TopChiller can design and manufacture all types of portable water chillers for you

- Cooling capacity ranges from to 2 ton to 50 ton

- Temperature control ranges from 20°F to 70°F.

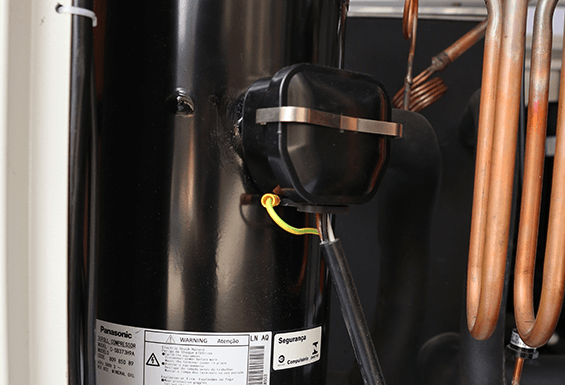

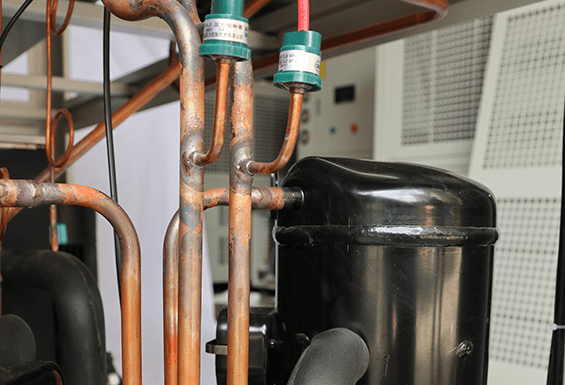

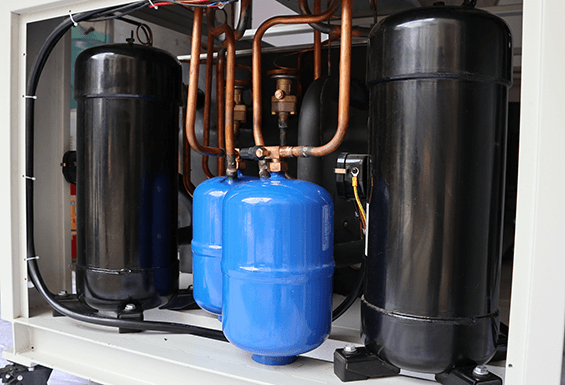

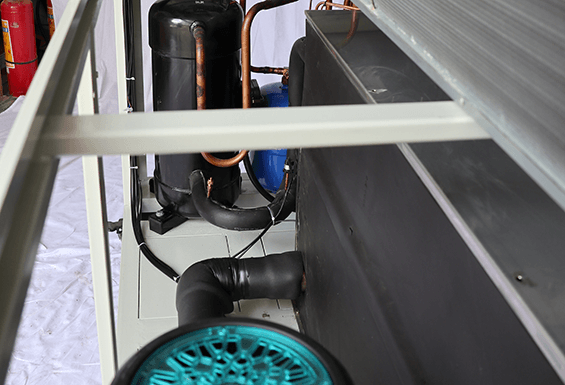

- Piston & scroll type top branded compressor

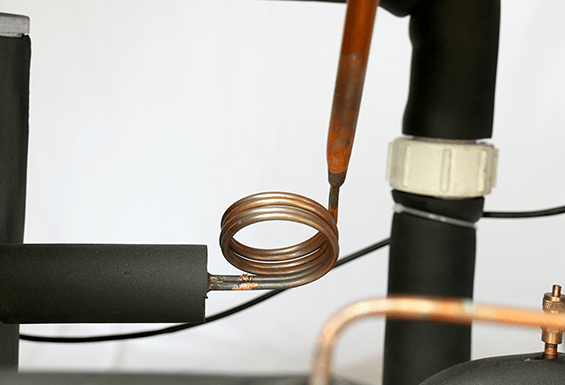

- Copper coated brazed plate heat exchanger

- Water-cooled type energy-efficient condenser

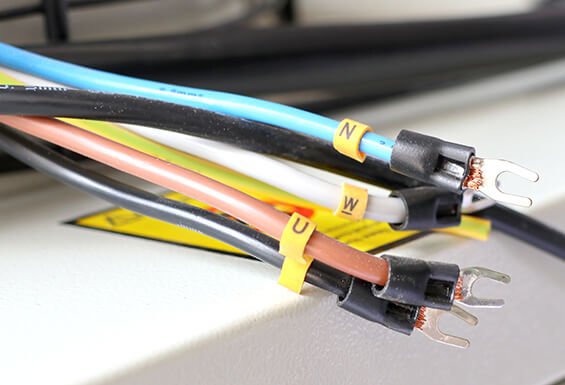

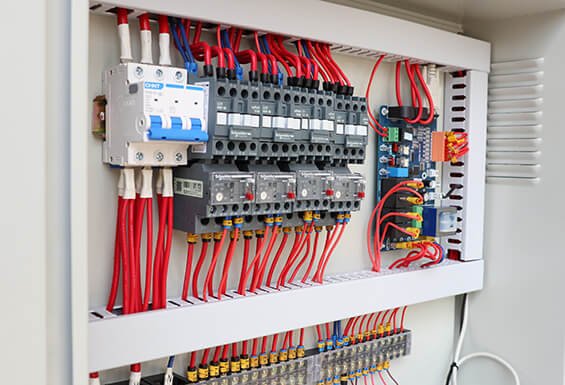

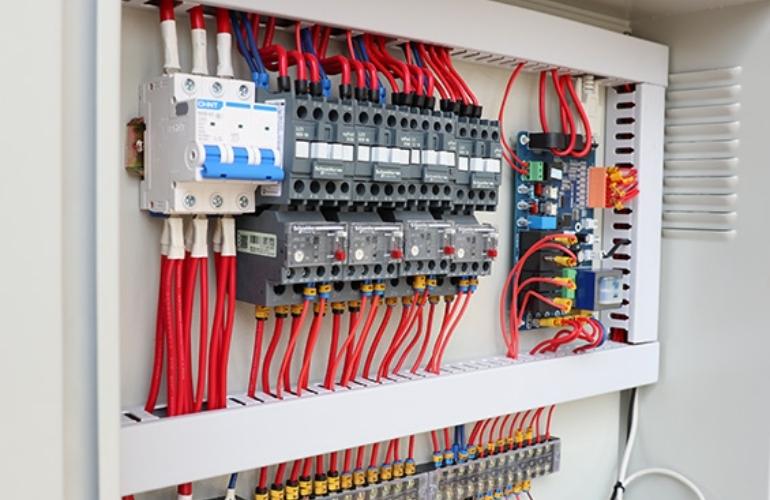

- Heavy gauge, magnetic contactors installation

- Easy maintenance, repairing & compatibility

- Warranty time for 24 months after purchase

Your Premier Portable Water Chiller Manufacturer and Supplier in China

Portable Water Chiller is a self-contained energy-efficient device that uses chilled water or glycol water mixture to provide a cooling effect inside the machine by working steadily on the refrigeration principle.

The chilled water of the Portable Water Chiller is stored inside the tank and flows around the machine to collect extra heat and release it out.

TopChiller is an ingenious company of China that has a strong quality set up for manufacturing Portable Water Chiller of different capacities and persistently researching for new technologies to meet regulatory standards.

Since 1999, TopChiller has got marvelous experience in its operation and now successfully exporting a full line of Portable Water Chiller models with different ranges to all over the world markets and earned reputed fame on the global map as best manufacturer and supplier.

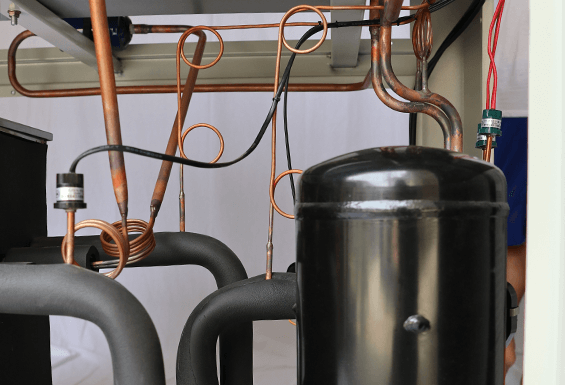

TopChiller designed Portable Water Chiller consists of branded components as a scroll or piston-type compressor, large capacity condenser, brazed plate evaporator, and heat exchanger, PID temperature controller, protection devices, magnetic contactors, and protection devices.

Portable Water Chiller is renowned for its vast range of outstanding benefits as given below:

- Portable Water Chiller is configured to provide streamline cooling effect to single or multiple processes featured by a reservoir that transfer chilled water around the whole equipment by recirculating pump forcing chilled water to flow persistently for heat absorption.

- TopChiller designed Portable Water Chiller is configured with water-cooled condensers that dissipate the collected heat from the machine to chilled water circulation around the condenser and consequently re-ready coolant for another cycle of heat absorption.

- Portable Water Chiller maintains the regular temperature of refrigerant entering inside compressor by using automated PLC temperature controller that prevents the compressor from leakage and other damages by high heating.

- TopChiller designed Portable Water Chiller featured with the reverse flow does not have any water tank configuring direct circulation of chilled water in pipelines from an outside water reservoir.

- Portable Water Chiller with the standard flow has a water tank installed inside the unit for streamlining and equalized water transferring.

TopChiller branded Portable Water Chiller is used for different applications as given below:

The medical industry, pharmaceutical industry, laboratories, hospitals, commercial areas, large markets, plastic industry, and food processing.

Are you looking way around to buy the best optimized and stabilized working Portable Water Chiller for your application to increase the product capabilities?

Are you incisively searching over to find the best manufacturer and supplier of Portable Water Chiller in China for getting assistance to level up your own business?

You are directed to the right destination. TopChiller is the best manufacturing company to rely on. Contact TopChiller today for getting updates and clear your queries by discussing with our trained engineers and experts.

TopChiller team is bound to provide the best supporting assistance and buying guide to our clients for purchasing the best Portable Water Chiller perspective to your application requirements at smart rates.

General Description:

A Portable Water Chiller is mobile cooling equipment that helps with efficient heat removal. It is used for cooling industrial machinery used in different production and manufacturing processes. Due to its small size, you can easily relocate it depending on your need and convenience.

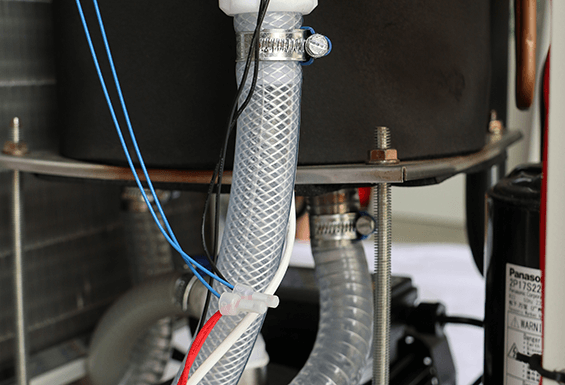

A Portable Water Chiller manufactured and supplied by TopChiller has a modern and compact design. It contains all the essential components as well as updated features for efficient cooling results. These high-quality parts include an efficient compressor, condenser, evaporator, and expansion valve. In addition to these, it also has wheels and casters for easy relocation. It also comes with flexible hoses making the installation easier for you.

Portable Water Chiller, designed by TopChiller, is famous for its diverse range of applications, including industrial plants for blow molding, machine molding, chemical processing, welding, food and dairy industry, beverage manufacturing, etc.

If you are looking forward to a high-quality customized Portable Water Chiller System, the TopChiller brand shall be your priority. With over 20 years of experience, we know how to satisfy our precious clients by fulfilling their cooling needs at a very affordable price.

Contact us right now to get the most affordable portable water cooling system.

Features and Advantages:

The following notable features make Portable Water Chiller models manufactured by TopChiller worth buying:

- The variable-speed compressor technology with hermetic sealing saves 30-50% energy. It has an inverter drive to offer power spikes protection to the compressor.

- Non-ferrous copper brazed plate evaporators prevent rusting and foul smell problems. It also comes with an inlet strainer and large filters for easy and fast servicing.

- Liquid line and refrigerant suction sensors for sub-cooling and superheat readings. It also has tank level, compressor discharge temperature, and chilled water in and out temperature and pressure sensors.

- Portable Water Chiller has a small footprint that can easily fit in a standard shipping container. It also comes with lift-off panels and full access on all sides. It also has round coils for easy relocation.

- Proprietary Control Platform with Integrated Ethernet Interface for various open protocols including the web server, DNS, FTP, NTP, etc. It also has optional cloud services.

- Data Sheet

- Image Gallery

- Main Parts

- Video

| Portable Water Chiller Technical Specifications | |||||||||||

| Model Items | AW-3W | AW-4W | AW-5W | AW-6W | AW-8WD | AW-10WD | AW-12WD | AW-15WD | AW-15WT | AW-20WD | |

| Cooling Capacity | kcal/h 50HZ/60HZ | 8170 | 11266 | 14018 | 16340 | 22532 | 28036 | 32680 | 43172 | 42140 | 56760 |

| 9804 | 13519 | 16822 | 19608 | 27038 | 33643 | 39216 | 51806 | 50568 | 68112 | ||

| KW 50HZ/60HZ | 9.5 | 13.1 | 16.3 | 19 | 26.2 | 32.6 | 38 | 50.2 | 49 | 66 | |

| 11.4 | 15.72 | 19.56 | 22.8 | 31.44 | 39.12 | 45.6 | 60.24 | 58.8 | 79.2 | ||

| Input Power | KW | 3.07 | 3.87 | 5.3 | 5.95 | 7.75 | 10.6 | 11.9 | 16.25 | 15.85 | 19.71 |

| Max Current | A | 7.5 | 9.4 | 12.9 | 14.4 | 18,8 | 25.7 | 28.9 | 39.4 | 38.2 | 47.8 |

| power source | 3PH~380V/415V/480V~50HZ/60HZ(3PH~200V/220V 50HZ/60HZ) | ||||||||||

| Refrigerant | Type | R22/R407C/134a/404A/410A | |||||||||

| Control | Capillary / Thermostatic expansion valve | ||||||||||

| Compressor | Type | Hermetic scroll ( piston ) | |||||||||

| Power(KW) | 2.7 | 3.5 | 4.55 | 5.2 | 3.5×2 | 4.55×2 | 5.2×2 | 7×2 | 4.55×3 | 8.96×2 | |

| Condenser | Type | Shell and tube/ SS plate type heat exchanger | |||||||||

| Cooling water (m³/h) | 2.1 | 2.9 | 3.6 | 4.2 | 5.7 | 7.1 | 8.3 | 11 | 10.8 | 14.4 | |

| 2.4 | 3.3 | 4.1 | 4.8 | 6.6 | 8.3 | 9.6 | 12.8 | 12.5 | 16.7 | ||

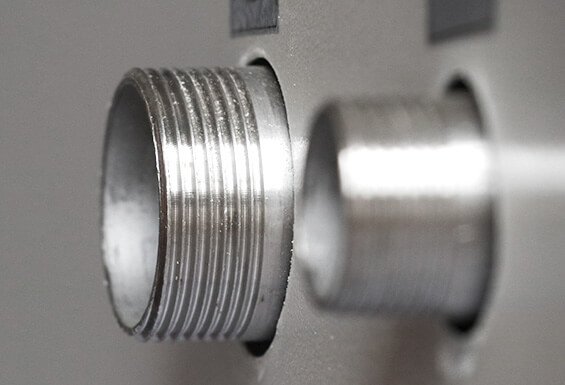

| Inlet/outlet pipe (inch) | 1 1/2″ | 1 1/2″ | 1 1/2″ | 1 1/2″ | 1 1/2″ | 1 1/2″ | 1 1/2″ | 2″ | 2″ | 2″ | |

| Evaporator | Type | SS Tank with cooper coil / Shell and tube/Plate heat exchanger | |||||||||

| Chilled water | 1.63 | 2.25 | 2.8 | 3.27 | 4.5 | 5.6 | 6.53 | 8.63 | 8.43 | 11.35 | |

| 1.96 | 2.7 | 3.36 | 3.92 | 5.4 | 6.73 | 7.84 | 10.36 | 10.1 | 13.62 | ||

| Water tank(L) | 60 | 60 | 60 | 90 | 150 | 200 | 200 | 330 | 330 | 330 | |

| inlet/outlet pipe (inch) | 1″ | 1″ | 1″ | 1″ | 1-1/2″ | 2″ | 2″ | 2″ | 2″ | 2″ | |

| Water pump | Power(kw) | 0.37 | 0.37 | 0.75 | 0.75 | 0.75 | 1.5 | 1.5 | 2.2 | 2.2 | 2.2 |

| Max lift(m) | 22 | 22 | 30 | 30 | 25 | 25 | 25 | 28 | 28 | 28 | |

| Max flow (m³) | 5.4 | 5.4 | 8.1 | 8.1 | 8.1 | 13.5 | 13.5 | 25.2 | 25.2 | 25.2 | |

| Safety protection | Compressor inner protection, over current protection, high/low pressure protection, over temperature protection, flow rate protection, phase sequence/phase missing protection, low level coolant protection, anti freezing protection, exhaust overheat protection | ||||||||||

| Dimension | L(mm) | 910 | 910 | 910 | 910 | 1250 | 1250 | 1250 | 1600 | 1600 | 1600 |

| W(mm)) | 480 | 480 | 480 | 480 | 680 | 680 | 680 | 750 | 750 | 750 | |

| H(mm)) | 1000 | 1000 | 1000 | 1000 | 1380 | 1380 | 1380 | 1600 | 1600 | 1600 | |

| Net weight(KG) | 125 | 135 | 160 | 180 | 230 | 260 | 330 | 420 | 420 | 460 | |

| Note: The above specifications are according to the following design conditions: 1, Chilled water inlet/outlet temperature 12℃/7℃. 2, Chiller temperature control range 5℃/35℃. We reserve the right to modify the specification without further notice. | |||||||||||

Why TopChiller is Your Reliable Portable Water Chiller Manufacturer and Supplier In China?

Portable Water Chiller-An Ultimate FAQ Guide by TopChiller.

- What is a Portable Water Chiller?

- What are the Outstanding Features of a Portable Water Chiller?

- How Does a Portable Water Chiller Work?

- What are the Components of a Portable Water Chiller?

- What are the Benefits of a Portable Water Chiller for your Business?

- What are the Process Flow Adjustments for your Portable Water Chiller?

- How to Adjust the Low Flow Bypass of your Portable Water Chiller?

- What is the Control Components of a Portable Water Chiller?

- What are the Indications Displayed on a Portable Water Chiller?

- What Does the Water System of your Portable Water Chiller Include?

- How to Check the Refrigerant Charge of your Portable Water Chiller?

- What are the Optional Accessories for your Portable Water Chiller?

- What Type of Alarms is Present in a Portable Water Chiller?

- How to Replace the Components of your Portable Water Chiller?

- What are the Precautions Related to a Portable Water Chiller?

- What are the Control Errors and their Solution of a Portable Water Chiller?

- How to Troubleshoot your Portable Water Chiller?

What is a Portable Water Chiller?

A Portable Water Chiller is a self-contained configuration system that includes all the essential chiller components to remove extra heat.

It features a unique design configuration and has a small footprint. Different components installed in this single unit include a compressor, process pump, refrigeration circuit, reservoir, electrics, and controls.

It is also mobile making the relocation process easier for you. This is why it is known as the portable. It is always installed close to the process being cooled.

Portable Water Chiller has a diverse cooling capacity range of 1-40 tons. What makes it different from other portable chillers is the particular type of condenser installed in it.

A water-cooled condenser is installed in this unit to eliminate the process heat. It is used to manage small process loads.

It can also be used in applications requiring exceptional flows, temperatures, fluids, or pressures. It is always ideal for temporary use as well as test applications.

Energy Saving Portable Water Chiller Designed by TopChiller

What are the Outstanding Features of a Portable Water Chiller?

A Portable Water Chiller offers many benefits, making your cooling applications easier, efficient, and more convenient. Some of these features are:

- Highly efficient copper brazed plate or stainless steel water-cooled condenser

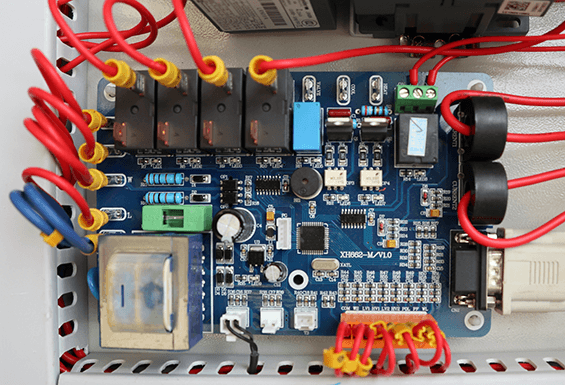

- PLC control featuring self-diagnostics

- Heavy gauge powder-coated steel cabinet

- Brass service valves with external installation

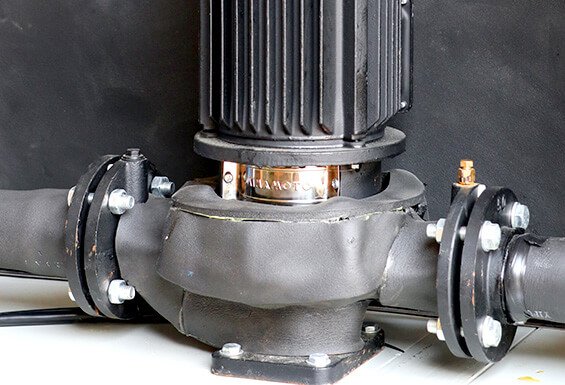

- Efficient centrifugal pumps with stainless steel construction

- Copper braze plate or stainless steel evaporator

- LAN/WIFI/LTE connectivity to help in predictive maintenance

- Big magnetic contactors

Portable Water Chiller Magnetic Contactors

How Does a Portable Water Chiller Work?

Several steps take place to complete the cooling cycle of a Portable Water Chiller. These steps are broken down for your easy understanding in this section.

- The hot process fluid via the process valve reaches the pump reservoir.

- The pump pulls water from the storage and sends it to the evaporator. This takes place by passing it through a flow switch and a filter.

- The evaporator cools the fluid and returns it to the process via the tube and the process valve.

- The refrigerant is vaporized and turned into a gaseous state by the evaporator. This is accompanied by heat removal from the process fluid.

- The compressor compresses the low-pressure vaporized refrigerant. As a result, it is changed into high-temperature and high-pressure vapors sent to the receiver.

- Municipal water or water tower removes heat from the vapor. As a result, the high-pressure vapor is converted into a high-pressure liquid.

- The expansion valve (TXV) returns high-pressure liquid to the evaporator and converts it to low-temperature low-pressure liquid.

What are the Components of a Portable Water Chiller?

Different parts join together to form a well-functional Portable Water Chiller. Some of the main components are mentioned below, along with their purpose.

Compressor

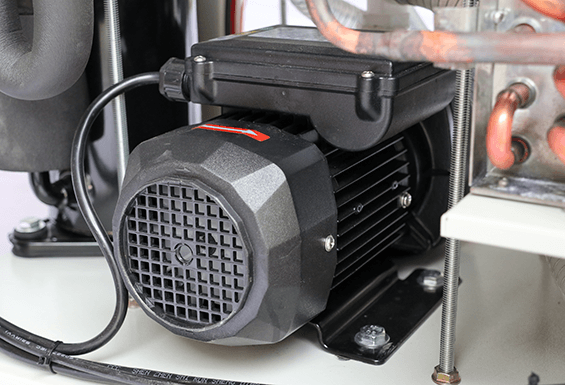

It comes with highly efficient solid-state interior motor protection. This is rubber-mounted, which helps in the reduction of vibration and noise.

Condenser

During the condensation process, the vapors can cool to a liquid state. This takes place without difference in pressure, latent heat, or temperature.

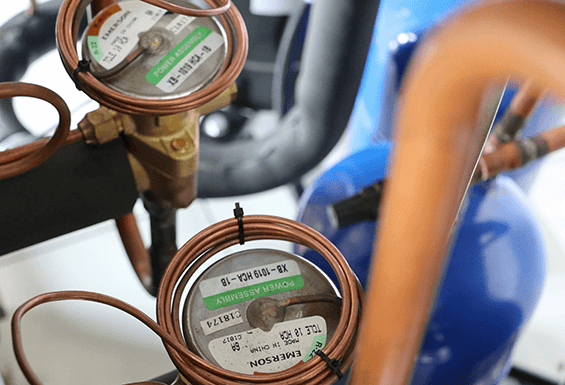

Expansion Valve

It is necessary to lower the valve opening if the temperature at the evaporator’s outlet is extremely low.

It is necessary to increase its opening if the temperature is higher. This helps in controlling and maintaining the required evaporation temperature.

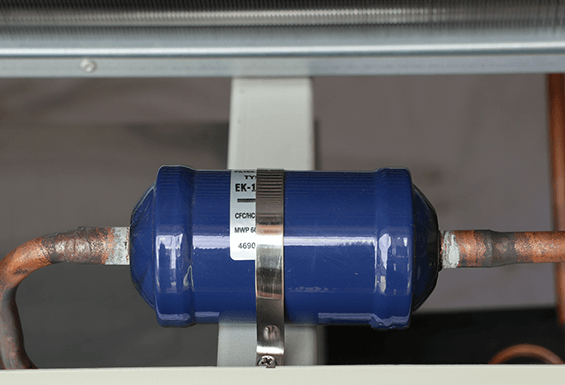

Filter Dryer

The refrigerant is filtered via molecular sieves desiccant to eliminate traces of moisture and impurities.

Using this filter means you won’t have to worry about it wearing out. This is because it comes with easy operation and indefinite life.

Liquid Line Solenoid Valve

A solenoid valve is installed at the filter dryer outlet. This valve prevents the liquid refrigerant from approaching the compressor when the system is shut down.

Evaporator

The fluid is cooled using a heat exchanger, either a tube in tube type or plate type. The evaporator generates turbulence to improve heat transfer. It is engineered to have a smaller pressure drop than other systems.

Pump

Stainless-steel impeller housing pump features high volume and high and low-pressure maintenance.

A mechanical seal is guaranteed to last for a long time and not leak. Overload is prevented by a safety feature provided by the pump motor.

Tank

When there is reduced heat transfer from a closed tank, FRP or stainless steel well-insulated tank conserves the energy.

Frame

All internal components are approachable for free maintenance. The weather-resistant paint coating is added to withstand tough environmental conditions.

Portable Water Chiller Danfoss Compressor

What are the Benefits of a Portable Water Chiller for your Business?

There are a lot of benefits of using a Portable Water Chiller. Some of the most notable benefits you can get are written below:

- Easy to maintain and repair

- High flow efficiency and performance

- Comes with compact efficiency

- Convenient wash down due to rugged protection

- Highly economical, reliable, and durable

What are the Process Flow Adjustments for your Portable Water Chiller?

A trouble-free and effective operation requires determining and setting the optimum water flow rate.

In the process loop, the pressure losses tell the water flow rate. More significant flow rates generally lead to more turbulent flow, resulting in low maintenance and better temperature control.

The evaporators are usually flow-sensitive; hence, operation efficiency depends on the liquid flow.

In order to achieve maximum Portable Water Chiller efficiency, the flow rate per ton of rated capacity should be around 2.4 GPM.

When the liquid flow is low, the efficiency is reduced. The evaporator might also be damaged in certain situations due to ice building.

The motor overload safety circuit will be tripped with an excessive liquid flow.

For adjusting process flow, follow these steps:

- To start the process pump, turn it on.

- Allow a few seconds for the system to be cleared of any air.

- Look for a consistent reading on the digital coolant pressure gauge.

- Perform flow tests on the unit to see if it is functioning correctly.

- All process valves must be open if a low flow condition exists.

Portable Water Chiller Water Flow Switch

If the flow is low and all process valves are open, the following information should be considered:

- The low refrigerant pressure limit switch might trigger due to low flow.

- A flow bypass must be installed in the processing circuit to run at low flow. There is a chance that a portion of the flow will be redirected back to the Portable Water Chiller.

- As a result, the overall flow remains higher than the limit.

- A bypass may have been pre-installed on some models.

How to Adjust the Low Flow Bypass of your Portable Water Chiller?

Adjusting bypass valves is a critical step for the normal functioning of your Portable Water Chiller. It also helps maintain the flow and prevents the system unit.

- For Manual Low Flow Bypass Valves

In case of adjusting the low flow bypass valve manually, follow this guide:

- Begin with the bypass valve, which is closed, and slowly open it.

- Stop when the digital display shows that the low refrigerant pressure is in the desired operating range.

- For Automatic Low Flow Bypass Valves

In case of adjusting the low flow bypass valve automatically, follow this guide:

- The top of the valve has an adjusting stem or a “T” handle.

- When the stem or the “T” handle is turned clockwise, there is a reduction in bypass flow. It is because more pressure is applied to the valve’s spring.

- The spring is relieved, and the counterclockwise bypass flow turns the adjusting stem and “T” handle.

- Keep going until the digital low-pressure display reading for your Portable Water Chiller refrigerant is within the usual operating range. Now stop moving the adjustable stem or the “T” handle.

- Lower the spring pressure to increase bypass if the digital lower pressure display reading is lower than average.

What are the Control Components of a Portable Water Chiller?

Various control components work together in providing smooth and easy control of your Portable Water Chiller. These components are:

- Setpoint lockout jumper

- Illuminated on/off switch

- Probe calibration

- Up and down arrow keys

Portable Water Chiller Controller

What are the Indications Displayed on a Portable Water Chiller?

There are various indications displayed on your Portable Water Chiller. Some of these are:

- Output

- Suction

- Discharge

- To Process

- Display

- Main Menu

- Alarm Codes

- Status Lights

- Water Level

- Percent Loading

Portable Water Chiller LCD

What Does the Water System of your Portable Water Chiller Include?

The automated water makeup system constantly monitors the storage tank, which tops it off as needed. The structure of the water system involves the following steps:

- Fluid pipes or appropriate hoses should be used for building the connection.

- Build a link between the plant’s water supply and the water makeup.

- Makeup water supply pressure should be no less than 20 psi at all times.

- In the makeup water supply line, install a shutoff valve. Outside the unit, attach this valve.

- For the sake of protecting your water from contamination, use a reverse-flowing prevention device. Use one that complies with the local codes.

- When using glycol at temperatures below 48°F, do not use an automated water makeup mechanism.

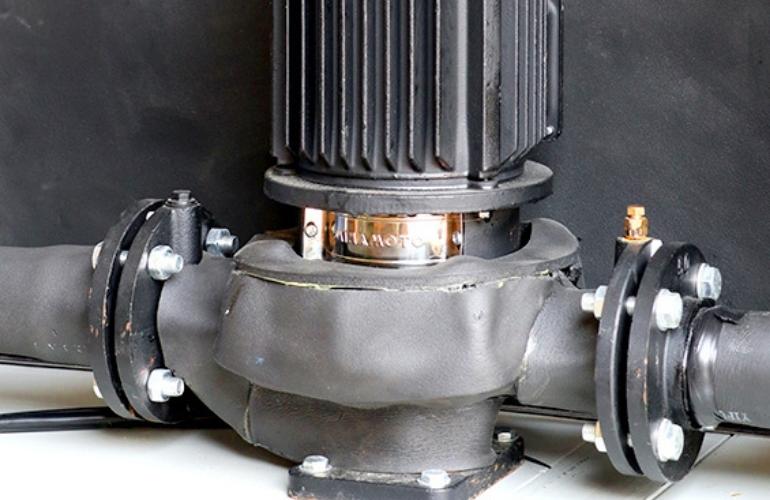

Portable Water Chiller Water Pump

How to Check the Refrigerant Charge of your Portable Water Chiller?

To the evaporator, the metering devices used are known as thermostatic expansion valves. This remains standard in all Portable Water Chiller models.

There also is a moisture detector in the sight glass installed in all models. Refrigerant charge should be checked when the system is running normally by taking the following steps:

- Sight glass is covered by a plastic cap that must be removed.

- Let system temperature and pressure settle by turning the system on.

- No foam or bubbles should be seen in the sight glass when running the machine at 100% capacity. It should not be operated in the capacity control mode.

- An experienced refrigeration technician should be called if any foam or bubbles are seen in it. It is because these bubbles are an indication of refrigerant loss.

- The moisture indicator is represented by the “dot” in the center of the sight glass. At all times, it should be green.

- Compressor life is shortened if the color is yellow or white, indicating that moisture has entered the system.

- Replacement of the filter-drier should be done by a refrigeration professional.

What are the Optional Accessories for your Portable Water Chiller?

Different optional accessories available for your Portable Water Chiller are:

Low Flow Bypass Valve

If the process requires flow rates less than those specified in the design, you will need a low flow bypass valve.

Overhead Piping Kit

Installing an overhead piping kit can help keep the storage tank from overflowing when overhead piping is turned off.

In the “from process” line, a full line-size solenoid valve is interlocked with the pump. There is a check valve in the “to process” line (a valve that only moves in one direction).

Process Line Shut Off Valves

To and from process lines are connected via full-size ball valves at the unit exit. The flow rate of the process may be adjusted using these valves.

The flow rate can also be cut off to isolate the Portable Water Chiller.

E-Stop Button

The E-stop button is a mushroom-shaped button that, when pressed, stops all of the activities.

Fused or Non-Fused Disconnect Switch

An on-board disconnection button makes it easy to turn off the unit’s power supply.

Visual and or Audible Alarm

These alarms help in telling about the out-of-spec operation circumstances. Two different types of alarms exist:

Audible Alarm

A simple buzzer can trigger alarms.

Visual Alarm

An audible sound is emitted, and a beacon is flashed.

Reverse Flow Piping

For open-circuit operations, a reverse flow Portable Water Chiller is the best choice. The process functions as the reservoir keeping the flow circuit is nearly the same.

The water is returned to the pump suction under the action of gravity. Since the chiller lacks a reservoir, so external level control and water makeup are required.

Portable Water Chiller Emergency Stop

What Type of Alarms is Present in a Portable Water Chiller?

When the controller detects an alarm, both the specified and displayed process variables alternately flash on display.

When a safe state is reached, these alarming problems should be solved. When a power-up situation exists, additional warnings are displayed, such as RST being flashed on the controller’s display.

The alarm stage is the last place where information is sent to the user. The “on” LED flashes whenever an alarm is triggered.

The controller has three sorts of alarms built-in, which are discussed below:

1-First Alarm Type

The first sort of alarm is a sort of annunciating cycling, and it’s the most common. However, the compressor will continue to run even if this alert is triggered.

This is followed by code flashing contrary to the process variable. These alarms are discussed below:

DtA

The change from the setpoint alert will turn on for a more extended period than allowed by the deviation temperature setting (dT).

This is when the time exceeds deviation temperature ignore time (dtt).

TAH

A warning alert will flash when the process temperature exceeds the alarm setting (htA).

2-Second Alarm Type

Before latching and needing a reset, the second annunciating type will follow three cycles in one hour. This sort of alert is the PAL low refrigerant pressure alarm.

The strobe and the bell will energize when the system is under low pressure. But when the pressure is restored, they will turn off.

PAL

When the lower refrigerant pressure switch detects a low pressure for an extended period, the (Pressure alert low) flashes (lpl), it will cycle thrice in an hour.

3-Third Alarm Type

Latching type alarms are the third type of alarm. The compressor is automatically cut off when this alarm goes off, and it must be individually reset when the problem is fixed.

This sort of alarm indicates excessive sensor and pressure failure. When the alarm is on, the following lights will flash:

RSt

Flashes after a power loss are restored.

PSH

The high-pressure refrigerant switch is illuminated with flashes. A manual reset of the high-pressure switch may be required to recognize this latching alarm.

SF2

It tells that the process temperature sensor is indicating range exceeding.

THS

Indicating that the compressor has been turned off due to the process’s high temperatures, which might cause harm to the compressor (Hts)

FAL

When the low flow state continues for a more extended period than allowed, the flow alarms low light flashes, which must exceed the low flow of ignoring time.

TAL

As soon as the sensor for leaving water senses a temperature lower than the low-temperature alarm setpoint, the compressor is switched off (spl).

The compressor maintenance alarm serves as the final alarm. The run light flashes, but the display would not show that an alert has occurred.

How to Replace the Components of your Portable Water Chiller?

For replacing your Portable Water Chiller components, follow these steps:

- Disconnect the power source.

- Open the chiller and locate the component to be replaced.

- Remove the component.

- Install the new component at its designated place properly.

- Close the chiller.

- Turn on the power source.

- Check if the replaced component is working correctly or not.

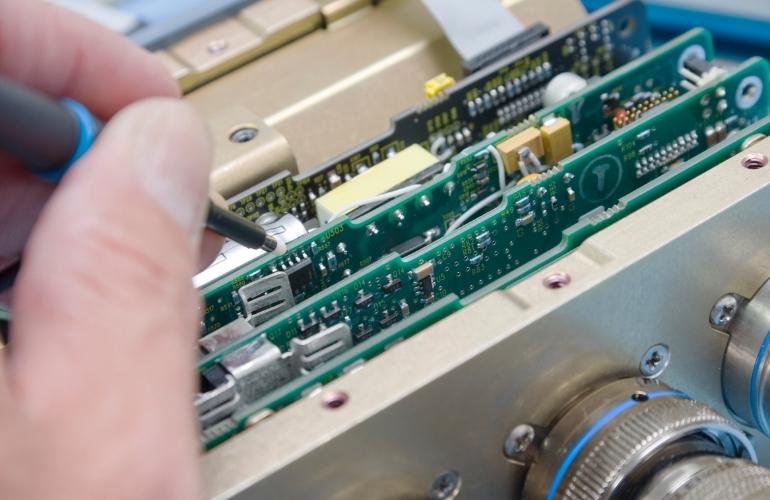

Portable Water Chiller Parts Replacement

What are the Precautions Related to a Portable Water Chiller?

When using a Portable Water Chiller, you should consider some essential precautions.

Remember that following these precautions will provide you with trouble-free operation and use. Some of these points are:

- You must get well familiar with your Portable Water Chiller and its user manual for easy operation and usage.

- The owner must see that the equipment is properly installed, operated, and maintained.

- Examine the warning and safety notices of your unit. Operator injury or death and severe mechanical damage might happen if all warnings are not observed.

- Due to the excessive refrigerant charge and voltage, all safety measures must be followed throughout the installation, starting, and service period.

- It should only be installed, started, and serviced by professionals.

- Precautions in the labels, handbook, tags, manuals, and stickers on the equipment should be followed during the operation.

- Wear safety goggles and gloves while working.

Some Important Warning Labels

Some important warning labels always displayed on the unit for safe operation are:

- Dangers of excessive voltage.

- Under-Pressure refrigeration system.

- Only technical expertise is required to repair the system.

- You might be injured by misusing this equipment.

- Before installing or servicing your equipment, always turn off the power and isolate the area.

- The refrigerant in this device is under high pressure.

- Refrigeration leaks can cause physical harm and property damage if released under high pressure.

- When operating on or around this equipment, use caution.

- In line with ASHRAE/ANSI Standard 15, install all refrigerant relief valves accordingly. Follow the complete Safety Code for Mechanical Refrigeration.

- There should be plenty of ventilation for the unit operation

- It is dangerous to inhale refrigerants. This is because the accumulation of refrigerant in a confined environment can disturb oxygen levels oxygen. As a result, workers might suffocate.

What are the Control Errors and their Solution of a Portable Water Chiller?

The different control errors often observed in a Portable Water Chiller and discussed below:

Error No 1

Control is not lit up, and the system is not operating.

Solutions

- Plug the power cord correctly.

- Look for any power cord damage.

- Check fuses and breakers.

- Check the voltage and power being supplied.

- See the TIC indicator lights. Replace if needed.

Error No 2

The control is lit up, but the compressor is not operating.

Solutions

- Observe the primary supply voltage.

- Check the fuses.

- Observe the phase to phase voltages.

- Look at phase continuity and compressor wiring.

How to Troubleshoot your Portable Water Chiller?

For troubleshooting your Portable Water Chiller, follow these guidelines:

High Discharge Pressure

Remove the unwanted condenser gas.

Compressor not Working Efficiently

Charge the refrigerant.

Low Suction Pressure

Replace the suction switch.

Poor Outlet Temperature

Decrease flow to rate capacity.

Heavy Noise Production

Install it on a leveled surface.

Low Water Trip

Rectify the tank problem.

Inefficient Portable Water Chiller Temperature

Protect from heat and provide sufficient ventilation.

Portable Water Chiller Troubleshooting