higher concentration level to a lower concentration, the ambient temperature is maintained in a controlled range.

Boiling Point

When the pressure on the glycol is reduced, the boiling point also decreases.

However, on applying higher pressure, the boiling point is also raised. Thus a liquid has a higher boiling point than the gaseous state.

Step 1

As the refrigerant glycol is compressed, the space between the particles reduces, and pressure increases.

The high pressure compels the molecules to gain higher speed, and they tend to come closer. The coolant is now forced to flow through the refrigeration system.

Step 2

The coils containing the refrigerant are in direct contact with the fermenter fluids. When the fermentation process takes place and releases heat, the heat is transferred to the coils, thus raising the temperature of the coolant.

Step 3

The condenser is responsible for converting the high-temperature, low-pressure gaseous refrigerant into a liquid state by applying the phenomenon of supercooling.

This process takes place when the refrigerant flowing through the condenser coils loses its heat to the ambient air or chilled water surrounding the coils.

The phenomenon of thermal exchange takes place at this stage.

Step 4

The expansion valves allow the refrigerant to expand, thus reducing its heat and transferring it to the ambient air. In this way, the heat is completely taken out of the whole system.

Step 5

The refrigerant is returned to the compressor, where the whole cycle takes place over and over again. It is a self-sufficient process that does not need any external help.

However, motors and fans enable you to obtain faster and better results as the heat exchange becomes more efficient and fast.

What are the Benefits of a Fermentation Chiller for your Business?

A Fermentation Chiller provides many benefits that help you obtain maximum productivity from your application. Some of these are explained below:

Maximum Efficiency

As glycol is an efficient coolant and produces excellent results when used in the refrigeration cycle, it makes the chiller highly efficient.

It has a low boiling point, and therefore, the temperature regulation becomes quite convenient.

Variety

There is an extensive range of capacities, sizes, and models for you to choose from.

You can pick the one according to the preference of your application. There’s a choice between a mobile and stationary type as well.

Durability

Due to its stainless steel body and highly resistant coating are safe against the damaging agents like corrosion and oxidation.

The increased tensile strength allows it to endure high pressure and resist mechanical damage. It lasts for many years

Easy Operation

The control panel can be operated with great convenience, and you can operate it from a remote site as well.

You can set all the variables at a set value, and any deviation from the set range would initiate the ringing of an alarm.

The alarm indicates that something has gone wrong and seeks the operator’s attention.

In this way, you can keep a strict check on the operation. It is crucial for the quality of the fermentation product and the productivity of your application.

What is the Basic Agent Used in a Fermentation Chiller?

The essential agent used in a Fermentation Chiller is glycol as a coolant. It has all the coolant properties and, therefore, produces excellent results when used in the chiller. It is a much better choice than water.

The main properties include:

Higher Heat Retention

As compared to water, glycol is a more efficient heat holder as it can absorb higher amounts of heat for maximum time. This property helps in producing cooling in the system.

Lubrication

It acts as a lubricant and reduces the friction between the sliding parts. This is also a way of reducing heat production and interference in the normal working of the system.

Performance in Extreme Temperature

Due to its antifreeze properties, glycol does not freeze quickly and keeps flowing through the coils.

This keeps the refrigeration cycle running even at very low temperatures where all other coolants freeze and cause obstruction in the normal flow.

It also helps you save on the money spent on purchasing antifreeze for your Fermentation Chiller.

Easily Available

Glycol is easily available in the market. The price is also affordable, and it does not require frequent changes like other coolants. It is pretty easy to maintain its level for an extended period.

What are the Uses of a Fermentation Chiller?

Fermentation Chiller is used in the following industries:

- Brewing Factories

- Pickling Units

- Juice Factories

- Alcohol Production Units

- Wineries

- Food Processing Factories

- Fermented Foods Units and Stores

- Bakeries Making Bread

- Cheese Production Factories

Fermentation Chiller controls the temperature to allow maximum fermentation, which directly increases productivity.

Any change in the optimum temperature can lead to time waste, ingredients, and money because of the failed fermentation process.

Restores the True Flavor

You can obtain the most appropriate flavor and highest quality fermentation product with precise temperature control.

Fermentation Chiller Applications

How to Check the Quality of your Fermentation Chiller?

It is essential to check the quality of your Fermentation Chiller because you cannot take a risk by investing in a device that is not up to the mark.

To check the quality, you must keep the following factors in mind:

Factory Testing

Always go for factory testing because it helps assess your chiller’s performance in variable external conditions.

Annual Testing

Annual testing is also required to detect any fault and evaluate the normal function of the Fermentation Chiller.

Certifications

Following certifications must be present for ensuring the maximum performance:

- REACH Certificate

- UNI EN ISO 9001: 2008 Certificate RoHS Certificate

- Food and Drug Administration Certificate (FDA)

- AHRI Certificate

- ANSI Certificate

- CE Certificate

Fermentation Chiller Factory Testing

What are the Tips and Tricks for Accurate Temperature Regulation for your Fermentation Chiller?

Accurate temperature regulation is an essential factor in the performance of a Fermentation Chiller. It can be improved by using the tips and tricks:

Use a Thermometer

A thermometer provides you with accurate temperature measurement, thus making the temperature regulation more precise.

The thermometer reading can be used to adjust other conditions like pressure and humidity for the process occurring in the Fermentation Chiller.

It also helps you keep a record and assess the performance accordingly.

Temperature Sensors

These advanced sensors work by detecting any slight change in the temperature. Improving the chiller’s performance becomes easier when the slightest change is indicated and reported.

The sensors produce output through an alarm or a light.

Automated Systems

The sensors and the automatic detection and correction help you obtain uninterrupted performance.

Proper Maintenance

By keeping a record of the maintenance routine, you can compare and assess the chiller’s efficiency with changing external factors and any other influences.

Refrigerant Level Monitoring

Lower refrigerant levels tend to lower the efficiency as well as affect the overall life of the chiller.

The refrigerant quality and life is also an essential factor. Always use the one that does not cause pollution and does not affect the environment.

Fermentation Chiller Temperature Sensor

How to Obtain Maximum Efficiency of your Fermentation Chiller?

To obtain the highest efficiency of your Fermentation Chiller, keep the following things into consideration:

Inspection and Monitoring

Carry out a detailed inspection and monitoring routine after every month. It shall be more elaborate if conducted annually.

You must keep a record of each evaluation to assess the effect of various external factors and other conditions on the performance of the chiller.

Certification

Make sure you go through all the necessary certifications. It helps maintain your Fermentation Chiller and detects any damages and leakages at an early level.

Distribution System Cleaning

Any dirt, mold, debris, fungus, or chemical accumulation in the pipe can lead to semi and complete obstruction. It hinders the normal refrigeration cycle and reduces the efficiency to a great deal.

By providing clean water and good quality coolant, you can reduce this problem.

You must carry out a vacuum and cleaning routine to maintain the patency of your distribution system.

Lubrication

When two surfaces slide against one another, heat is produced, and both the parts undergo erosion, which causes irreversible damage to the system.

Therefore it is essential to lubricate all parts. Also, the heat released can significantly reduce the efficiency as it interferes with the normal function.

Damage Repair

The damaged and broken parts must be replaced soon as they are detected. It prevents your system from long-term damage.

Fermentation Chiller Inspection

How to Differentiate Between an Air Cooled and a Water Cooled Fermentation Chiller?

The air-cooled and water-cooled Fermentation Chiller can be differentiated on the following terms:

Usage of Water

The water cooled type uses a steady supply of chilled water, which flows around the condenser coils and allows heat transfer. It requires a cooling tower and water tank.

The air cooled type uses a constant ambient air flow for heat exchange purposes. It is equipped with motors and fans that provide a constant air currents supply.

Site of Installation

Water cooled type can be installed indoors while its cooling tower is outdoors. At the same time, the air cooled type works best in the outside environment where it receives sufficient ambient air and good ventilation.

Noise and Vibration

Although both types of Fermentation Chillers are equipped with mechanisms to control the noise and vibration, the water cooled type produces less noise as compared to the other.

Water Cooled Fermentation Chiller

What are the Most Suitable Compressor Types for a Fermentation Chiller?

The most suitable compressor types for your Fermentation Chiller include the following:

Scroll Compressor

It provides continuous compression force to the coolant with the help of one fixed and one orbiting scroll. It is efficient enough to deal with high cooling loads.

Screw Compressor

It works by trapping the coolant with the help of two rotors in the compression casing. The other name of the screw compressor is the rotary compressor. It works best for medium cooling loads.

Centrifugal Compressors

It depends on the centrifugal force for the compression of the coolant. The most suitable applications include those having low to moderate cooling loads.

Fermentation Chiller Screw Compressor

What is the Capacity of a Fermentation Chiller?

The capacity of a Fermentation Chiller refers to the ability to produce sufficient temperature regulation for a certain application. Various categories work against the given cooling loads.

The average capacity ranges from 10KW to 280KW. It depends upon the size, type of compressor, and refrigerant choice.

For maximum performance, maximum capacity must be reached. Therefore the choice of Fermentation Chiller is made according to the demand of the application.

The capacity can be sufficiently increased by connecting multiple units in a series. It can be done in case of highly high cooling loads.

What is the Sizing Strategy for your Fermentation Chiller?

The sizing strategy of your Fermentation Chiller involves the following factors:

Application Demand

The greater the cooling loads, the greater the need to displace the heat and the greater the size of the chiller.

If it is to be used in an industry where a whole batch of the product depends on the chiller function, the size shall be considered beforehand.

Available Space

The size dramatically depends upon the site of installation and the available space. Indoor Fermentation Chiller occupies less space than outdoor ones.

Also, the portable type can be easily transported from one place to another and does not occupy any considerable space.

Capacity

If the chiller’s capacity is low, it is obvious to have a smaller size compared to the one with a higher capacity. There shall be room for fans and additional motors as well.

What is the Significance of Using Water in your Fermentation Chiller?

There is a considerable change in the performance of a Fermentation Chiller with the use of glycol only and the use of a mixture of glycol with water.

Although the cooling mechanism of water and glycol is very different, the mixture of both helps achieve better results as the favorable properties add up.

Water boils at a lower temperature and brings the system’s temperature to a lower level than the glycol.

If water is used alone, it can freeze in the coils and lead to complete blockage and cracking of the coils. Also, water is an unstable compound and tends to cause corrosion in the distribution system.

Thus the antifreeze and anti-corrosion properties of glycol allow you to have a more stable and long-lasting coolant.

What is the Right Proportion of Water and Glycol for your Fermentation Chiller?

The glycol water mixture contains 60% of glycol in proportion to 40% water. This ratio is most suitable for antifreeze properties to manifest at their best.

Using this proportion, you can eliminate algae and bacterial growth in the very common distribution system. 1-2% glycol is toxic to bacteria and algae.

However, if it is at 1%, it promotes the growth of bacteria, and therefore it must be regulated strictly.

What are the Installation Instructions for your Fermentation Chiller?

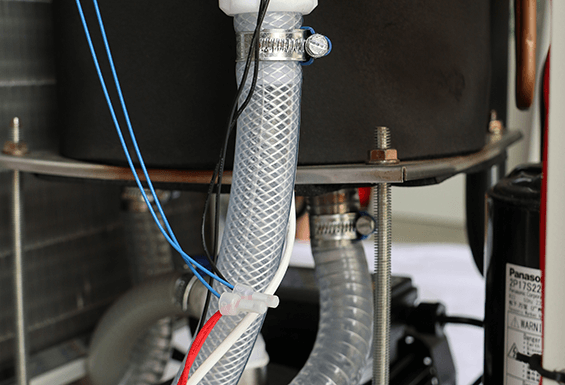

The installation instructions for your Fermentation Chiller are as follows:

- Decide the installation site according to the type and size of your chiller.

- Create a proper ducting or piping system for the supply of water and air.

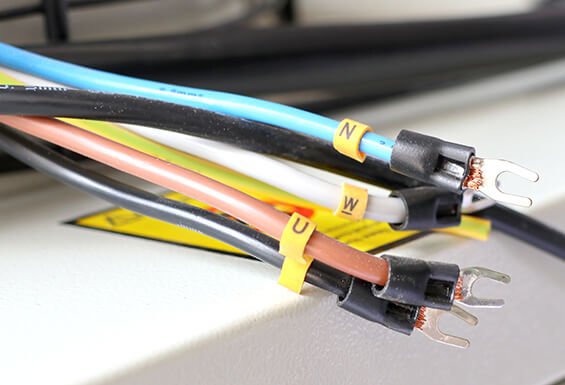

- Establish steady electricity and water connection.

- Position all the wires and pipes in place.

- Fill the reservoir with the coolant or water according to the demand of the Fermentation Chiller.

- Make sure the glycol pressure and concentration are appropriately adjusted.

- All the flush systems and supply valves must be checked if they perform their function well.

- Drain the water and add the glycol.

- Turn the pump on and open the valve.

- The thermostat needs setting and adjustment.

- Set the temperature protection and allow the chiller to function.

Fermentation Chiller Piping Installation

What are the Common Problems and Solutions of a Fermentation Chiller?

The common problems regarding the Fermentation Chiller and their solutions are as follows:

Failure to Turn On

Reasons

- Inadequate electricity supply

- A phase of electric supply

- Switch tripping

- Short circuit

- Poor wiring

- Lack of insulation

- Insufficient water or coolant

- Frozen refrigerant or water in the distribution system

Solution

- Inspect the wiring and electrical supply to rule out any connection defect.

- Make sure the electric supply is sufficient and steady.

- Use antifreeze and check the refrigerant.

Defective Pumping

Reasons

- Any mechanical defect in the compressor, evaporator, expansion valves, or the motor.

- Leakage in the distribution system.

Solution

- Make sure that all the components are competent enough to make the system work.

- Seal any leakage points by locating them.

Poor Cooling

Reasons

- Fluctuating voltage

- Substandard refrigerant

- Obstruction in the distribution system

Solution

- Clean the coils thoroughly and use a vacuum.

- Use a filter to prevent any dirt and debris from entering the system.

- Only use a high-quality refrigerant with no adverse effects.

Fermentation Chiller Troubleshooting